Heat exchanger

A technology of heat exchangers and heat sinks, applied in heat exchange equipment, indirect heat exchangers, heat exchanger types, etc., can solve problems such as damage to the outer edge of heat sinks, deformation of heat sinks, difficulty in condensing water, etc., and achieve flow Smoothness, preventing deformation of ribs, and increasing aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below by means of illustrations.

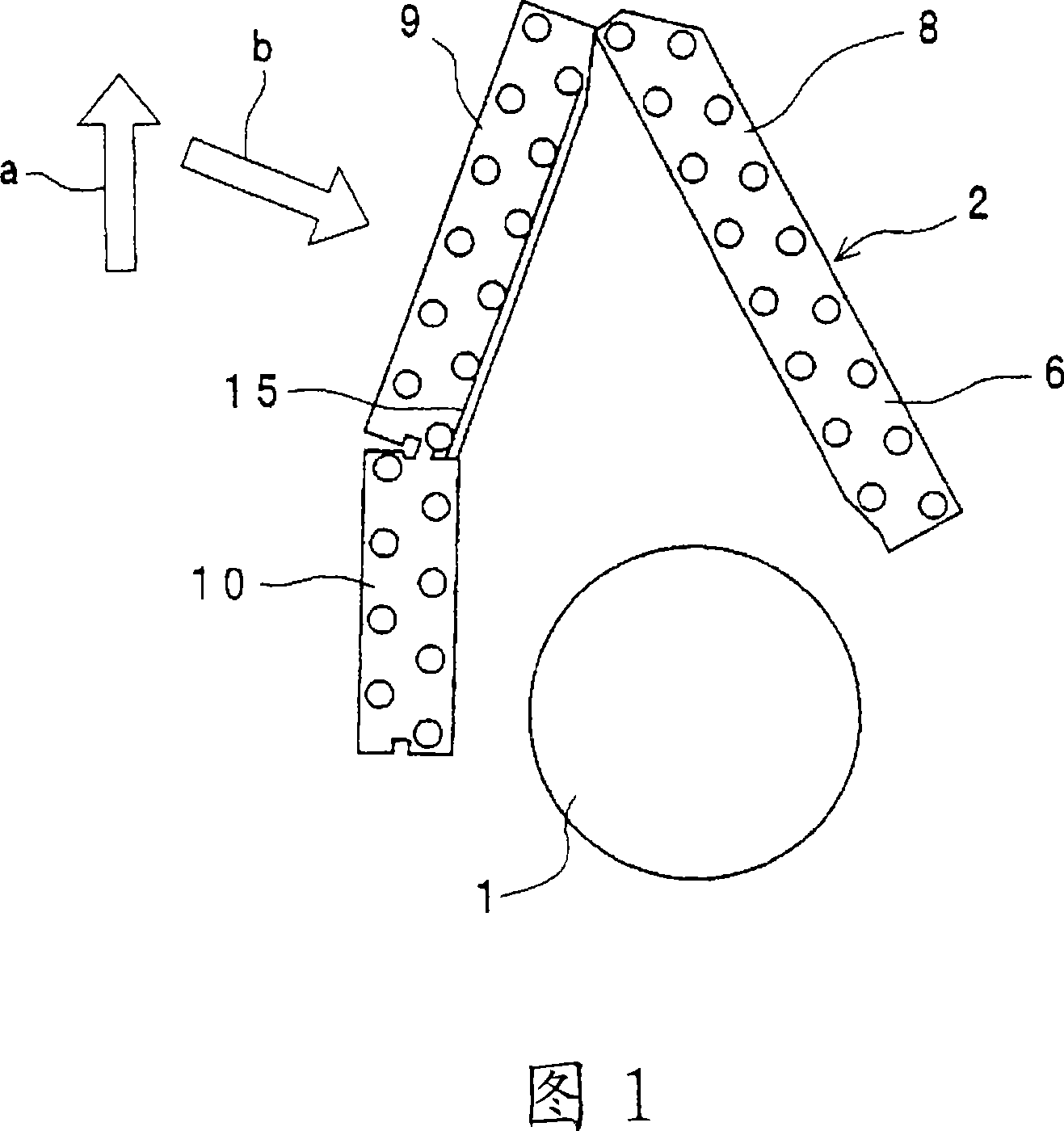

[0050]Fig. 1 is a schematic sectional view of an air conditioner using a heat exchanger according to an embodiment of the present invention. In Fig. 1, 1 is a blower fan, and 2 is a heat exchanger. In addition, in FIG. 1 , arrow a indicates that the heat exchanger is arranged vertically upward in the air conditioner in use, and arrow b indicates the flow direction of wind as a heat transfer medium. In FIG. 1 , for the sake of simplification, the case for accommodating the blower fan 1 and the heat exchanger 2 and the like are omitted.

[0051] In this air conditioner, the blower fan 1 is rotated, and the air sucked in via the heat exchanger 2 is blown out from an air outlet not shown.

