Electric motor with a position detector

A technology of detectors and motors, applied in the field of motors, can solve the problems of no effect of electromagnetic interference, improve anti-interference, and difficulty in simultaneously suppressing thermal movement to the position detector

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

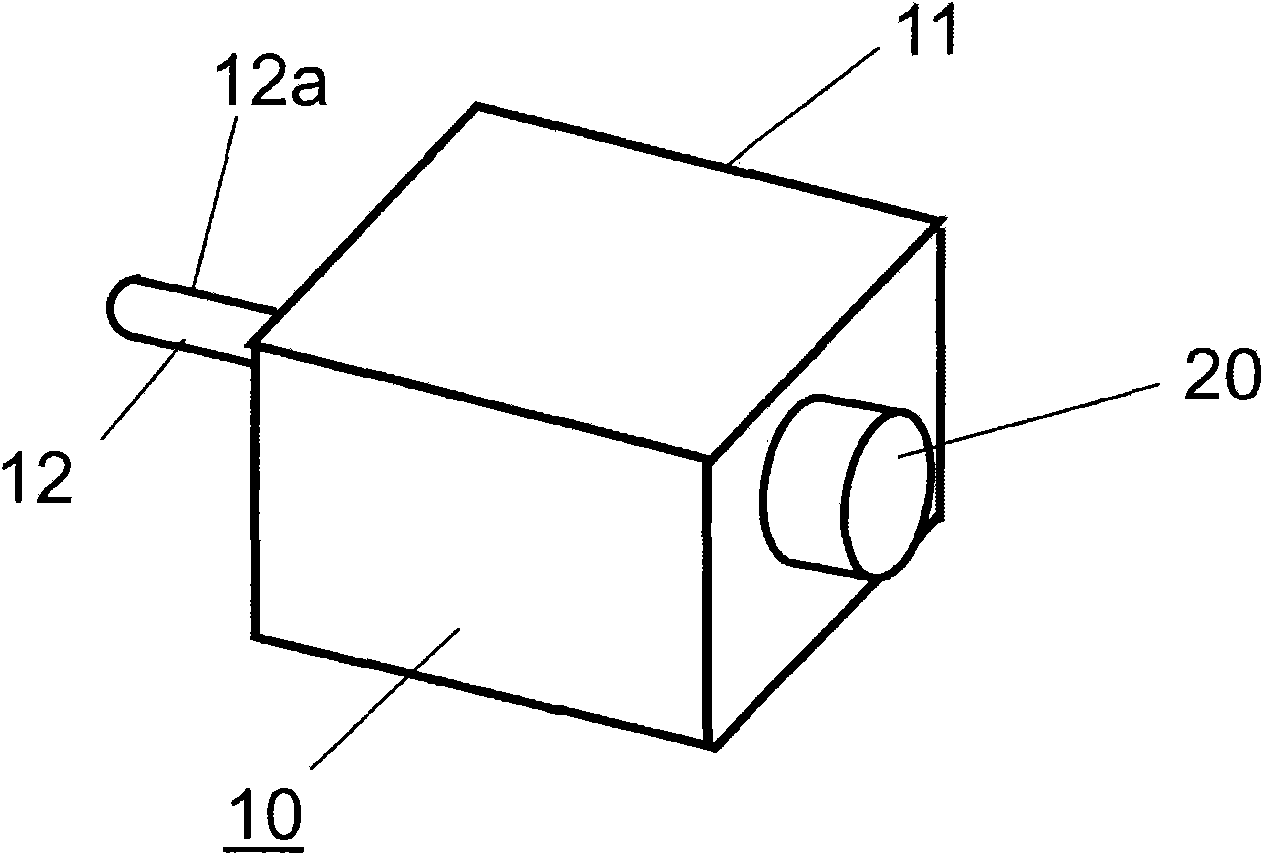

[0025] figure 1 It is an external view of a motor with a position detector according to Embodiment 1 of the present invention. like figure 1 As shown, a motor 10 , which is a motor with a position detector, has a rotating shaft 12 for rotationally driving a load extending from a motor main body 11 . figure 1 In the diagram, the output shaft 12a on the output shaft side for the drive output is extended with respect to the rotating shaft 12 . In addition, a position detection unit 20 having an appearance of a substantially cylindrical shape is arranged on the opposite side to the output shaft side, that is, on the opposite side to the output shaft.

