Cover glass for semiconductor package and method for producing same

A manufacturing method and package technology, applied in semiconductor/solid-state device manufacturing, glass manufacturing equipment, semiconductor devices, etc., can solve problems such as adverse effects, omissions, and precision damage to productivity of solid-state imaging devices, so as to prevent display Defective, malfunction suppression, less platinum pitting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

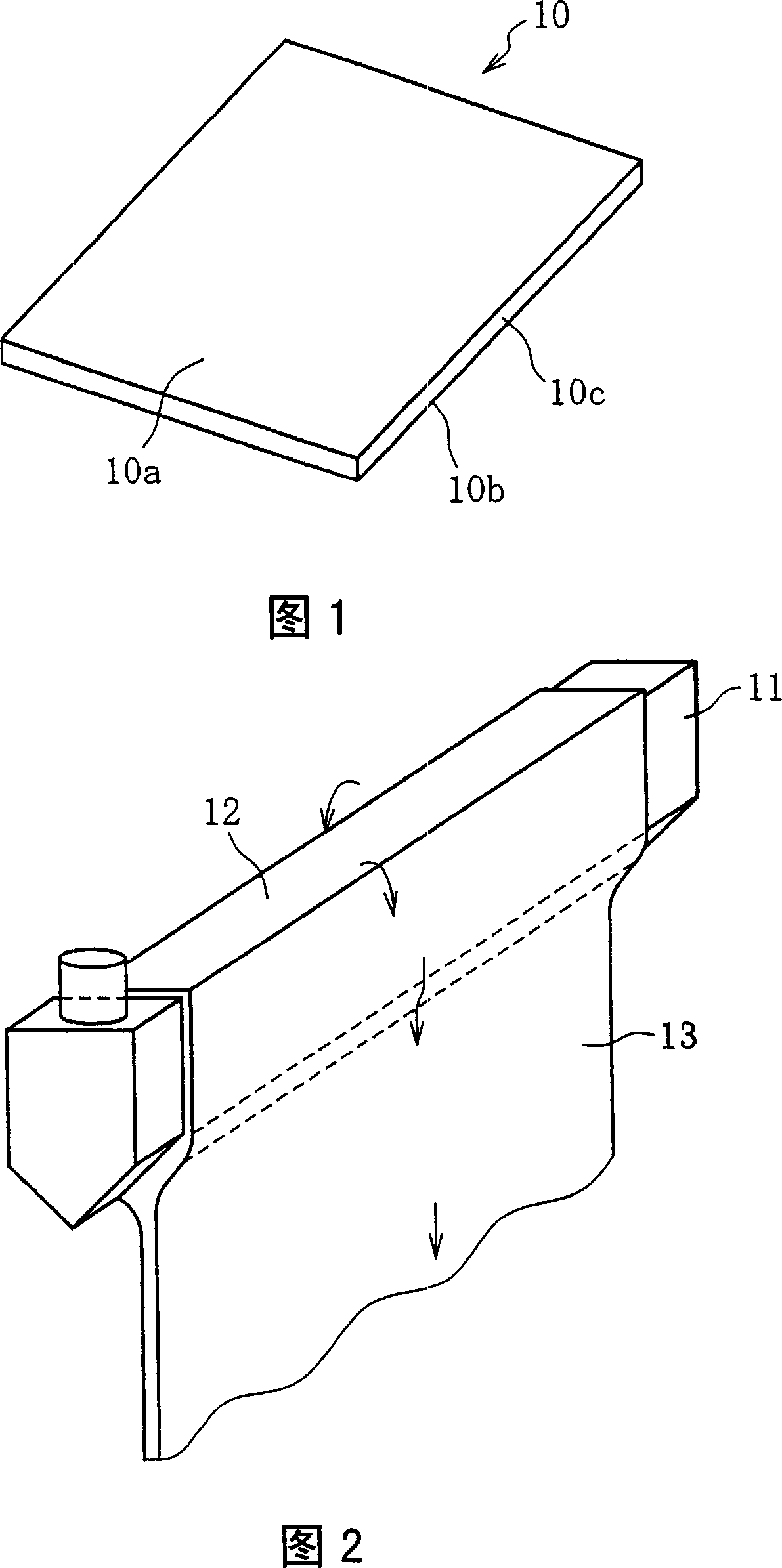

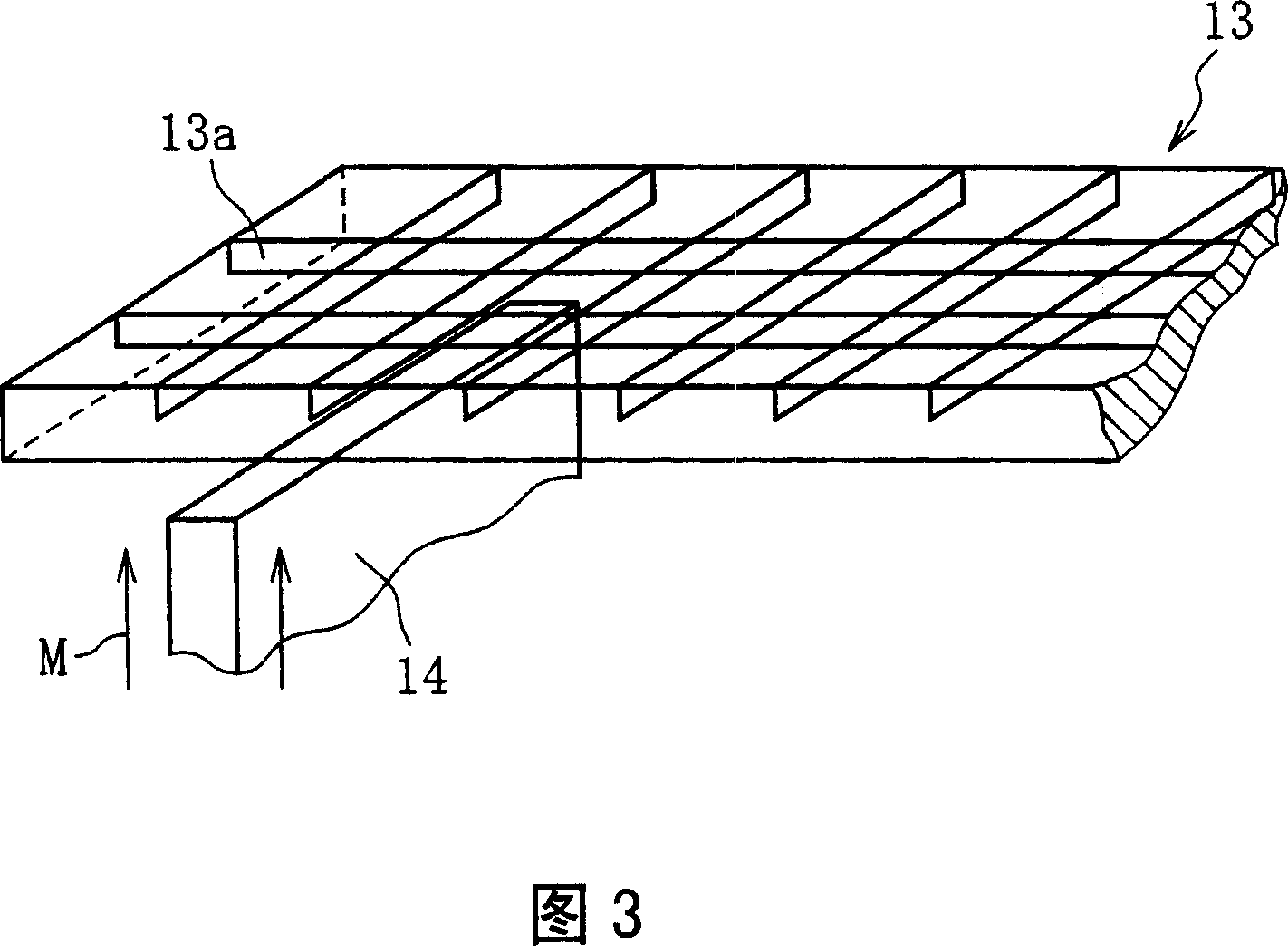

[0024] The light-transmitting surface of the cover glass for a semiconductor package of the present invention is a non-polished surface, and its surface roughness (Ra) is 1.0 nm or less. This kind of cover glass with high surface quality can be formed by down-draw method or float method. As the down-draw method, although the overflow down-draw method or the slit down-draw method is suitable, especially for the case of the overflow down-draw method, since the glass surface is a free surface and does not come into contact with other members, by controlling the melting conditions or forming conditions, it is possible to obtain It has a desired thickness (0.05-0.7 mm in the case of a cover glass for a semiconductor package) and is excellent in surface smoothness, and is therefore preferable. That is, when the overflow down-draw method is used, since the surface (light-transmitting surface) can not be ground to obtain a smooth surface, it is possible to produce a surface roughness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com