Joint device for flexible pipe

A joint device, flexible technology, applied in the direction of hose connection device, pipe/pipe joint/pipe fitting, mechanical equipment, etc., can solve the problems of failure, time waste, difficult penetration, etc., to reduce the construction space, reduce Material usage, effect of reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

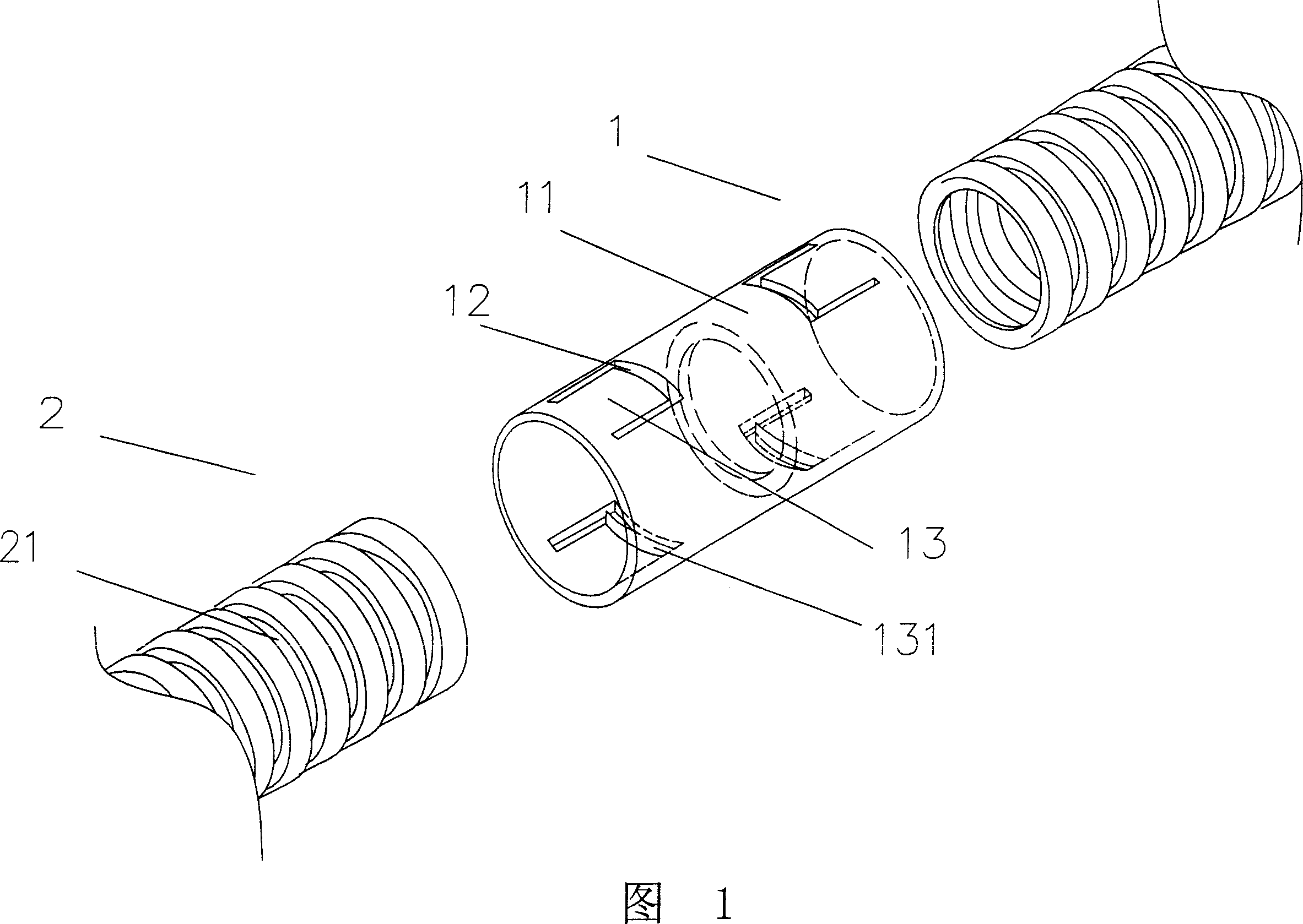

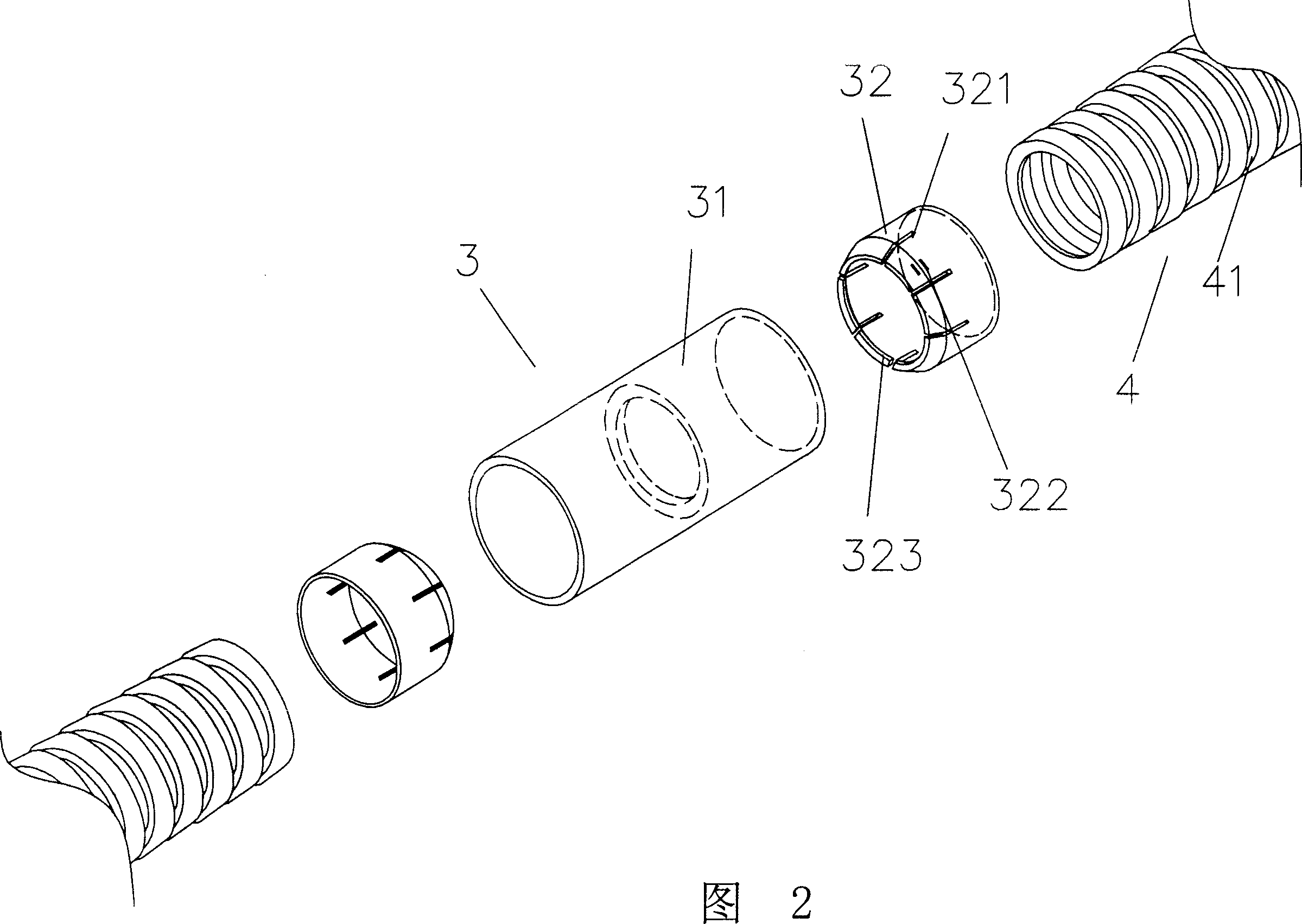

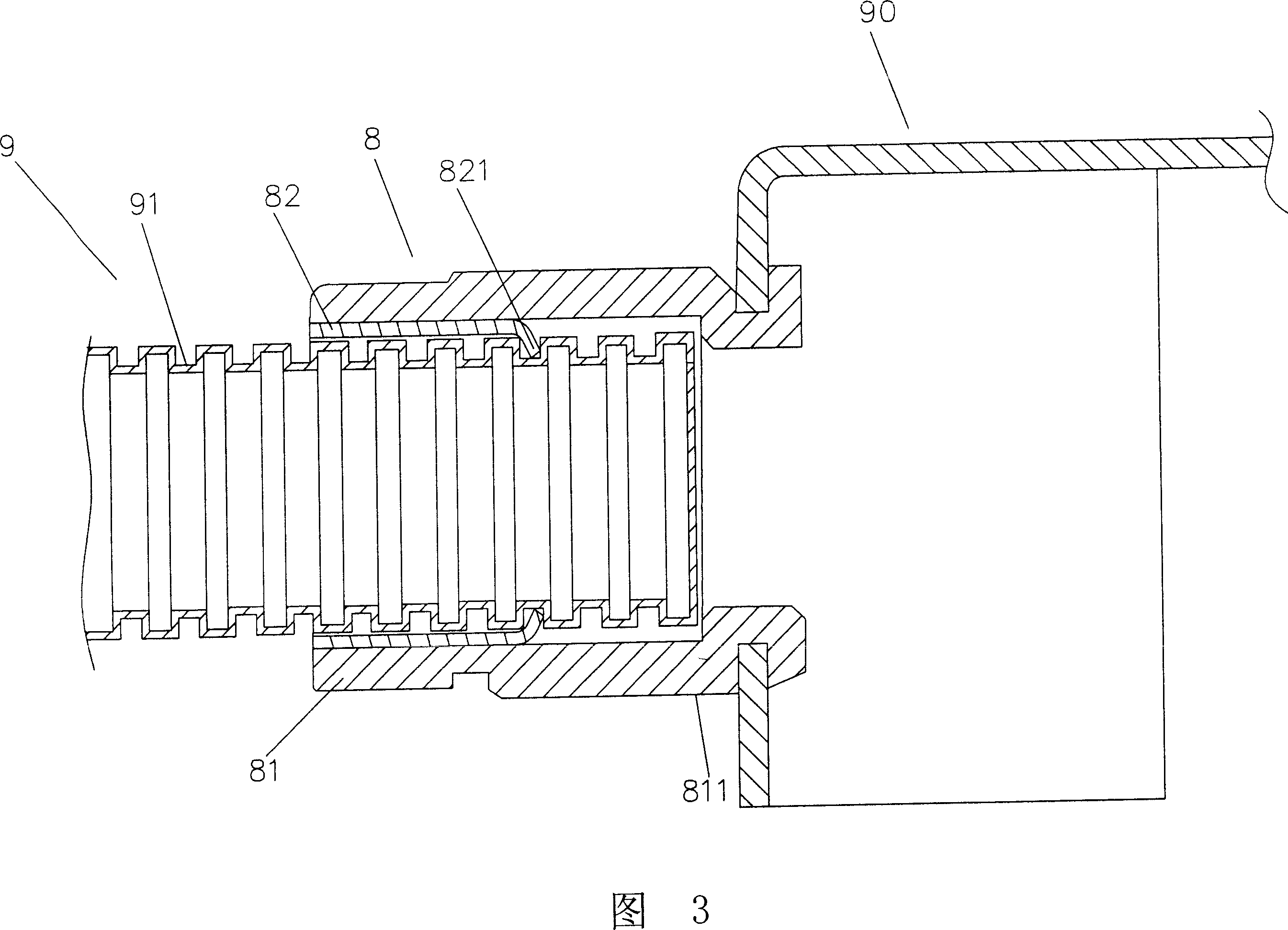

[0046] In order to understand more easily the device of the present invention and the effect that can be achieved, the accompanying drawings are described as follows.

[0047] Please refer to Figures 4-5 first, the present invention is mainly composed of at least one gasket ring 5 and a main body 6, wherein the gasket ring 5 is a cut ring body, and the two end faces of the cut part are corresponding slopes , so that the contact surface of the two end surfaces can be larger after they are closed, and can be more tightly bonded, at least one convex rib 51 is provided on the inner peripheral surface, and at least one insert 52 is provided on the outer peripheral surface, and at the same time At least one protruding puller 53 is provided on the outer edge of the washer ring 5. In this embodiment, the puller 53 is two corresponding pullers, which are used as force application points when the washer ring 5 is rotated. , the main pipe body 6 is a hollow circular pipe body, and a guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com