Vacuum processing chamber for very large area substrates

A technology for vacuum processing chamber and substrate processing, which is used in coating, gaseous chemical plating, discharge tube, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

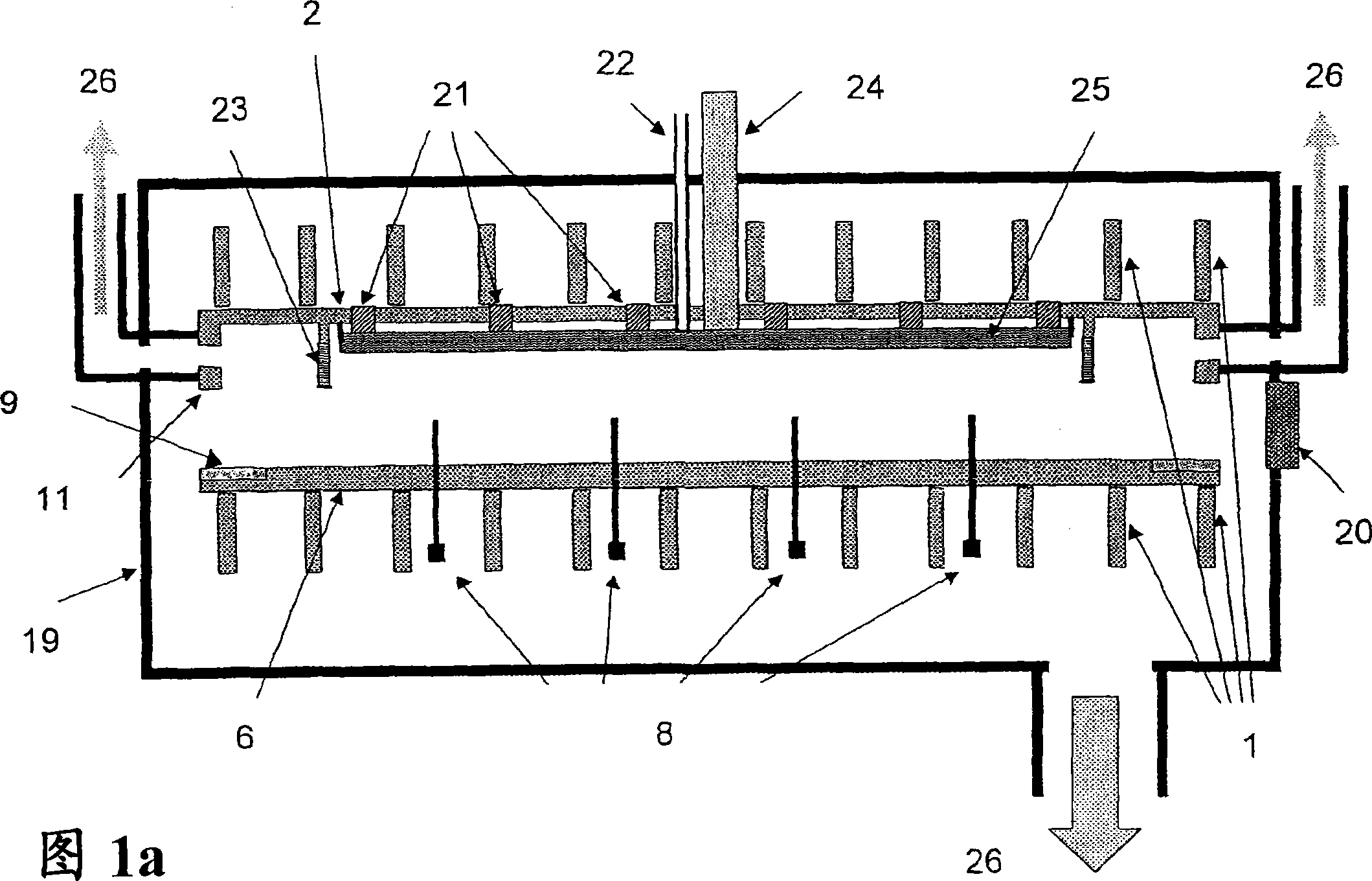

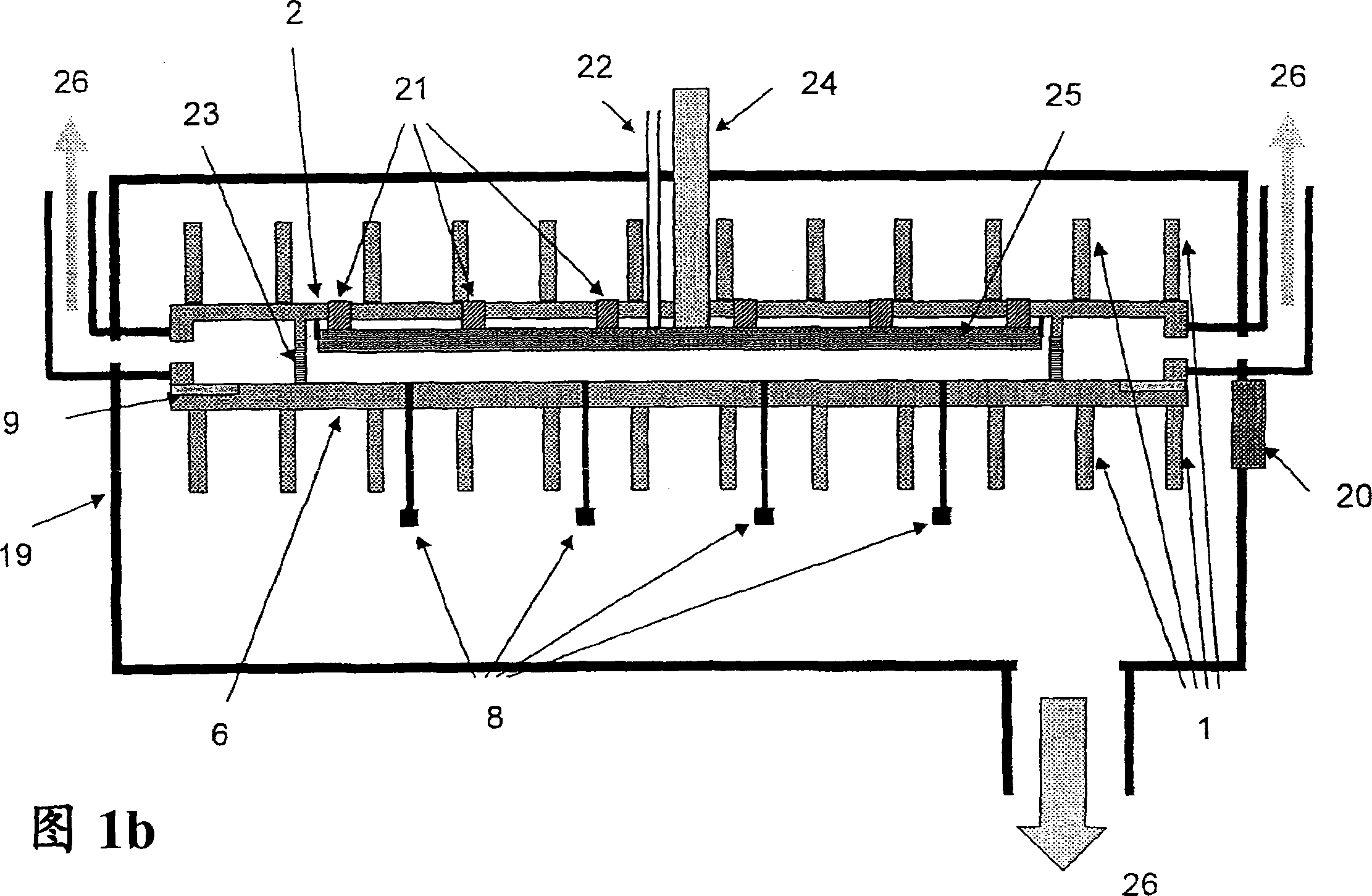

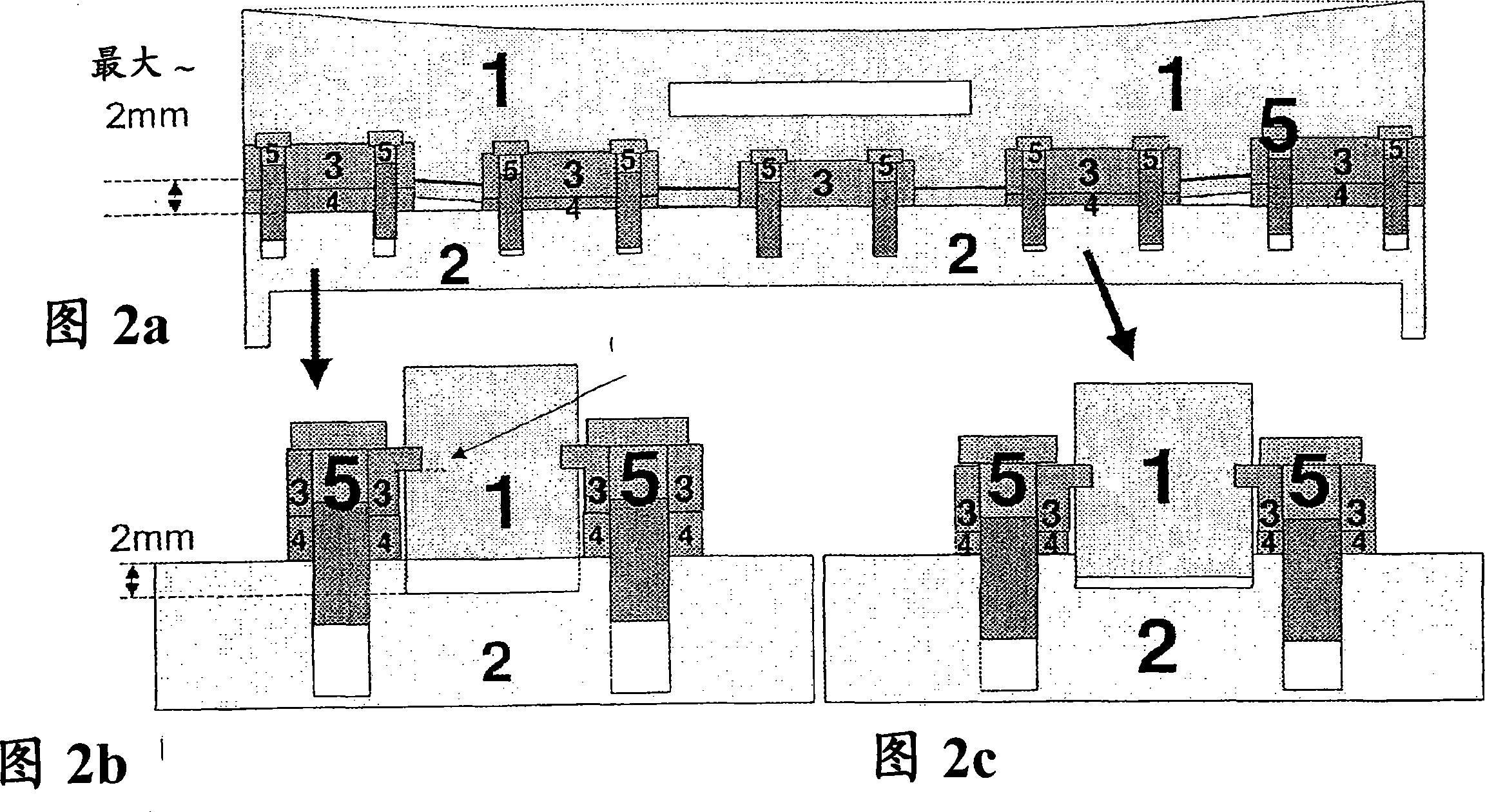

[0046] Therefore, the present invention is based on a new reactor concept. The reactor is divided into two parts: the reactor bottom 6 and the reactor top 2 (see Figure 1). The reactor top 2 is preferably connected to an external vacuum process chamber 19 via a reinforcement 1 (connection not shown in Figure 1 ). The reactor bottom 6 (or bottoms in the case of a single external chamber multi-reactor system) is vertically movable such that a gap is opened between the reactor side wall 11 and the sealing plate 9 . When the reactor is fully opened, the gap widens and the lifting pin 8 starts to protrude. The loading fork (not shown in FIG. 1 ) can then place the substrate on the lift pins for loading, or retract the substrate from the lift pins 8 by lifting the substrate through the door valve 20 from below. This "inverted shoebox" type of opening has the main advantage that the height of the reactor wall 11 and thus the corresponding plasma gap can be relatively small. If the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com