Connecting structure of plastic intake manifold and EGR (exhaust gas recirculation) pipe

A technology for connecting intake manifolds and pipes, applied in the field of automotive gasoline engine intake systems, can solve problems such as failure of plastic intake manifolds, and achieve the effects of ensuring sealing, low cost, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and example the present invention will be further described:

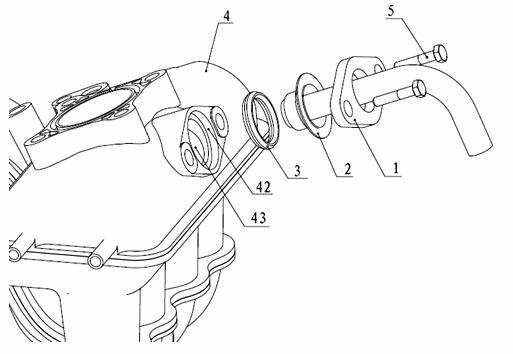

[0017] Such as figure 1 As shown, the connection structure between the plastic intake manifold and the EGR pipe includes a plastic intake manifold 4, an EGR pipe 2, a connecting flange 1, a rubber sealing ring 3, etc., and their assembly sequence is: firstly, the rubber sealing ring 3 Assemble it into the EGR interface sealing groove 42 on the plastic intake manifold 4, then insert the EGR pipe 2 into the EGR exhaust gas inlet interface 43 on the plastic intake manifold 4, and finally connect the connecting flange 1 and the The plastic intake manifold 4 is fixed.

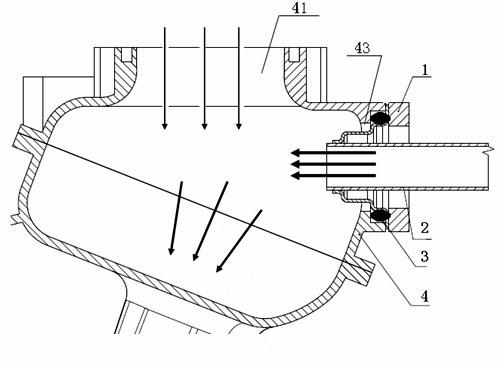

[0018] The specific working principle is as follows: figure 2 Shown:

[0019] 1. Realization of the cooling function: cooling the high-temperature exhaust gas entering the plastic intake manifold 4 is realized by reasonably arranging the position of the EGR exhaust gas inlet port 43 .

[0020] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com