Crystal-chip polishing method

A wafer and polishing machine technology, which is applied to surface polishing machine tools, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of inability to adjust the pressure of the upper polishing disc, inability to realize stepless speed regulation, poor processing stability, etc. , to achieve the effect of improving polishing accuracy, small impact impact, and high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

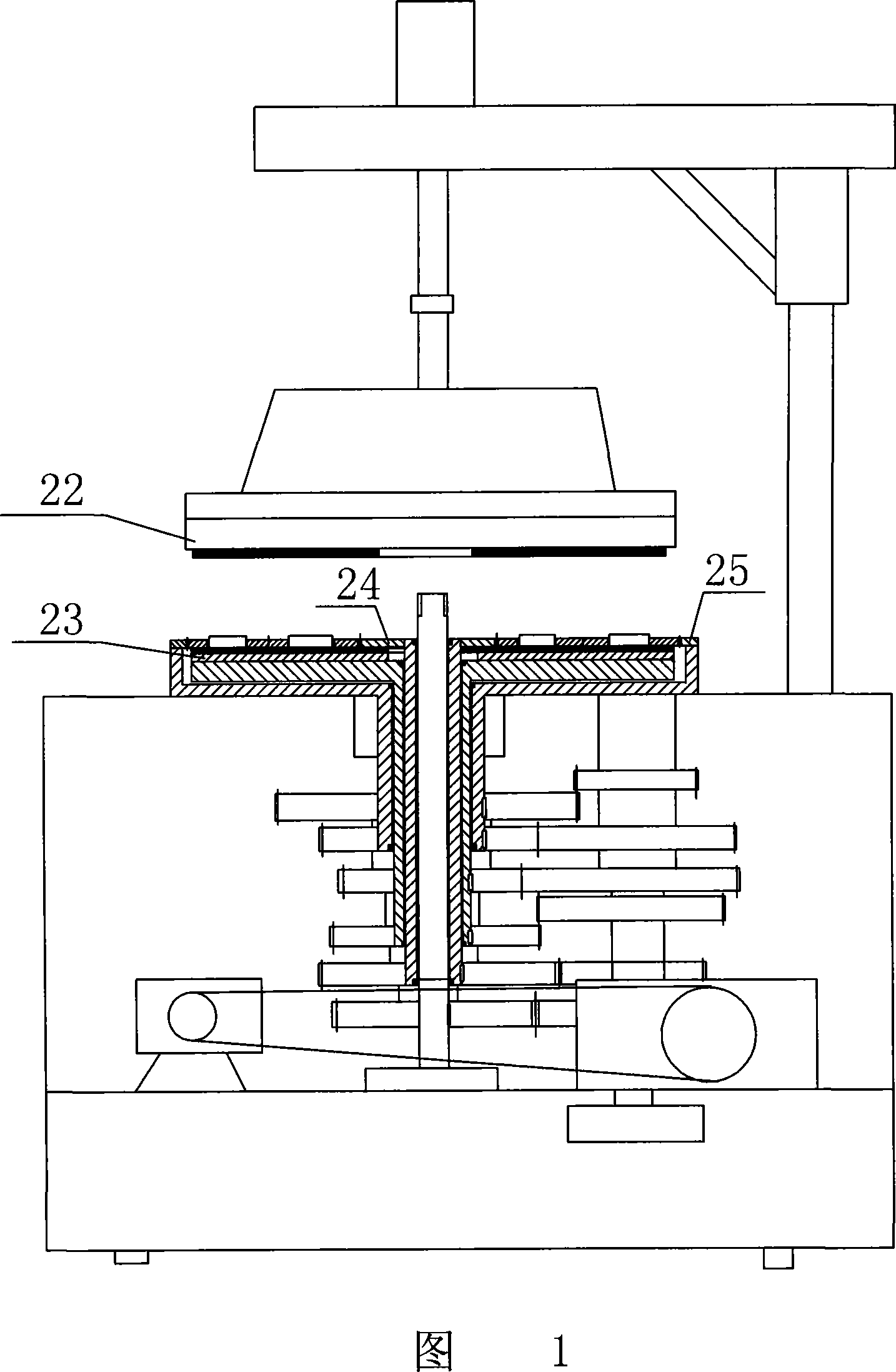

