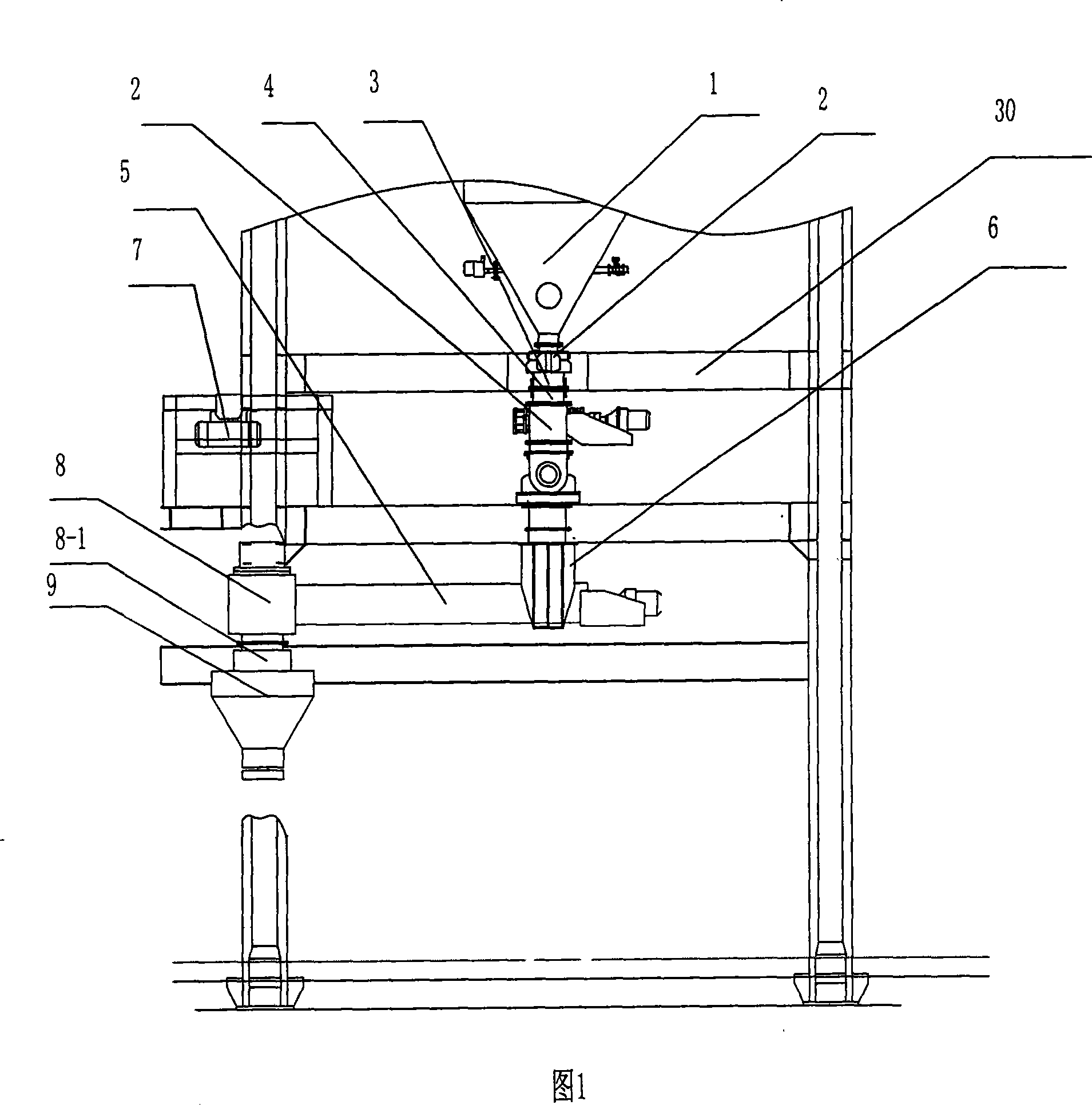

Method and apparatus for humidifying multi-stage spraying powdery materials and powder dust-free loader based on multi-stage spray powder humidification

A technology of humidification device and spray device, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of insufficient humidification of powder, blockage, and water sloshing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

