Method for achieving uniform chemical mechanical polishing in integrated circuit manufacturing

A manufacturing process and integrated circuit technology, applied in the direction of circuits, semiconductor/solid-state device manufacturing, electrical components, etc., to achieve the effect of reducing non-uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

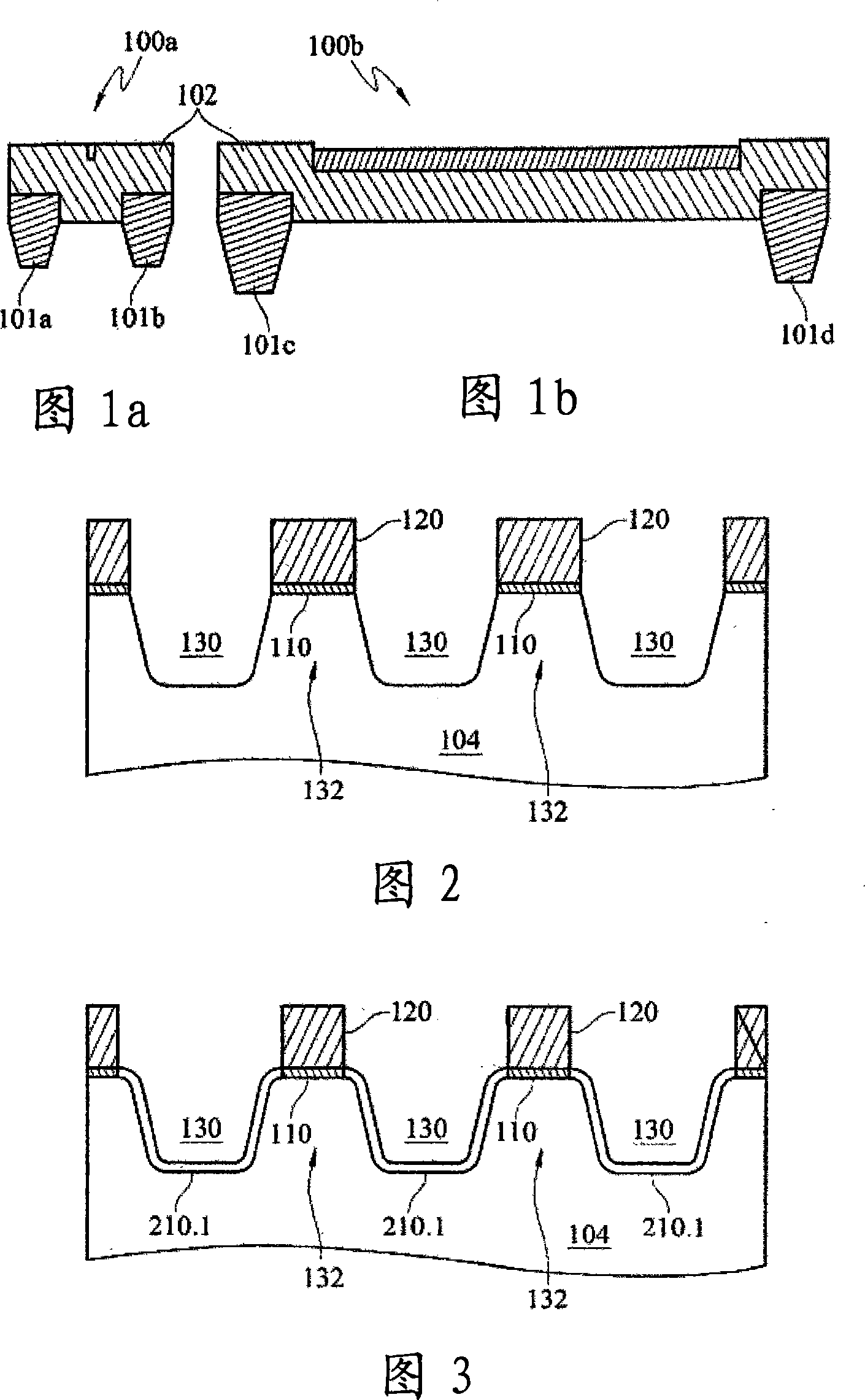

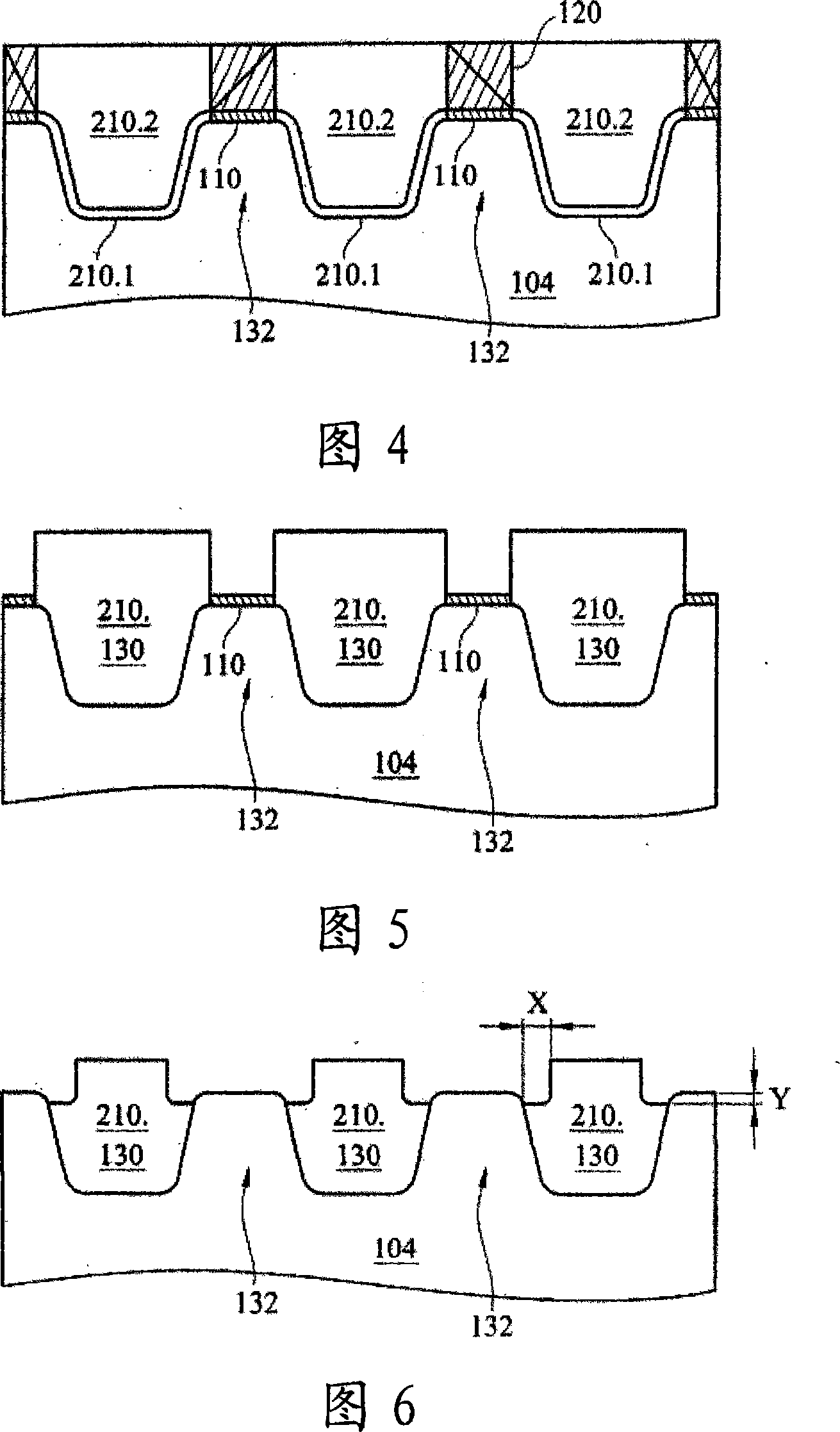

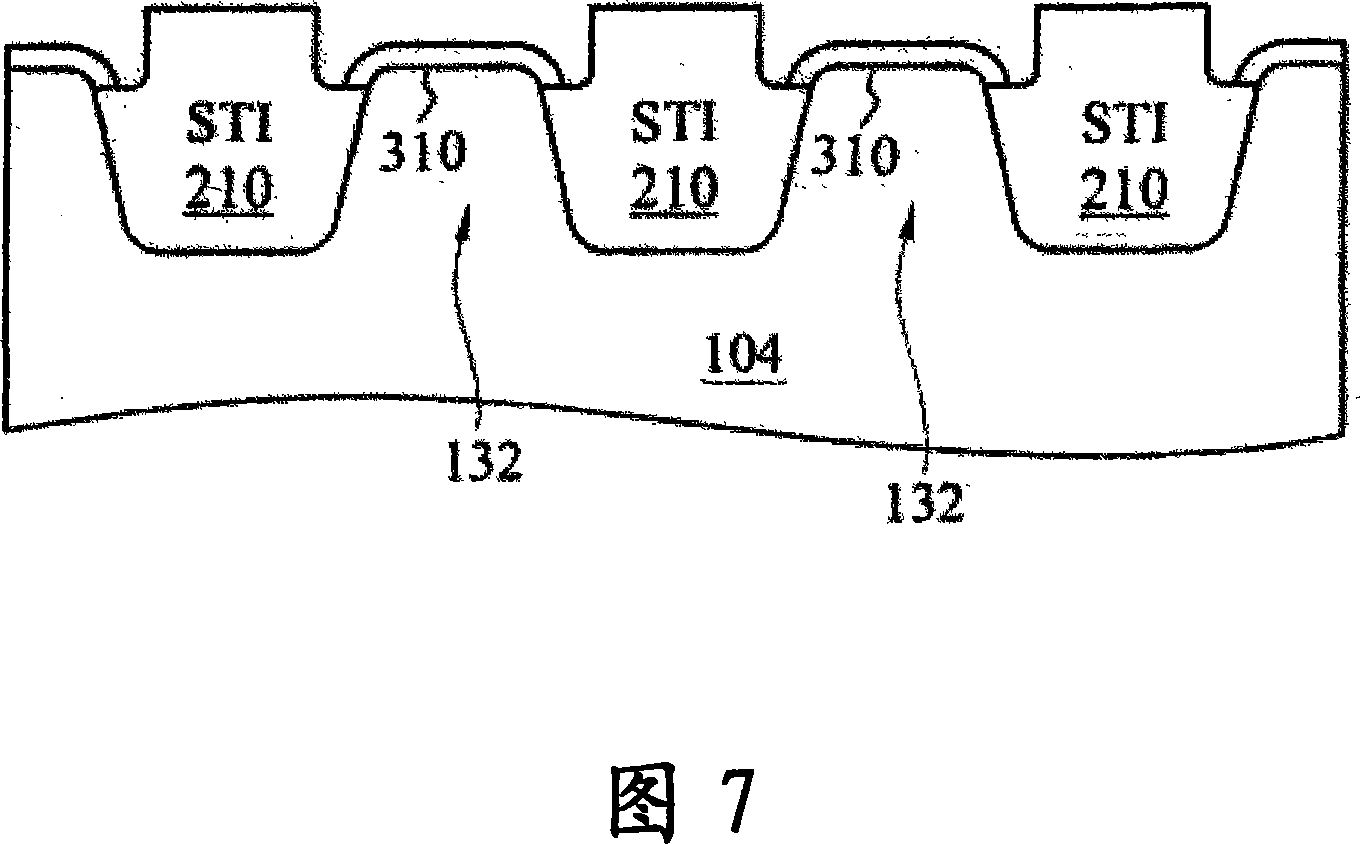

[0042] In order to further illustrate the technical means and effects that the present invention adopts for reaching the intended purpose of the invention, the method for achieving uniform chemical mechanical polishing in the integrated circuit manufacturing process proposed according to the present invention will be specifically described below in conjunction with the accompanying drawings and preferred embodiments. Embodiments, methods, steps, features and effects thereof are described in detail below.

[0043] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of preferred embodiments with reference to the drawings. For convenience of description, in the following embodiments, the same elements are denoted by the same numbers.

[0044] Through the description of the specific implementation mode, when the technical means and functions adopted by the present invention t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap