Flexible static compensation type coil moment-increasing fluid gyroscope

A micro gyroscope and compensation technology, applied in the field of micro gyroscope, can solve the problems of difficult to precisely process motor drive bearings, high process requirements, complex structure, etc., and achieve the effects of low cost, simple system structure and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and processes are provided, but the protection scope of the present invention is not limited to the following implementations example.

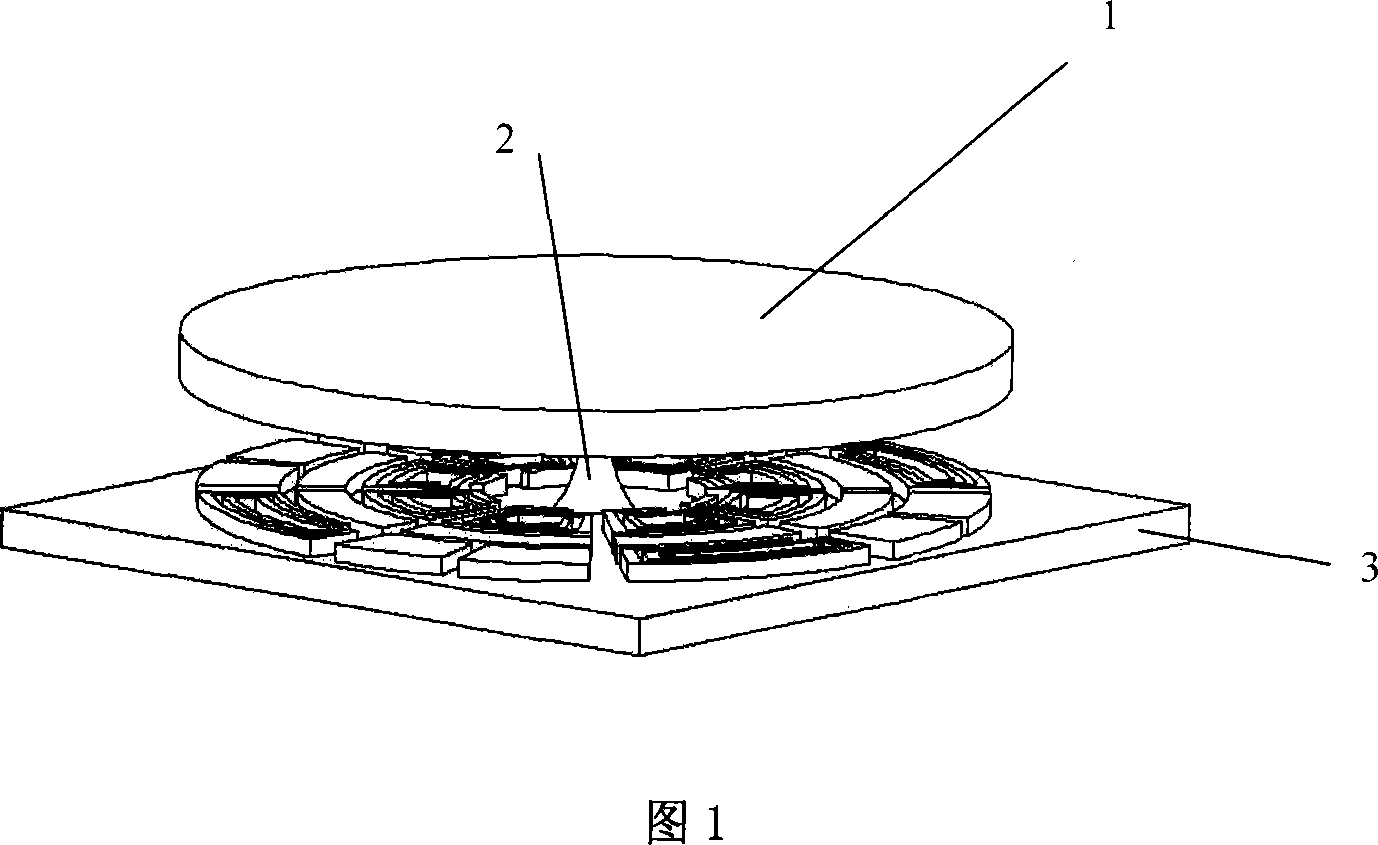

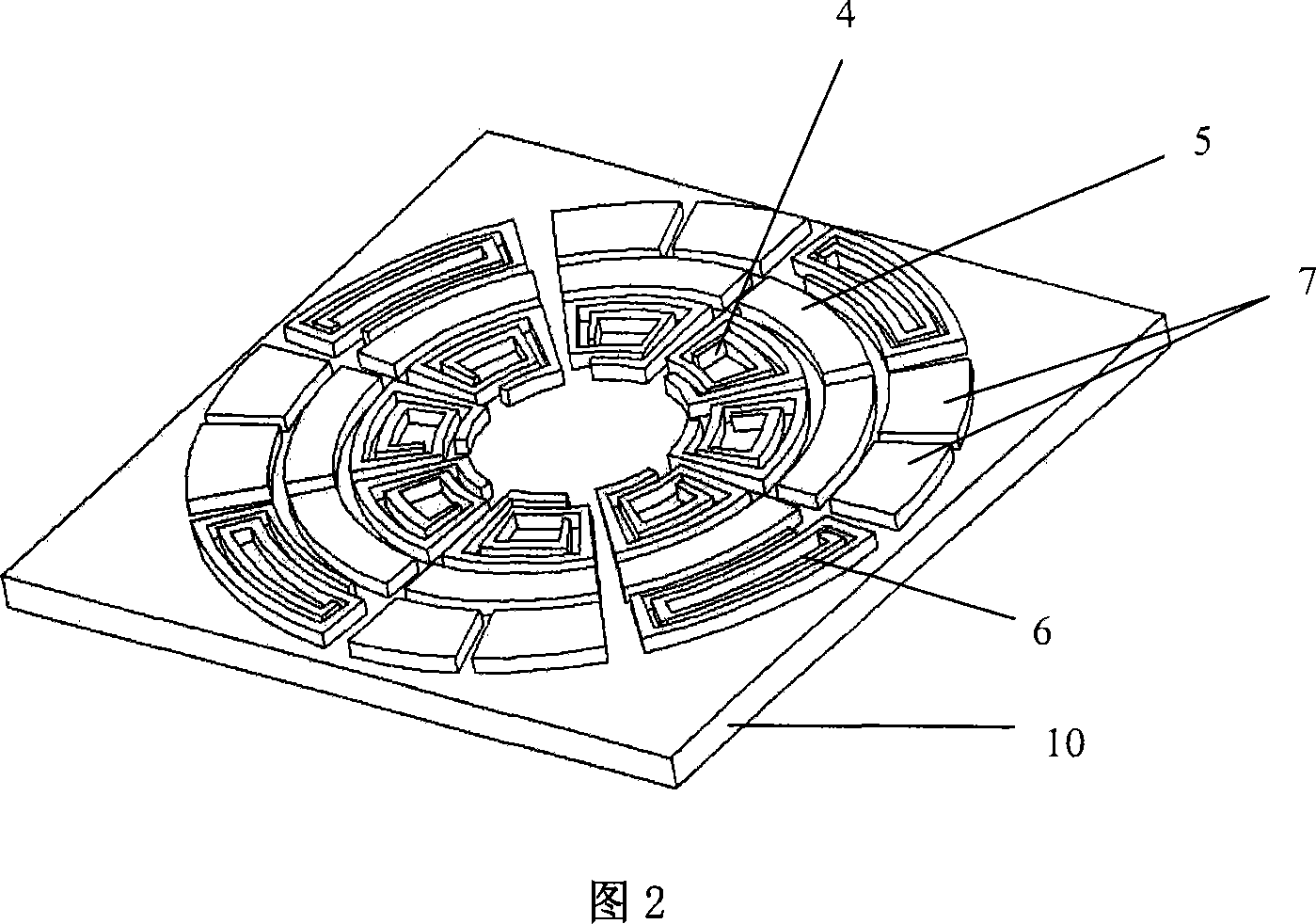

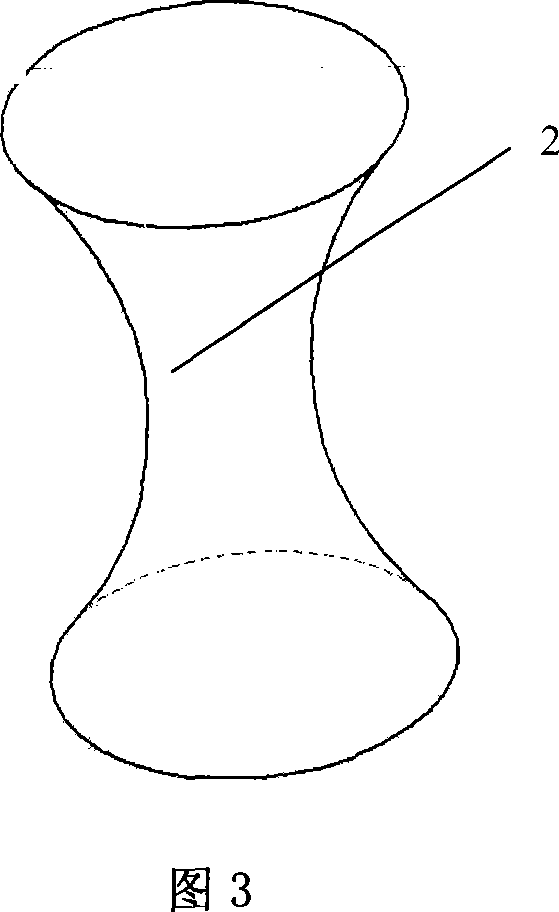

[0014] As shown in FIG. 1 , FIG. 2 , FIG. 3 , and FIG. 4 , this embodiment includes: a rotor 1 , a flexible beam 2 , and a stator 3 . The rotor 1 and the stator 3 are connected as a whole through the flexible beam 2, and the flexible beam 2 will be deformed as the relative positions of the rotor 1 and the stator 3 deviate. The rotor 1 is composed of a first base body 8 and an annular cavity 9 . The second base 10 of the stator 3 is processed with a rotating drive coil 4 , a detection electrode 5 , a feedback torque adding coil 6 , and a flexible compensation electrostatic electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com