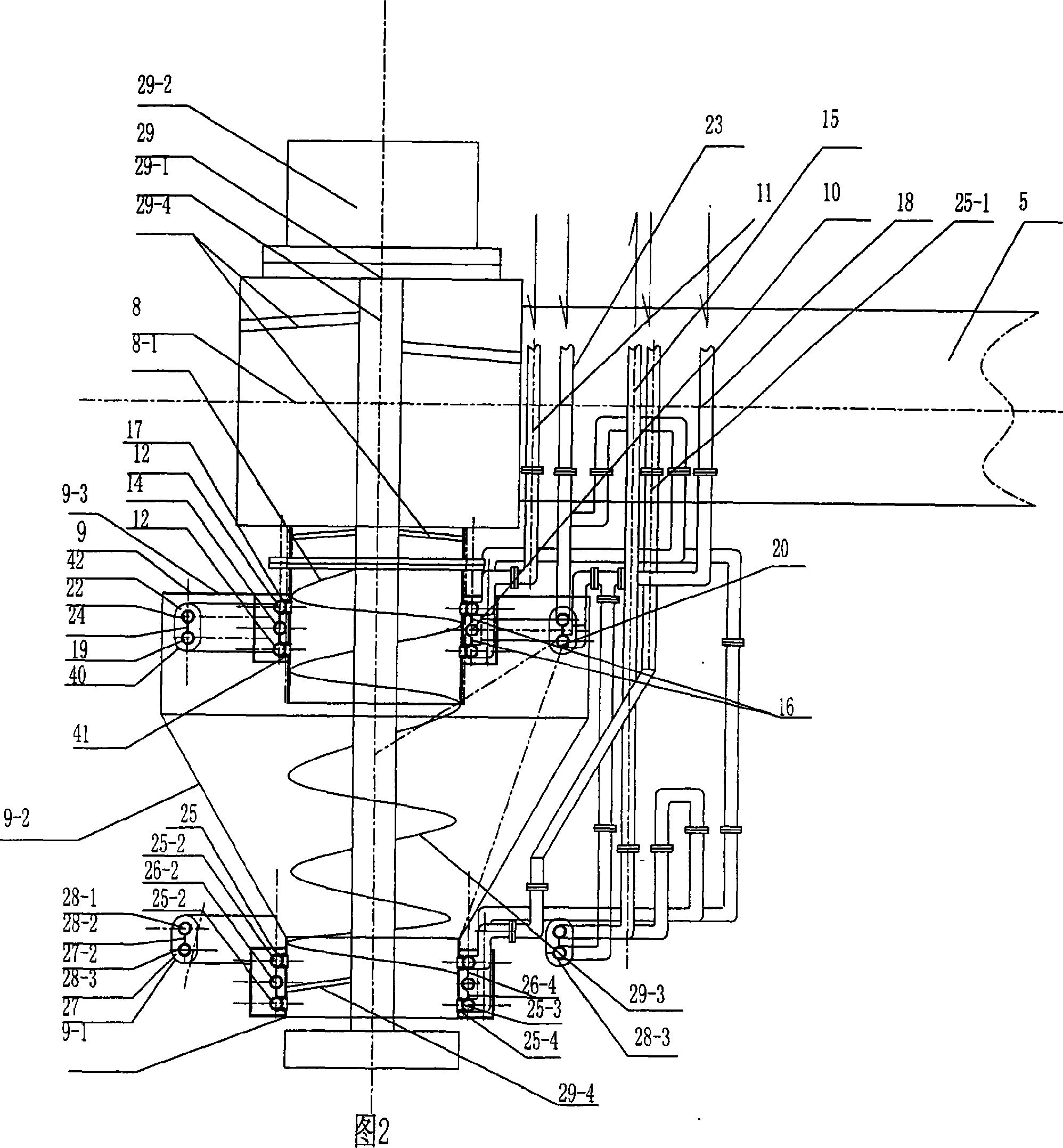

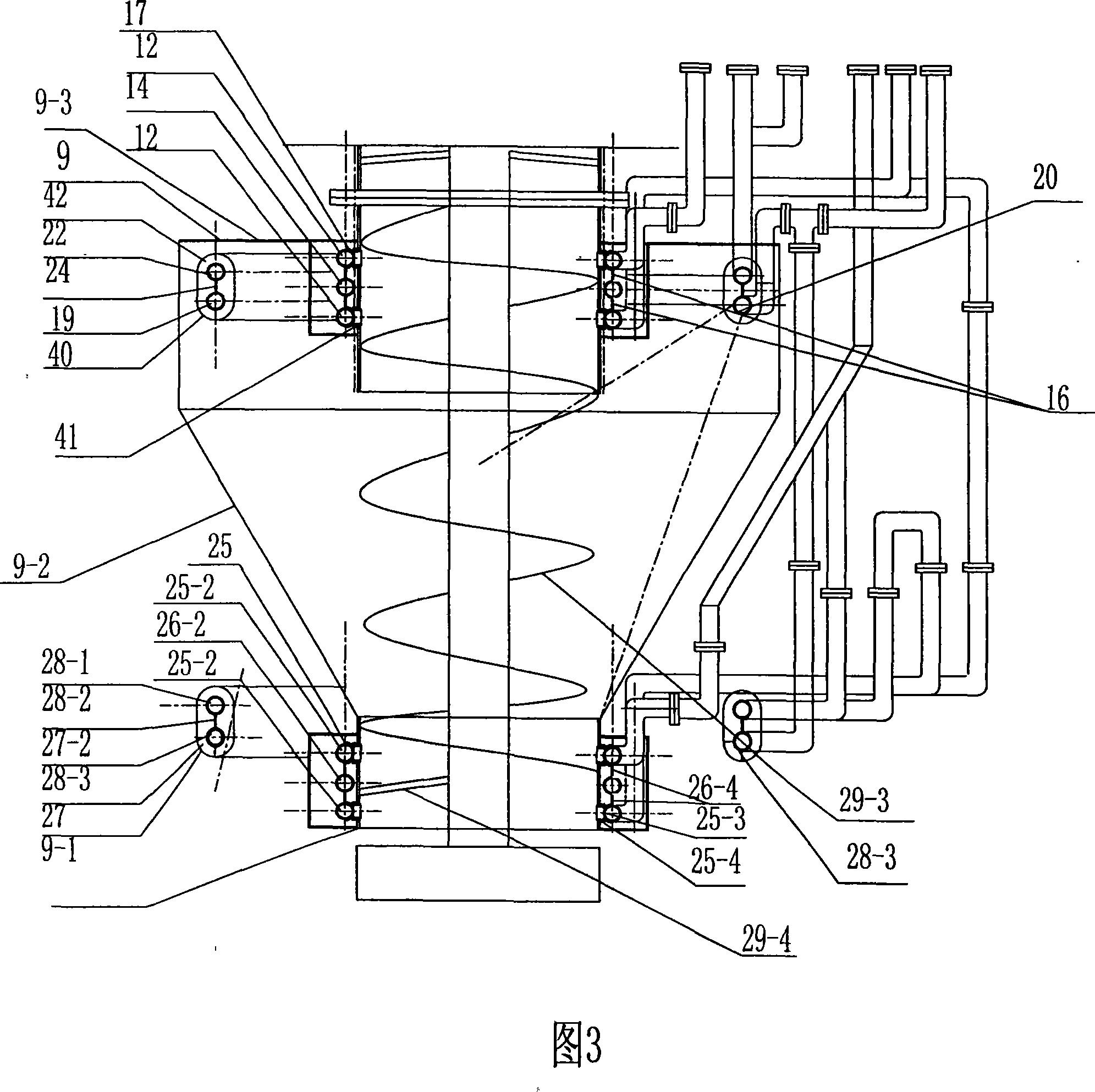

[0024] In the method of the present invention, the output powder is transported through the conveying device, and after the first-stage humidification is performed on the powder in the conveying device, the powder that has not been fully humidified is transported to an enlarged diffuser to generate dust, and then in the enlarged The raised dust is humidified in the second stage in the release container, and then discharged. After the powder is humidified in two stages, the dust is sprayed and dusted before being discharged. Spray and press the discharged dust again.

[0025] Before spraying and humidifying, the spraying and humidifying device shall be heated, deiced and thawed or blocked.

[0026] In the conveying device, the powder is humidified at the first stage while pushing the powder for scraping and stirring.

[0027] The multi-stage humidification method of the present invention has multiple types such as two-stage, three-stage, and four-stage. Among them, the humid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com