Engine power assembly

A technology of engine and frame, which is applied in the direction of engine components, engine cooling, machine/engine, etc., and can solve problems such as cylinder liner wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

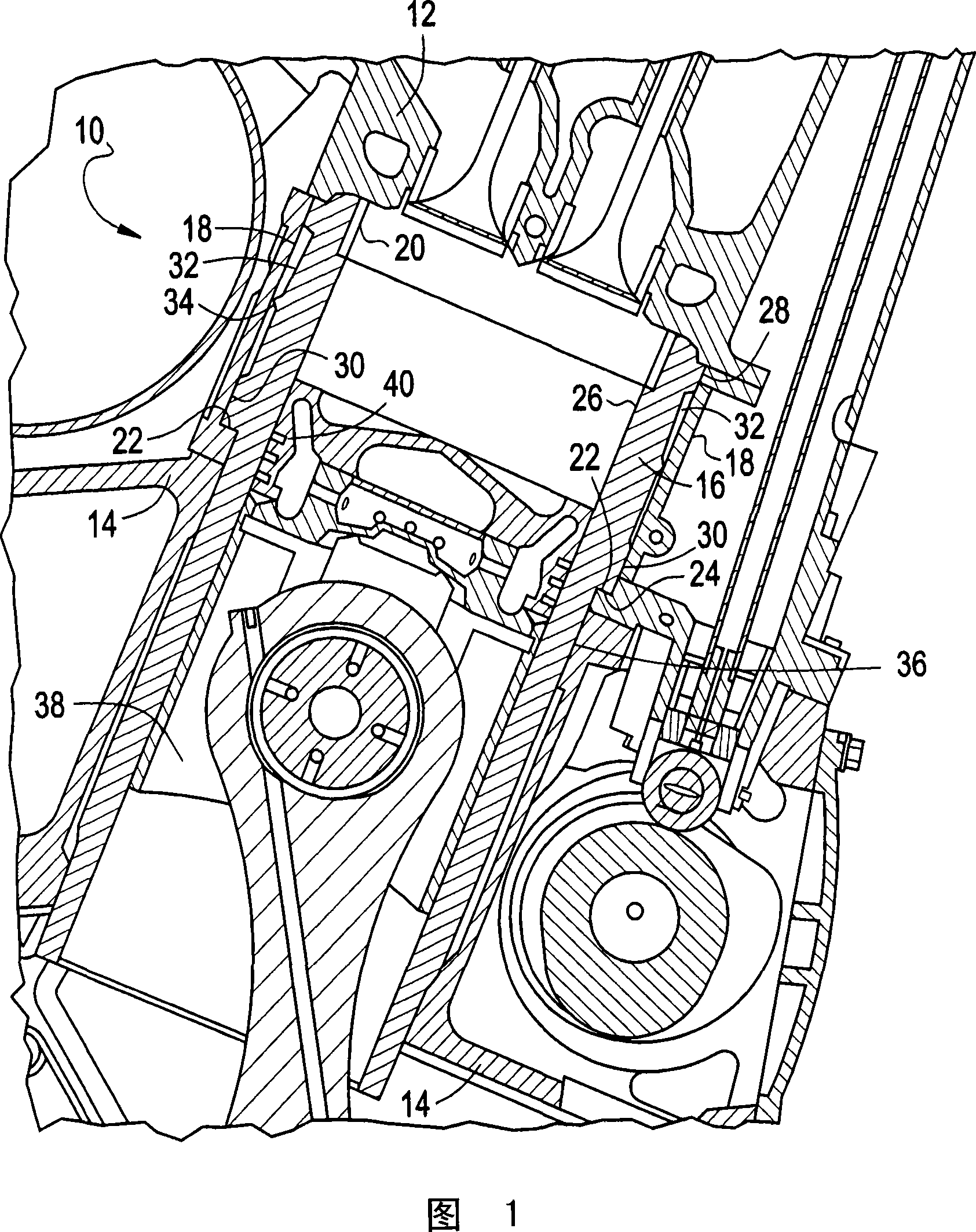

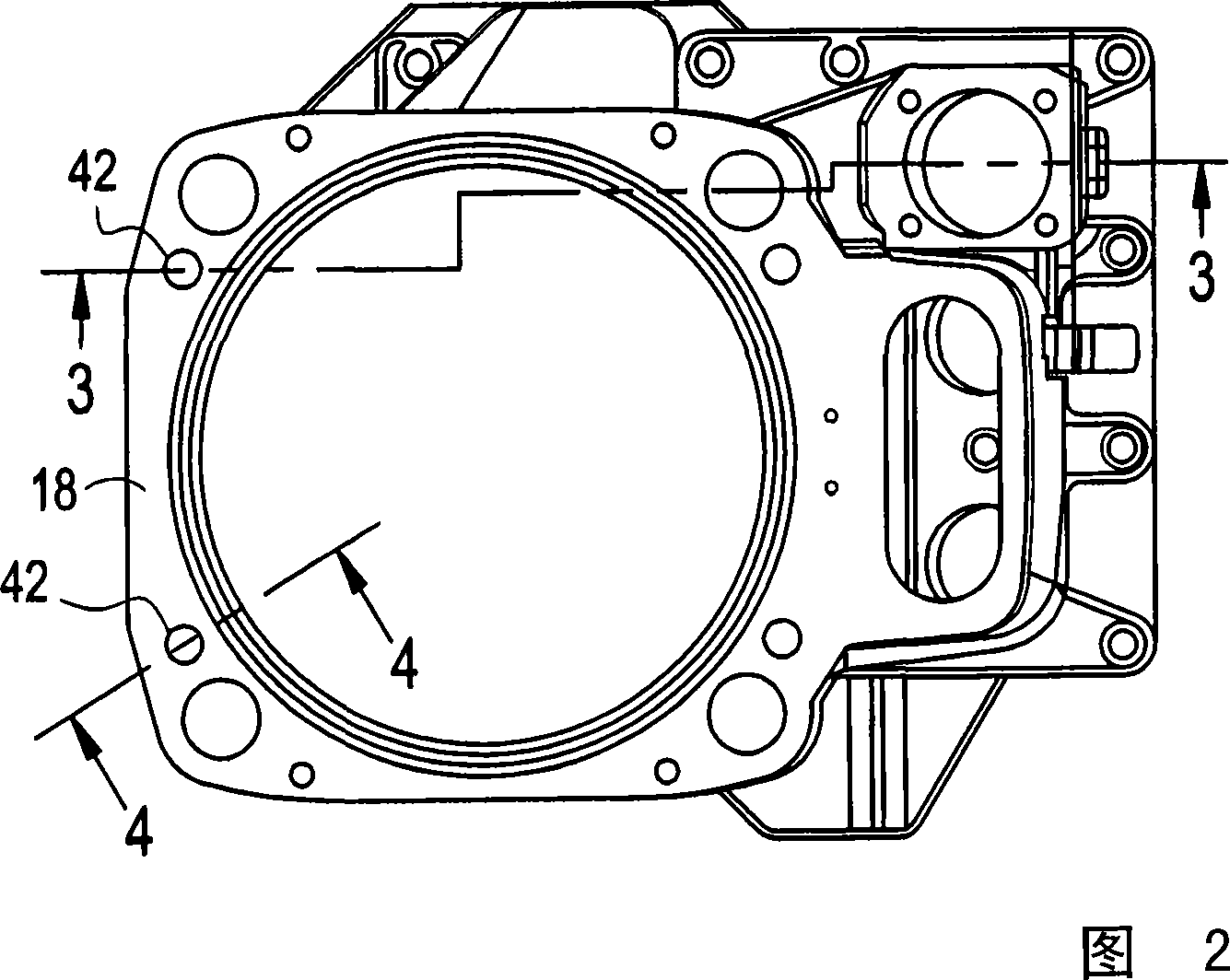

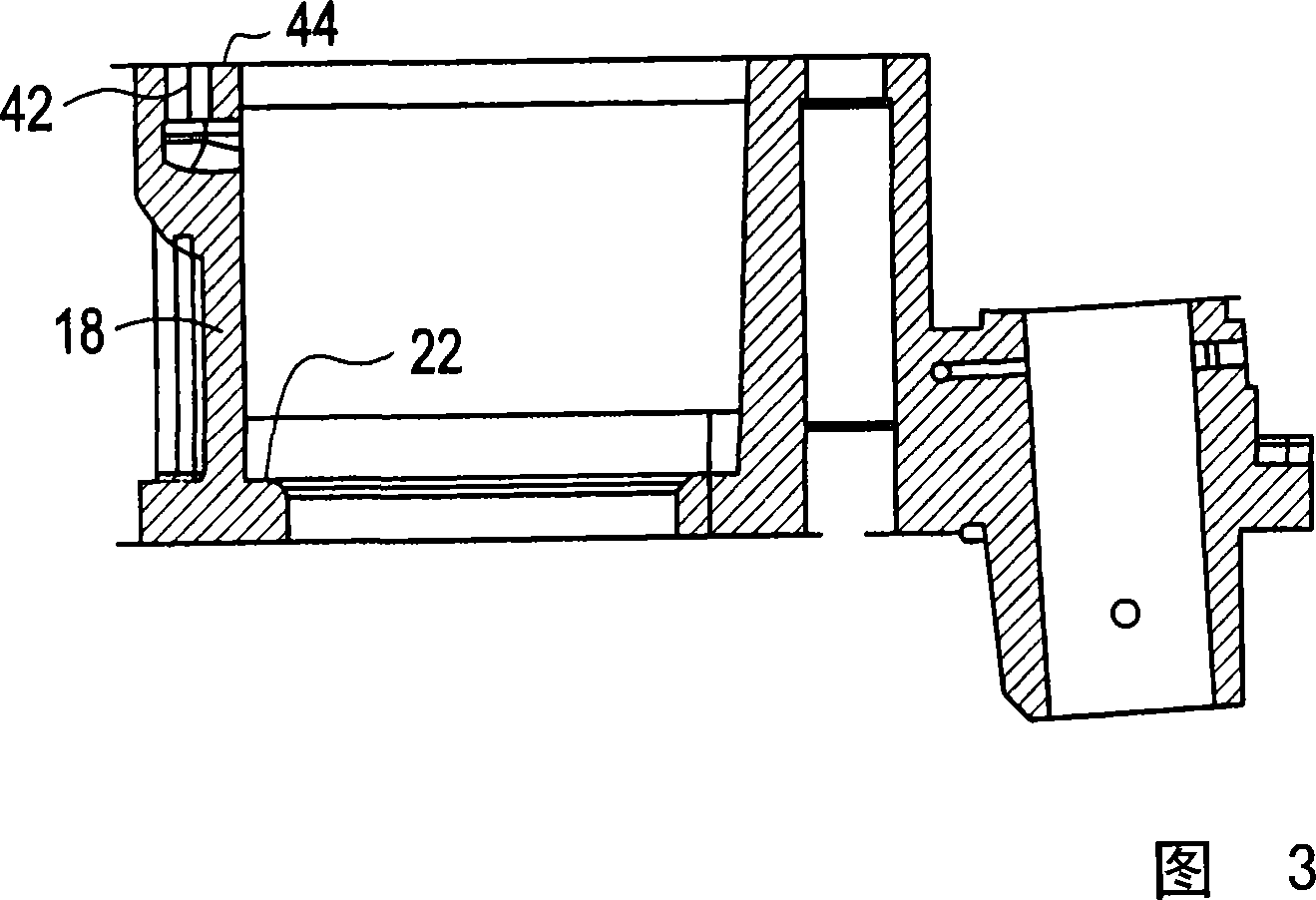

[0015] As shown in FIG. 1 , a first embodiment of an apparatus 10 of the present invention includes a cylinder head 12 , an engine frame 14 , a cylinder liner 16 , a spacer plate or water jacket 18 and a combustion ring 20 . An upward facing flange 22 may be provided on the inner surface of the water jacket 18 , as best shown in FIG. 3 , and a downward facing shoulder 24 may be provided on the outer surface of the cylinder liner 16 . The shoulder 24 is designed to abut against the flange 22 so that the cylinder liner 16 is supported by the water jacket 18 . The water jacket 18 is then supported by the engine frame 14 . This avoids direct support of the cylinder liner 16 by the engine frame 14 , thereby minimizing wear on the cylinder liner 16 .

[0016] A combustion ring 20 is disposed at the junction between the cylinder liner 16 and the cylinder head 12 to protect the head gasket from damage from exposure to the hot combustion gases. For clarity purposes, piston 38 is show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com