Method of manufacturing semiconductor device

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve problems such as deterioration of storage element operating characteristics, difficult to achieve withstand voltage of MOS transistors, and excessive thickness of tunnel insulating film, etc. Achieve the effect of preventing reverse tunnel failure and inhibiting malfunction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

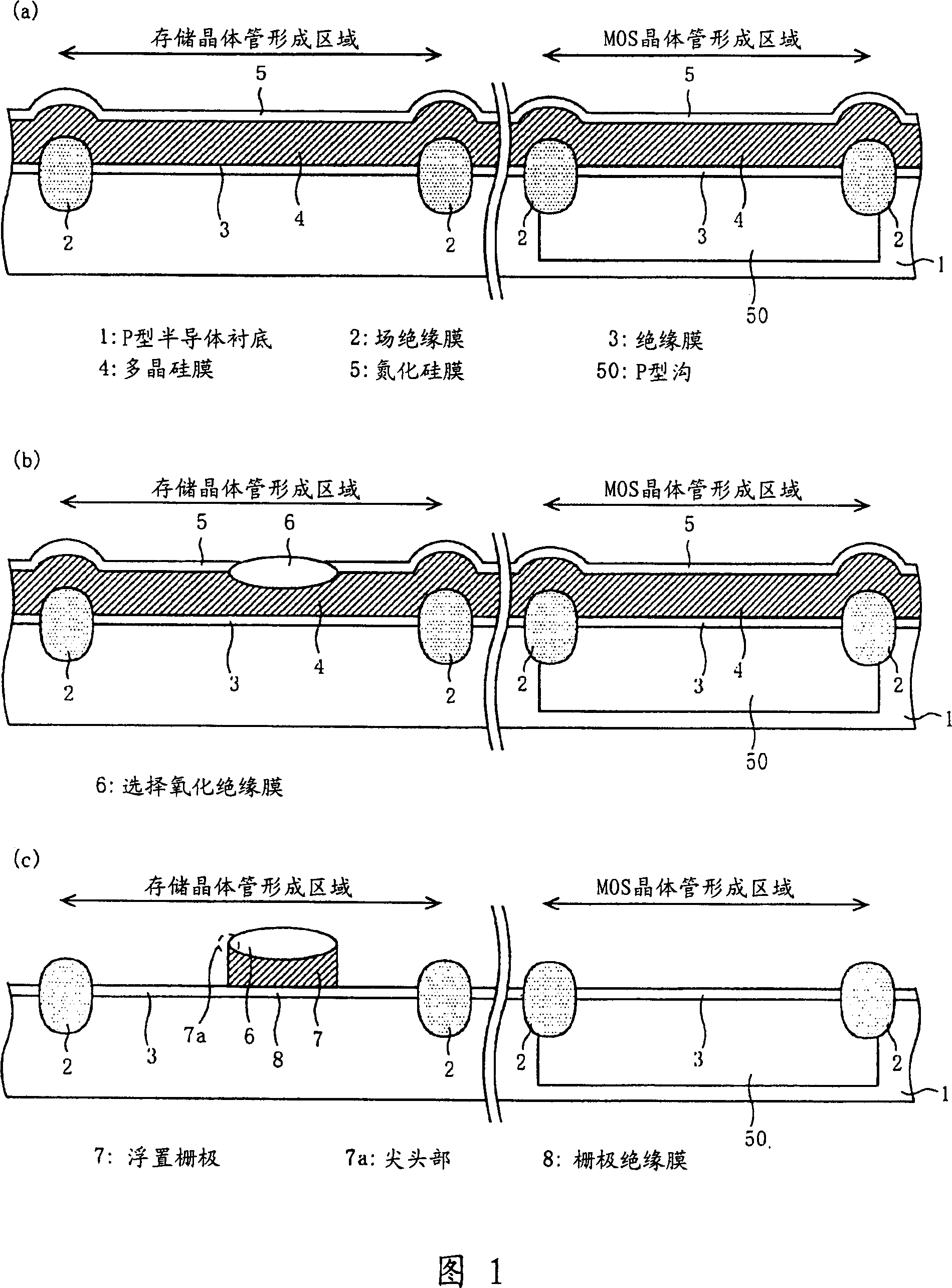

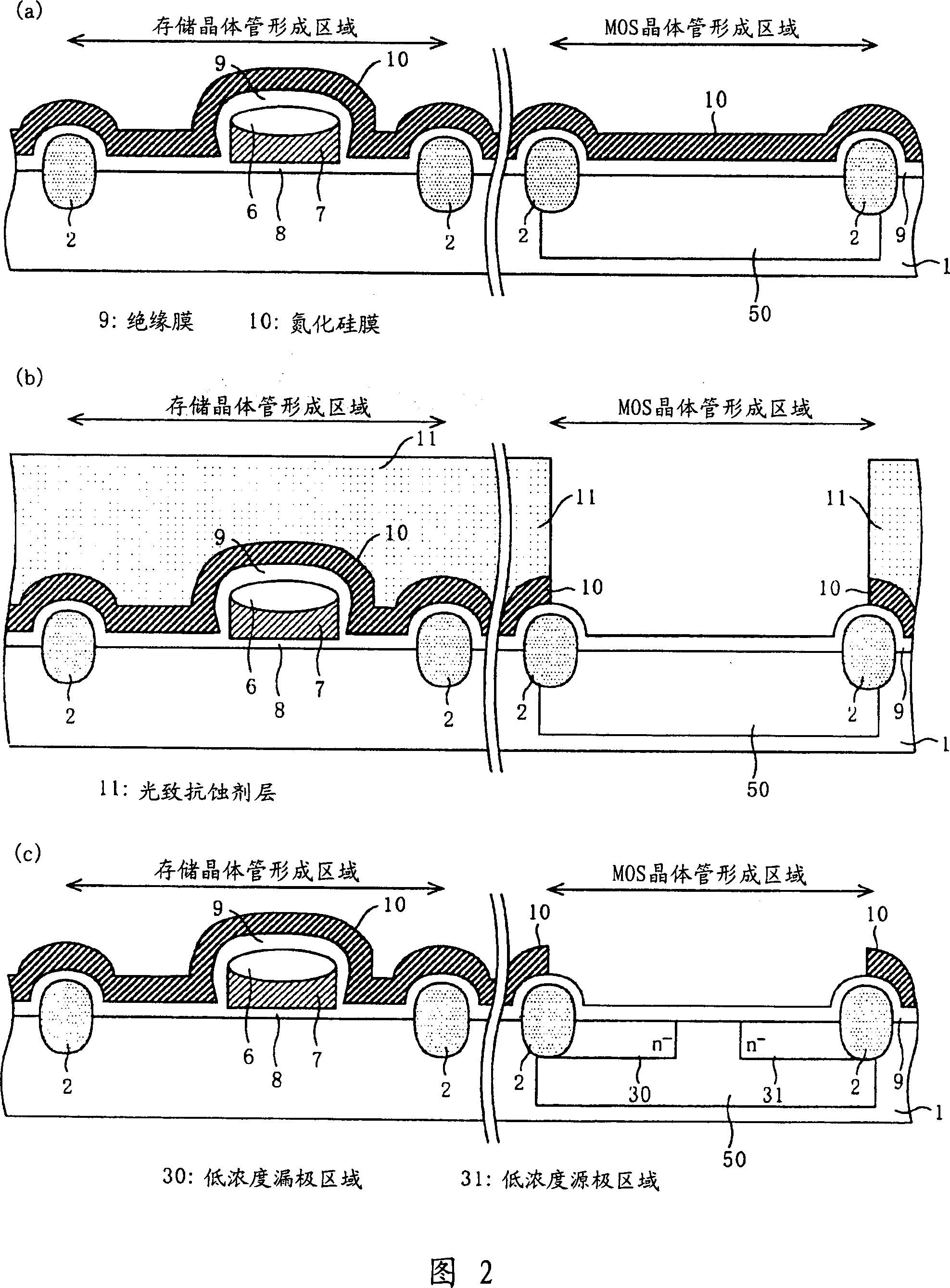