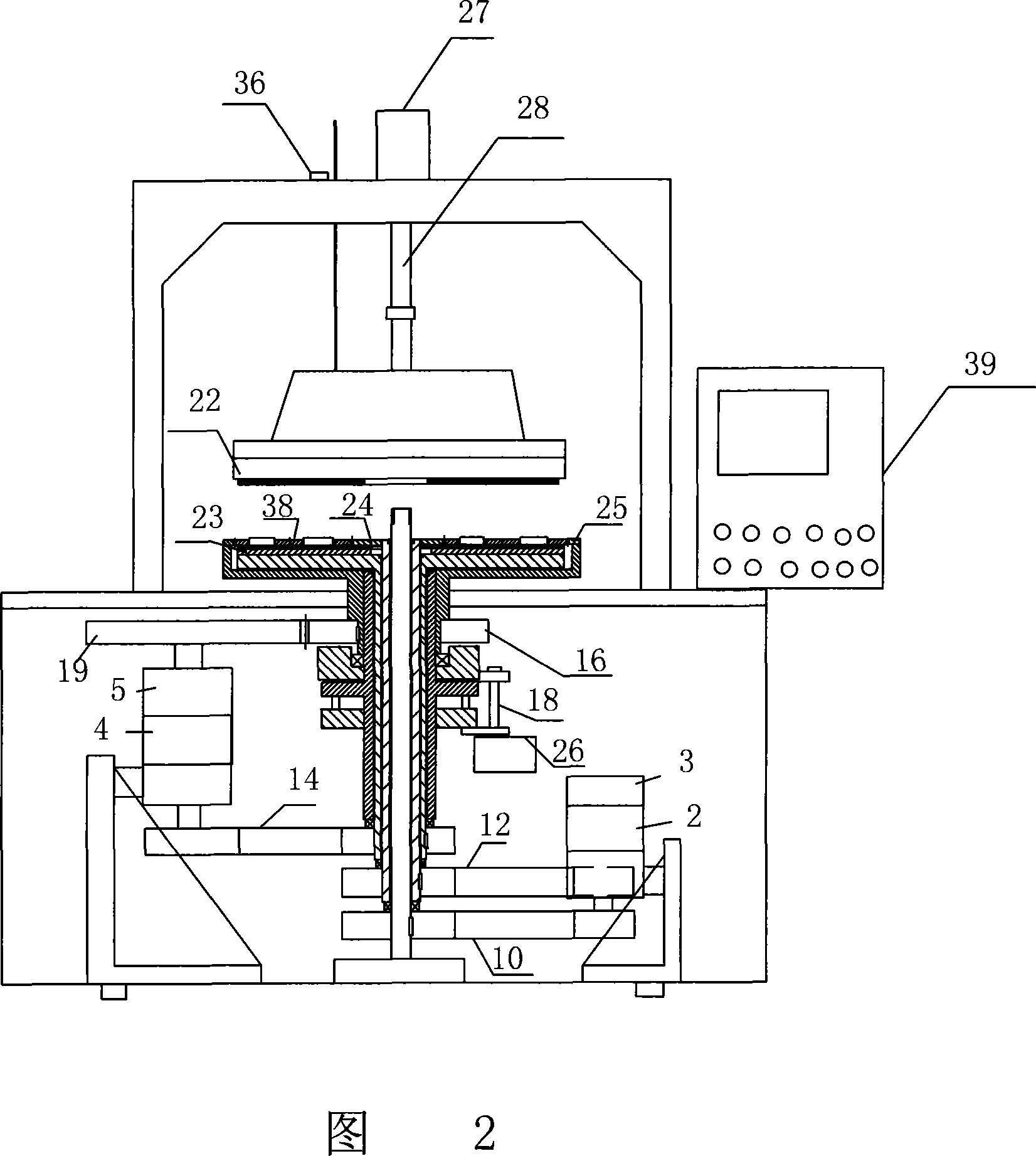

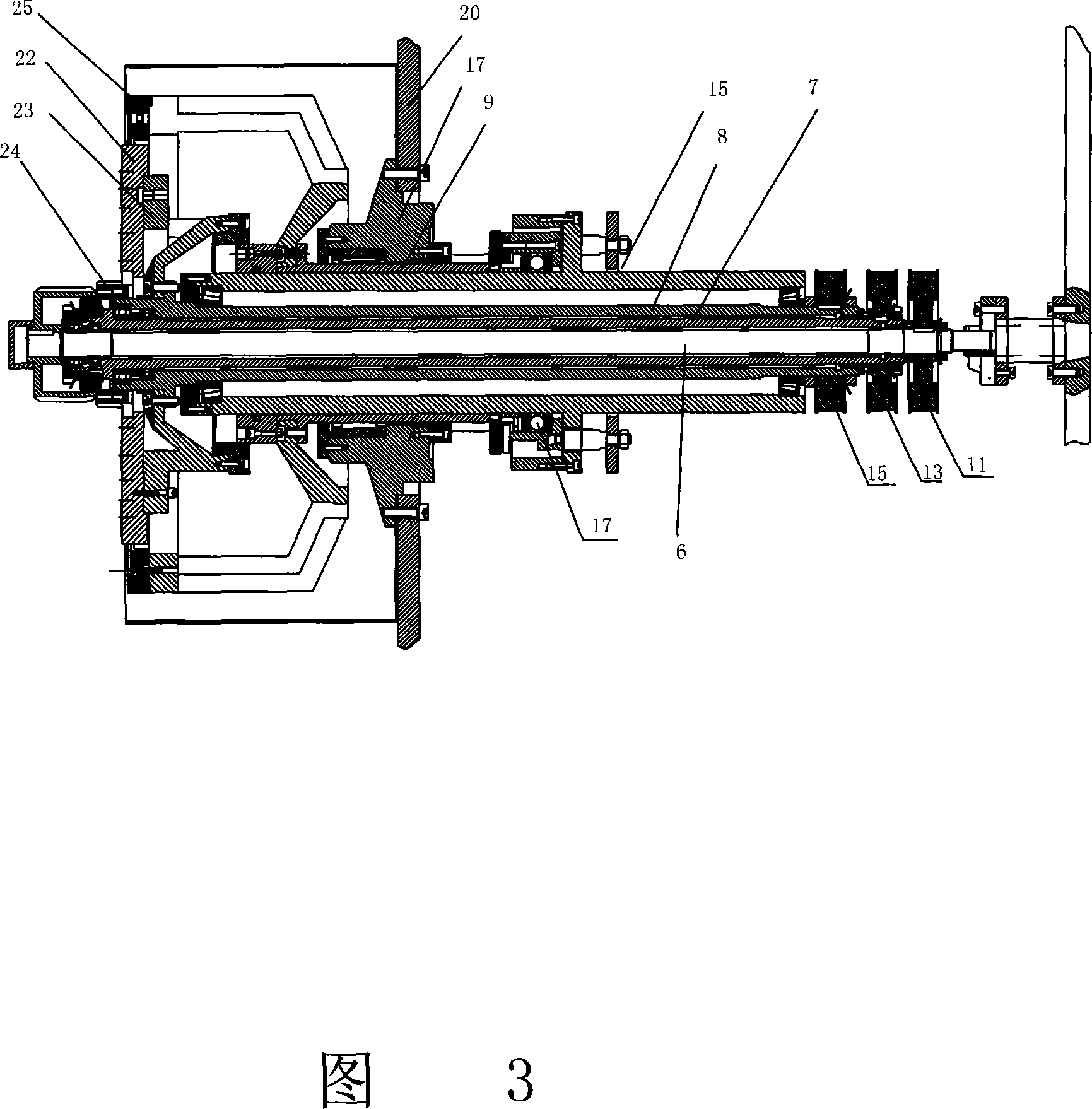

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

[0029] Referring to Fig. 2~Fig. 9, a kind of polishing method of wafer, this method mainly comprises the following steps:

[0030] (1) Place the wafer to be processed on the planetary wheel of the polishing machine;

[0031] (2), start the polishing machine, after the self-test of the polishing machine is normal, set the process parameters according to the wafer to be processed: the speed control curve of each variable frequency motor, the pressure control curve of the cylinder, the temperature and flow of the polishing solution;

[0032] (3) Control the lowering of the cylinder connected to the upper polishing disc and receive the signal from the position sensor. When the upper polishing disc reaches the working position, the cylinder stops and connects the upper polishing disc to the long axis;

[0033] (4) Check whether the polishing liquid delivery device is norma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com