Improved ion beam utilization during scanned ion implantation

A technology of ion implantation and ion beam, which is applied in the direction of discharge tubes, electrical components, circuits, etc., can solve the problems of easy understanding, reduction of processing amount, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

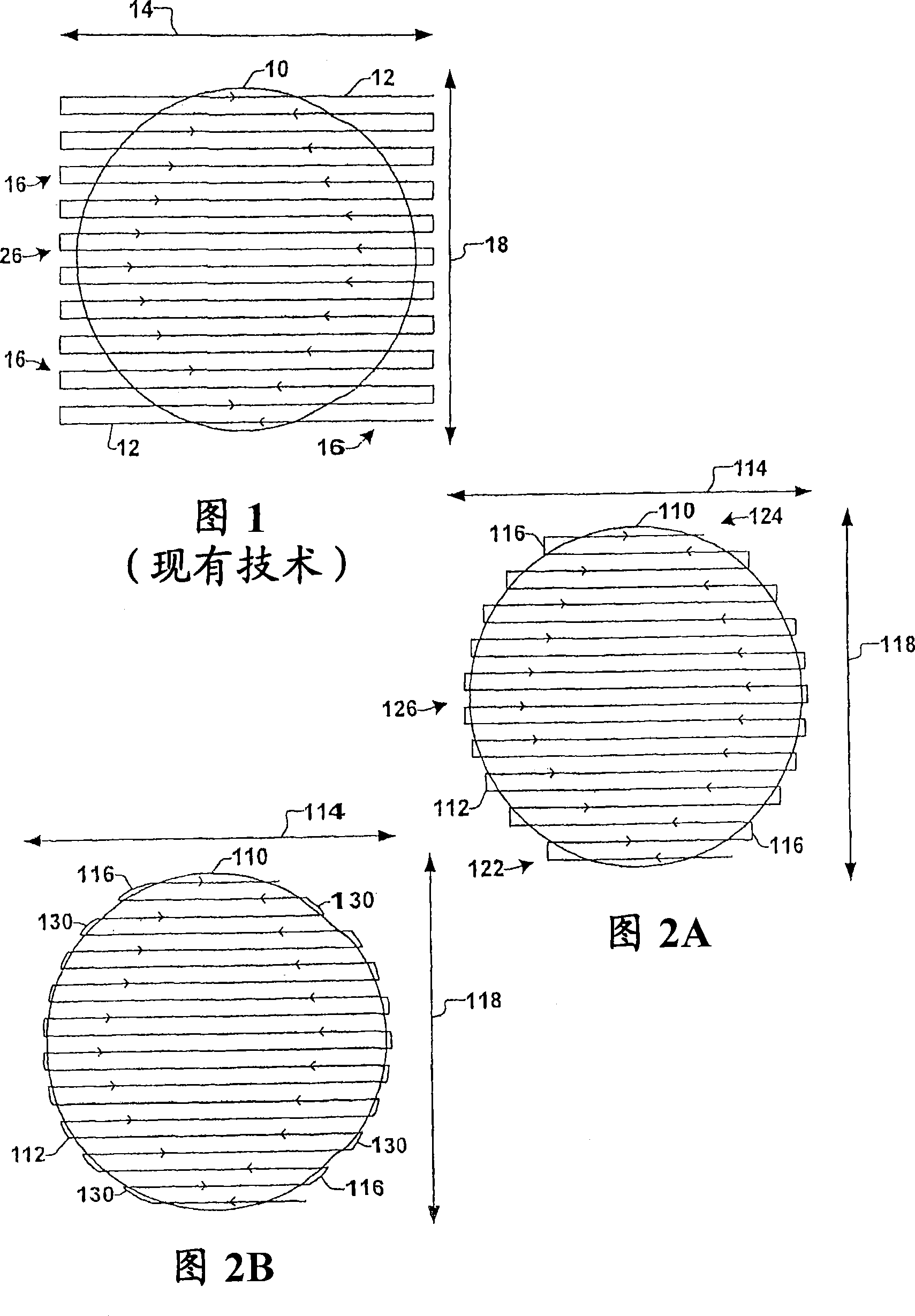

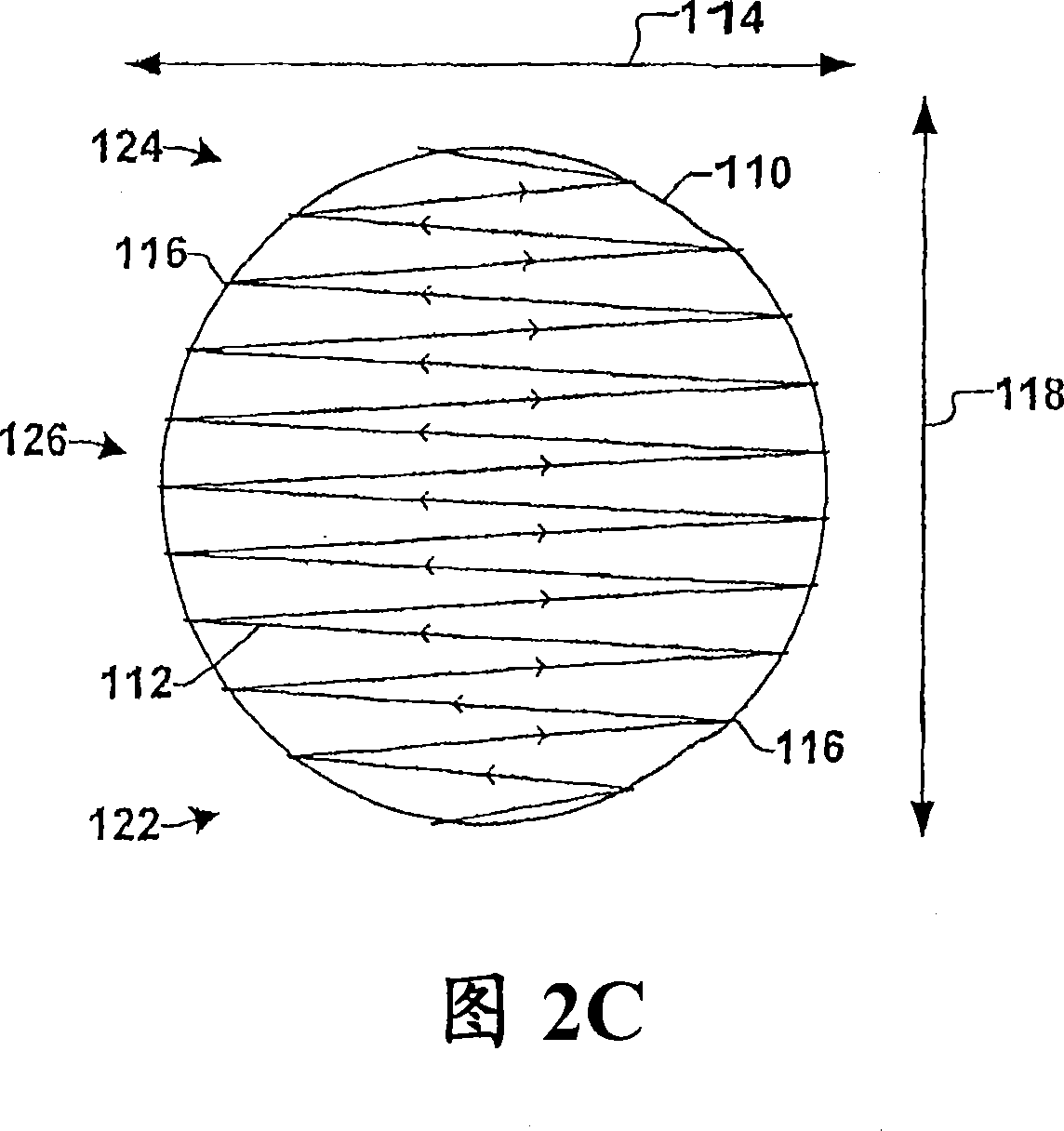

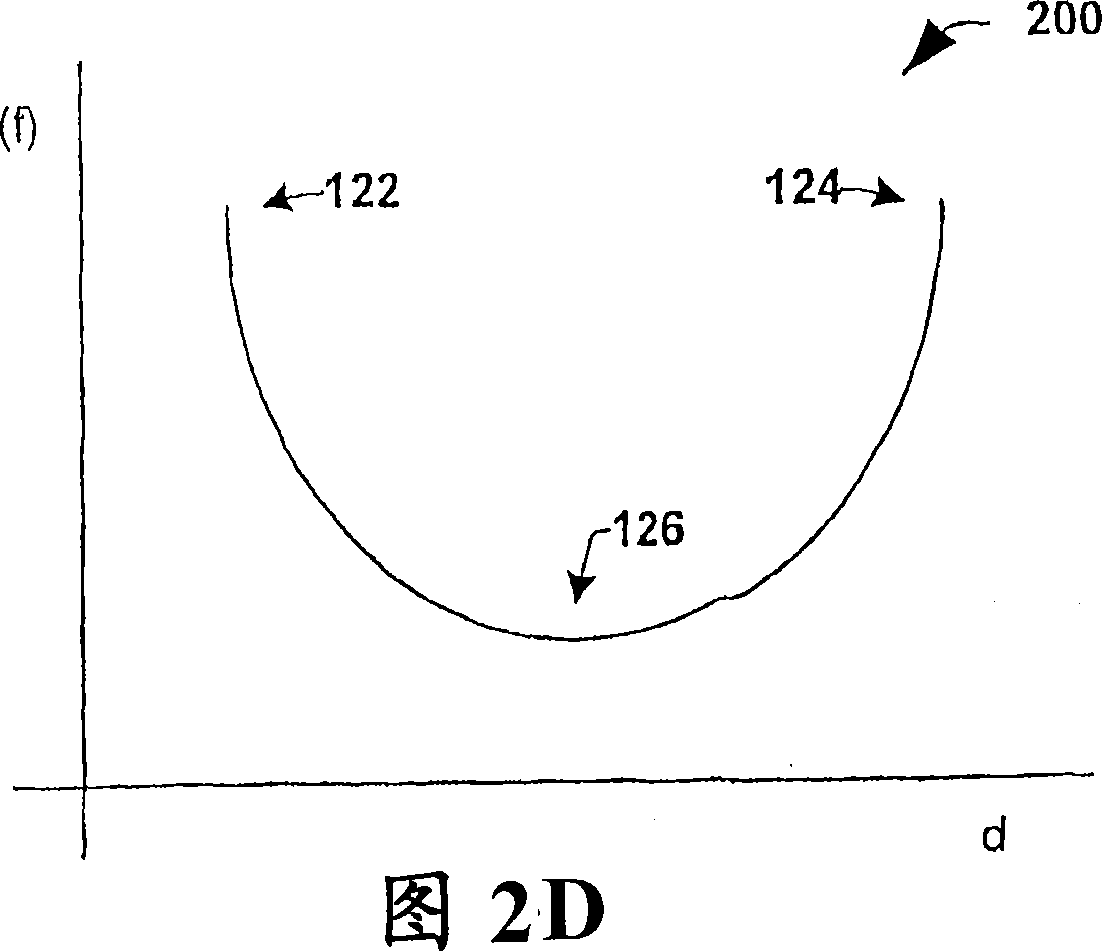

[0020] The present invention involves moving a workpiece, ie, a substrate, relative to a substantially stationary ion beam such that the resulting scan pattern resembles the shape of the workpiece. One or more aspects of the invention will now be described with reference to the drawings, wherein like reference numerals refer to like elements throughout. Note that the drawings and the following description are illustrative only and should not be considered limiting. In the following description, for purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of the invention. However, it will be understood by those skilled in the art that the present invention may be practiced without these specific details. Accordingly, it should be understood that there are many variations to the systems and methods of the invention in addition to those described herein, and such variations are within the scope of the invention and the append...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com