Acoustic panel and preparation system and preparation process thereof

A preparation system and sound-absorbing panel technology, which is applied in metal processing and other directions, can solve the problems of inconvenient wall connection of sound-absorbing panels, and achieve the effect of enhancing market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

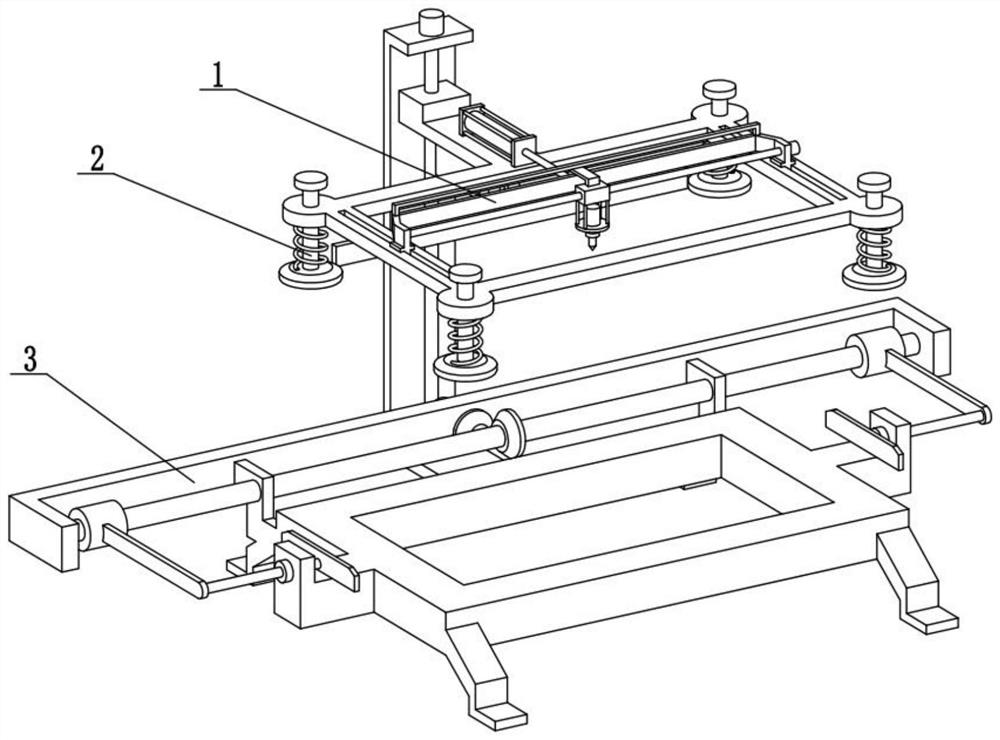

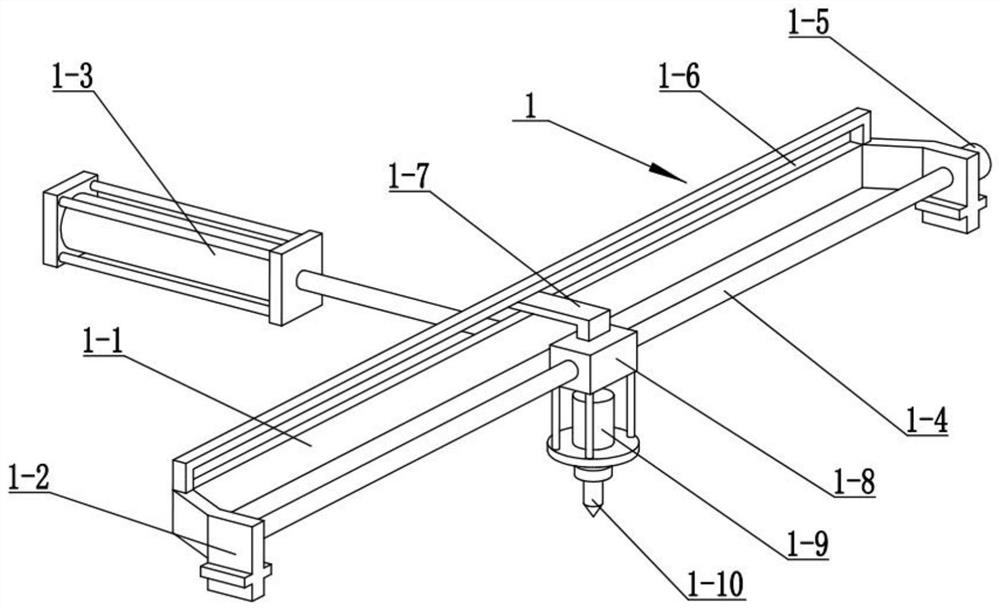

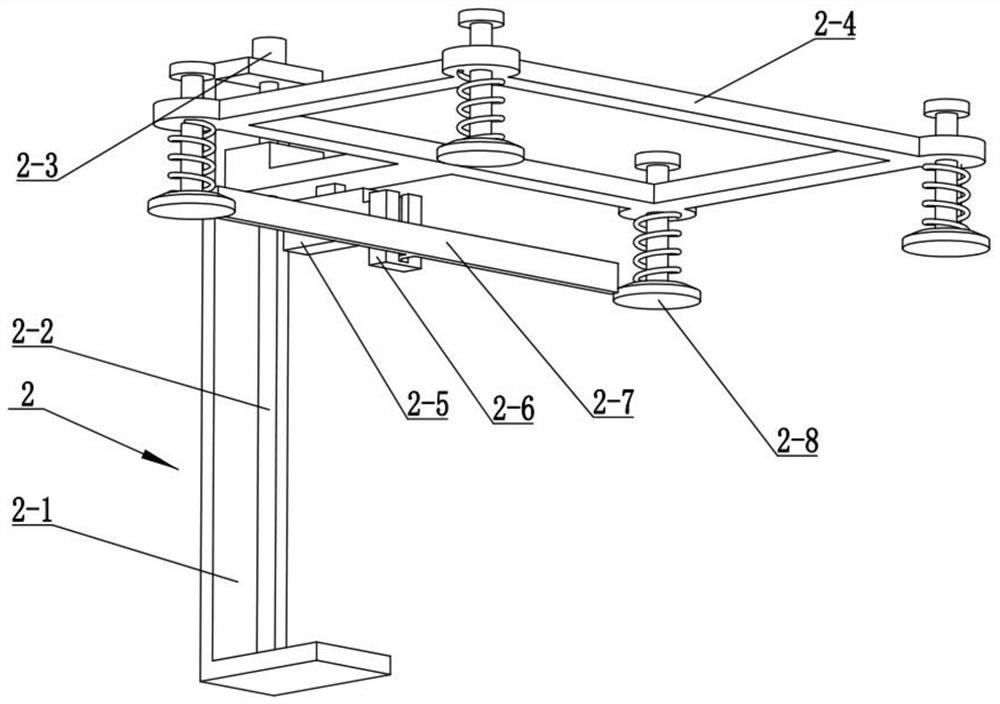

[0028] The following describes this embodiment with reference to the figures, a sound-absorbing panel preparation system, including a swing punching mechanism 1, a compacting slag cleaning mechanism 2 and a clamping and fixing mechanism 3, and the swing punching mechanism 1 is connected to the compacting slag cleaning mechanism 2, the pressing and slag removal mechanism 2 is connected to the clamping and fixing mechanism 3, and the swing punching mechanism 1 includes front and rear frames 1-1, horizontal screw 1-4, horizontal motor 1-5, moving shelf 1- 8. Lifting and shrinking rod 1-9 and drilling machine 1-10, horizontal screw 1-4 are rotatably connected to the front and rear frames 1-1, horizontal screw 1-4 is fixedly connected to the output shaft of horizontal motor 1-5, The horizontal motor 1-5 is fixedly connected to the front and rear frames 1-1, the moving frame 1-8 is connected to the horizontal lead screw 1-4 through threads, and the lifting rod 1-9 is fixedly connecte...

specific Embodiment approach 2

