Relay connection member, inspection device and method of manufacturing relay connection member

A technology for connecting components and manufacturing methods, which is applied in the direction of connection, conductive connection, measuring device, etc., and can solve the problem of disconnection of the wiring structure 106, poor electrical connection between the relay connection member 104 and the inspection circuit 105, and the failure to rule out the relay connection member 104 and the probe 102 are electrically connected to achieve good electrical conduction, ensure electrical conduction, and suppress positional deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, the best mode (hereinafter referred to as "embodiment") for implementing the inspection device and the relay connection member constituting the inspection device of the present invention will be described in detail with reference to the drawings. However, it should be noted that the drawings are schematic diagrams, and the relationship between the thickness and width of each part, the ratio of the thickness of each part, etc. may be different from the actual ones. Of course, the drawings also include parts with different dimensional relationships or ratios. .

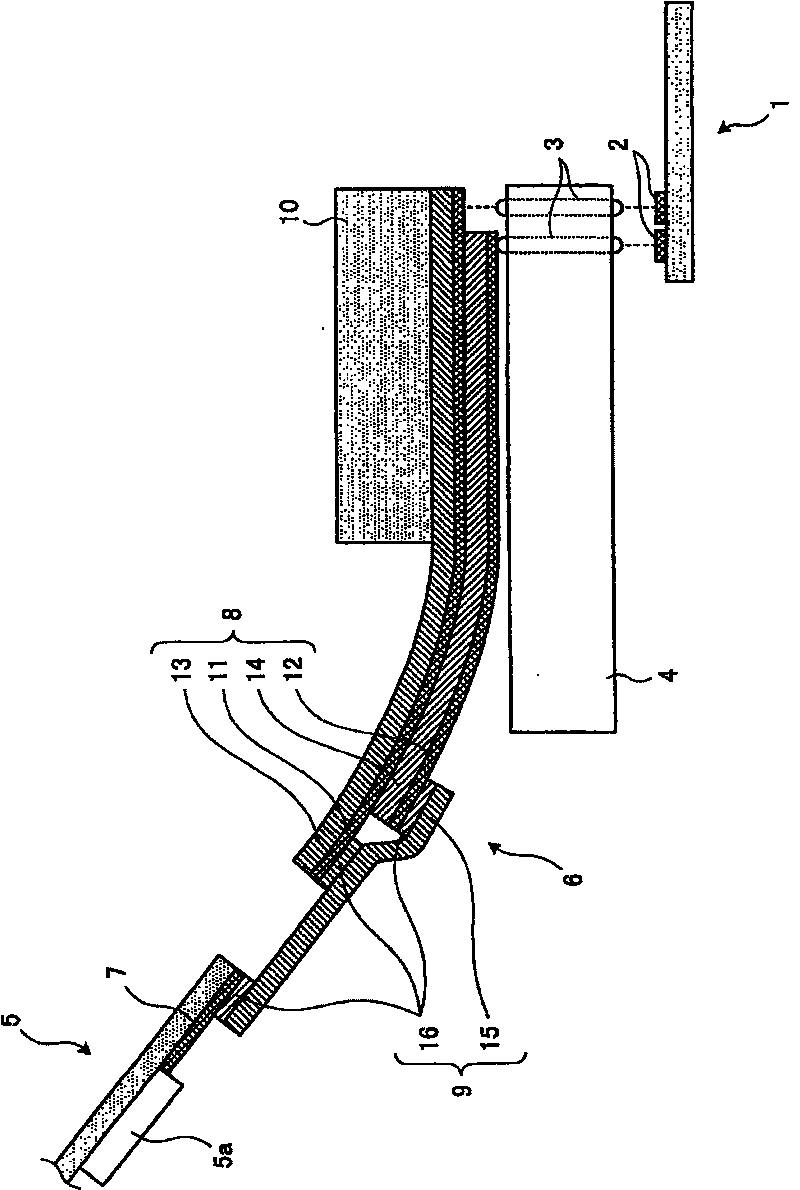

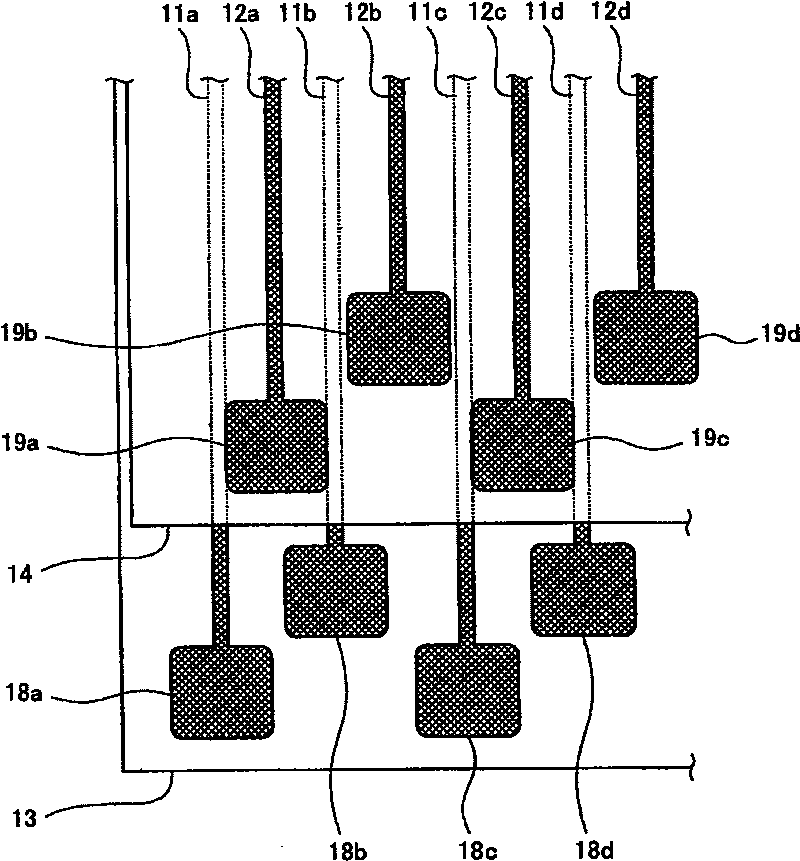

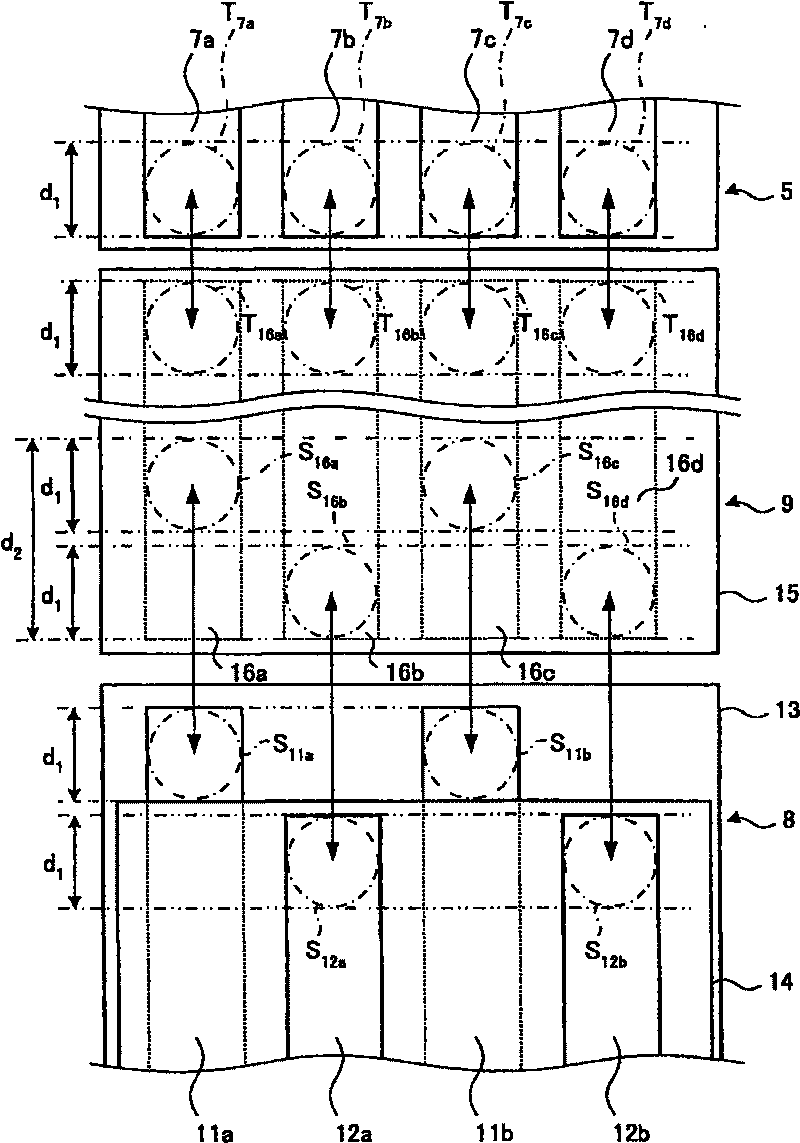

[0027] figure 1 It is a schematic diagram showing the overall configuration of the inspection device according to the embodiment. Such as figure 1 As shown, the inspection device of this embodiment includes: a probe 3 whose end is in contact with a terminal 2 of an inspection object 1; a probe holder 4 that holds the probe 3 at a predetermined position; An inspection circuit 5 outputting at leas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com