Mechanical hand with conveying and sampling functions

A technology of manipulators and machinery, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of manipulator sampling failure, maximum transfer sampling speed, inconvenient installation, complex structure, etc., to improve success rate and production efficiency, fast sampling speed, and mobile samples flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

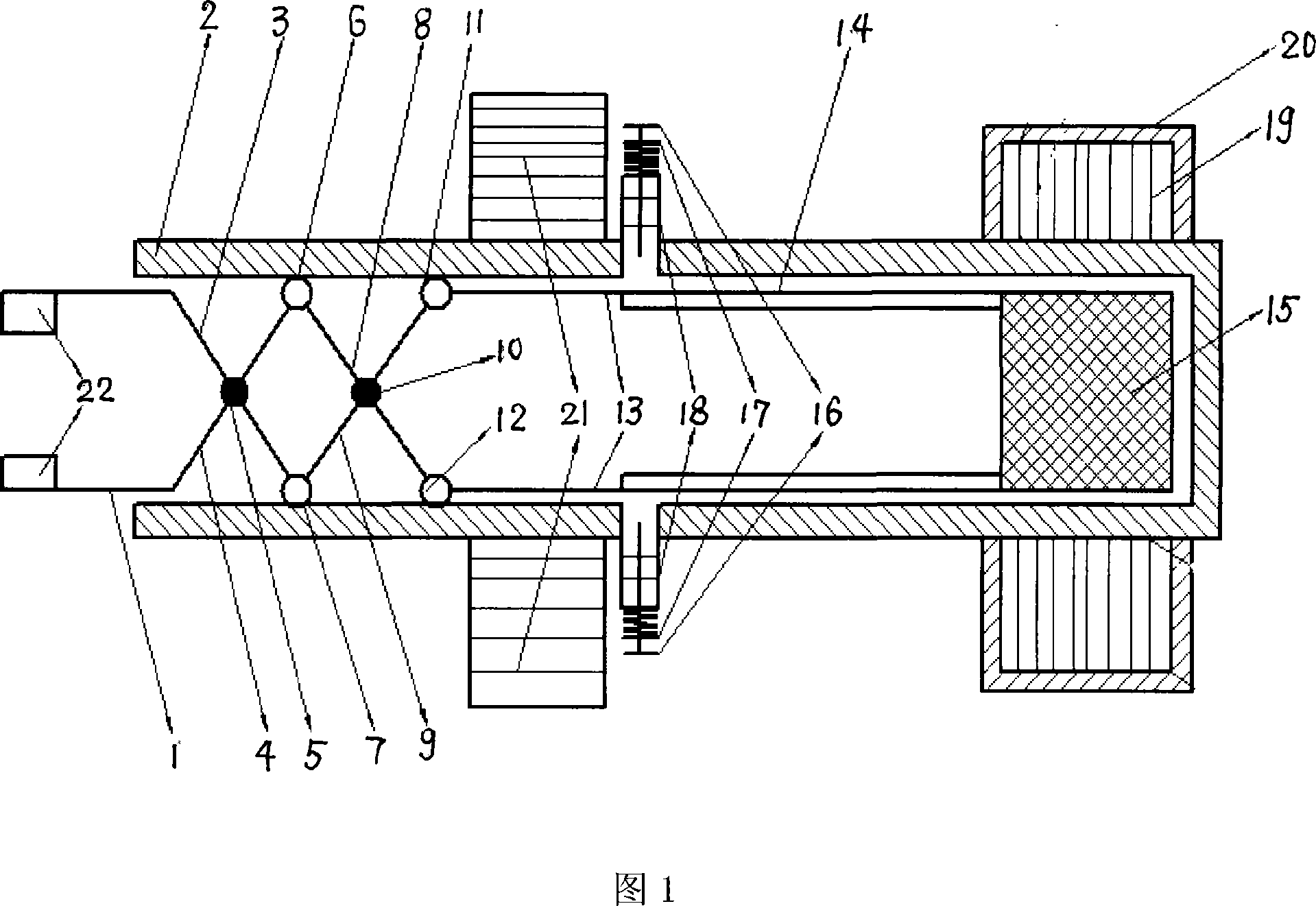

[0008] As shown in Figure 1, the clamping unit includes a sampling hook 1, a first stainless steel rod 3, a second stainless steel rod 4, a third stainless steel rod 8, a fourth stainless steel rod 9, a first navigation small roller 6, a second navigation small roller 7. The third small navigation wheel 11 and the fourth small navigation wheel 12 . The sampling hook 1 is connected to the front ends of the first stainless steel rod 3 and the second stainless steel rod 4 with good rigidity; the first stainless steel rod 3 and the second stainless steel rod 4 are connected by the first fixed fulcrum 5 of their cross point, the first The other end of the stainless steel rod 3 and the second stainless steel rod 4 connects the front ends of the third stainless steel rod 8 and the fourth stainless steel rod 9 through the first navigation small roller 6 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com