Offset support cantilever type piezoelectric inertia impact precision driver

An inertial impact, cantilever type technology, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problems of complex circuits and high costs, and achieve large travel and low cost. Low, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

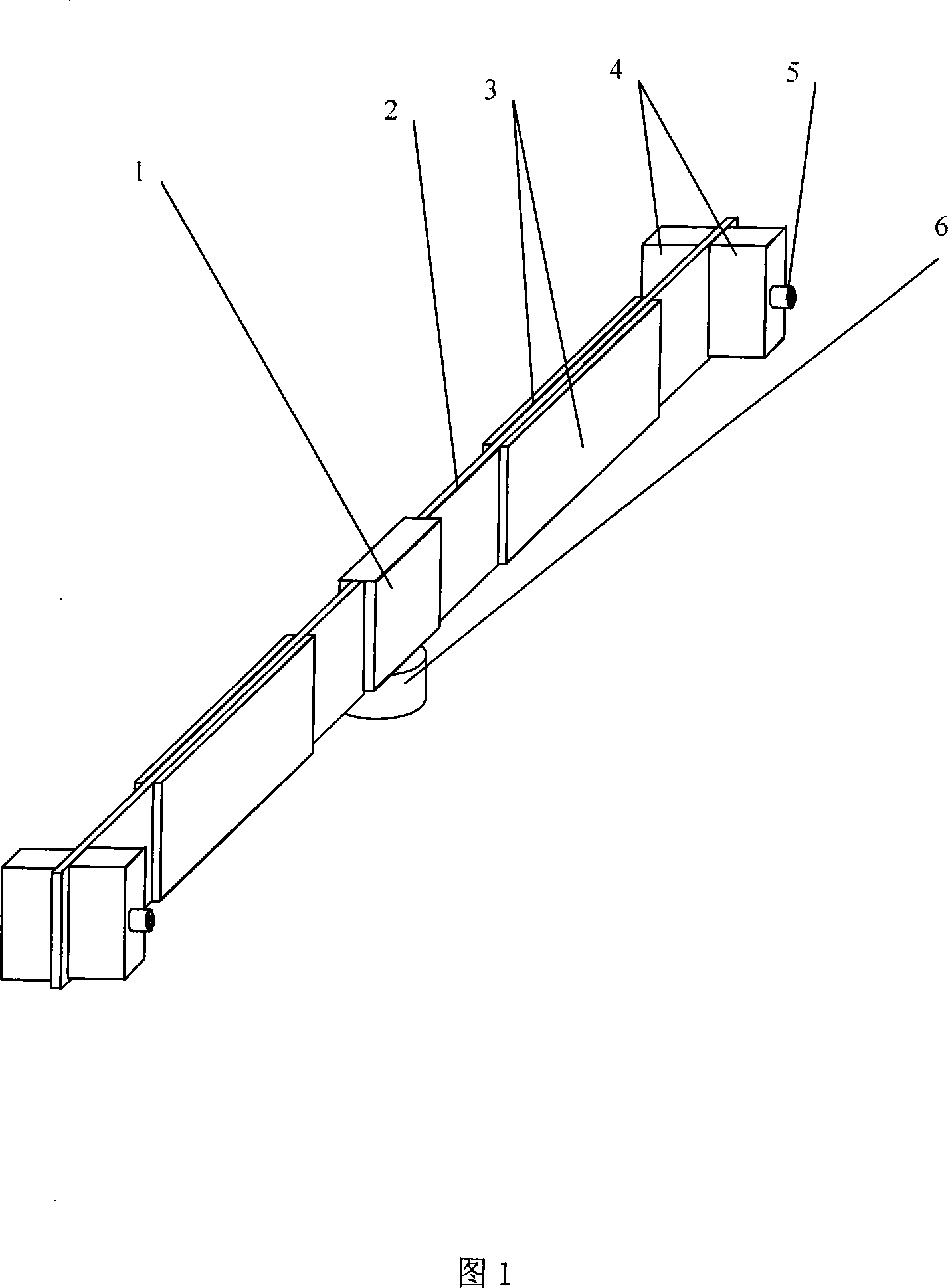

[0015] Referring to FIG. 1, the metal substrate 2 is respectively connected with four piezoelectric wafers 3 to form a piezoelectric bimorph. Both ends of the metal substrate 2 are respectively fixed to the impact mass 4 by screws 5, and the bias clamping device 1 is fixed between the metal substrate 2. The lower part of the offset clamping device is fixedly connected to the main mass 6 .

