Speaker and method of producing the same

A speaker and resin-made technology, applied in the direction of sensors, electrical components, etc., can solve problems such as low sound pressure, magnetic influence, etc., achieve good performance, improve bonding strength, and achieve flattening effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0028] Hereinafter, the present invention will be described in conjunction with Embodiment 1.

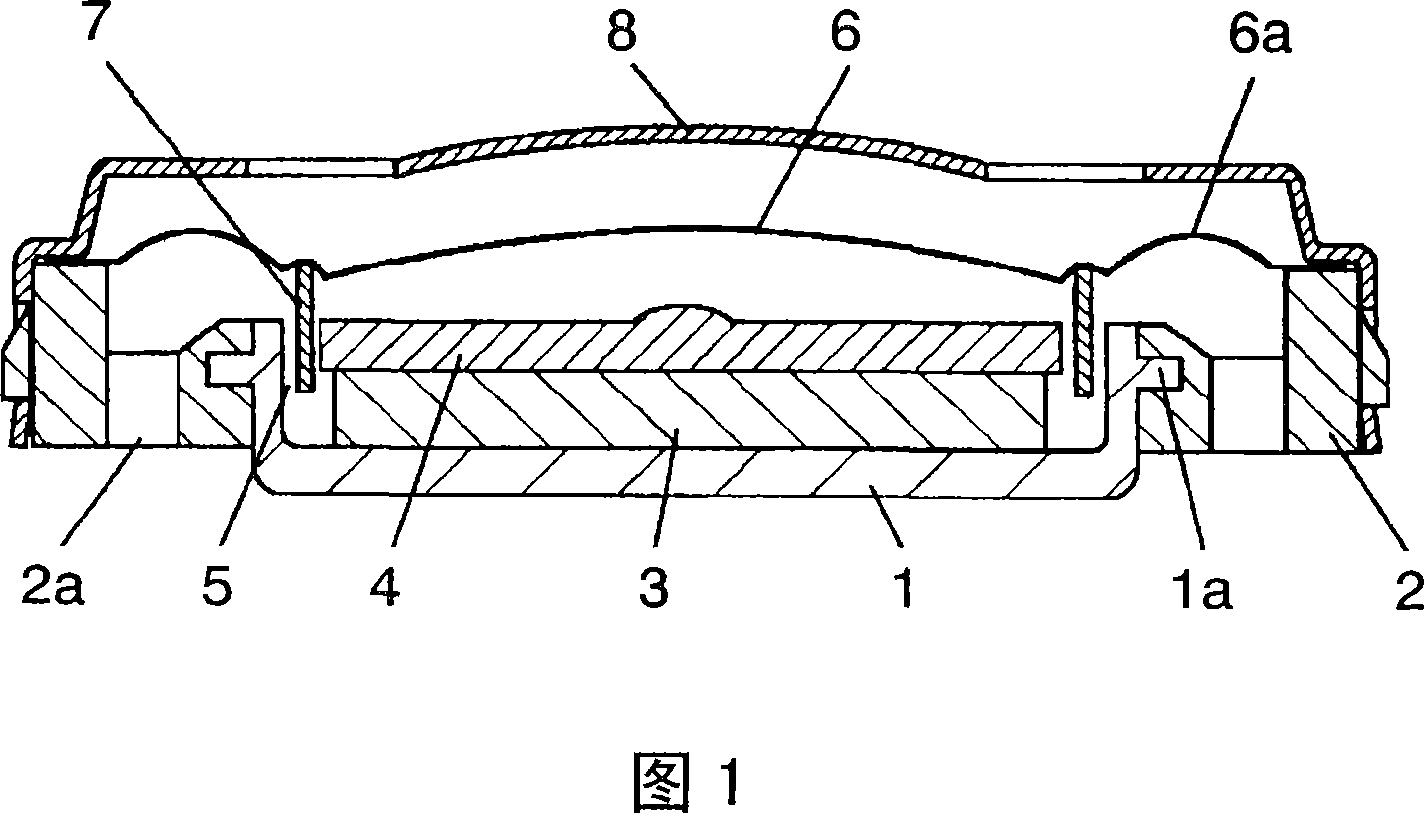

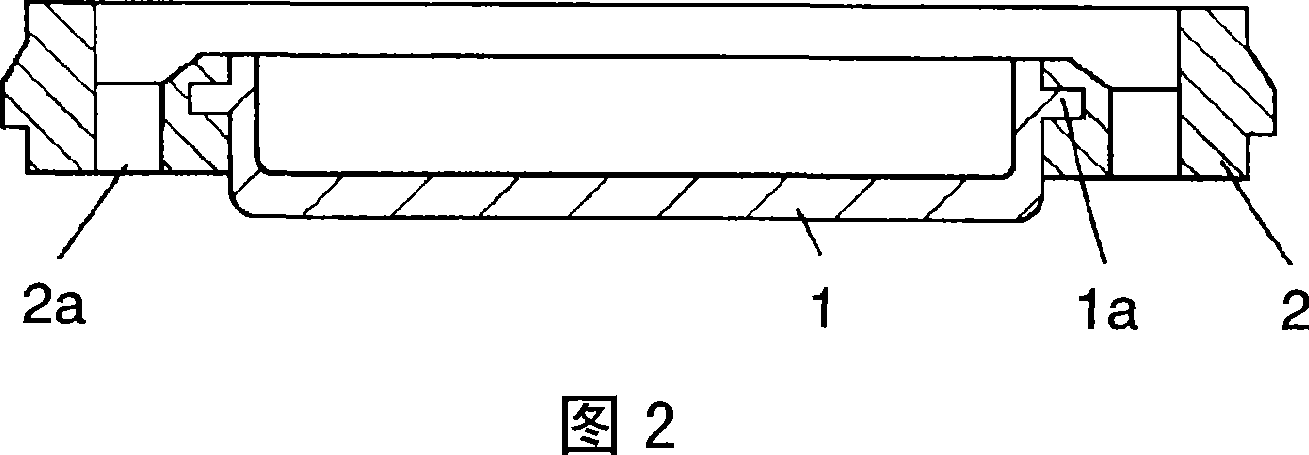

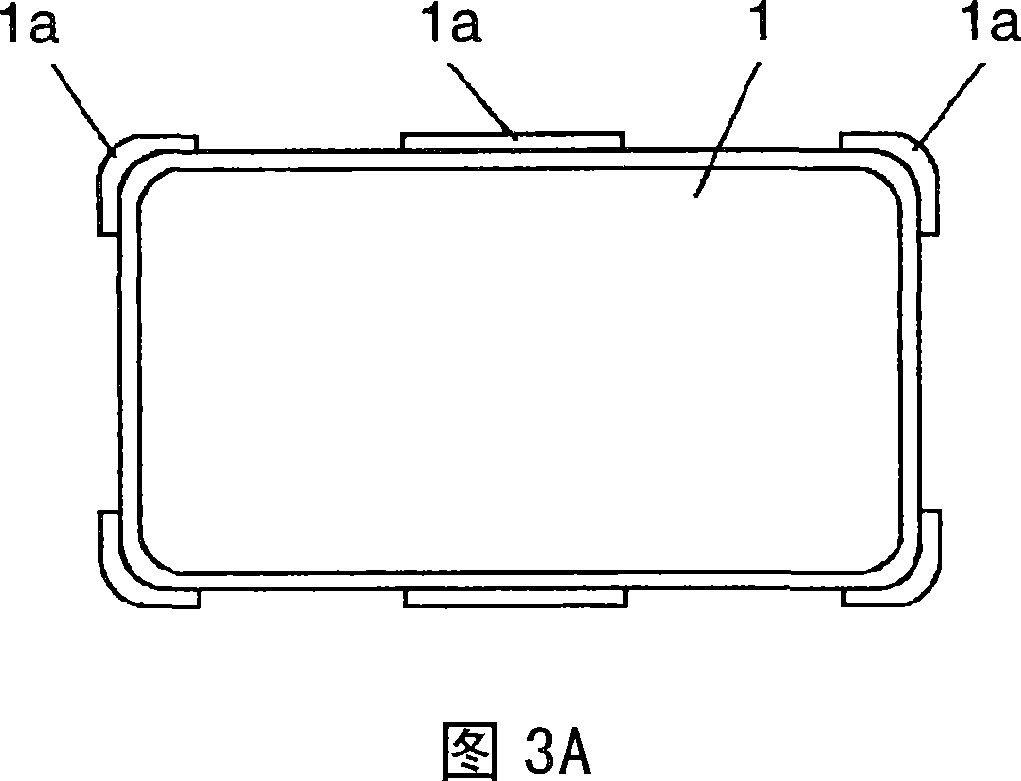

[0029] FIG. 1 is a cross-sectional view showing the structure of a loudspeaker manufactured by a loudspeaker manufacturing method according to Embodiment 1 of the present invention. Fig. 2 is a cross-sectional view showing a frame on which a yoke is insert-molded to be used in the speaker. 3A, 3B, and 3C are a plan view, a front sectional view, and a side sectional view showing a yoke used in the speaker, respectively. In FIG. 1 , FIG. 2 , FIG. 3A , FIG. 3B , and FIG. 3C , the yoke body 1 is formed into a rectangular plate shape using a magnetic metal material. In addition, tongue-shaped flange portions 1 a are symmetrically provided on each corner portion and long side of the yoke body 1 , and the flange portions 1 a protrude outward from a position lowered by a predetermined dimension from the upper end surface of the yoke body 1 . By providing a collar portion at a position low...

Embodiment approach 2

[0040] Next, the present invention will be described in conjunction with Embodiment 2.

[0041] In Embodiment 2, the structure of the voice coil used in the speaker of Embodiment 1 is different. Since the configuration other than this is the same as that of Embodiment 1, the same reference numerals are assigned to the same parts, and detailed description thereof will be omitted. Hereinafter, only different parts will be described with reference to the drawings.

[0042] 5 is a cross-sectional view showing the structure of a speaker manufactured by the speaker manufacturing method according to Embodiment 2 of the present invention. In FIG. 5 , the voice coil 9 is constituted by forming coils of a predetermined pattern in a coiled state on the front and back sides of a resin base material.

[0043]The center of the diaphragm 10 with the edge 10a integrally provided on the periphery is bonded to the base material of the voice coil 9 except the coil, so that the voice coil 9 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com