[0030] This embodiment will be described below in conjunction with the drawings. This embodiment will further illustrate the first embodiment. The swing punching mechanism 1 also includes a limit chute 1-6 and a top plate 1-7, and the top plate 1-7 is fixedly connected to the mobile shelf. On the top of 1-8, a limit chute 1-6 is arranged on the front and rear frame 1-1, and the rear side of the top plate 1-7 is slidably connected in the limit chute 1-6.

[0031] When the horizontal lead screw 1-4 drives the moving shelf 1-8 to move in the left and right direction, the moving shelf 1-8 will drive the top plate 1-7 to slide in the limit chute 1-6, which avoids the moving shelf 1-8 following the level The leading screw 1-4 rotates, so that the lifting and shrinking rod 1-9 and the drilling machine 1-10 can maintain a vertically downward state, and can also stabilize the lifting and shrinking rod 1-9 and the drilling machine 1-10 Effect, avoid the shaking caused by the vibration g...

specific Embodiment approach 3

[0032] The present embodiment will be described below in conjunction with the drawings. This embodiment will further illustrate the second embodiment. The swing punching mechanism 1 also includes a raised slider 1-2 and a trajectory cylinder 1-3, and the rear of the front and rear frames 1-1. The side is fixedly connected on the cylinder rod of the trajectory cylinder 1-3, and the tops of the two raised slide blocks 1-2 are fixedly connected to the left and right ends of the front and rear frame 1-1 bottoms respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com