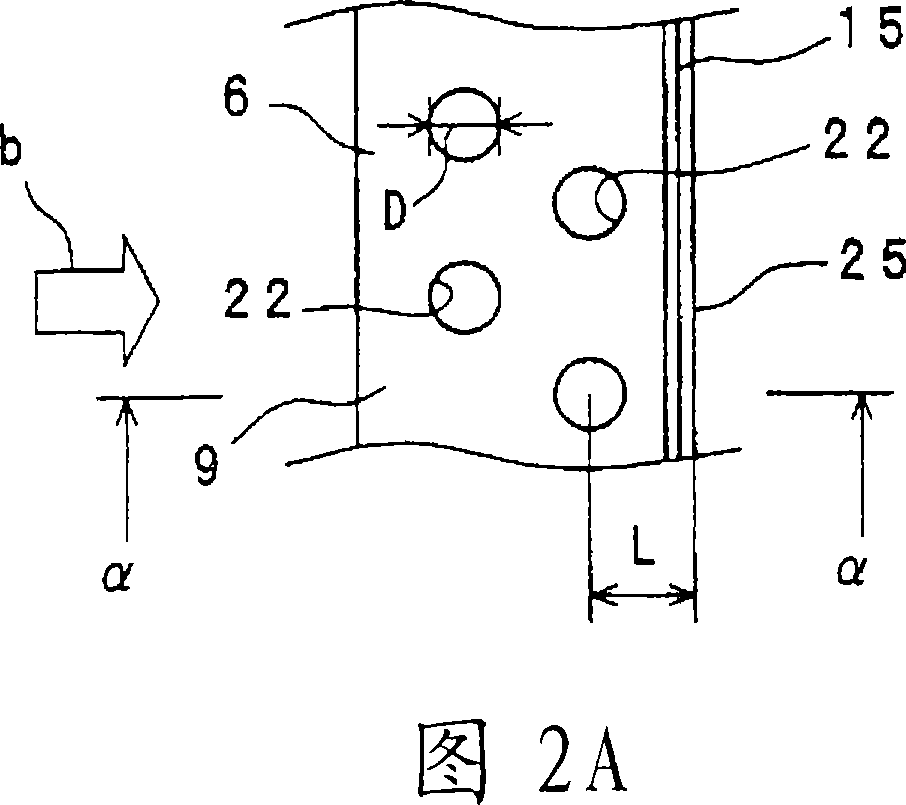

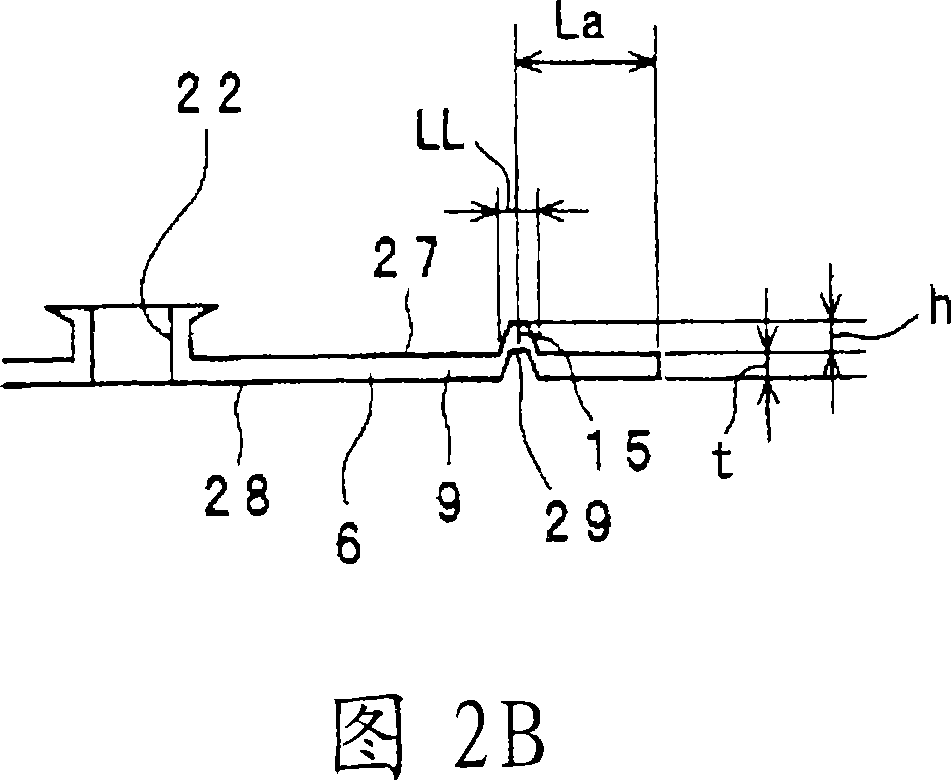

[0052] The heat exchanger 2 has a fan 6 and heat transfer tubes (not shown). The plurality of fans 6 are arranged at predetermined intervals in a direction perpendicular to the paper surface in FIG. 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com