Process and apparatus for producing bottle cap with pull ring and tear-off

A technology of production process and special equipment, which is applied in the field of production process and special equipment of ring-tear bottle caps, can solve the problems of waste of materials and labor, low production efficiency, unsafe production of ring-tear bottle caps, etc. Achieve the effect of saving labor force, improving utilization rate and reducing production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

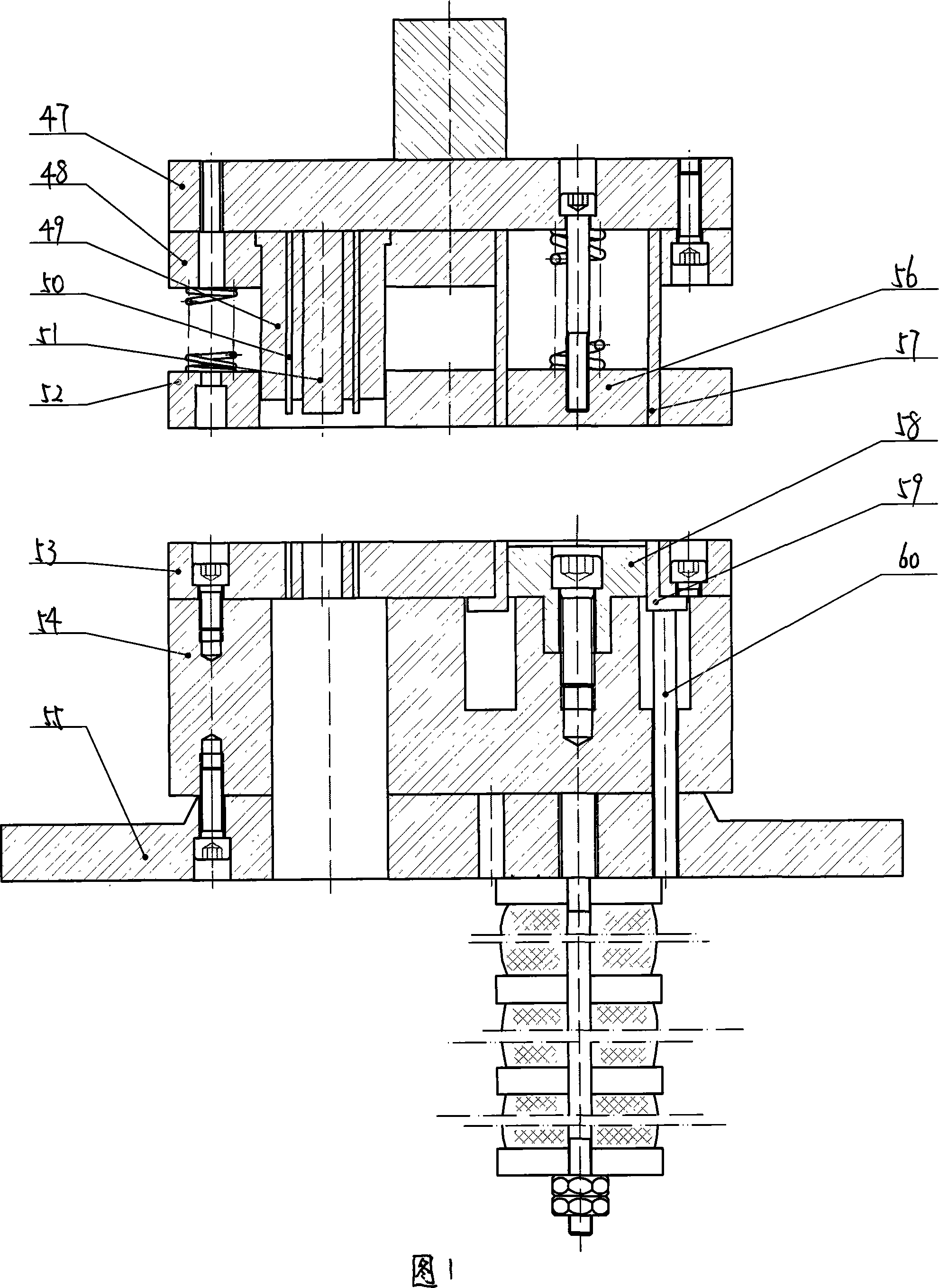

[0020] Embodiment 1, referring to Fig. 1, 2, 3, processing is made template 55 and die handle 47 of progressive die, installs lower mold backing plate 54 on template 55, installs lower mold 53 and forming convex on lower mold backing plate 54 Die 58, install ejector post 60 in formwork 55 and lower die backing plate 54, ejector post 60 slides in template 55 and lower die backing plate 54, install binder ring 59 on ejector post 60; 47 fixedly install fixed plate 48, unloading plate 52 and unloader 56, on fixed plate 48, fixedly install punching punch fixing plate 49 and forming punch and concave die 57, punching sheet is installed on punching punch fixing plate 49 The outer punch 50 and the inner punch 51 of the punching sheet; form a progressive die, and install the progressive die on the punching machine to complete the big ear blanking punching and blanking forming process;