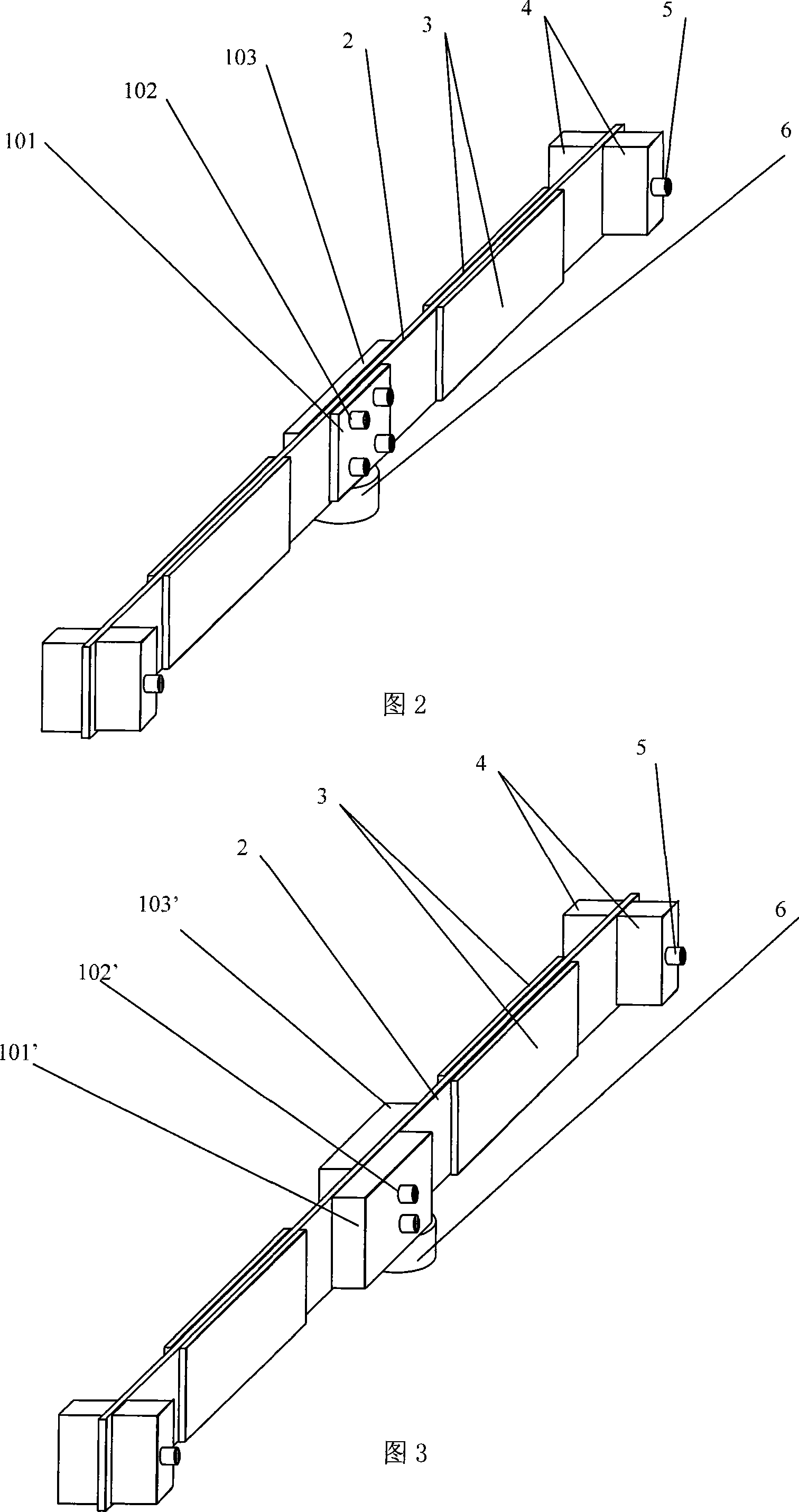

[0016] 2 is a biased support cantilever piezoelectric inertial impact linear precision driver, the piezoelectric wafer 3 is pasted on the metal substrate 2 with an adhesive, and the impact mass 4 is fixed on both ends of the metal substrate 2 with screws 5. Symmetrically arranged piezoelectric vibrators. The first pressure plate 101, the metal substrate 2 and the second pressure plate 103 are fixedly connected by screws 102, and the width of the first pressure plate 101 is smaller than that of the second pressure plate 103, thus forming the bias support of the piezoelectric vibrator. When ...

Embodiment 2

[0018] Accompanying drawing 3 is an offset support cantilever piezoelectric inertial impact rotary precision driver, which is composed of main mass 6, pressure plate three 101' and pressure plate four 103', piezoelectric wafer 3, metal substrate 2, impact mass 4 and the like. The piezoelectric wafer 3 is pasted on the metal substrate 2 with an adhesive, and the impact mass 4 is fixed on both ends of the metal substrate 2 with screws 5 to form symmetrically arranged piezoelectric vibrators. The third plate 101', the metal base plate 2 and the fourth plate 103' are fixedly connected with the screw 102', and the platen 101' and the platen 103' have the same width but are connected in dislocation, thus forming the bias support of the piezoelectric vibrator. When a symmetrical excitation electrical signal is applied, during the vibration process of the piezoelectric vibrator, two-way different impact torques will be generated due to the offset support, which realizes the one-way rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com