Straight-air radiating device and its control method

A ventilation and heat dissipation and control method technology, which is applied in cooling/ventilation/heating transformation, instrument cooling, instrument and other directions, can solve the problem of increased wind resistance and achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

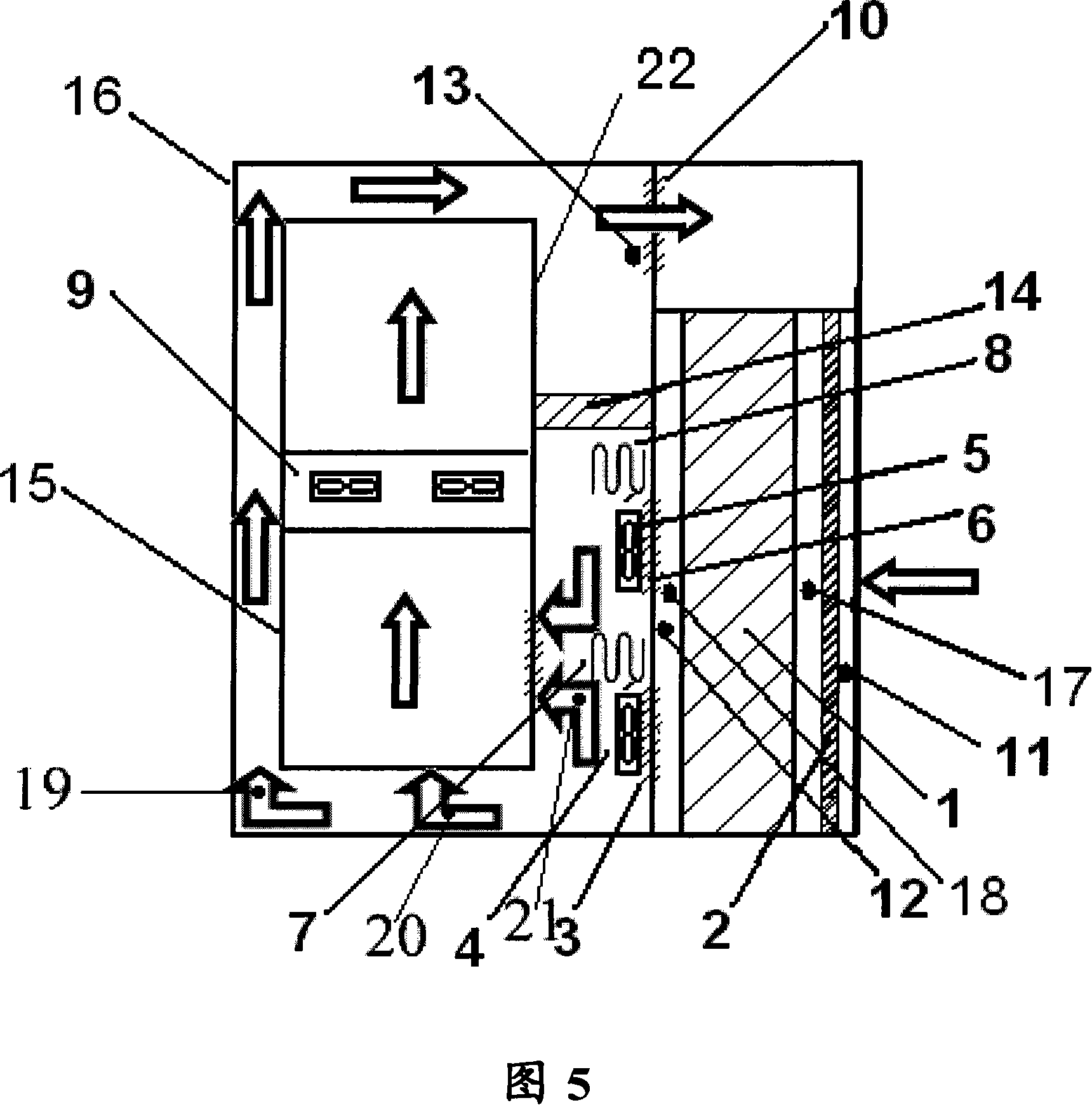

[0040] Figure 3 shows a structural diagram of a straight ventilation cooling device according to an embodiment of the present invention, including: a cabinet 16; an equipment subframe 15 arranged in the central area of the cabinet 16; a first air inlet 3 or 6 and a first air outlet 10 , are located on the first side of the cabinet 16; the windshield 14, which is arranged in the gap between the first side of the cabinet 16 and the equipment subframe 15, cuts off the first air inlet 3, 6 and the first air outlet 10 in this Communication at the gap; the first air duct 19 , which connects the first air inlets 3 , 6 and the first air outlet 10 , is formed by the gap between the other three sides of the cabinet 16 and the equipment subframe 15 .

[0041] This embodiment optimizes the design of the air duct, and uses the upper and lower a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com