Winding device

A technology of winding and control devices, which is applied in transportation and packaging, melt spinning, current collectors, etc., and can solve problems such as difficult spindle frame rotation centers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

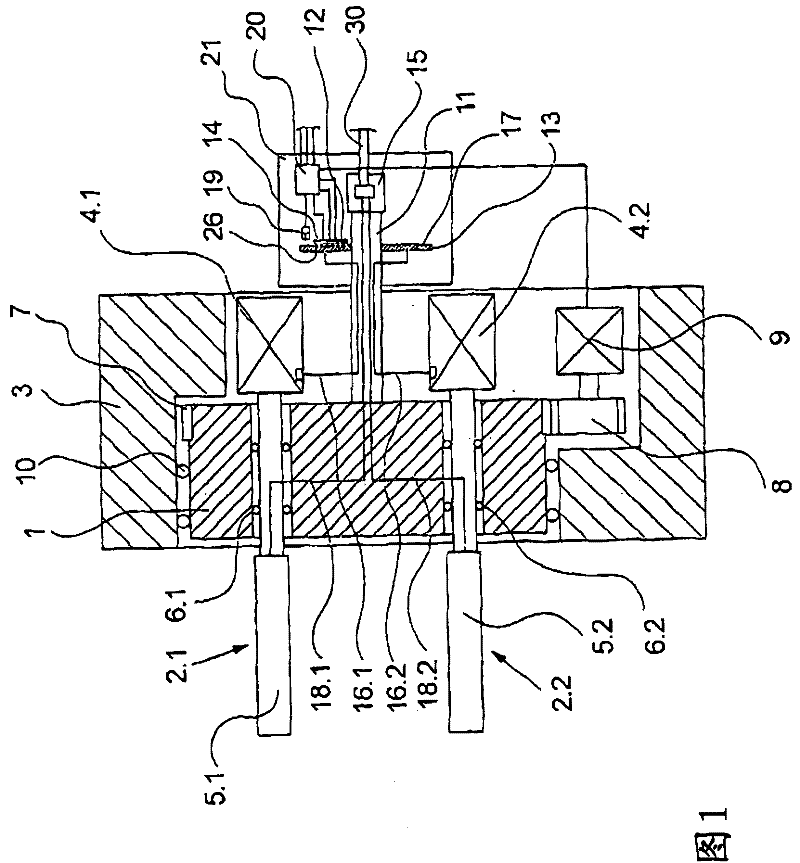

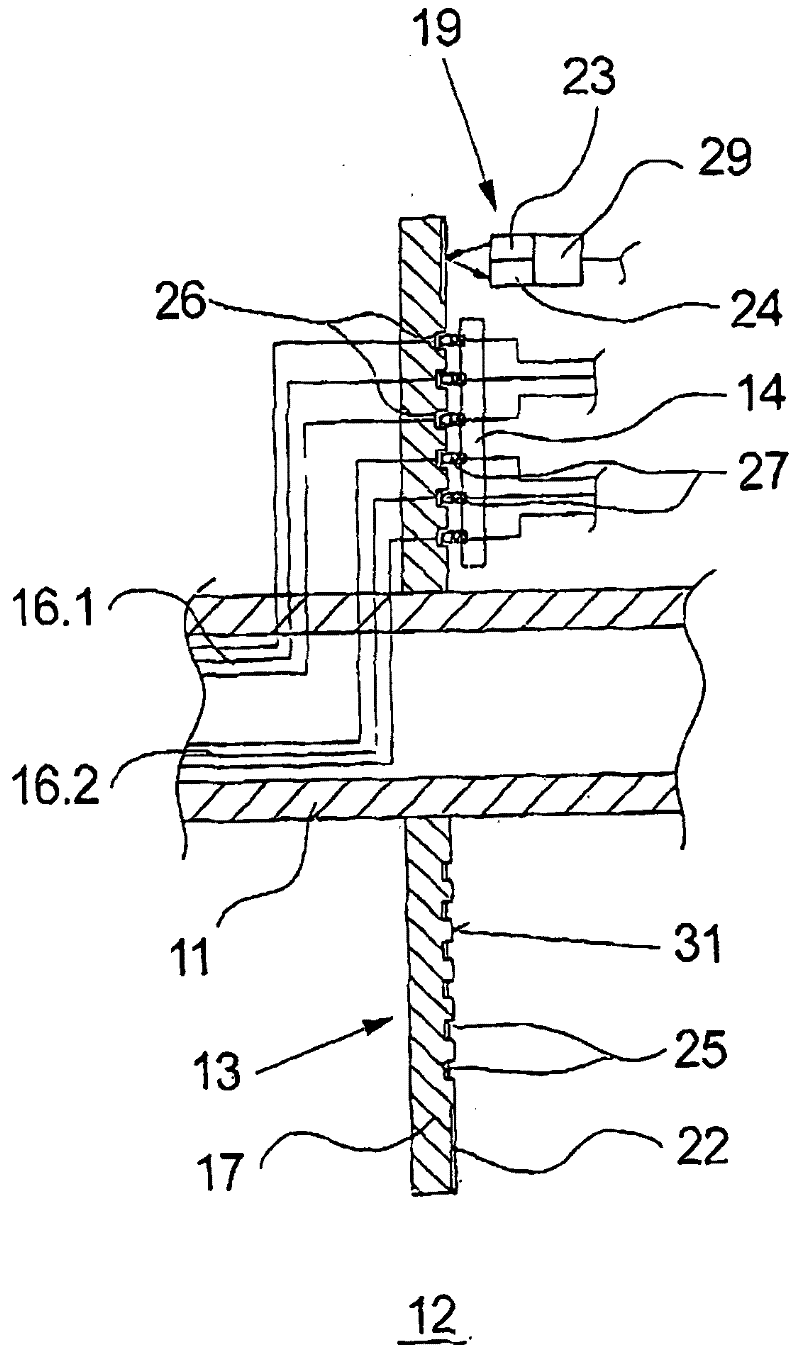

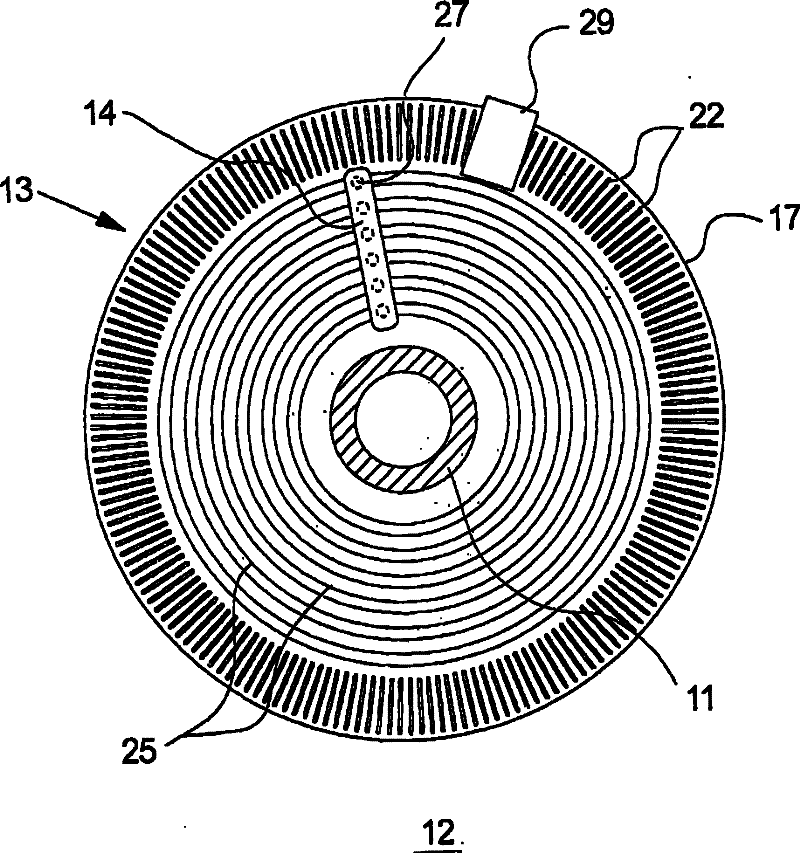

[0024] figure 1 The first embodiment of the winding device of the present invention is schematically shown in cross-sectional view.

[0025] This exemplary embodiment shows a spindle carrier 1 which is designed in the form of a cylinder and is mounted rotatably in a housing 3 via a housing bearing 10 . The spindle carrier 1 has a ring gear 7 on its circumference, which is connected via a transmission 8 to a geared motor 9 for driving the spindle carrier 1 . The geared motor 9 is controlled by a control device 20 .

[0026] Two winding spindles 2.1 and 2.2 are rotatably mounted on the spindle carrier 1 at a distance from one another, in particular offset from one another by 180°, via bearings 6.1 and 6.2. The bobbin spindles 2.1 and 2.2 are connected at one end to a spindle motor 4.1 and 4.2 respectively. The spindle motor 4.1 is arranged on the bobbin spindle 2.1, and the spindle motor 4.2 is arranged on the bobbin spindle 2.2. On the opposite side of the spindle carrier 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com