Microscope light source radiating device

A heat dissipation device and microscope technology, which is applied in the field of optical instrument components, can solve problems such as heating of the base of the microscope stand, achieve good directional heat dissipation, solve heating problems and damage work, and be easy and fast to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

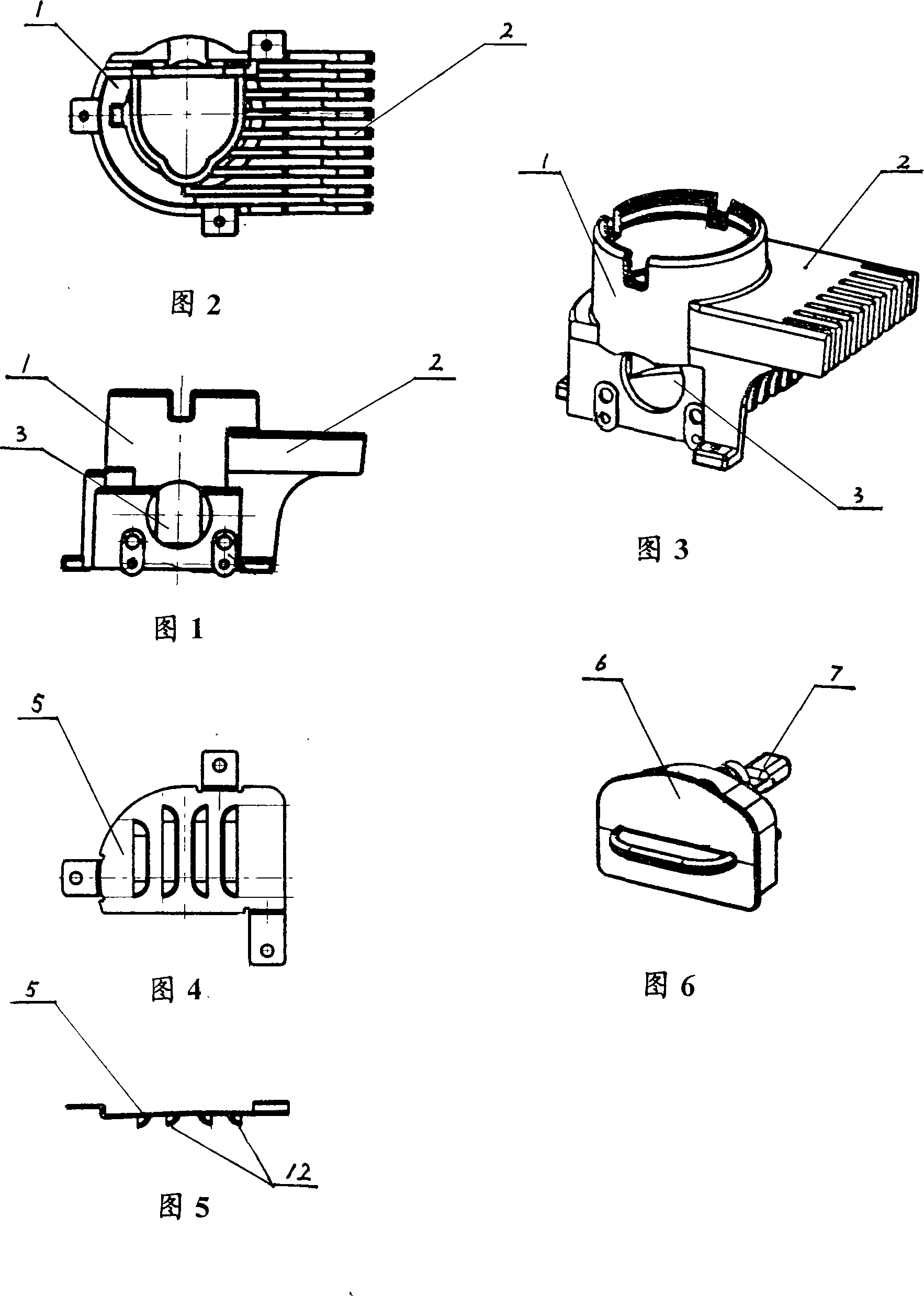

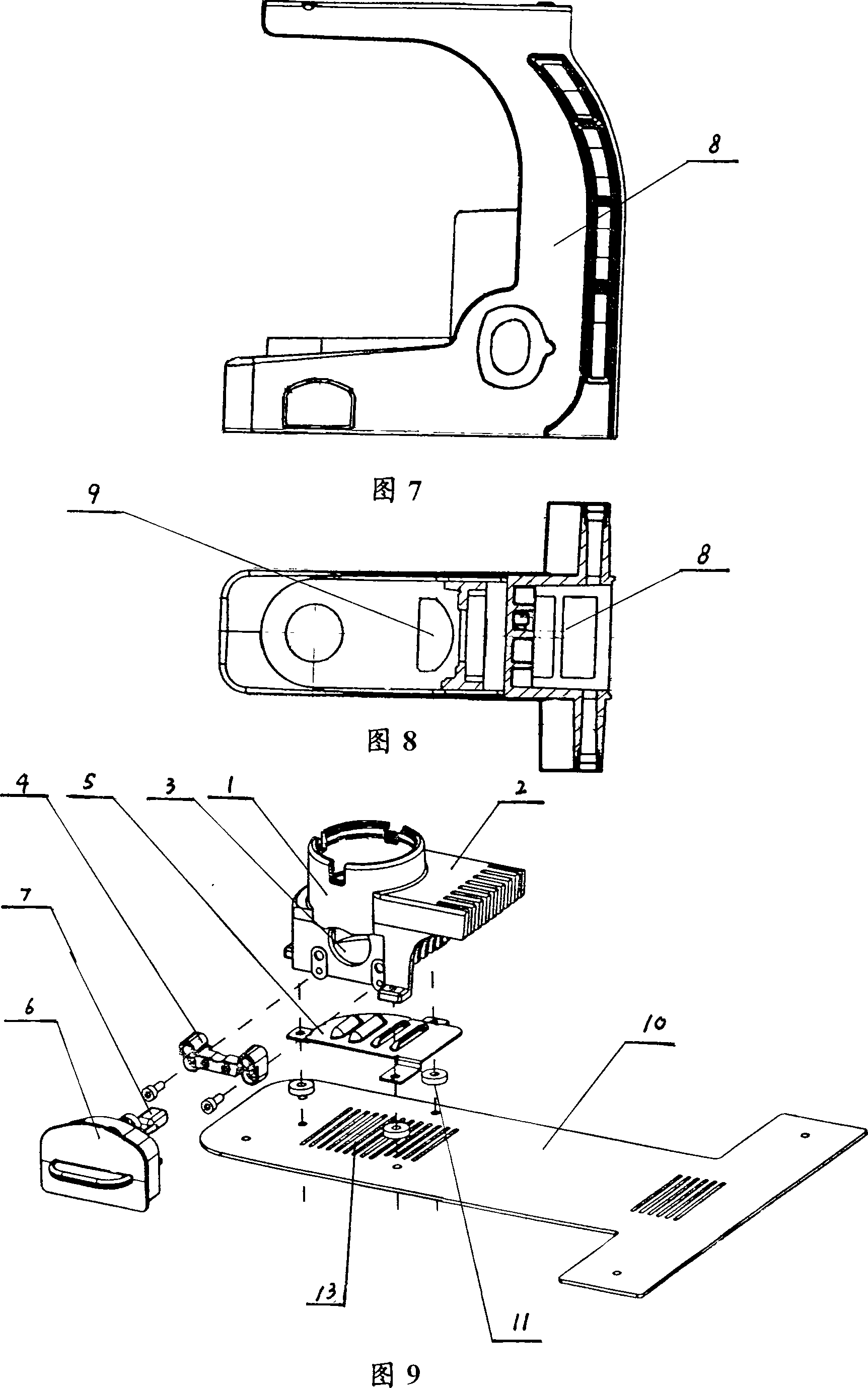

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] Referring to Fig. 1-Fig. 7, one side of the light-collecting mirror base 1 of the device is provided with directional cooling fins 2, and the directional cooling fins and the light-collecting mirror base are integrated; the lamp door socket 4 is positioned and connected to the The two sides of the round hole 3 of the directly lower part of the mirror base are connected to the bottom of the light-collecting mirror base with the radiating plate 5 provided with the louvers 12 opposite in the inclination direction; the halogen bulb 7 is installed on the lamp door 6, and the lamp door and the The lamp door sockets 4 on both sides of the round hole 3 at the bottom of the light collecting mirror base are mated and connected, and the halogen bulb 7 installed on the lamp door 6 is inserted into the round hole 3 at the bottom of the light collecting mirror seat.

[0020] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com