Substrate supporting/transferring tray

A substrate and tray technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of uneven temperature and difficult uniform heating of the substrate 1, and achieve the effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Next, preferred embodiments of the present invention will be described with reference to the drawings.

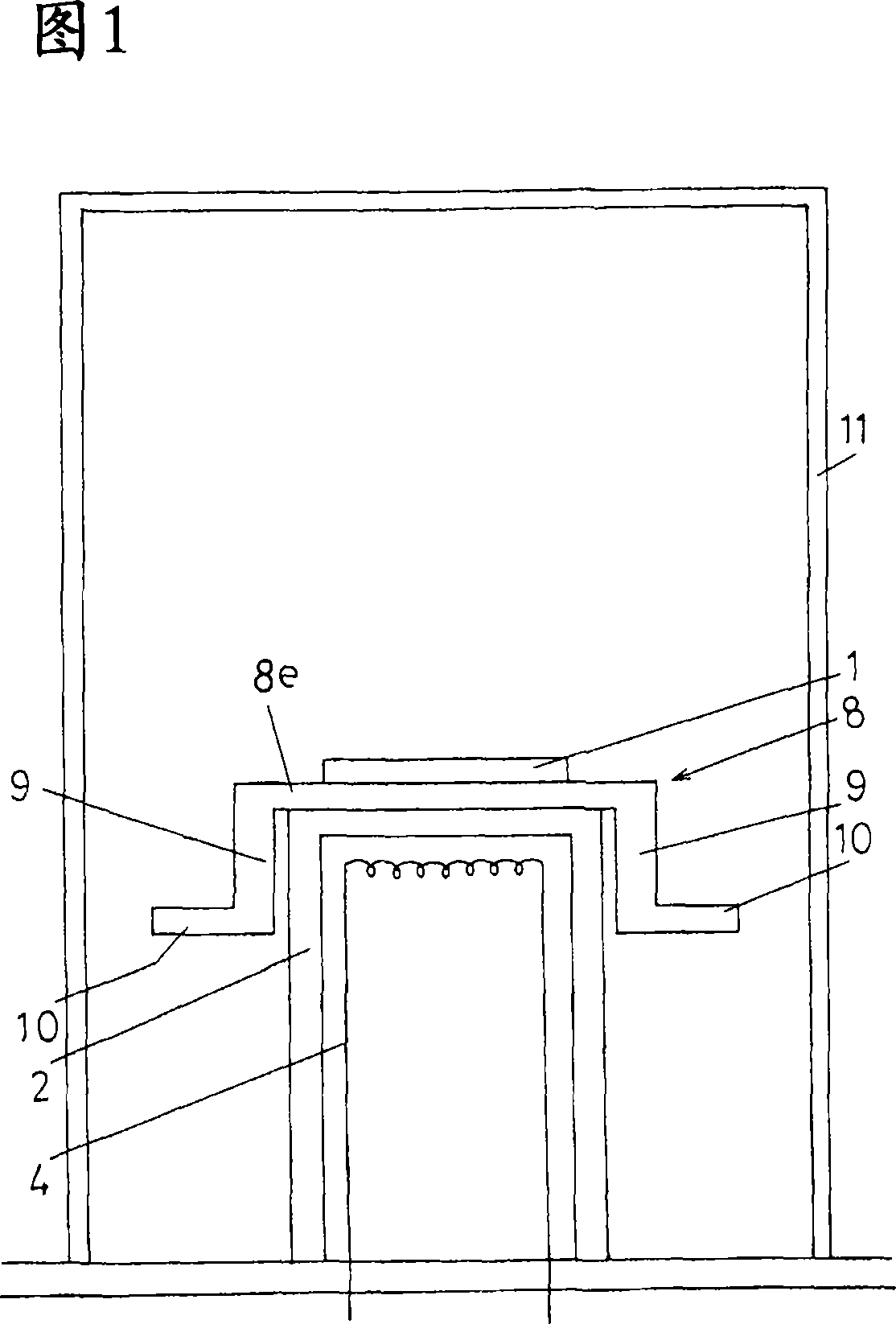

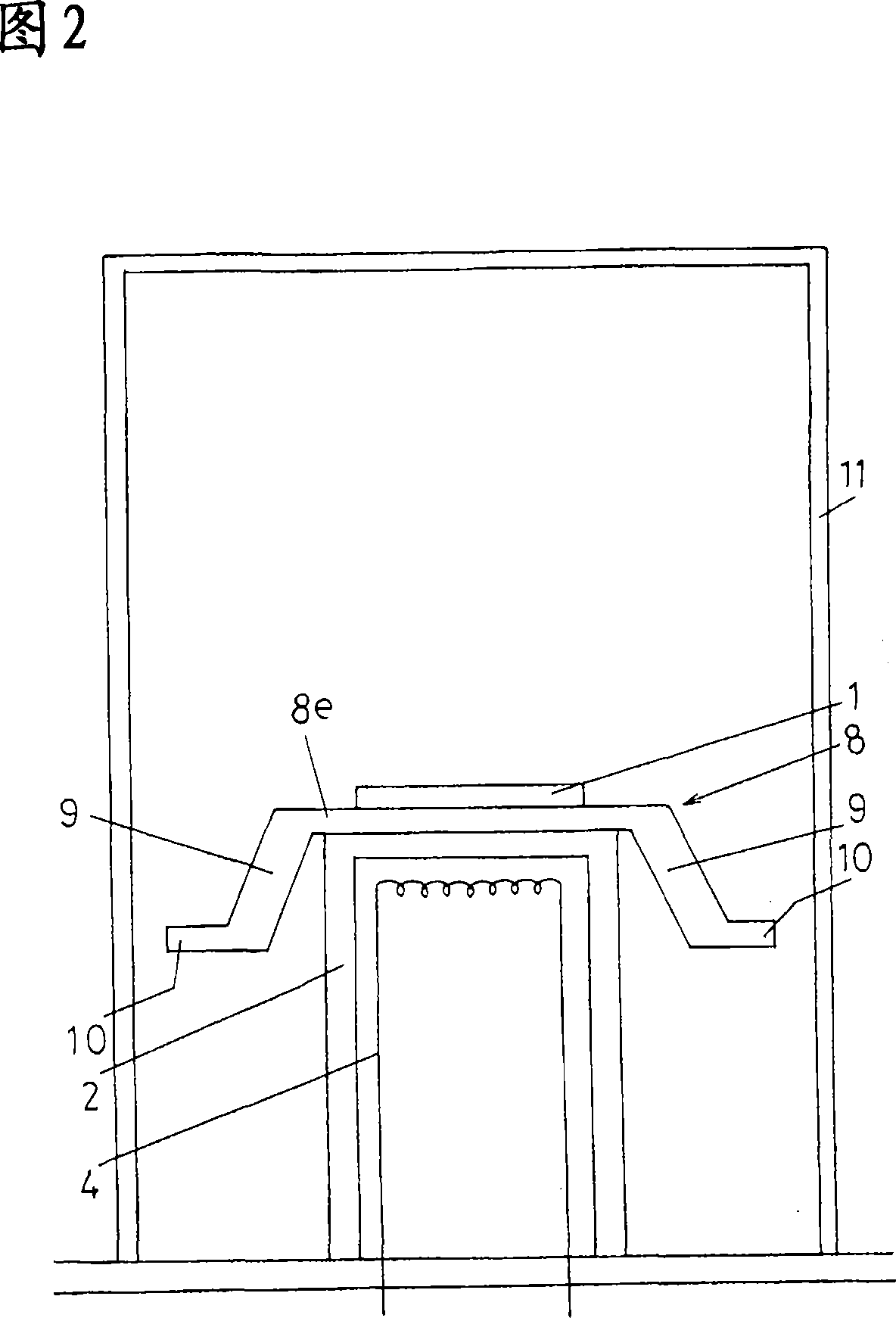

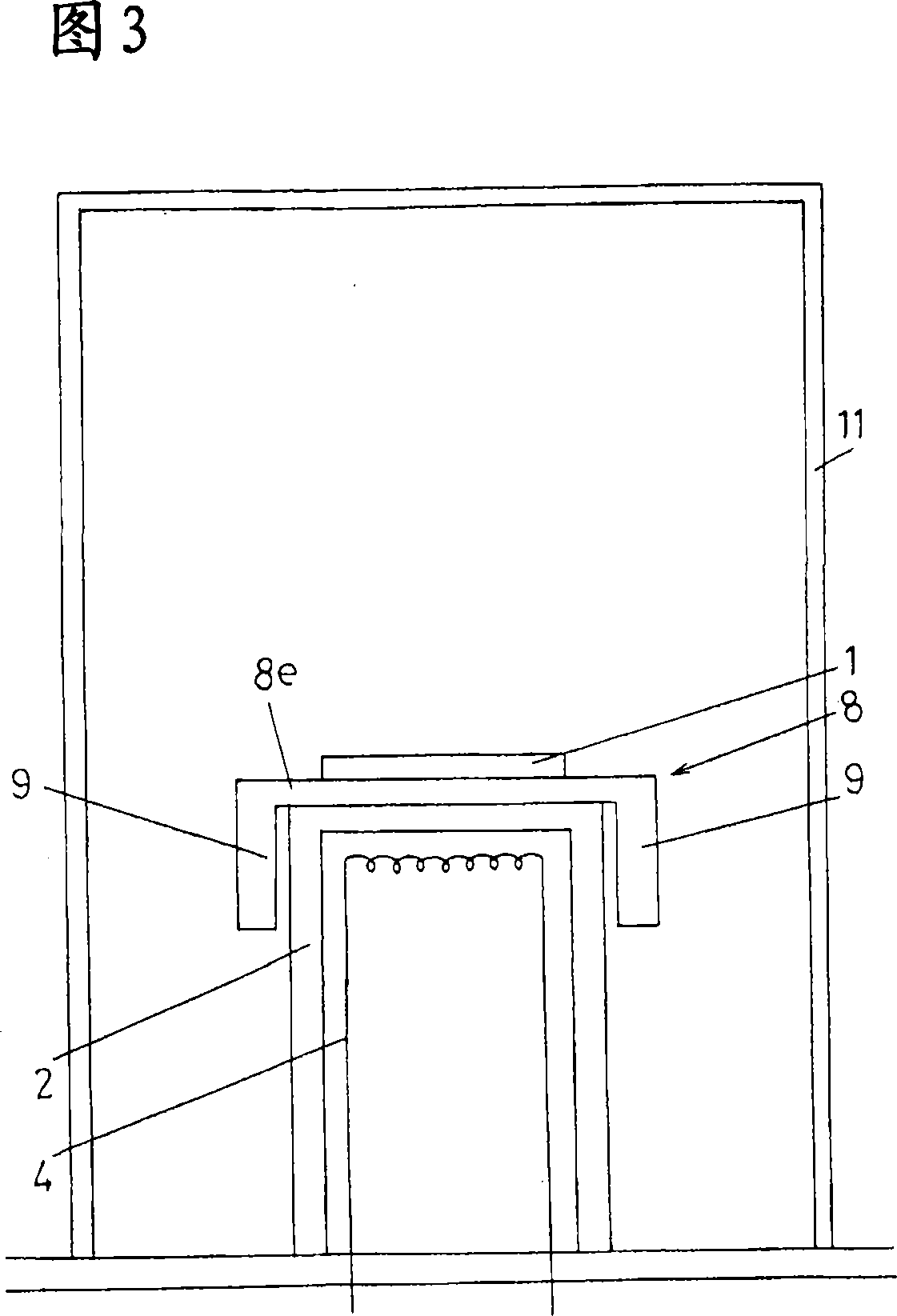

[0021] FIG. 1 is a diagram illustrating a first embodiment of the present invention.

[0022] A substrate support member 2 is provided inside a processing chamber 11 for heat-processing a substrate 1 . The substrate supporting member 2 has a heating member 4 for heating the substrate, which is composed of a thermoelectron generating member for electron impact heating, an infrared lamp for infrared lamp heating, and the like inside. Accordingly, the substrate 1 is heat-processed in the processing chamber 11 .

[0023] The heat treatment of the substrate 1 in the processing chamber 11 may be performed with the inside of the processing chamber 11 in a predetermined vacuum state, or may be performed with the inside of the processing chamber 11 in an atmospheric pressure state.

[0024] The substrate supporting and transporting tray 8 of the present invention is placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com