Semi-submersible sewage treatment aeration equipment

A sewage treatment and aeration equipment technology, applied in water aeration, water/sludge/sewage treatment, sustainable biological treatment, etc., can solve the problems of insufficient aeration of sewage, clogged pores, large amount of sewage, etc., to achieve Eliminate maintenance, improve quality and efficiency, and improve operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

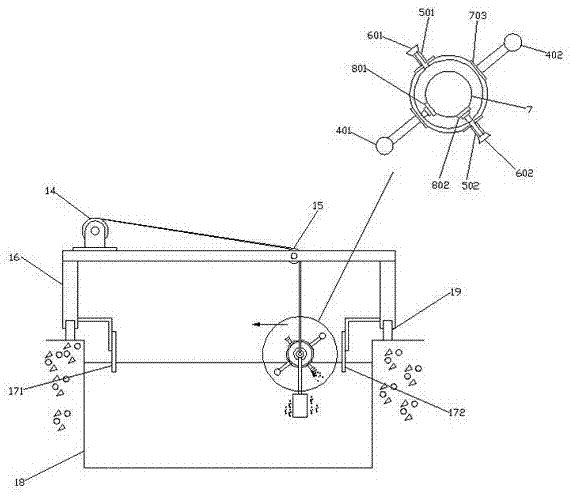

[0031] As the first embodiment of the invention, the first reversing rod 401 and the second reversing rod 402 are twice the length of the first spray rod 501 and the second spray rod 502 .

[0032] As the first embodiment of the invention, the interval angle between the first reversing rod 401 and the second spray rod 502 is 45 degrees.

[0033] As the first embodiment of the invention, the floating ball is made of honeycomb plastic material.

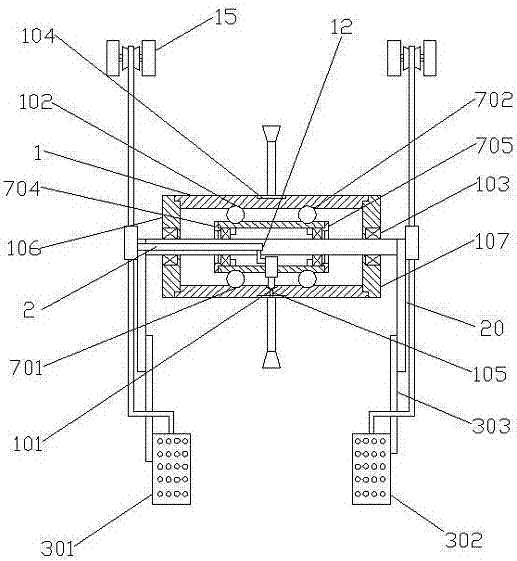

[0034] The mandrel 7 is cylindrical, and there are grooves on both sides of the cylinder. The left row of balls 701 and the right row of balls 702 are installed in the grooves. The left row of balls 701 and the right row of balls 702 are connected by a cage. The valve base 703, the first air valve 801 and the second air valve 802 are installed on the air valve base 703, bearings are installed inside the mandrel 7, and are connected with the main shaft 2 through the bearings, the left end cover 704 and the right end are respectively inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com