Production of non-tar cigarette

A manufacturing method, tar-free technology, applied in tobacco, tobacco processing, application, etc., can solve the problem of not producing tar-free cigarettes, and achieve the effects of preventing peroxidation and low extraction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

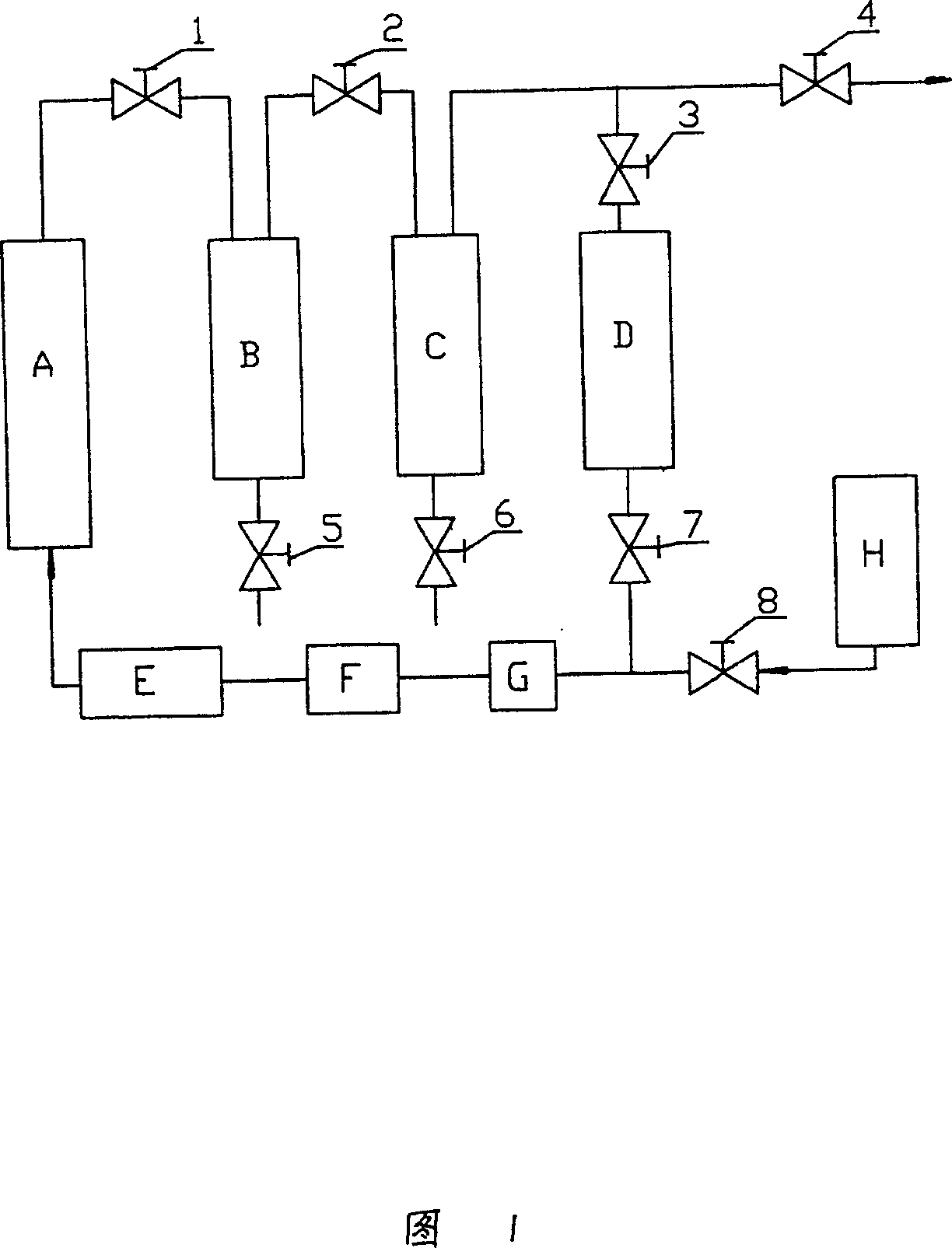

[0008] The key steps of this description will be further described below with reference to the accompanying drawings.

[0009] As shown in Figure 1, A is an extractor, B and C are decompression separators, C is a condenser, H is a CO2 storage tank, 1, 2, 3, 4, 5, 6, 7, 8 are valves, G is the flow meter, F is the compression pump, and E is the preheater.

[0010] Load 10 kg of tobacco leaves into the extractor A, open the valve 8, and the carbon dioxide enters the compression pump F from the storage tank H through the flow meter G. The pressurized carbon dioxide enters the extractor A from the bottom through the preheater E. The pressure was controlled to 30MPa, the temperature was 50°C, and the extraction was continued for 3 hours. The carbon dioxide with oil and moisture from the extractor A passed through the secondary decompression separators B and C, and the carbon dioxide passed through the condenser D and returned to the compression pump for recycling. You can also dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com