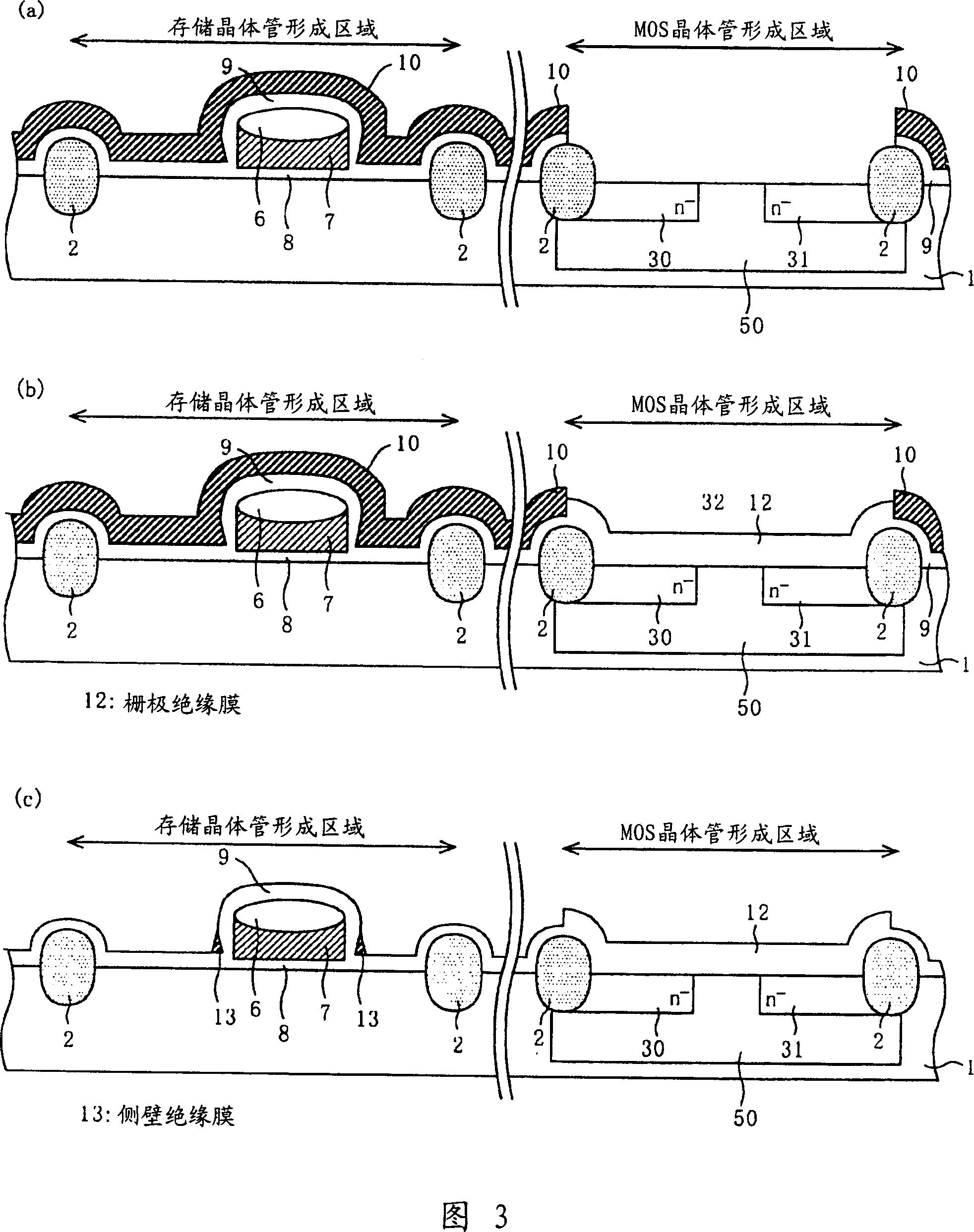

[0068] Next, a method of manufacturing a semiconductor device according to an embodiment of the present invention will be described with reference to the drawings. In addition, in the following description, an example of applying the present invention to a method of manufacturing a semiconductor device made of a P-type semiconductor substrate is introduced, but the present invention can also be applied to a method of manufacturing a semiconductor device made of an N-type semiconductor substrate. . In addition, in FIGS. 1 to 5 , the memory transistor formation region is formed on the left side, and the N-channel MOS transistor formation region is formed on the right side.

[0069] First, as shown in FIG. 1( a ), P-type impurities (boron) are ion-implanted into the surface of the P-type semiconductor substrate 1 in the MOS transistor formation region to form a P-type trench 50 . Then, on the surface of the semiconductor substrate 1, a field insulating film 2 having a film thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com