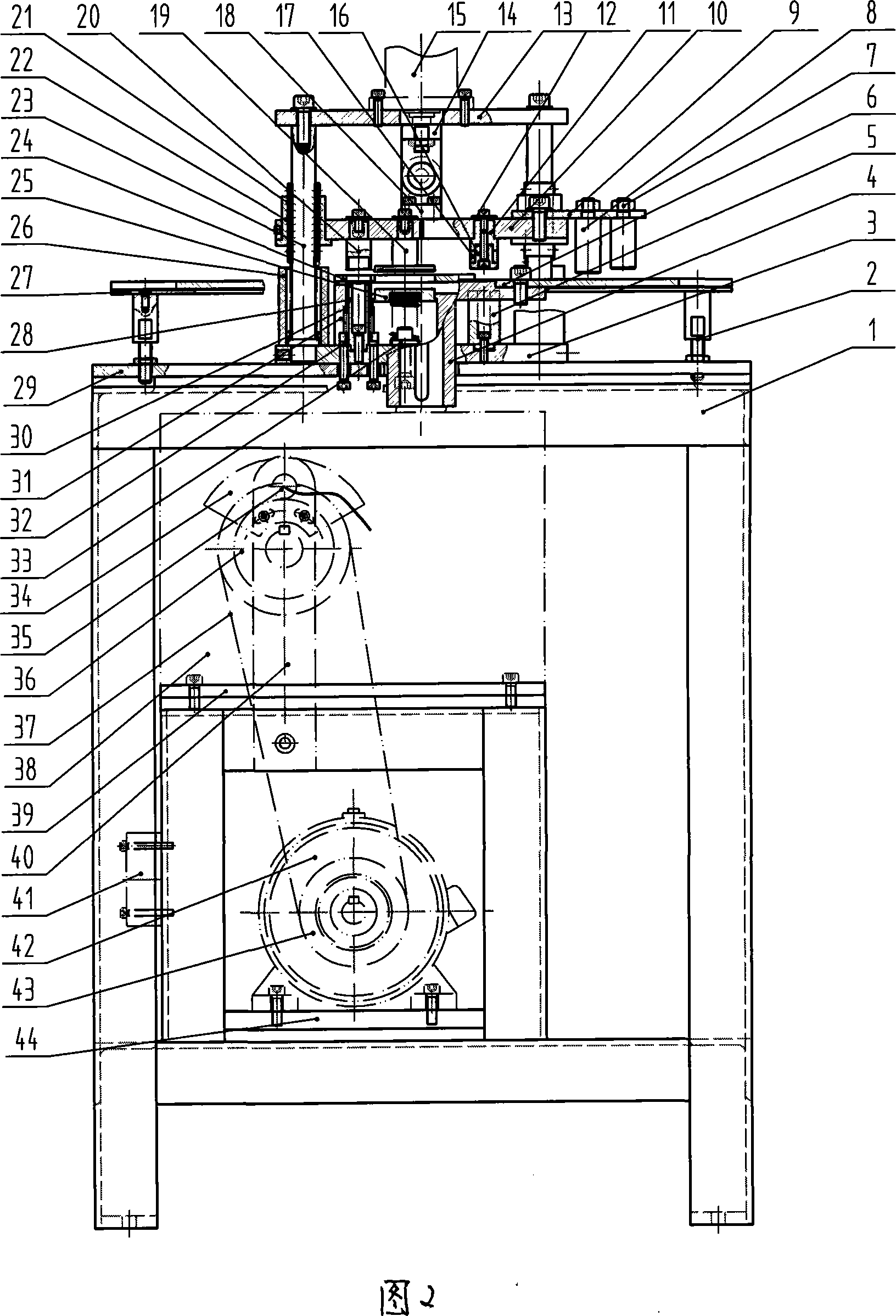

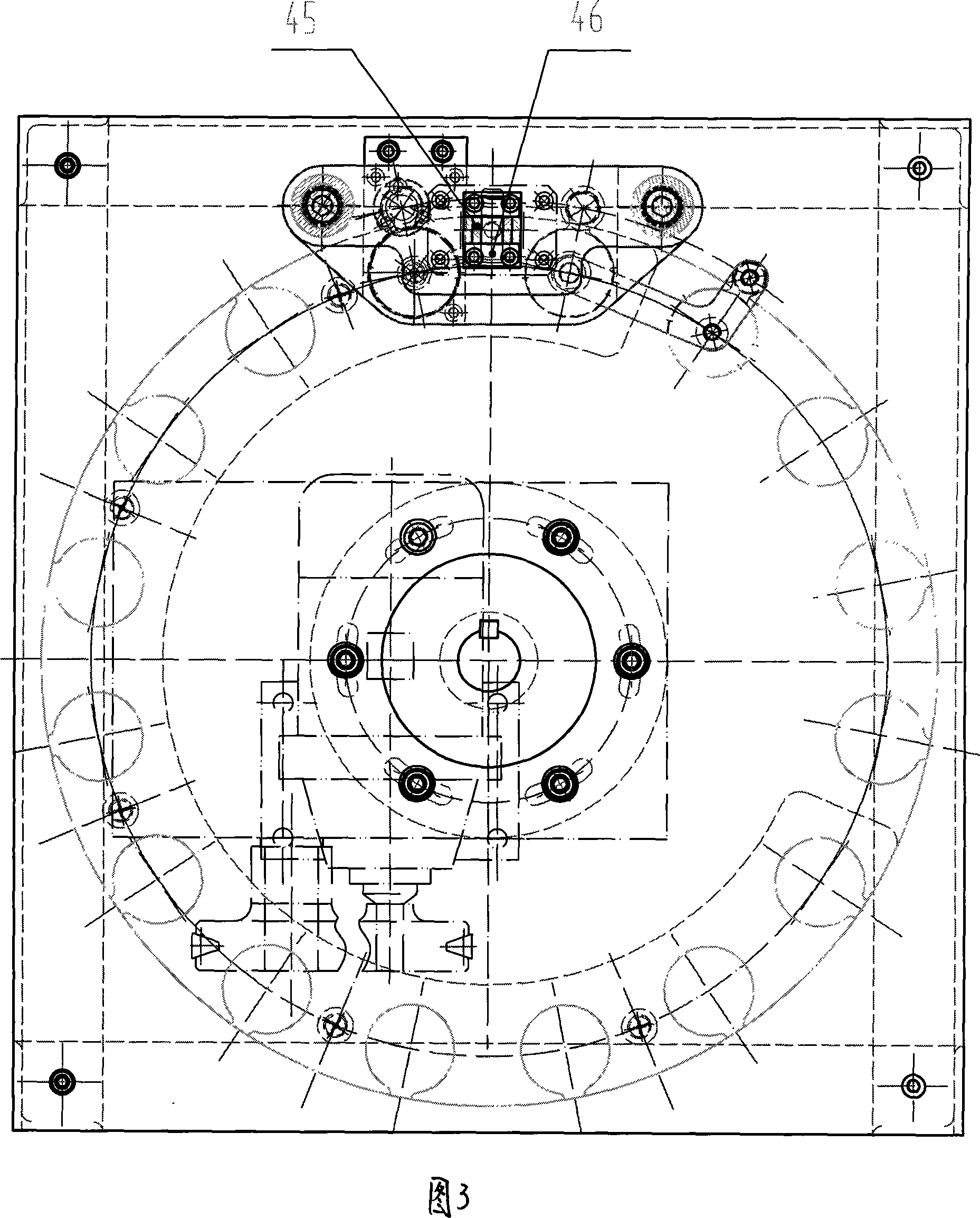

[0021] Machine base 1 of the turntable type ring press machine, on which the motor seat plate 44, mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com