Sharp-point brush bristle forming apparatus

A molding equipment and tip technology, which is applied in the field of tip brush filament molding equipment, can solve problems such as uneven temperature, achieve uniform temperature, improve work efficiency, and compensate for heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

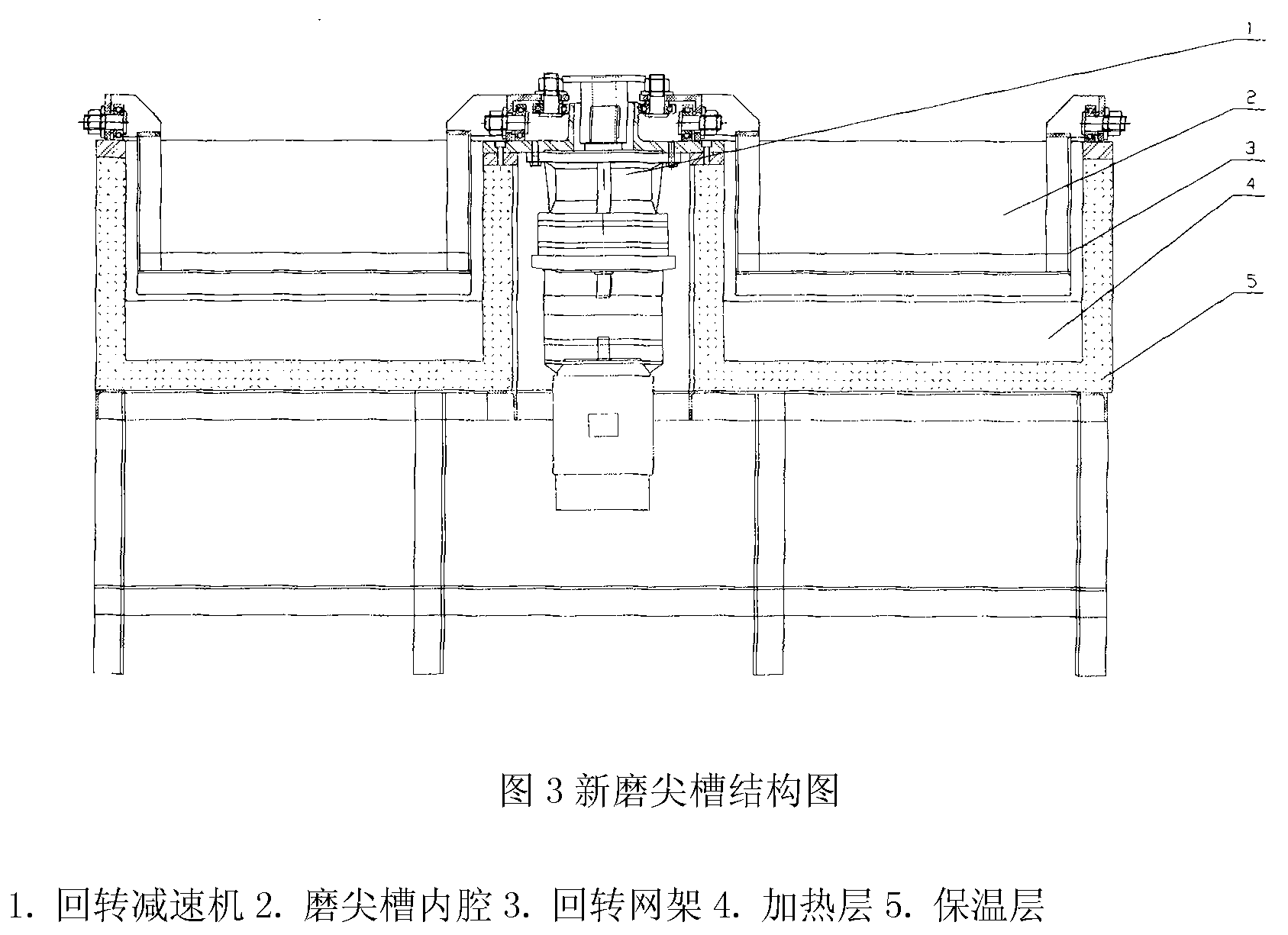

[0019] The technical scheme of the present invention is specifically described below in conjunction with accompanying drawing, appended image 3 The components represented by the reference signs in the figure are respectively 1. rotary motor; 2. sharpened groove inner cavity; 3. rotary grid frame; 4. heating layer; 5. insulation layer.

[0020] The forming equipment of pointed brush filaments adopted in the present invention includes a rotary motor 1, a sharpening tank inner cavity 2, a rotary grid frame 3, a heating layer 4 and a thermal insulation layer 5, wherein the rotary grid frame 3 is arranged in the sharpening tank inner cavity 2 Among them, the silk cake to be corroded is vertically fixed in the rotary grid 3, and the rotary motor 1 drives the rotary grid equipped with the silk cake to rotate in the cavity of the sharpening groove. The layer 5 is arranged around the heating layer 4 and the outer wall of the sharpening tank interior 2 .

[0021] In order to better ove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com