Filter muffler

A technology for filtering mufflers and mufflers, which is applied in the direction of intake mufflers, combined air filters and mufflers, machines/engines, etc., and can solve problems such as pressure loss and a large number of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

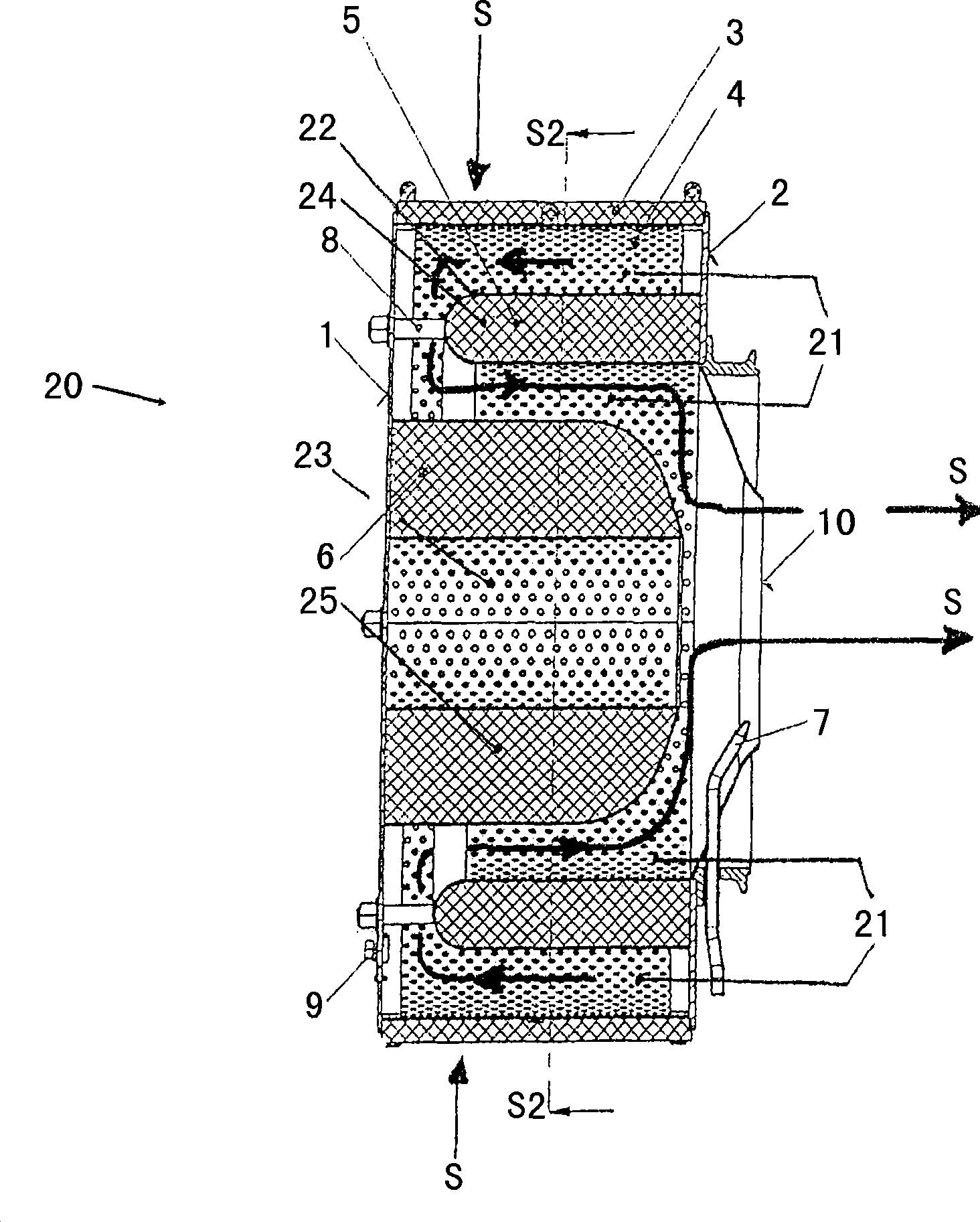

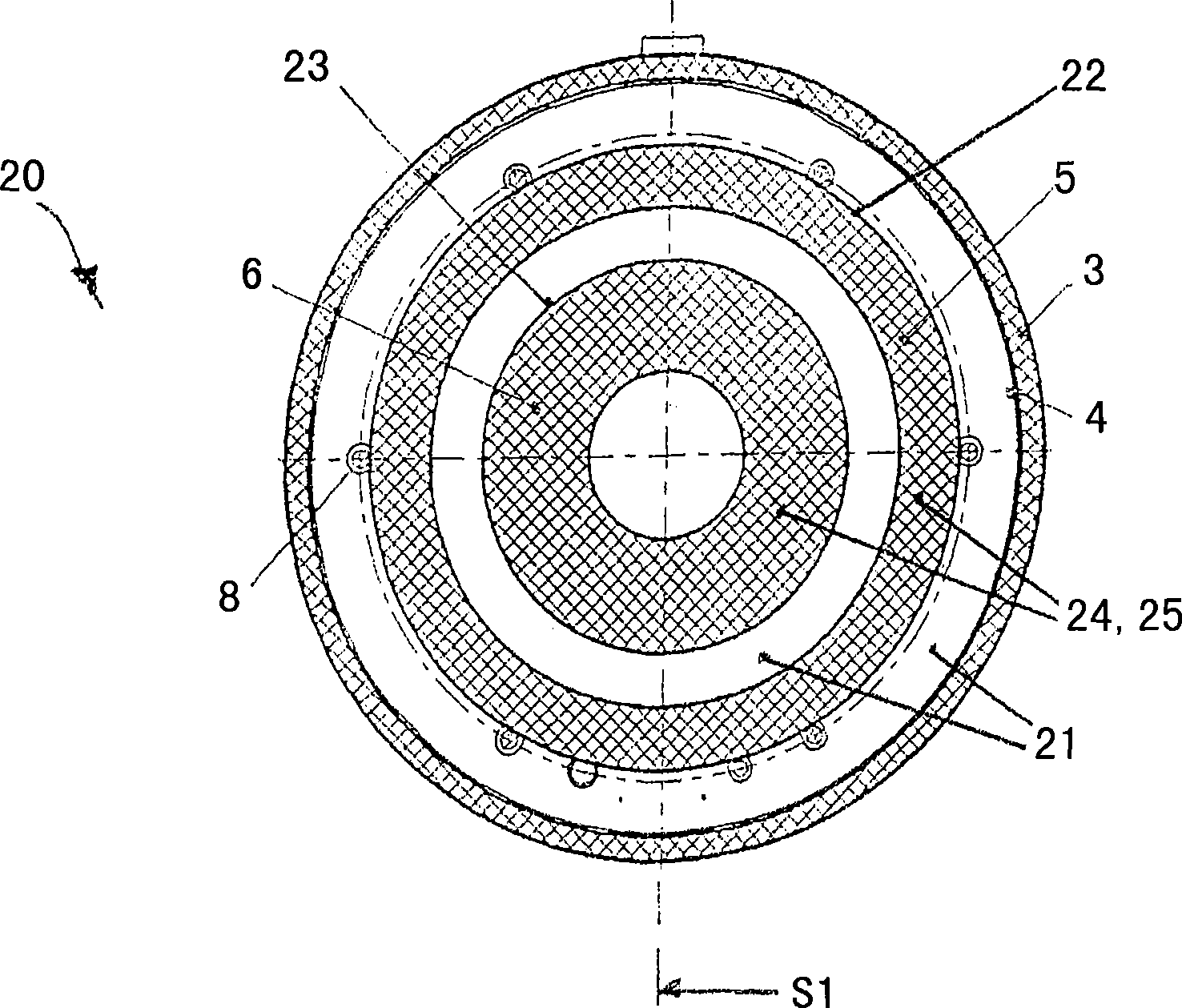

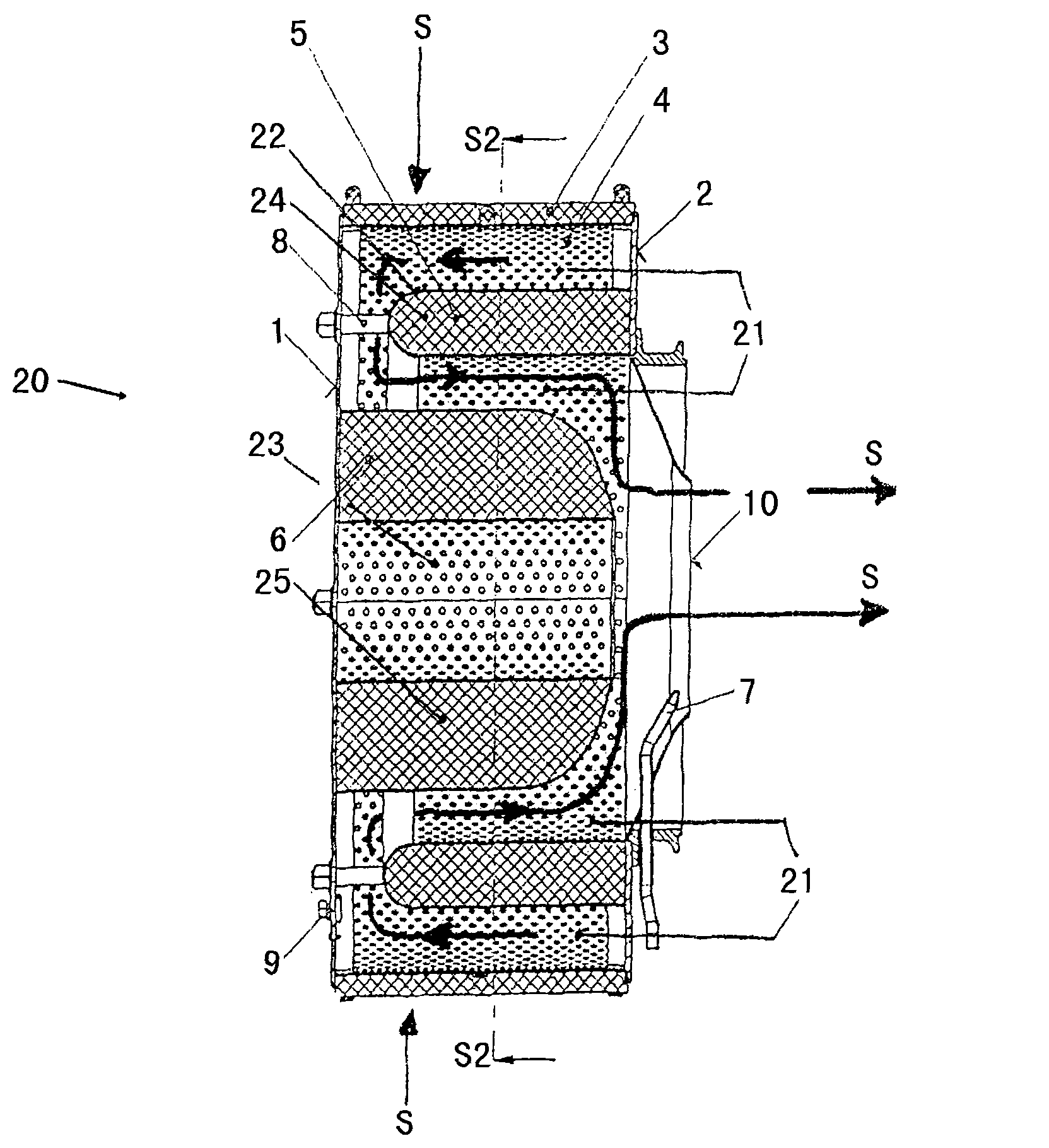

[0016] figure 1 Shown is a substantially cylindrical filter silencer 20, the housing of which essentially consists of a front wall 1 and a rear wall 2 which can be connected to a compressor not shown here. The cylindrical housing 4 is closed.

[0017] In order to buffer the sound waves from the compressor, a plurality of, in this embodiment, two ring-shaped silencing elements 5,6 are provided in the casing, and the annular silencing elements 5,6 are designed as an outer silencing element 5 and an external silencing element 5. The form of the inner sound-absorbing elements 6, which are arranged coaxially with each other and at a distance from each other, and which comprise the front wall 1 and the rear wall 2-they are used to pass through the cylindrical shell 4 of the shell perpendicular to the axis of the silencer shell 20 In the case of incoming fresh air, a substantially coaxial and labyrinthine flow channel 21 is formed between them, so that the fresh air flows at least a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com