A fast water-absorbing non-woven fabric and its processing technology

A processing technology, water-absorbing technology, applied in non-woven fabrics, textiles and papermaking, conjugated synthetic polymer rayon, etc., can solve the problem that the water-absorbing properties of non-woven fabrics cannot meet the requirements of use, lack of mechanical properties, and seaweed fiber water absorption The performance is not very strong, etc., to achieve the effect of enhancing water absorption, soft hand feeling, and fluffy fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

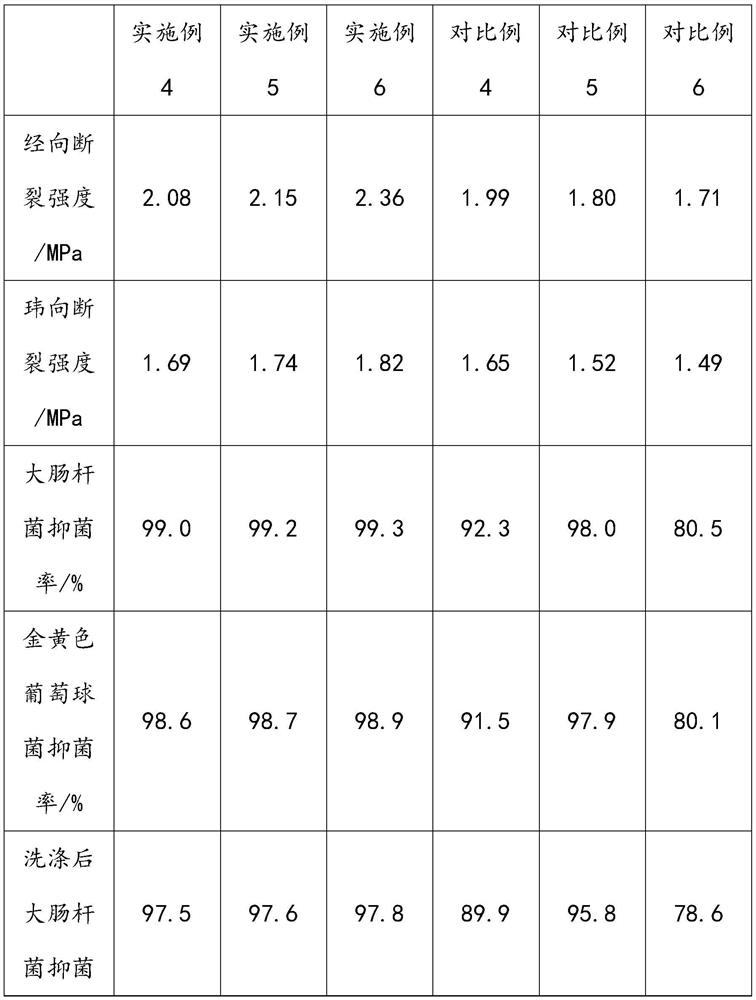

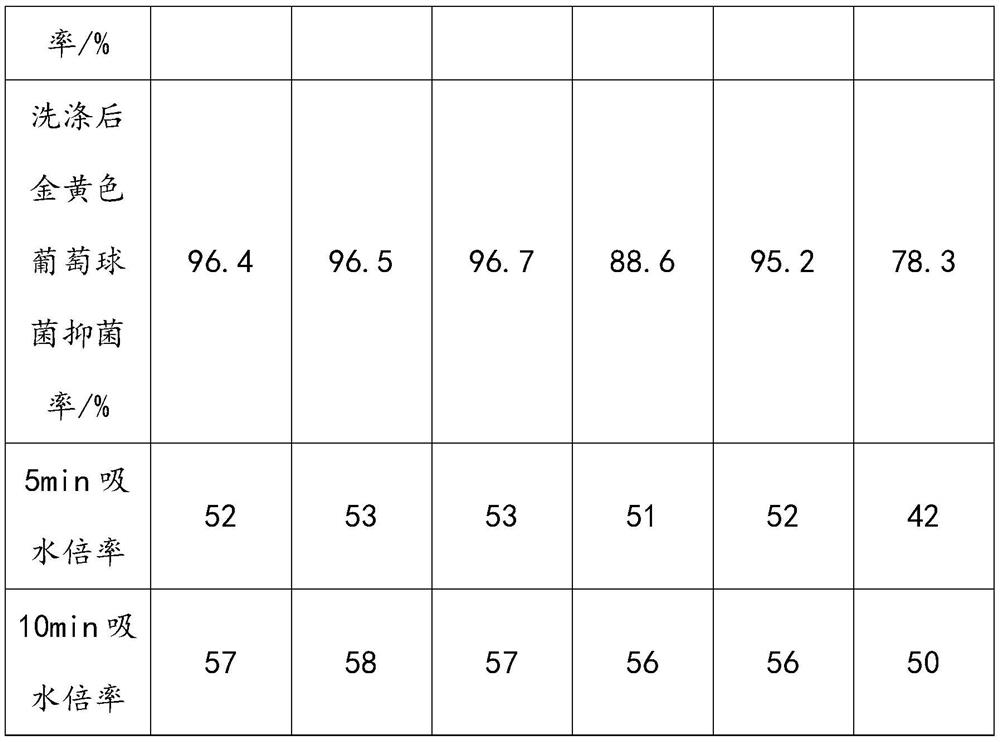

Examples

Embodiment 1

[0036] Functional fibers are prepared by the following methods:

[0037] (1) Complete the reaction in a reflux device with magnetic stirring, weigh 1.18g of oxalylhydrazide and add it to a three-necked flask, then add 1mL of absolute ethanol and 2-3 drops of acetic acid, and then drop it in through a constant pressure dropping funnel 1.01 g of 3-penten-2-one was refluxed until a large amount of white solids were precipitated, the reaction was stopped, cooling and suction filtration, the crude product was dissolved in absolute ethanol, and the functional monomer was obtained by low-temperature recrystallization;

[0038] (2) According to the solid-to-liquid ratio of 1g: 10mL, add carboxymethylcellulose sodium into pure water and heat to dissolve, then add acrylic acid, glycidyl methacrylate, functional monomer and N,N-methylenebisacrylamide Dissolve in pure water to form a mixed solution. After stirring for 7-8 minutes, add the obtained mixed solution to the sodium carboxymethy...

Embodiment 2

[0042] Functional fibers are prepared by the following methods:

