High pressure co-rail electric control fuel injection system

A fuel injection system, high-pressure common rail technology, applied in the direction of fuel injection pump, fuel injection device, fuel injection control, etc., can solve problems such as waste of resources, achieve low risk, reduce the difficulty of technological evolution and resistance to marketization, reduce The effect of development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

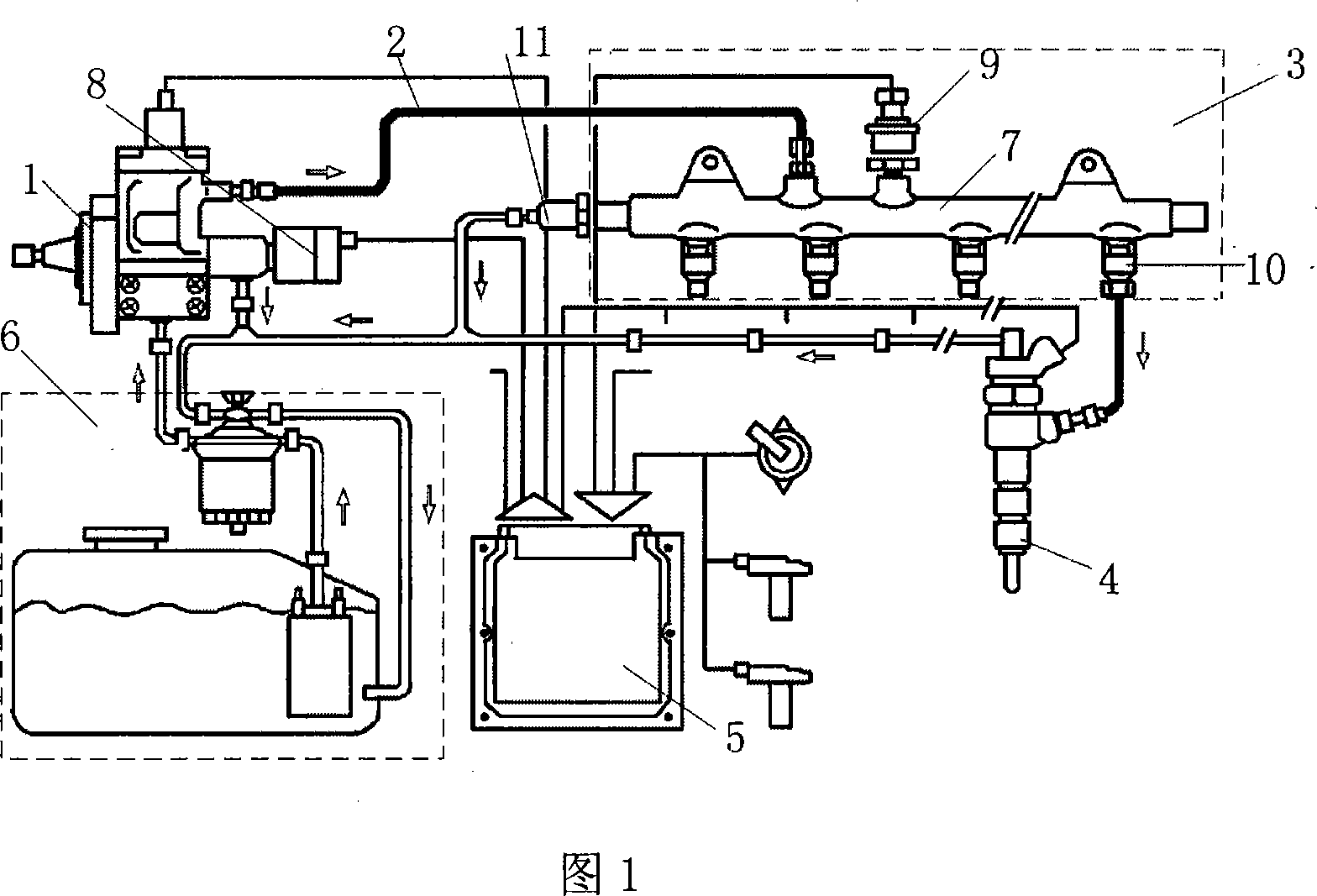

