Multi layer disc

A technology of optical discs and Blu-ray discs, which is applied in the direction of optical record carrier, optical record carrier manufacturing, optical recording/reproduction, etc., and can solve the problems of increased manufacturing cost of optical discs, deterioration of signal characteristics, and reduced output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Here, preferred embodiments of the multilayer optical disc according to the present invention will be described in detail with reference to the accompanying drawings.

[0024] The present invention is applicable to various types of multilayer optical discs in which a plurality of recording layers are laminated on a single substrate.

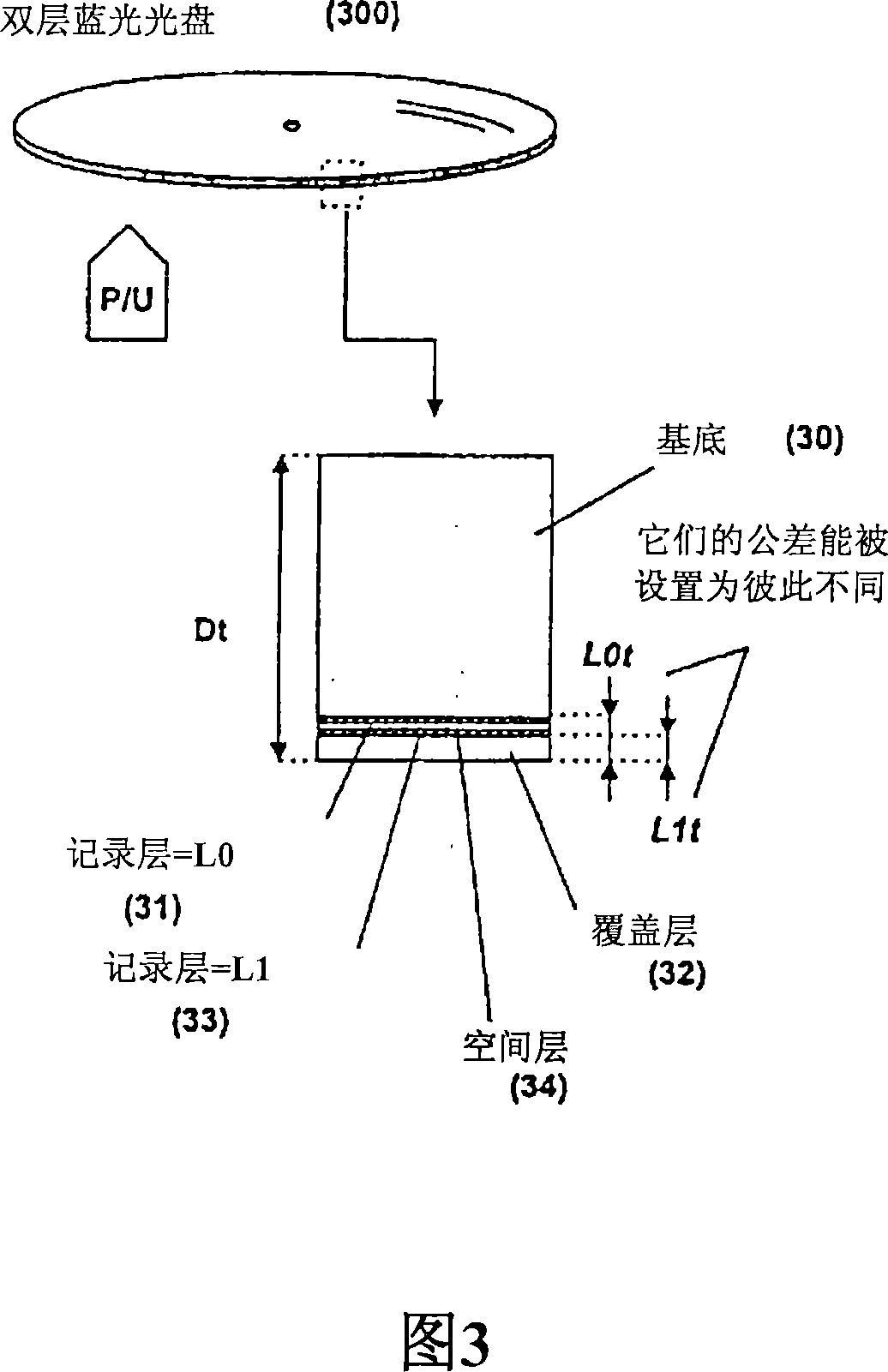

[0025] Referring to FIG. 3 , a dual-layer Blu-ray Disc (BD) 300 is shown. The dual-layer BD has a laminated optical disc structure including a substrate 30 , a first recording layer 31 ( L0 ), a space layer 34 , a second recording layer 33 ( L1 ), and a cover layer 32 .

[0026] The double layer BD300 has a total thickness Dt of 1200 μm. The sum of the thicknesses of the cover layer 32, the second recording layer 33, and the space layer 34 corresponds to the thickness from the exposed surface of the cover layer 32 to the first recording layer 31, that is, the thickness L0t, which is 100 μm, and in which the cover layer 32 With a refracti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com