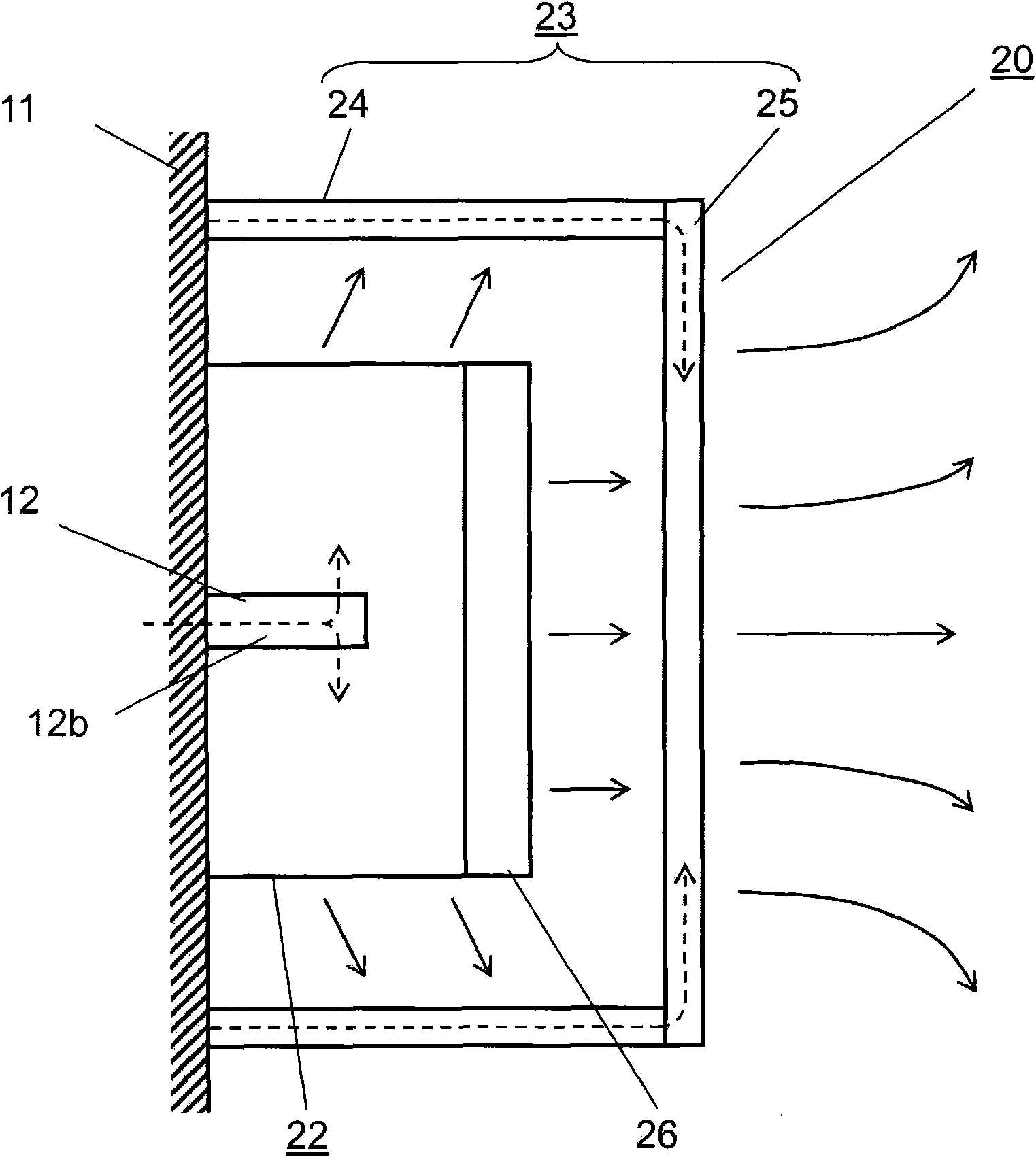

[0026] figure 2 It is a cross-sectional view of the main part of the position detection unit 20 of the motor 10 according to Embodiment 1 of the present invention. figure 2 The center represents the side opposite to the output shaft 12 b extending from the motor main body 11 on the opposite side of the rotating shaft 12 .

[...

