Folding type ICT needle bed fixture

A folding and needle bed technology, applied in the field of jigs, can solve the problems of structural deformation of the probe, broken and deformed plastic shell, no protection, etc., to prevent dust deposition, improve service life, and prevent shell damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

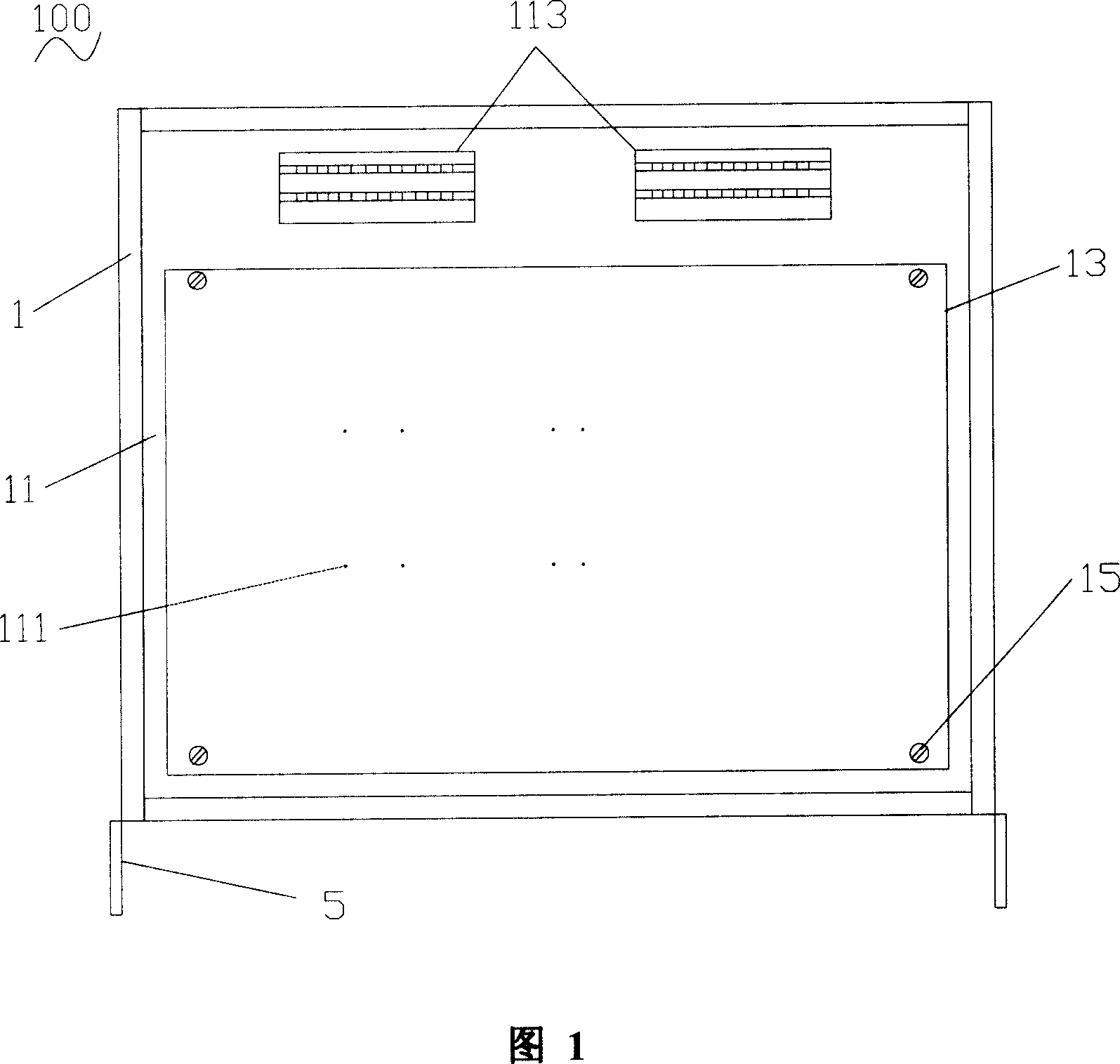

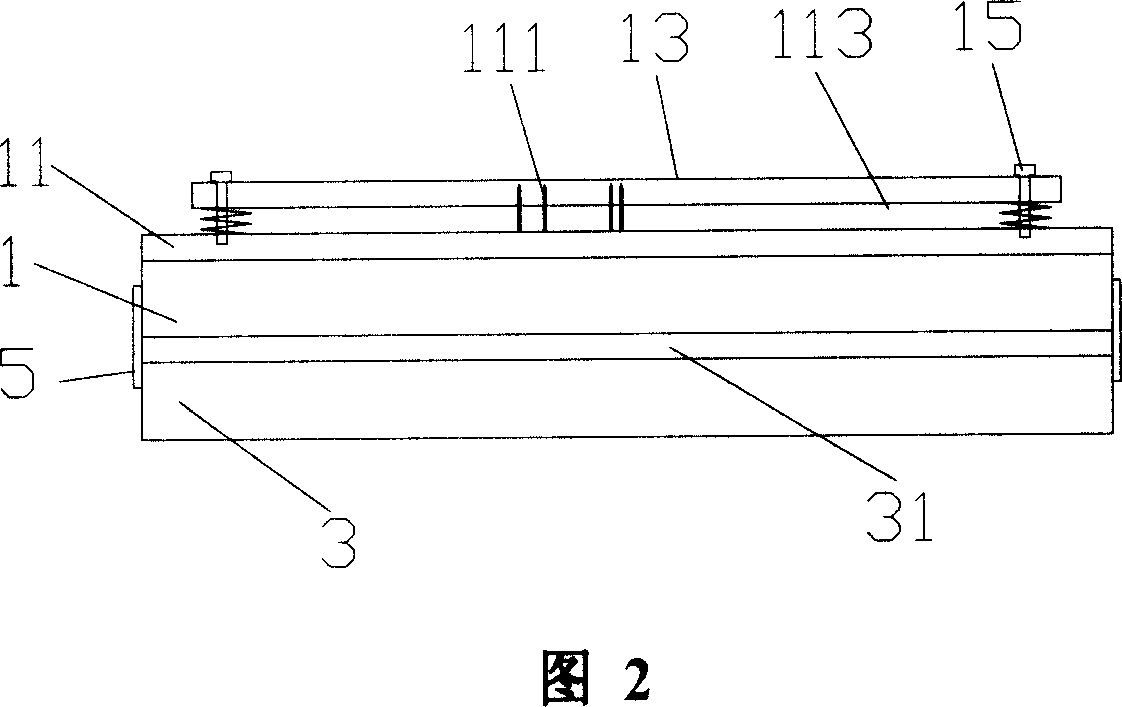

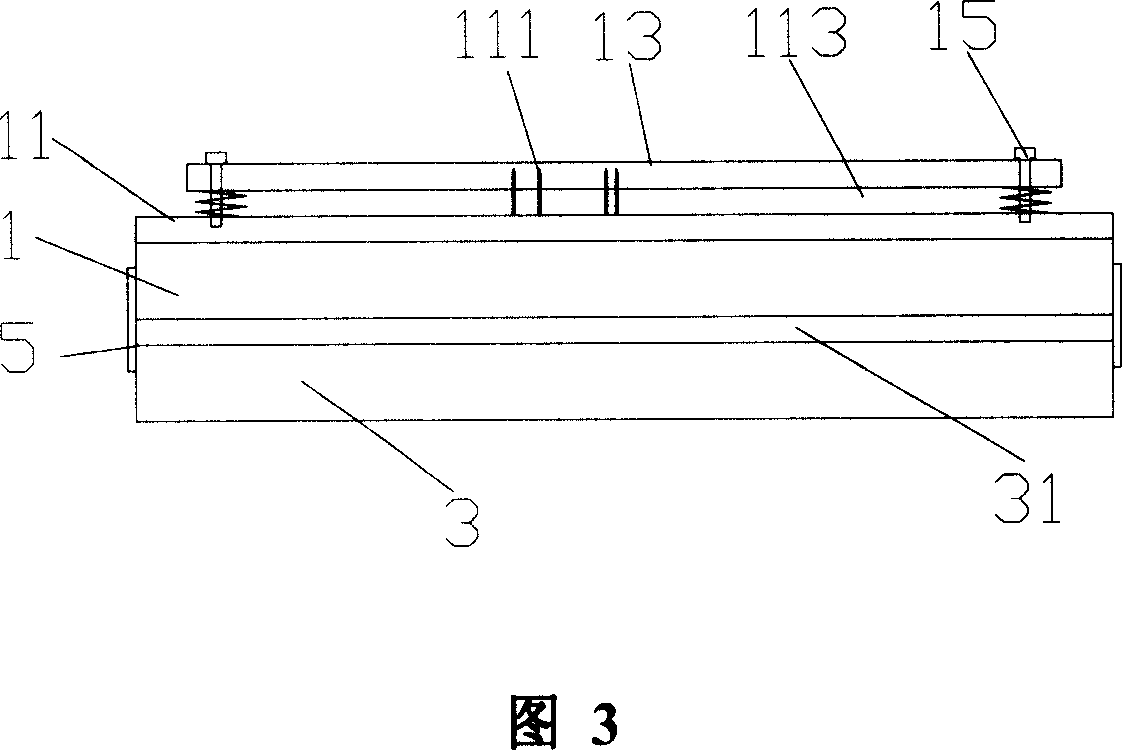

[0024] Please refer to shown in Fig. 1, the foldable ICT (IN-CIRCUIT TESTER, online testing platform) needle bed jig 100 of the present invention includes a main body frame 1, a needle board 11 arranged on the main body frame 1, and a probe arranged on the needle board 11. The needle 111 , the connector 113 , and the needle guard 13 arranged on the needle plate 11 . A cover body (not labeled) and a rotating device 5 that rotatably connects the cover frame 3 and the main body frame 1 .

[0025] Please refer to FIG. 2 and FIG. 3 at the same time, the four corners of the needle guard 13 are fixed on the needle plate 11 by the positioning member needle guard 15 , and the needle guard 13 is adjacent to the front edge of the needle guard 11 . The probes 111 are fixed on the needle plate 11 and are located below the needle guard plate 13. The number and arrangement of the probes 111 are the same as those of the existing ICT needle bed fixture, so in Fig. 1-Fig. 3 only schematically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com