Tapered metal pile and construction method for installation thereof

A metal ground, cone-shaped technology, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of long construction period, cumbersome, easy to produce damage, etc., and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

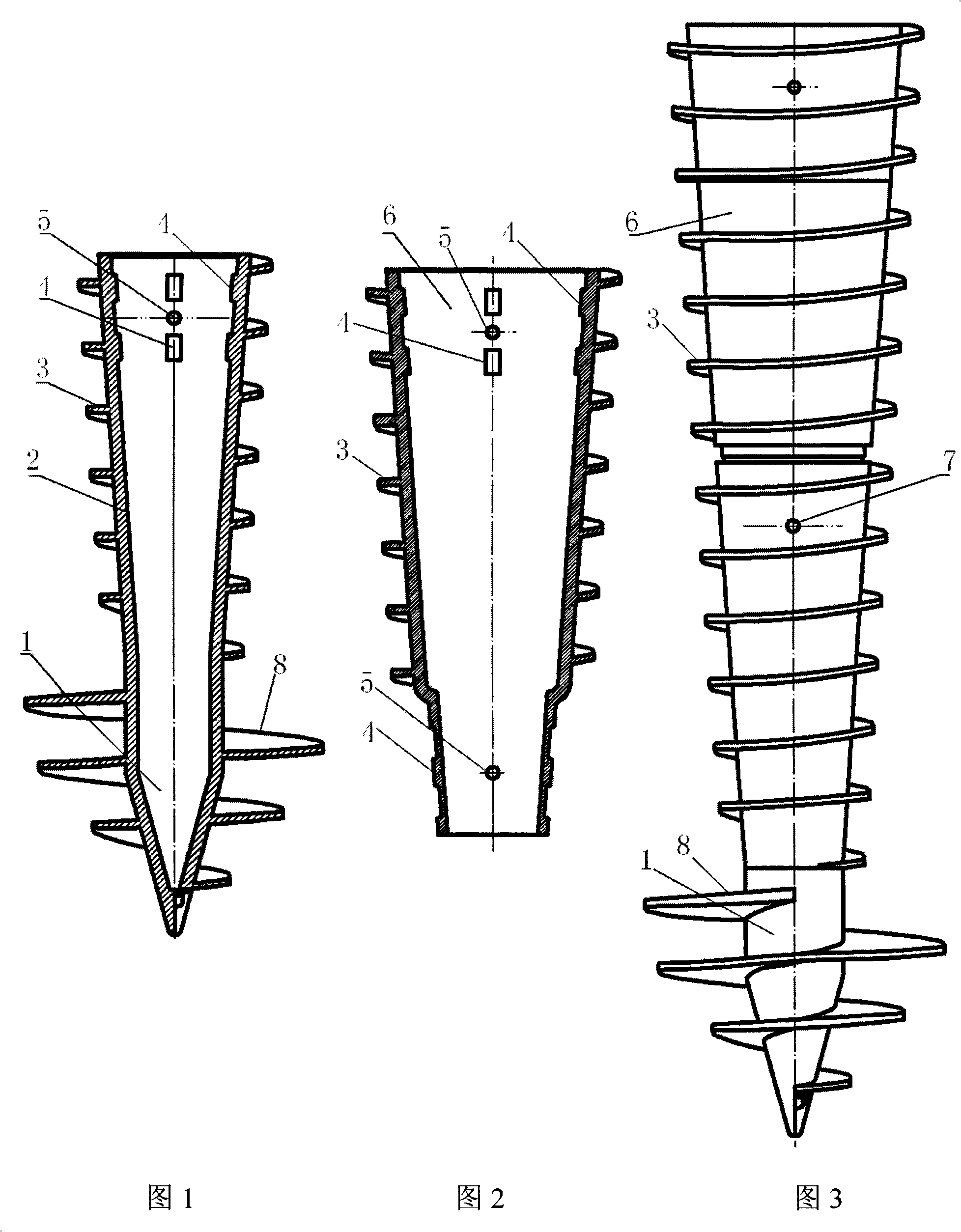

[0034] The tapered metal ground pile of this embodiment refers to Figure 1-3, which is a vertical single-column structure, including an auger bit 1 and a cone 2, the large diameter end of the cone is connected to the power source input joint, and the auger bit 1 and the cone 2 It is made of metal material, the drill bit and the cone 2 are integrated by casting or welding, and the metal ground pile is not taken out after being driven into the ground, and it is directly used as a pile body;

[0035] The auger bit 1 has an inverted conical structure, and the helical blade 8 spirals up around the axis, and the outer diameter gradually increases with the helical rise, forming a smooth helical cutting curve, which is convenient for the helical cutting of the soil layer by the blade, and meets the needs of drilling conical metal ground piles , and can be stably combined with the soil layer, and have strong support for the supported buildings or other ground objects. The thickness of t...

