Diversion structure of turbine low-pressure vapor inlet chamber, and parameter design method for same

A steam inlet chamber and steam turbine technology, which is applied in mechanical equipment, engine components, machines/engines, etc., can solve the problem of poor axial airflow stability and reliability, increased exhaust dynamic loss of axial flow blades, and inconsistent airflow angle at the chamber outlet. Uniformity and other issues to achieve the effect of reducing blade loss and work loss, reducing steam non-uniformity, improving stability and aerodynamic economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

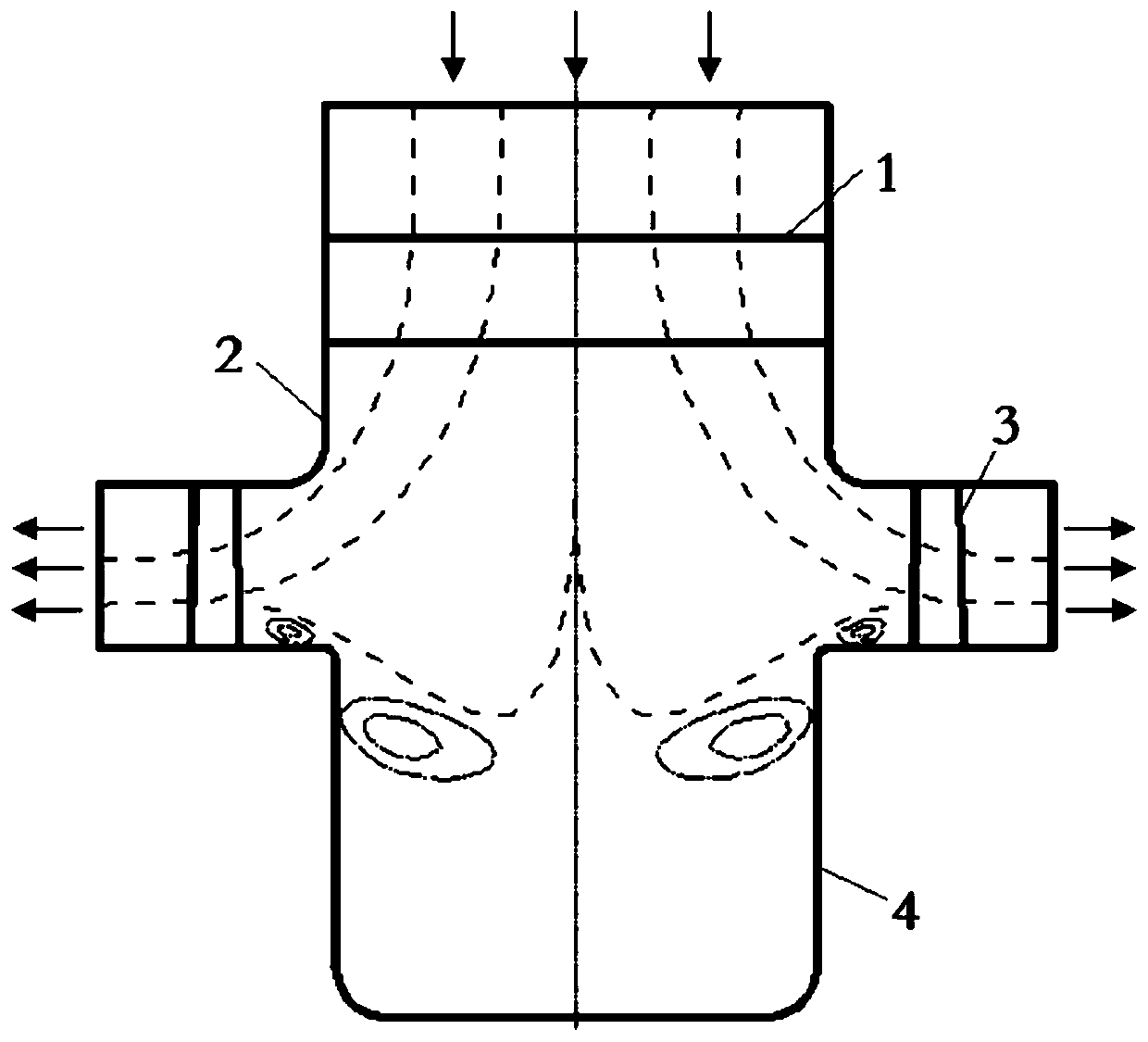

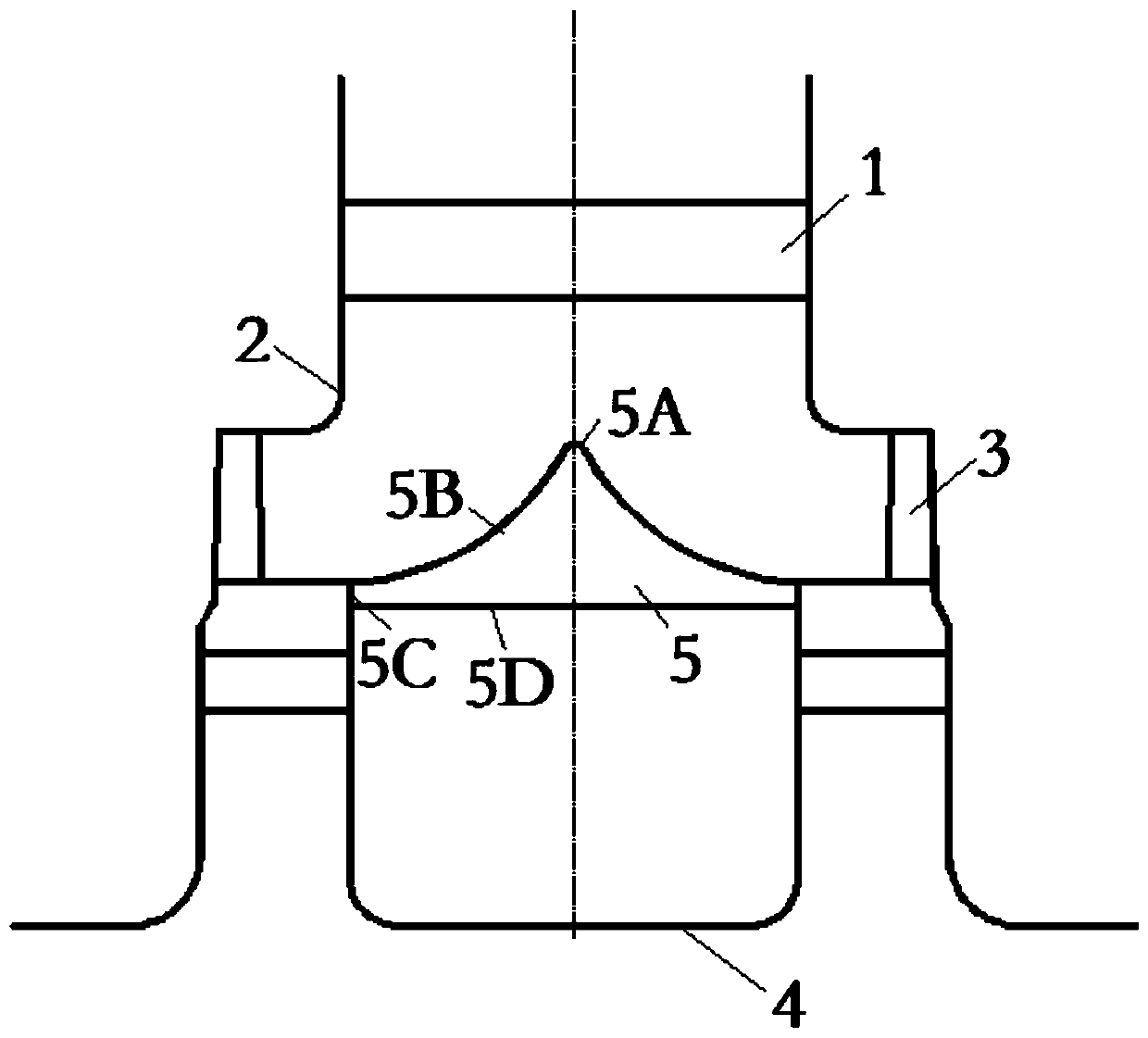

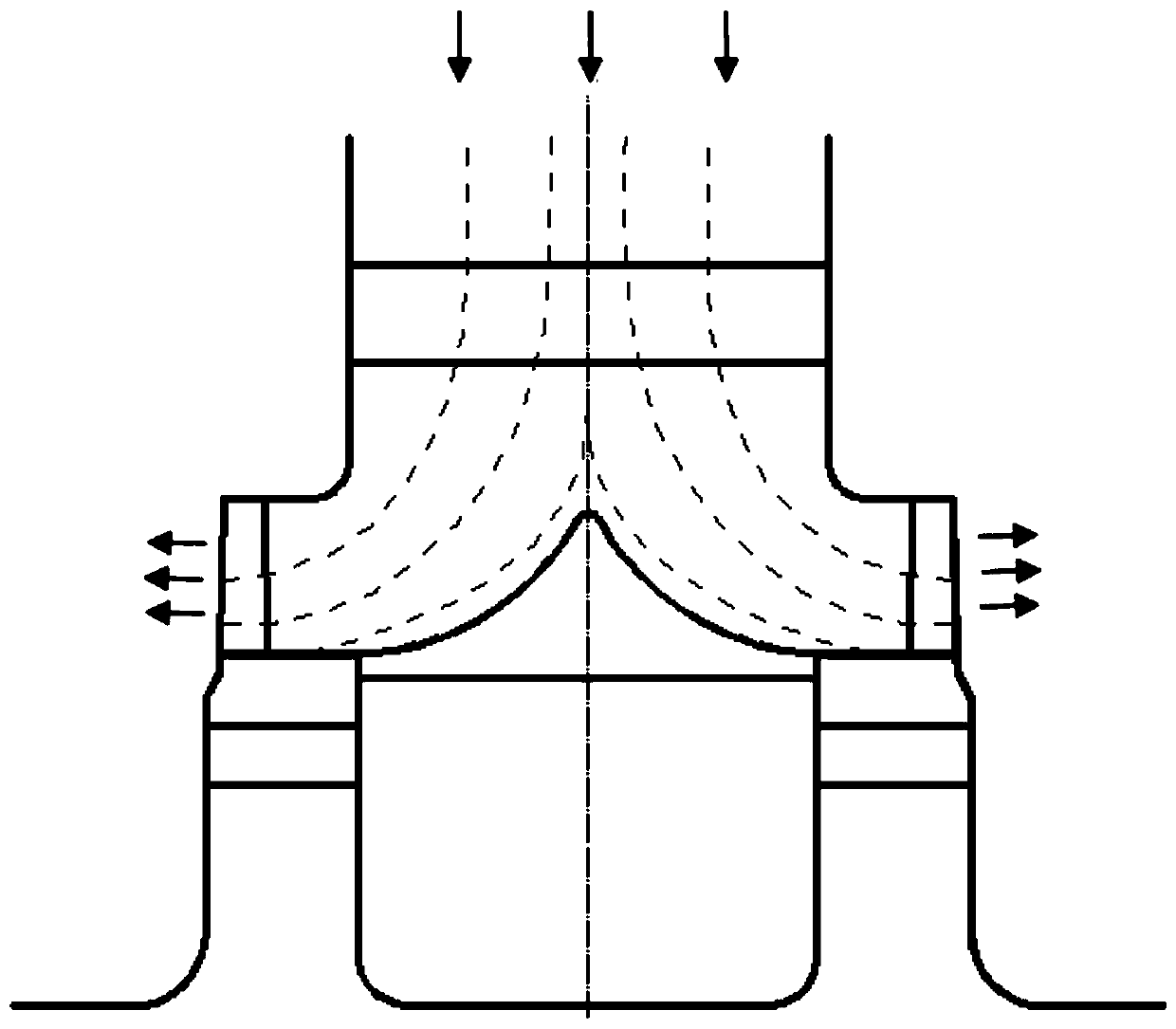

[0033] Such as figure 2 , image 3 As shown, in this embodiment, a flow diversion structure of a low-pressure steam inlet chamber of a steam turbine is specifically disclosed, including a steam inlet chamber 2, a wheel rotor 4, a first-stage vane 1 and two The sideways and symmetrically arranged first-stage moving blades 3 combine the intake chamber 2, the wheel rotor 4, the first-stage vane 1, and the first-stage moving blades arranged symmetrically on both axial sides of the wheel rotor 4 3 Assemble according to the corresponding technical specifications, such as figure 1 As shown, it is a traditional diversion structure of the low-pressure steam inlet chamber. Its working principle and structural composition have been explained in the background art, and will not be repeated here.

[0034] In order to further improve the diversion effect of the diversion structure of the low-pressure steam inlet chamber, a diversion structure is also included. The diversion structure is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap