Load switch operation axle link lock device

A load switch and interlocking device technology, applied in the field of electric power, to achieve the effects of flexible mechanical transmission, convenient operation, and simple interlocking structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

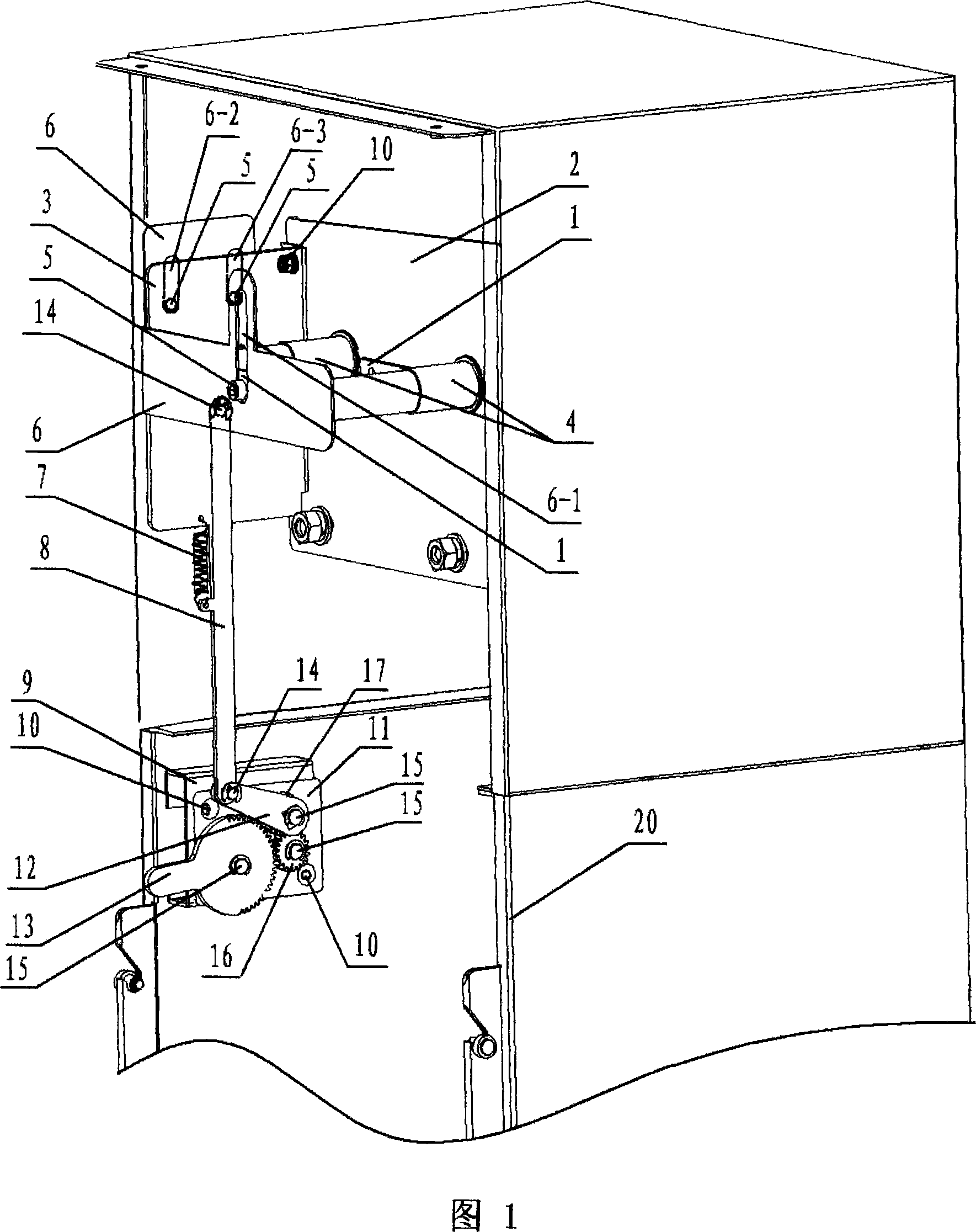

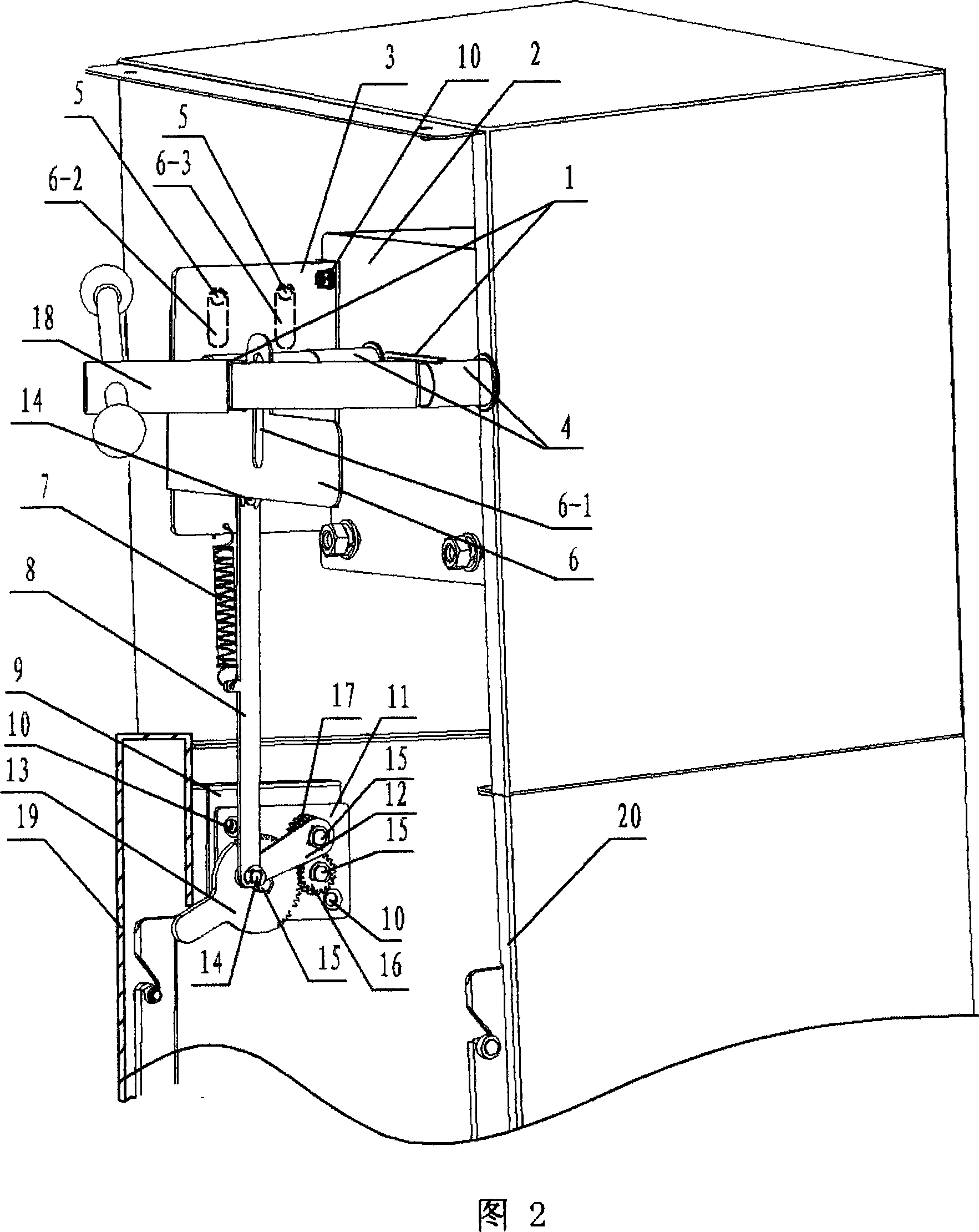

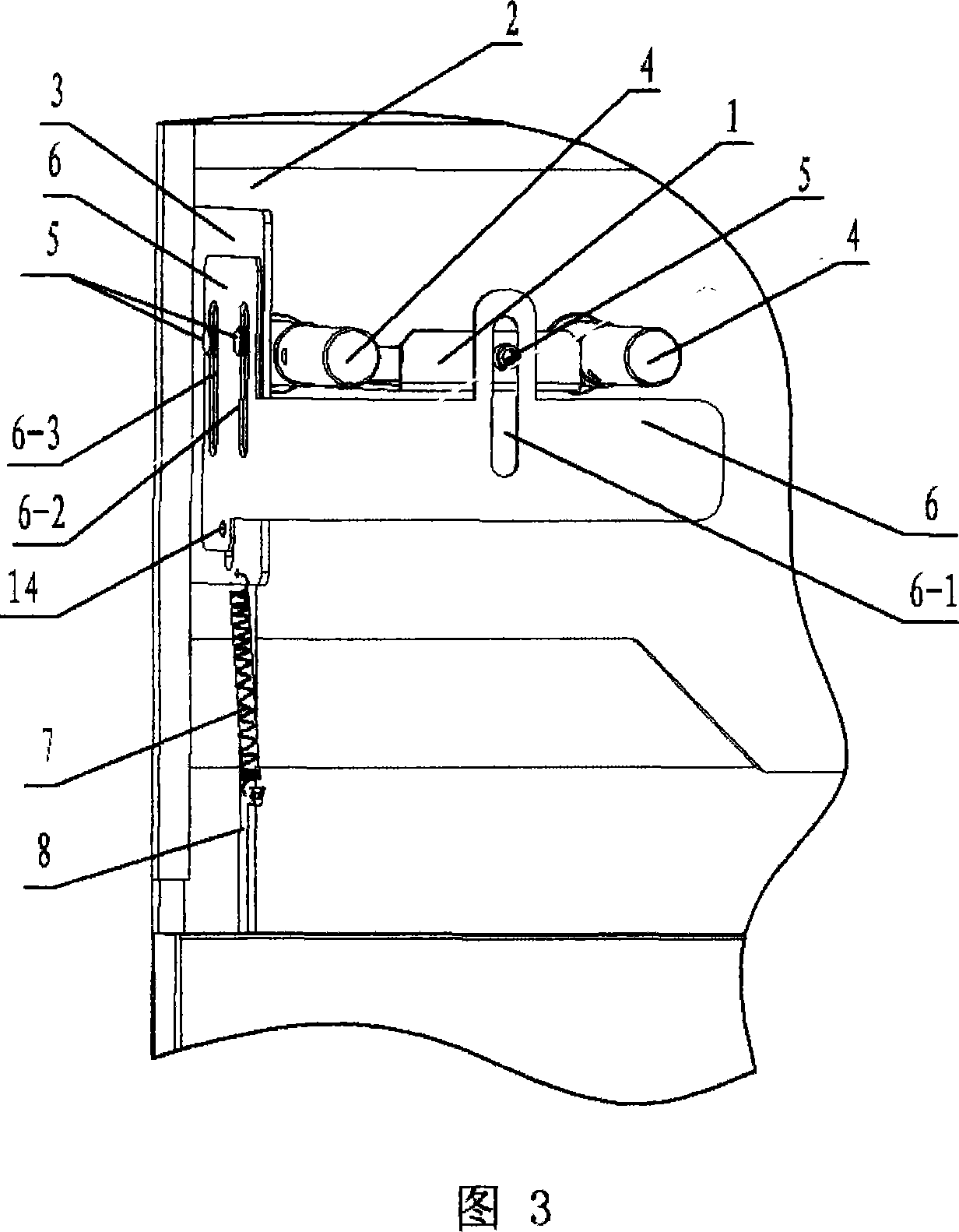

[0010] The purpose of the load switch operating shaft interlocking device of the present invention is that when the load switch lower door leaf 19 is closed, the operating handle 18 can be inserted into the mechanism operating shaft 4 for operation; when the lower door leaf 19 is opened, the operating mechanism operating shaft 4 and the right-angle interlocking plate are not allowed. 6 blocks the mechanism operating shaft 4 so that the operating handle 18 cannot be inserted and cannot be operated.

[0011] See accompanying drawing 1. Fig. 1 is a perspective view of the structure of the lower door 19 of the present invention when it is opened. It can be seen from Figure 1 that the load switch operation shaft interlocking device includes a fixed bent plate 1, a mechanism front plate 2, a fixed plate 3, a tension spring 7, a connecting rod 8, a side bent plate 9 of the chassis, a gear fixed plate 11, and a crank arm 12. Movable pin 14, fixed pin 15, chassis lower door leaf 19, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com