Image correction device and coating unit thereof

A coating and patterning technology, which is applied to the formation of conductive patterns, devices for applying liquid to surfaces, coatings, etc., can solve problems such as longer correction time for defective parts, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] (Embodiment 1)

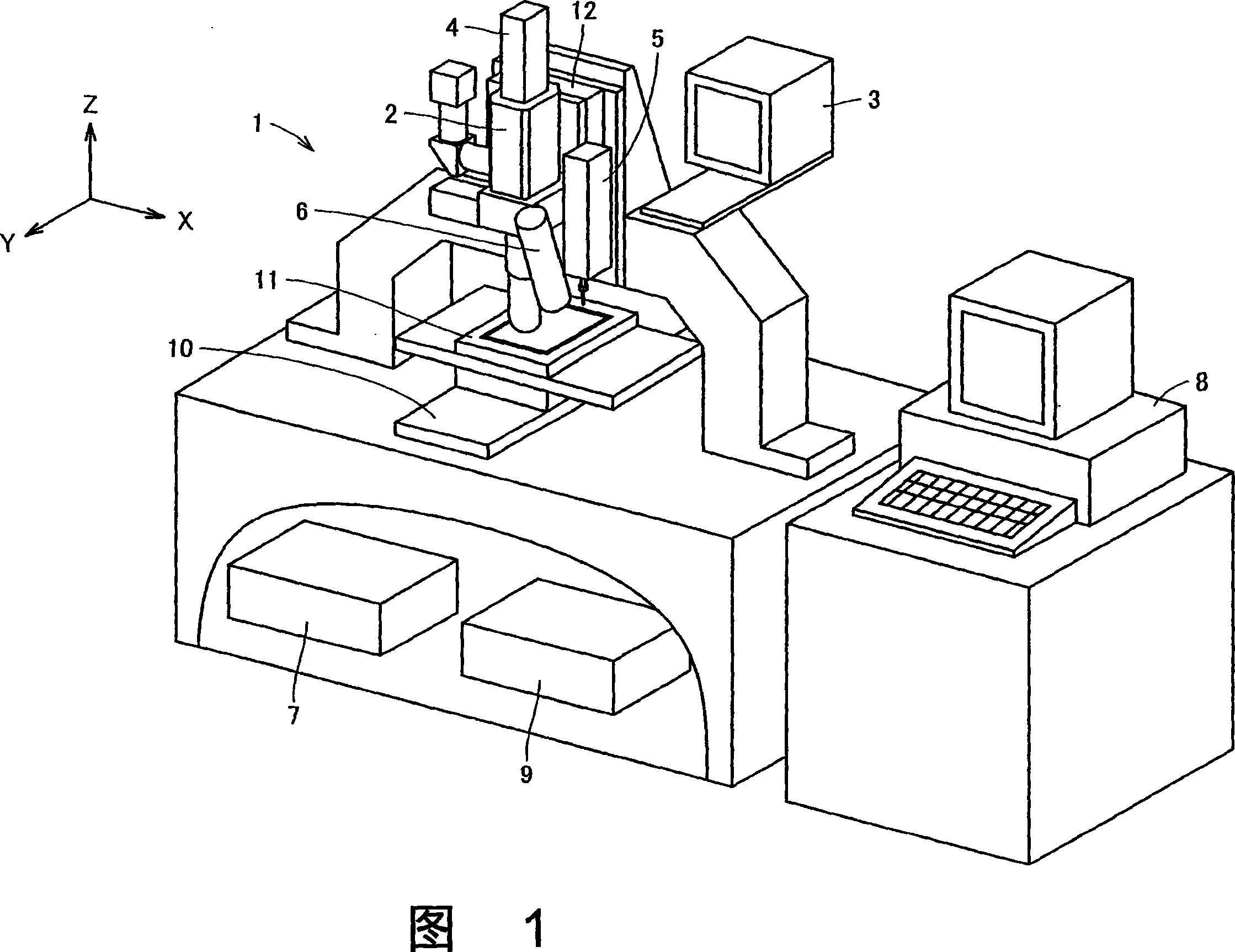

[0040] Fig. 1 is a view showing the overall structure of a pattern correction device according to Embodiment 1 of the present invention. In Fig. 1, figure correcting device 1 has: the observation optical system 2 that observes substrate surface; The monitor 3 that displays the observed image; Laser unit 4; Coating mechanism unit 5 that attaches the correction fluid to the tip of the coating needle and coats it on the defective part of the substrate; Substrate heating unit 6 that heats the correction fluid coated on the defective part; Identification The image processing part 7 of the defect part; the host computer 8 of the overall control device; and the control computer 9 of the control device mechanical part operation. In addition, there are: an XY-axis stage 10 for moving a substrate having a defective portion in the XY direction (horizontal direction); a claw portion 11 for holding the substrate on the XY-axis stage 10; The Z-axis stage 12 etc. wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com