Double-cylinder internal combustion engine

An internal combustion engine and inner ring technology, applied in the field of power machinery, can solve problems such as leakage and affect the reliability of engine pistons, and achieve the effects of easy manufacturing, low noise and simple movement form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

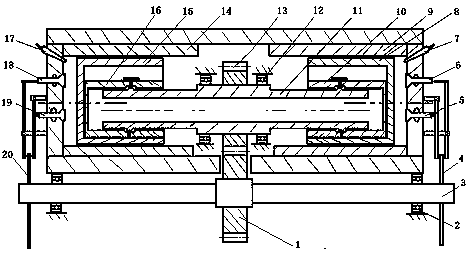

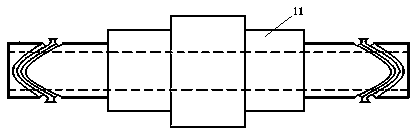

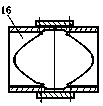

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings. Such as Figure 1-5 As shown, the double-cylinder internal combustion engine disclosed by the present invention consists of an air distribution gear (1), an air distribution shaft bearing (2), an air distribution shaft (3), a right air distribution cam (4), a right intake valve (5), Right exhaust valve (6), right spark plug (fuel injector) (7), right piston (8), right cylinder (9), right outer ring (10), double inner ring (11), inner ring bearing (12 ), inertia gear (13), left cylinder (14), left piston (15), left outer ring (16), left spark plug (fuel injector) (17), left exhaust valve (18), left intake valve (19), the left gas distribution cam (20) and the frame; the two groups of cylinders and pistons have the same shape and quality, and are symmetrically arranged at both ends of the double inner ring (11); the left piston (15), the right piston ( 8) The l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com