[0043] (1) Complete the reaction in a reflux device with magnetic stirring, weigh 1.18g of oxalylhydrazide and add it to a three-necked flask, then add 1mL of absolute ethanol and 2-3 drops of acetic acid, and then drop it in through a constant pressure dropping funnel 1.01 g of 3-penten-2-one was refluxed until a large amount of white solids were precipitated, the reaction was stopped, cooling and suction filtration, the crude product was dissolved in absolute ethanol, and the functional monomer was obtained by low-temperature recrystallization;

[0044] (2) According to the solid-to-liquid ratio of 1g: 10mL, add carboxymethylcellulose sodium into pure water and heat to dissolve, then add acrylic acid, glycidyl methacrylate, functional monomer and N,N-methylenebisacrylamide Dissolve in pure water to form a mixed solution. After stirring for 7-8 minutes, add the obtained mixed solution to the sodium carboxymethy...

Embodiment 3

[0048] Functional fibers are prepared by the following methods:

[0049] (1) Complete the reaction in a reflux device with magnetic stirring, weigh 1.18g of oxalylhydrazide and add it to a three-necked flask, then add 1mL of absolute ethanol and 2-3 drops of acetic acid, and then drop it in through a constant pressure dropping funnel 1.01 g of 3-penten-2-one was refluxed until a large amount of white solids were precipitated, the reaction was stopped, cooling and suction filtration, the crude product was dissolved in absolute ethanol, and the functional monomer was obtained by low-temperature recrystallization;

[0050] (2) According to the solid-to-liquid ratio of 1g: 10mL, add carboxymethylcellulose sodium into pure water and heat to dissolve, then add acrylic acid, glycidyl methacrylate, functional monomer and N,N-methylenebisacrylamide Dissolve in pure water to form a mixed solution. After stirring for 7-8 minutes, add the obtained mixed solution to the sodium carboxymethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com