Magnetic vibration reducing method and vibration dampener

A shock absorber, magnetic technology, applied in springs/shock absorbers, magnetic springs, springs, etc., can solve the problems of difficulty in reducing the resonance frequency, unsatisfactory low-frequency vibration effect, no shock absorption effect, etc., to reduce vibration transmission, No need for routine maintenance, the effect of reducing vibration interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: Magnetic shock absorption method

[0025] Vibration reduction is achieved by the repulsive force between the magnetic poles of the same sex and the air gap formed between the magnetic poles of the same sex to produce a damping effect.

Embodiment 2

[0026] Example 2: Magnetic shock absorber

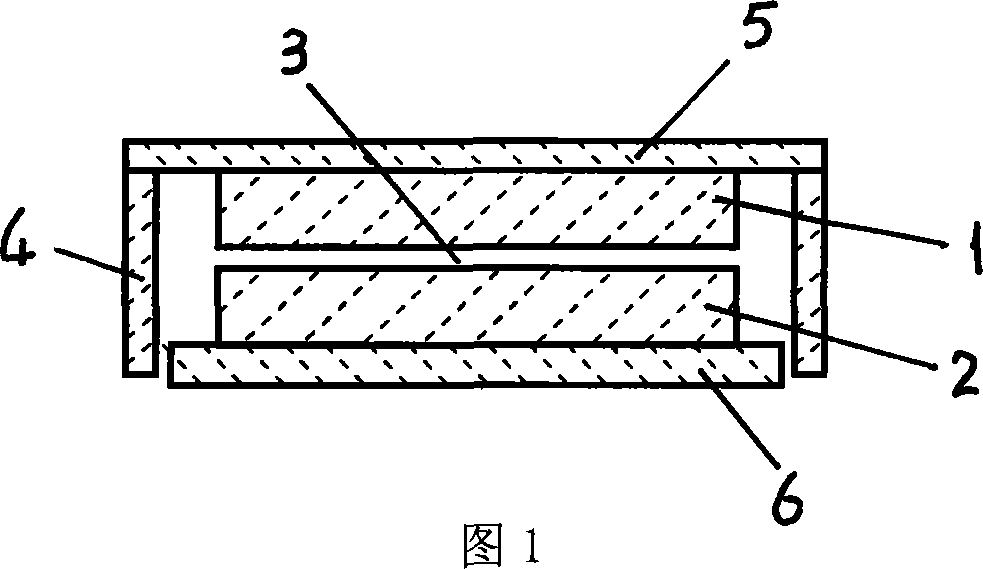

[0027] Referring to Fig. 1, an upper magnet 1 and a lower magnet 2 are set opposite to each other. Between the upper magnet 1 and the lower magnet 2, an air gap 3 that changes with load or vibration is formed by the repulsive force between the magnets.

[0028] As shown in Figure 1, in the specific implementation, a cylindrical casing 4 is provided, and the cylindrical casing 4 is divided into two parts that can move relative to the upper and lower parts in the longitudinal direction. In the shape housing 4, the lower magnet 2 is fixedly arranged on the bottom plate 6, and the upper magnet 1 is suspended and fixed under the top cover 5. The overall shape is flat cylindrical. This structure is easy to install and can keep the upper magnet 1 The horizontal stability between the lower magnet 2 and the closure of the magnetic circuit at the same time prevent magnetic flux leakage interference. The upper magnet 1 and the lower magnet 2 us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com