Embodiment 2

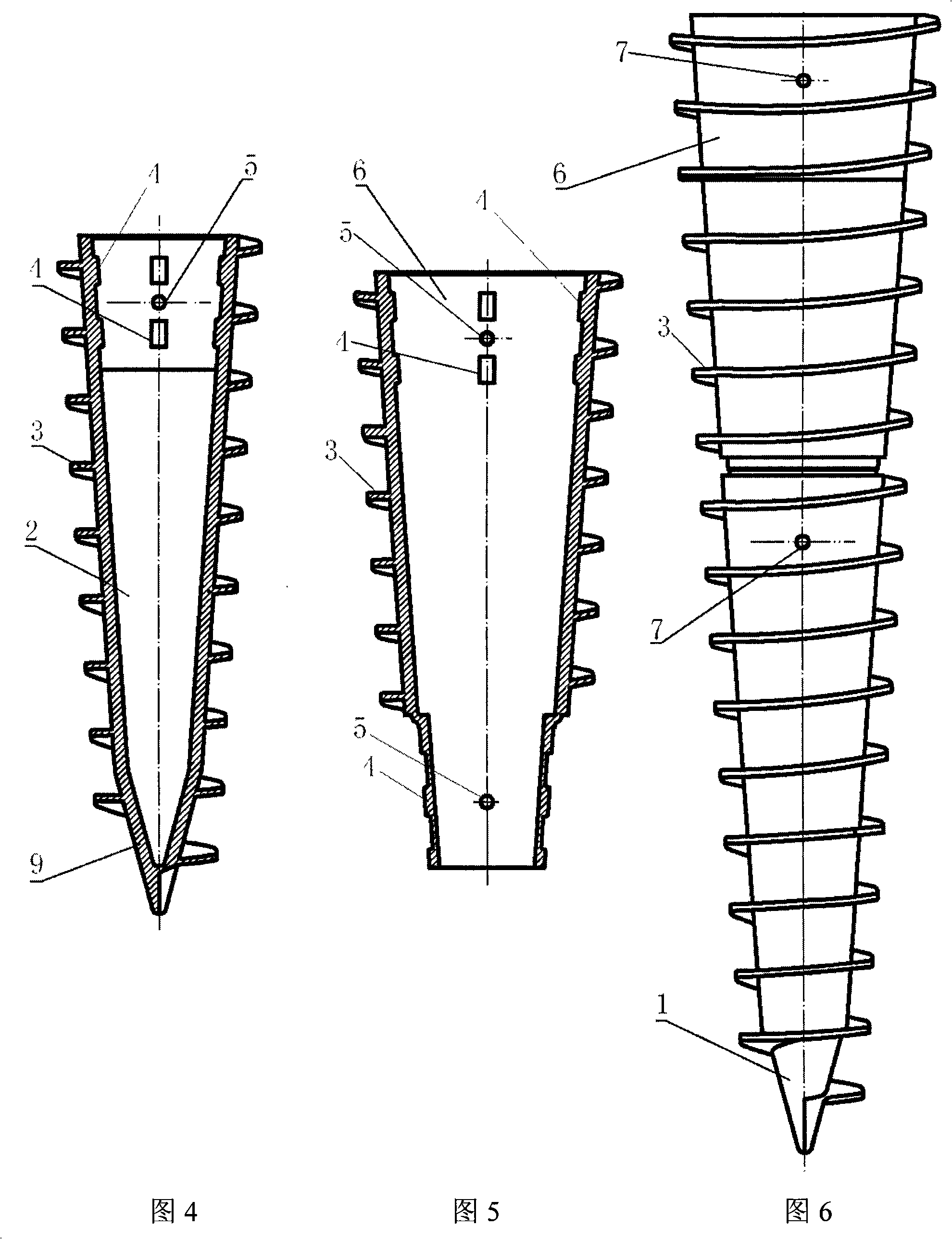

[0040] The difference between the conical metal ground pile of the embodiment and the embodiment 1 is: referring to Fig. 4-6, the drill bit is a sharp drill bit 9, the drill bit and the cone 2 are cast or welded as a whole, and the cone 2 is directly connected to the input joint of the power source .

Embodiment 3

[0042] The difference between the tapered metal ground pile of this embodiment and embodiment 1 is:

[0043] The outside of the upper end of the cone 2, the outside of the upper end of the connecting cone 6 and the inside of the lower end are respectively provided with positioning blocks 4, each of which is arranged in two layers evenly. The block 4 is correspondingly dislocated and connected, and the positioning block 4 outside the upper end of the connecting cone 6 is connected with the corresponding dislocation of the positioning block 4 set by the power source input joint; a drill pipe is connected on the connecting cone 6.

[0044] The installation and construction method of the conical metal ground pile of the above embodiment comprises the following operations:

[0045] 1. The drill bit and the cone 2 made of metal materials such as steel or iron are integrated by casting or welding, or the drill bit and the cone 2 are cast or welded as a whole;

[0046] 2. Connect the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com