Prefabricated high-voltage cable terminal

A high-voltage cable, prefabricated technology, applied in the direction of cable terminals, etc., can solve the problems of not conforming to the development trend of cable terminal prefabrication, heavy workload, low mechanical strength, etc., and achieve simple and convenient on-site assembly, high mechanical strength, and reduced process technology effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

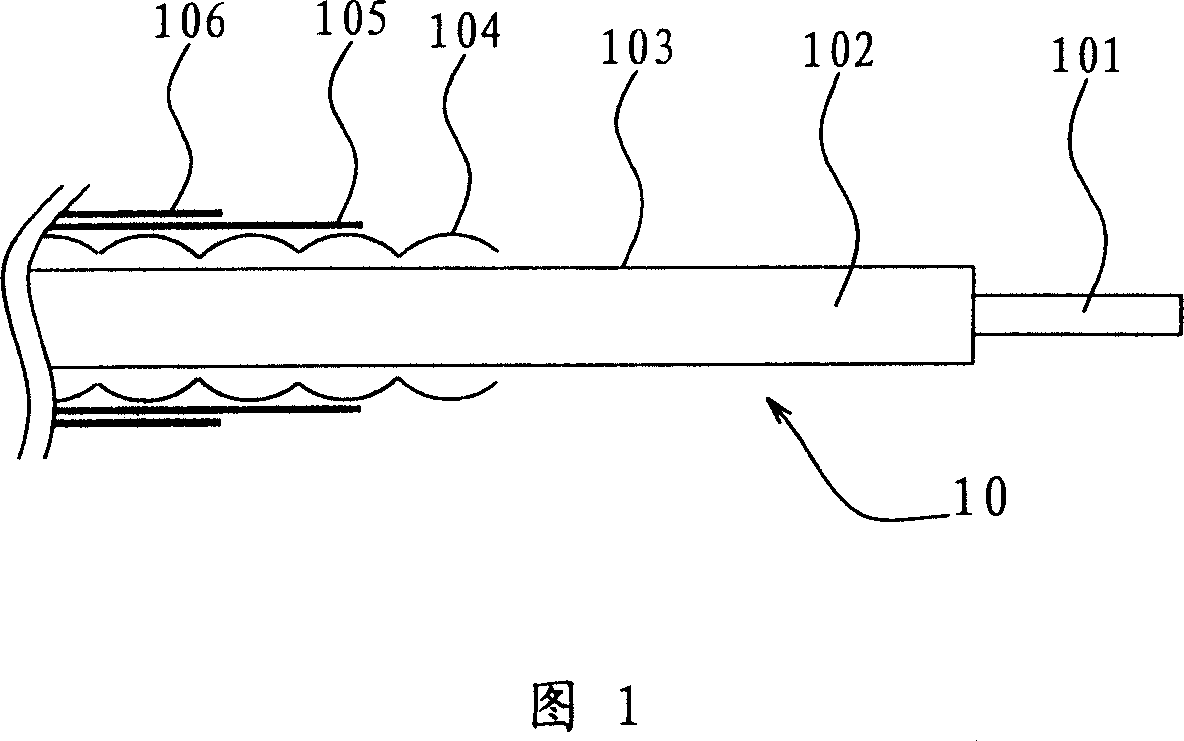

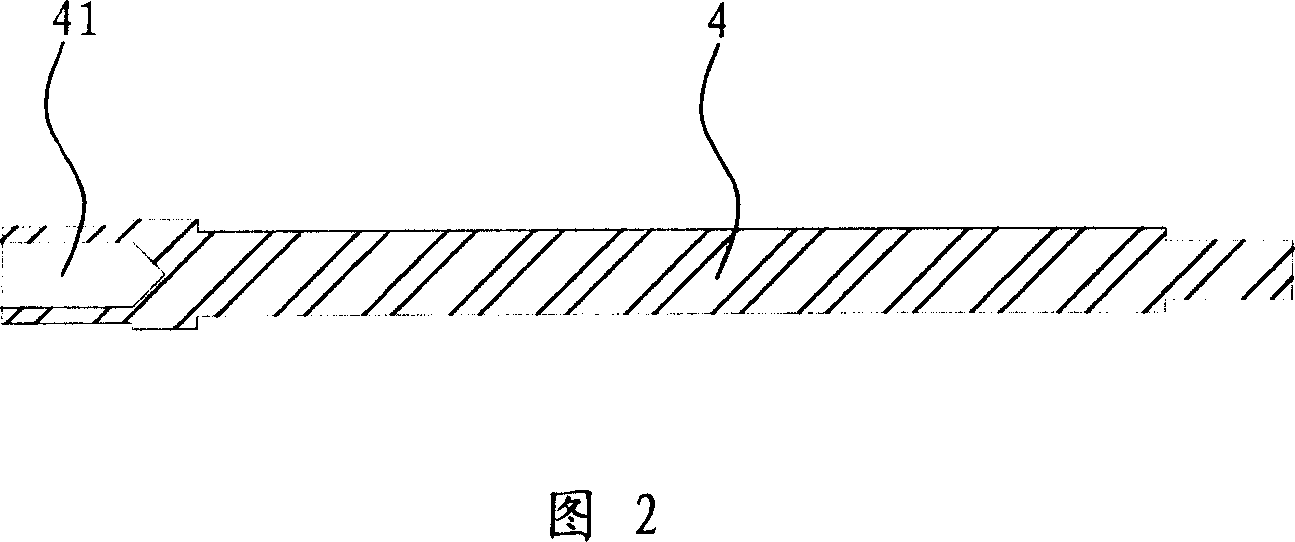

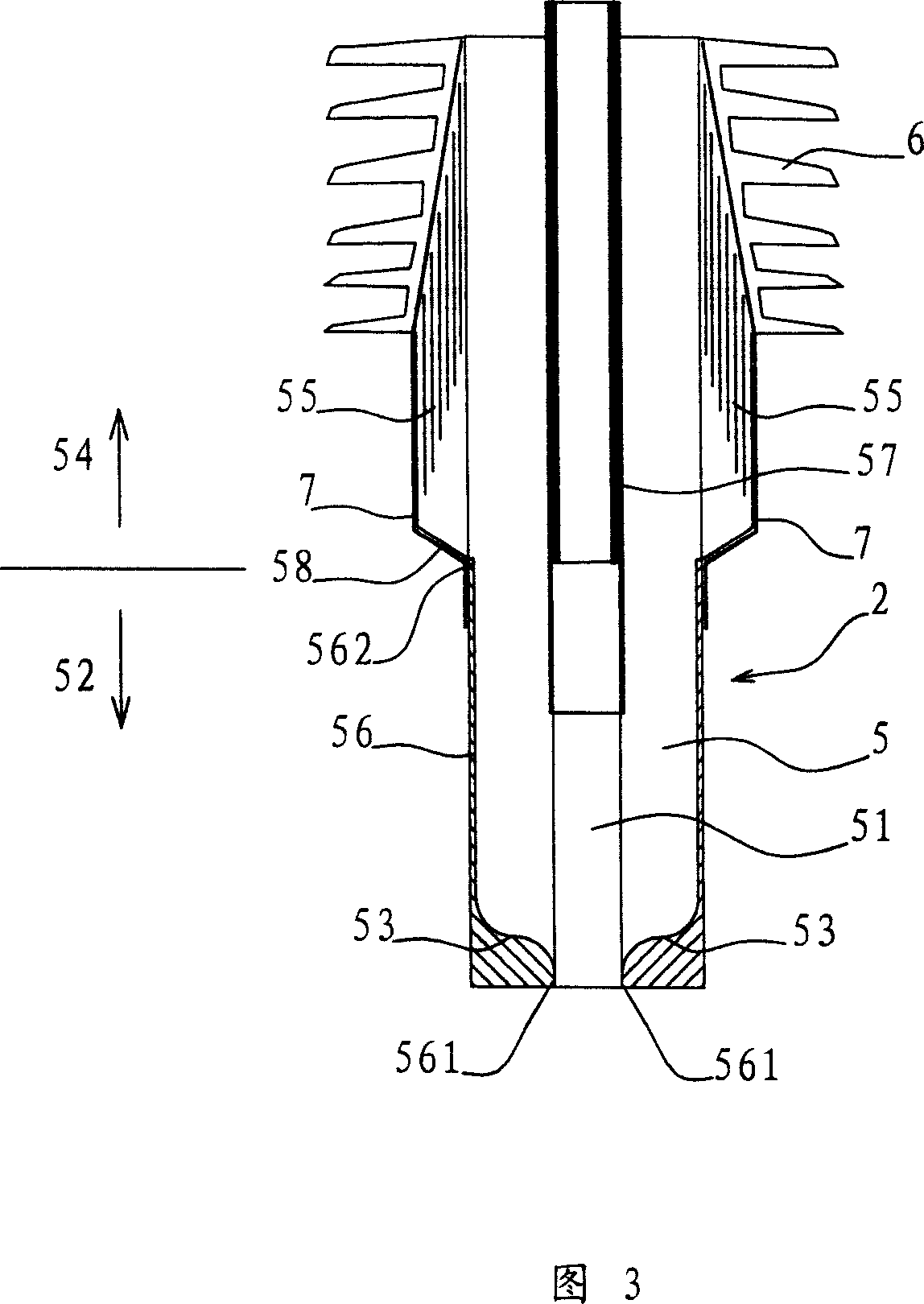

[0032] Referring to Fig. 1, Fig. 2, Fig. 3 and Fig. 6, according to a preferred embodiment provided by the present invention, it includes a shell 1, an insulator 2 whose root is nested in the shell 1, and a head mounted on the insulator 2. part of the pressure equalizing cover 3 and the lead-out conductor 4 passing through the center hole of the insulator 2.

[0033] The difference between the present invention and the prior art is that the insulator 2 includes a main insulating part 5 and an outer insulating part 6, the outer insulating part 6 covers the upper part 54 of the main insulating part 5, and the main insulating part 5 has a through A central hole 51, the central hole 51 is provided with a high-voltage shielding layer 57, the lead-out conductor 4 is directly connected to the cable guide core 101, and its connection 41 is located in the middle and lower part of the high-voltage shielding layer 57 in the central hole 51 , the root 52 of the main insulating part 5 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com