Linear motor driven terminal executor of picking robot

A technology for picking robots and end effectors, which is applied to picking machines, agricultural machinery and implements, and manipulators. It can solve problems such as difficult fingers to grasp, easy to bruise adjacent fruits, and interference with picking actions, and achieve smooth and reliable movement. Simple and compact, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

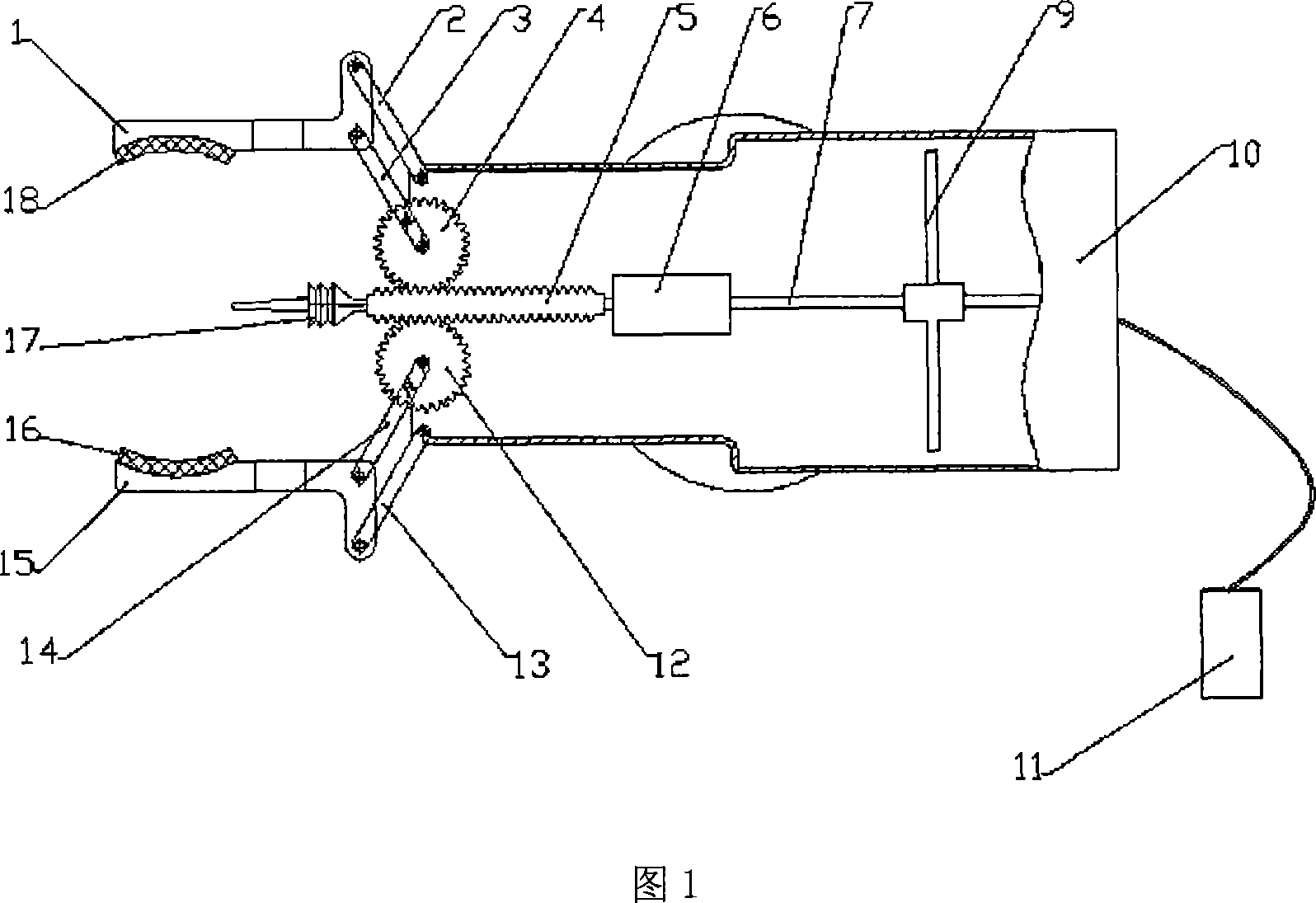

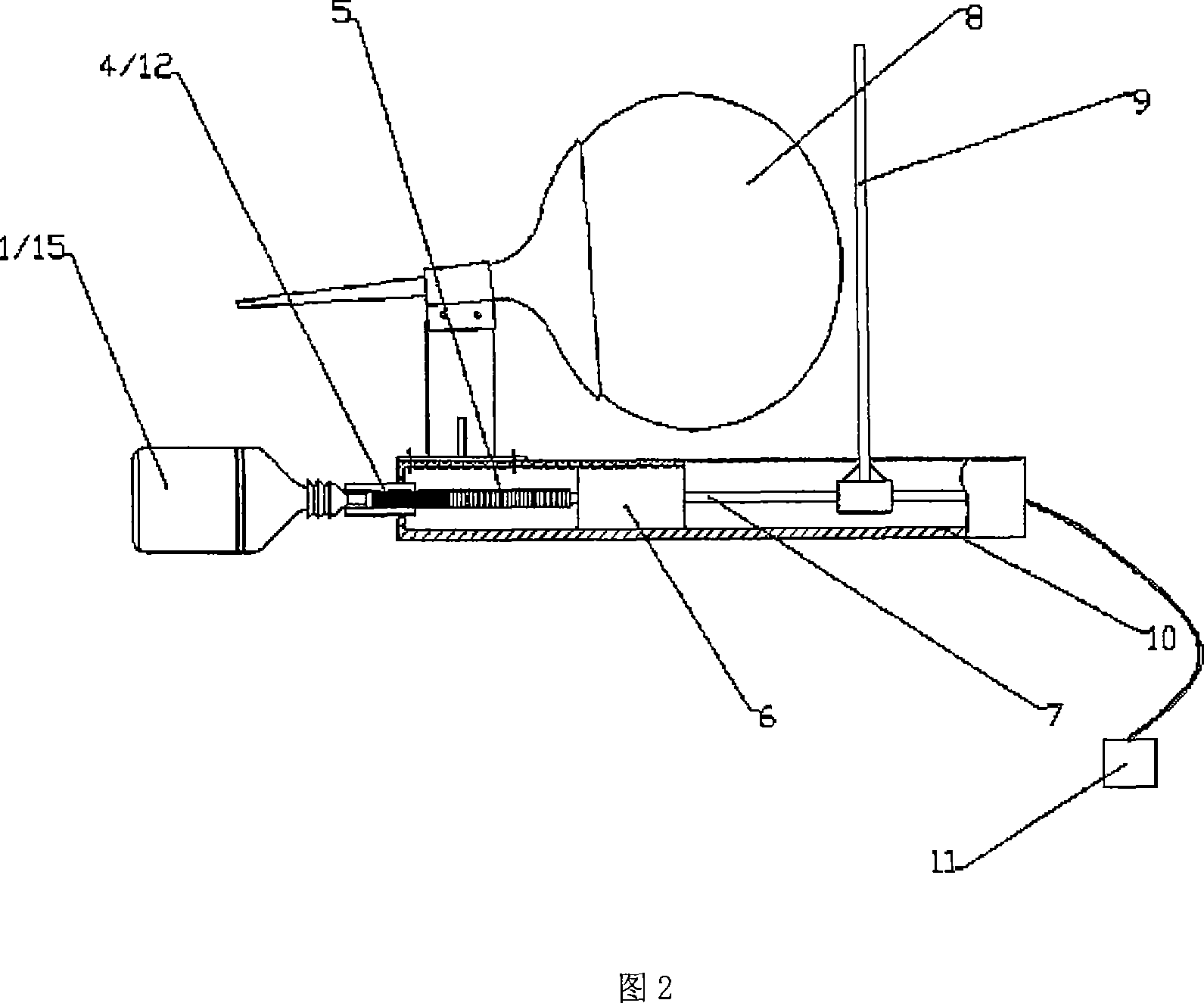

[0008] As shown in Figures 1 and 2, the end effector of the picking robot driven by a linear motor is driven by a linear motor, the stator (6) of the linear motor is fixed to the housing (10), and the mover (7) of the linear motor is opposite to the linear motor. The stator (6) moves linearly. The linear motor mover (7) is fixedly connected to the suction cup (17), the double-sided rack (5) and the push plate (9) from front to back in order to drive the suction cup adsorption device, the air bag blowing device and the finger opening and closing mechanism respectively.

[0009] In the sucker adsorption device, the sucker (17) is connected to the vacuum generator (11) through a vacuum hose, and the vacuum generator (11) generates a vacuum negative pressure to make the sucker (17) generate suction; the linear motor mover (7) The linear motion can drive the suction cup (17) to advance and retreat in a straight line.

[0010] In the air bag blowing device, the air bag (8) is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com