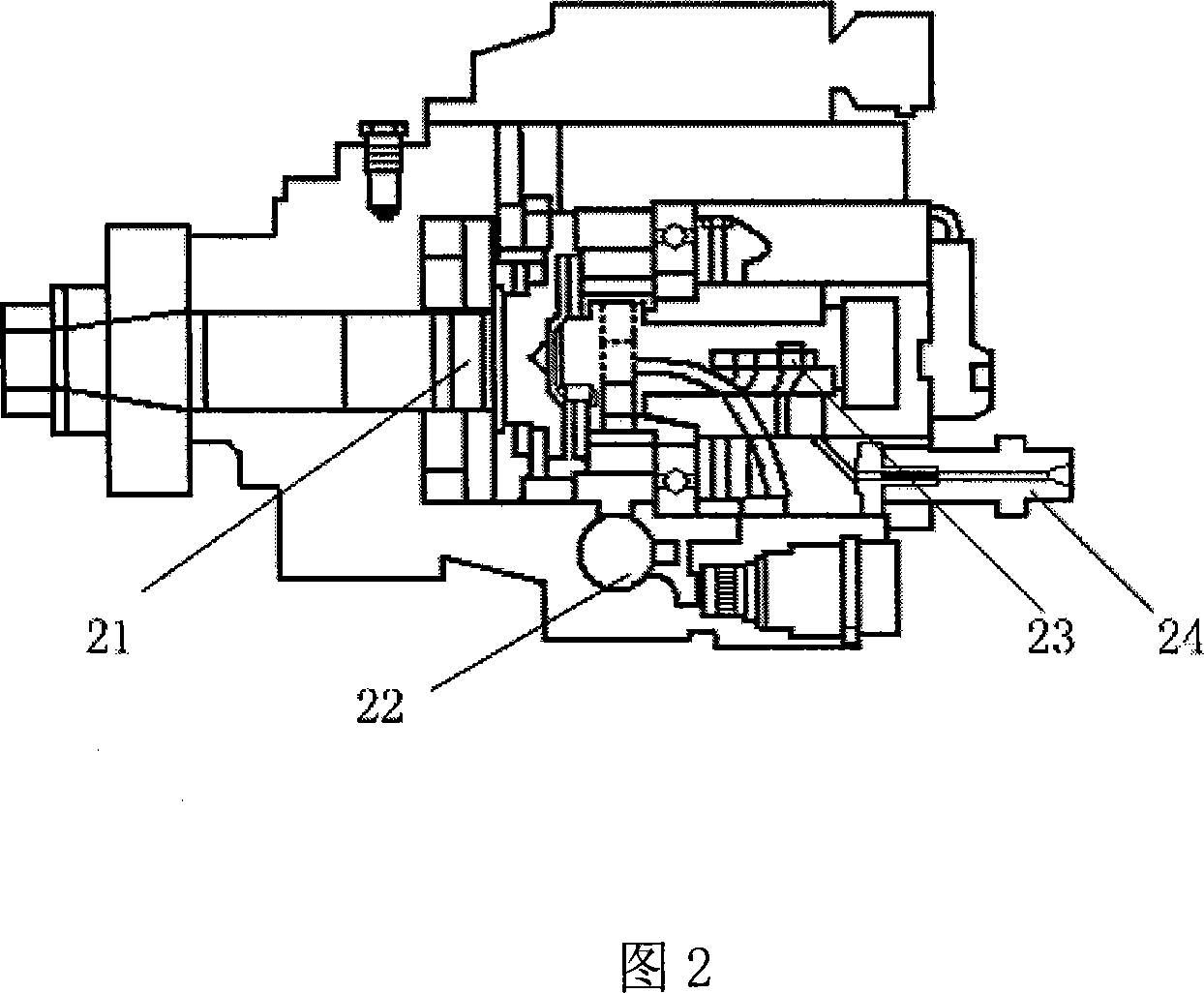

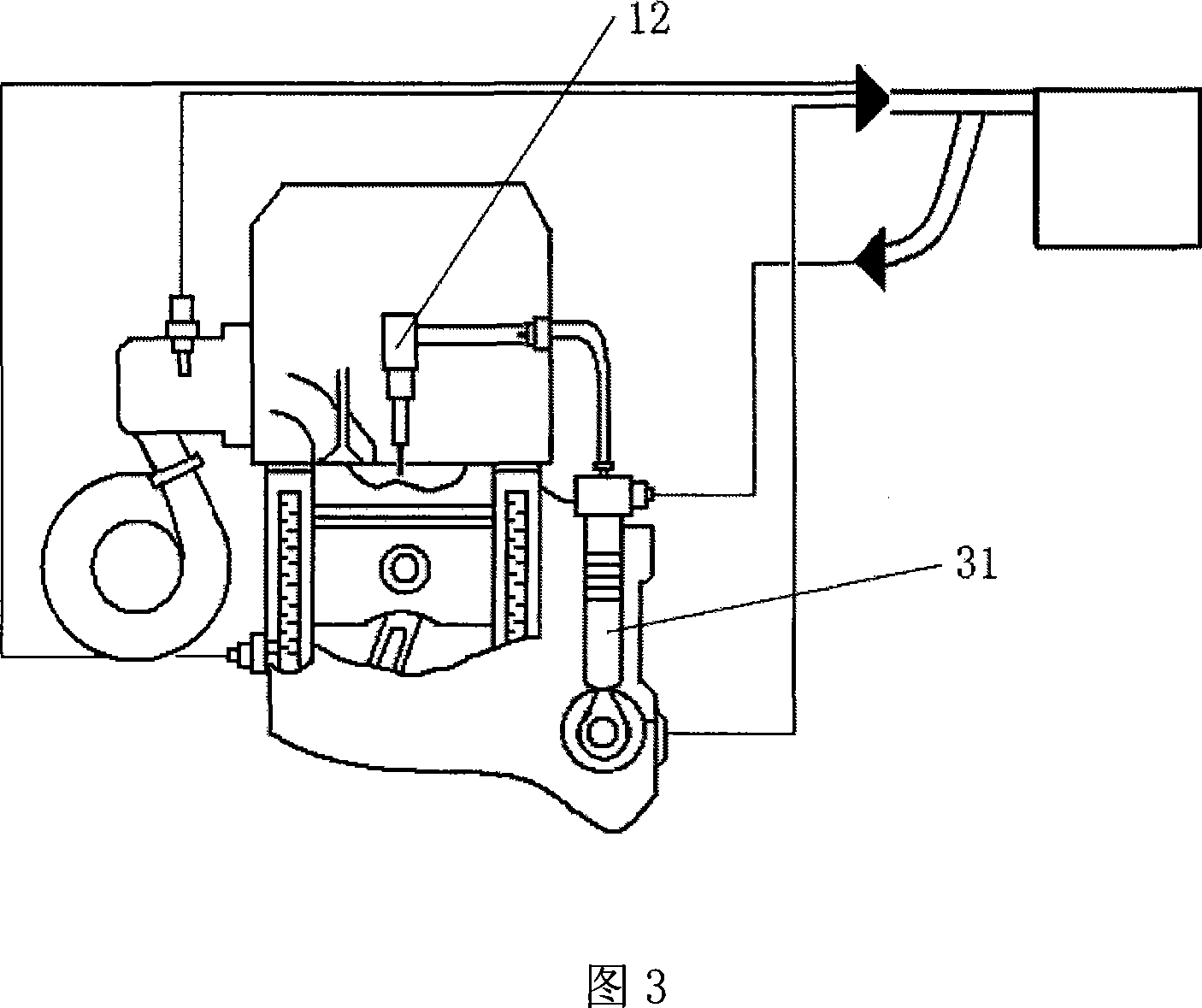

[0026] Fig. 13 is a schematic diagram of the high-pressure common rail electronically controlled fuel injection system provided by the present invention. The high-pressure common rail electronically controlled fuel injection system is mainly composed of six parts: low-pressure oil circuit 6, electronically controlled high-pressure oil pump 131, high-pressure oil pipe 2, high-pressure fuel rail 3, electronically controlled fuel injector 4, and ECU (electronic control unit) 5. . Among them, the electronically controlled high-pressure oil pump 131 and the low-pressure oil circuit 6 make full use of the existing non-high-pressure common rail electronically controlled fuel injection system (the non-high-pressure common-rail electronically controlled fuel injection system refers to electronically controlled fuel injection systems other than the hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com