Quick connection unit for section steel frame and internally filled light steel wall body and assembly method thereof

A quick connection and steel frame technology, applied to walls, building components, buildings, etc., can solve the problems of shortened construction period, poor assembly flexibility, unstable connection, etc., and achieve the effects of convenient construction, improved work efficiency, and flexible and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

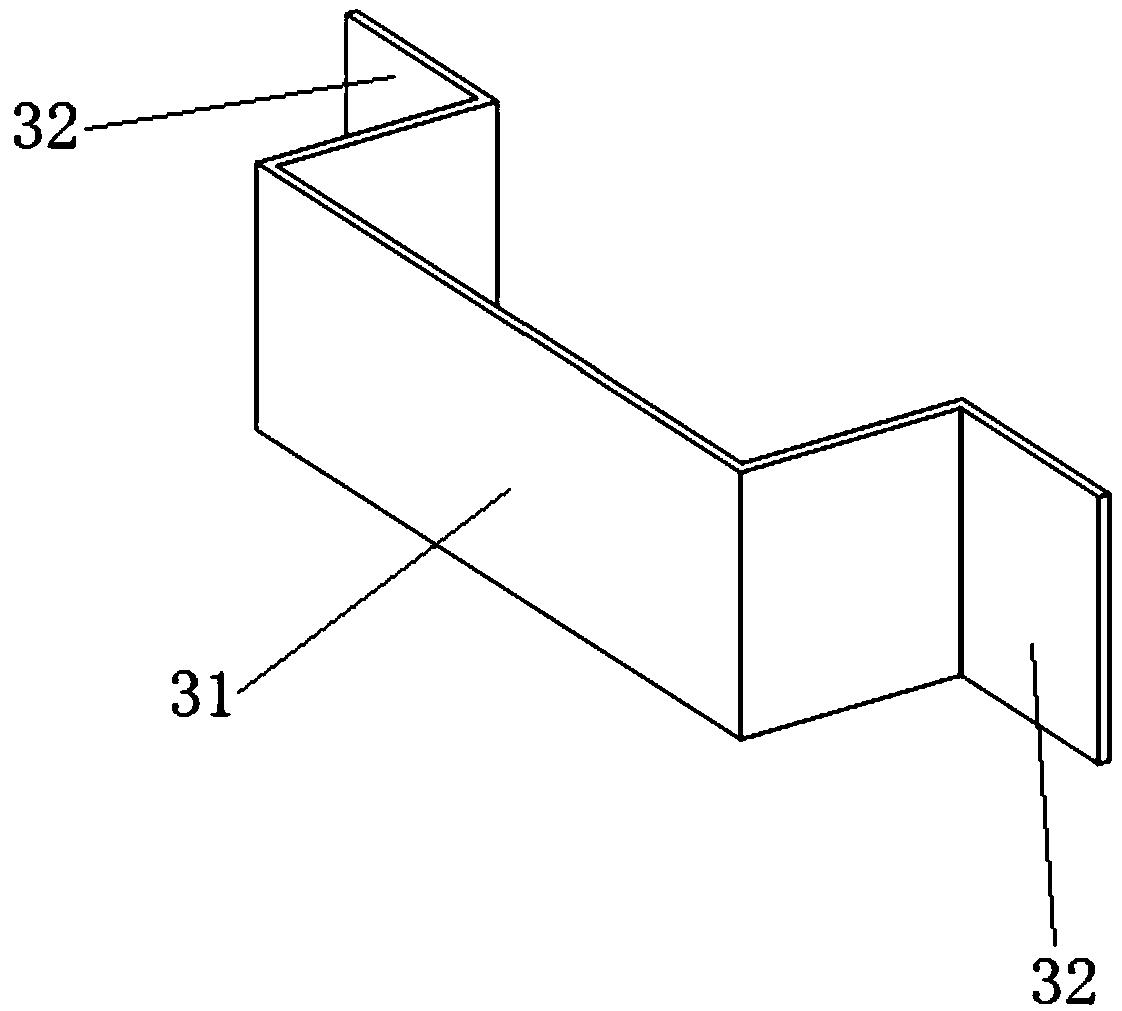

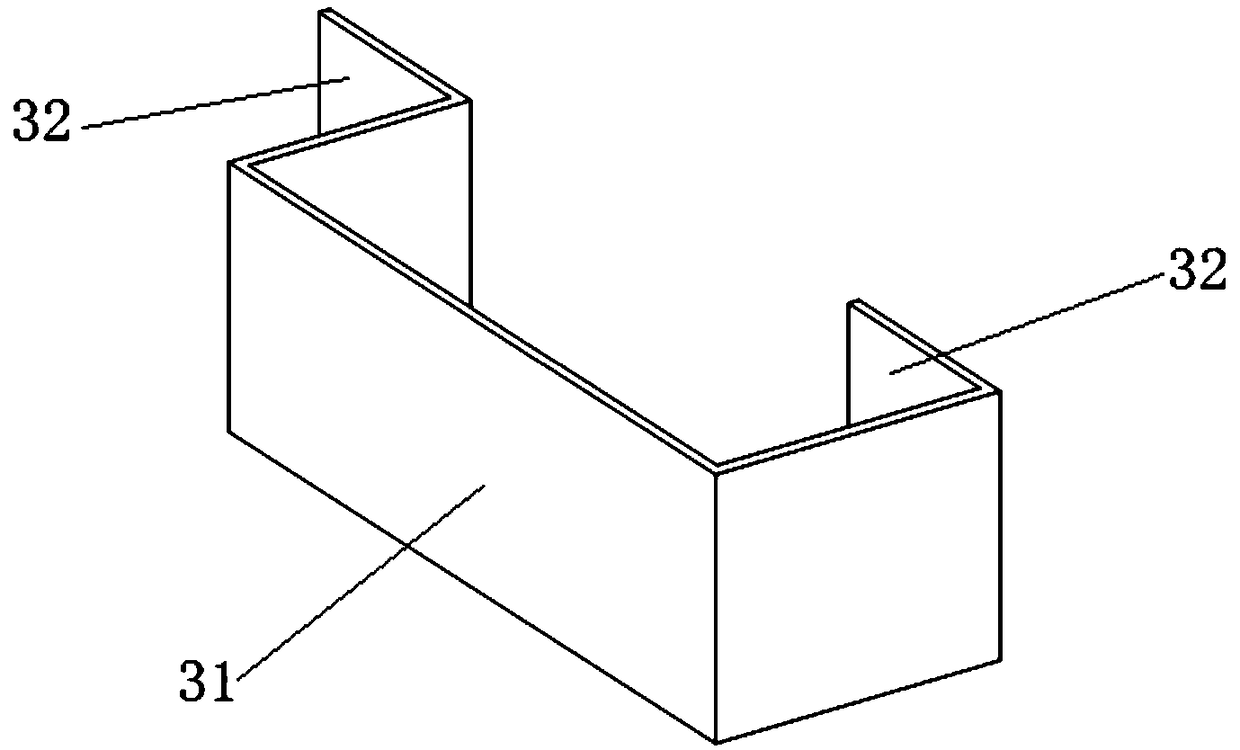

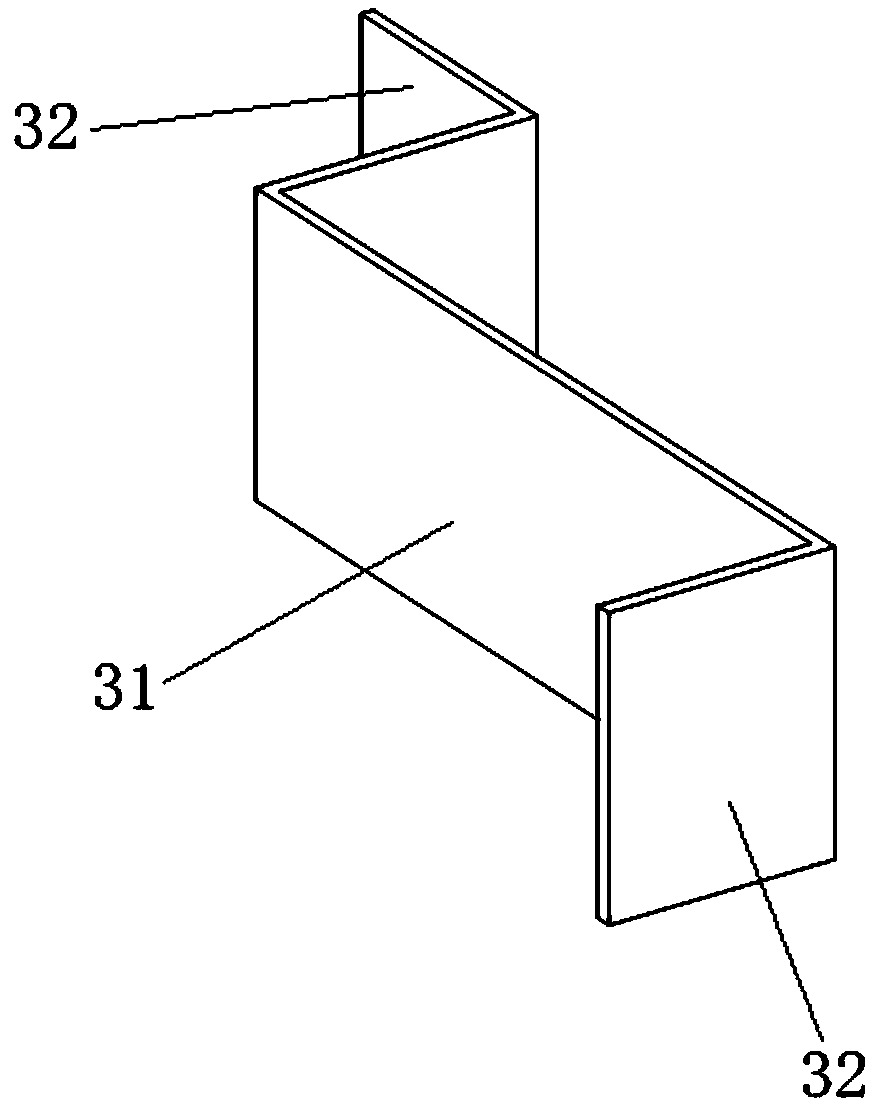

[0045] combine Figure 1 to Figure 4 as well as Figure 11As shown, a light steel wall quick connection unit filled with a steel frame in this embodiment includes a steel frame 1 and a light steel wall 2, the light steel wall 2 is located inside the steel frame 1, and the light