Embodiment approach 2

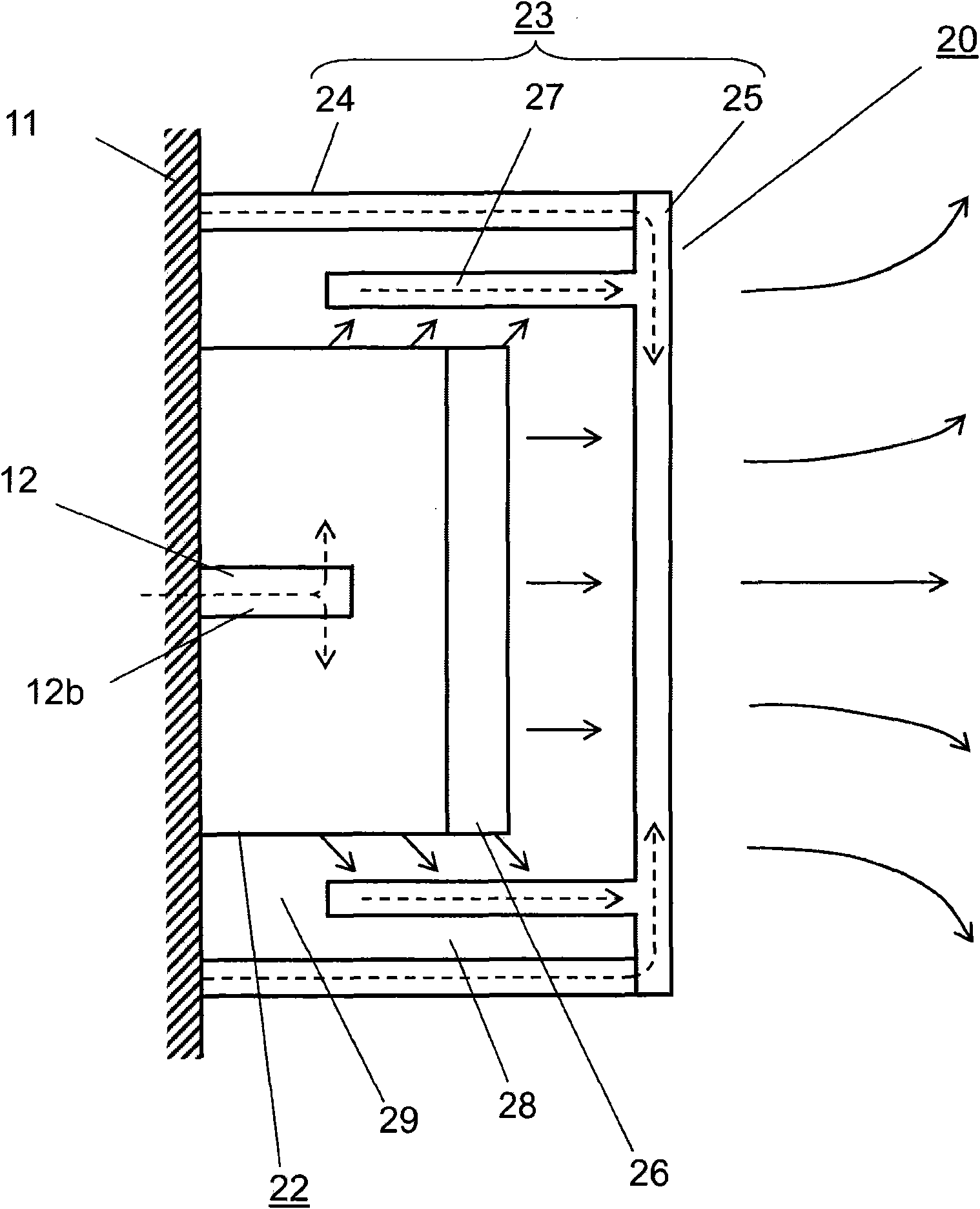

[0038] image 3 It is a cross-sectional view of the main part of the position detection unit 20 of the motor 10 according to Embodiment 2 of the present invention. image 3 In the figure, the side opposite to the output shaft where the output shaft 12 b extends from the motor main body 11 is also shown. Additionally, with figure 2 The same components are denoted by the same symbols, and detailed descriptions are omitted. In comparison with Embodiment 1, the detector cover 23 of the motor 10 of this embodiment further includes a cylindrical wall portion 27 .

[0039] The cylindrical wall portion 27 has a hollow cylindrical shape and is integrally formed with the metal bottom portion 25 . The cylinder wall portion 27 is disposed on the inner peripheral side of the cylinder portion 24 , parallel to the cylinder portion 24 with a gap 28 therebetween, and extends from the bottom portion 25 toward the position detection unit 20 . That is, by installing the detector cover 23 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com