steel wall 2 The light steel keel is fixedly connected with the steel frame 1 through the steel clip 3. Different from the prior art, the steel clips 3 have different structural forms according to the type of heavy steel in the steel frame 1 and the position of the light steel wall 2 in the steel frame 1, and the steel clips 3 of each structural form have different structural forms. The following structural features: the steel clip 3 is provided with an enclosing part 31 which is enclosed with the installation surface of the steel frame 1 and is used to wrap the light steel keel. The pick lug 32 that fits; The light steel wall body 2 is connected with the steel frame 1 according to the following struc...

Embodiment 2

[0052] combine Figure 9 and Figure 10 As shown, a light-steel wall quick-connecting unit filled with a section steel frame in this embodiment has the same basic structure as in Embodiment 1, the difference being that the steel frame 1 in this embodiment adopts a square steel pipe, such as Figure 9 As shown, when the light steel wall 2 is installed along the inner wall of the steel frame 1, that is, the light steel wall 2 is centrally arranged in the middle of the square steel pipe, and the surrounding part 31 of the steel clip 3 is in the shape of "凵" , and the pick ears 32 are turned outwards at both ends of the surrounding part 32, and are used to fit and connect with the wall surface of one side of the square steel pipe; as Figure 10 As shown, when the light steel wall 2 is installed along the outer wall of the steel frame 1, that is, the light steel wall 2 is set on one side of the square steel pipe at this time, and the surrounding part 31 of the steel clip 3 is in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com