Triple-port fiber-optical loop unit

A fiber optic circulator and three-port technology, which is applied in the coupling of optical waveguides, can solve the problems of low coupling efficiency, poor stability, and high cost, and achieve the effects of increasing or decreasing the number of ports, good stability, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

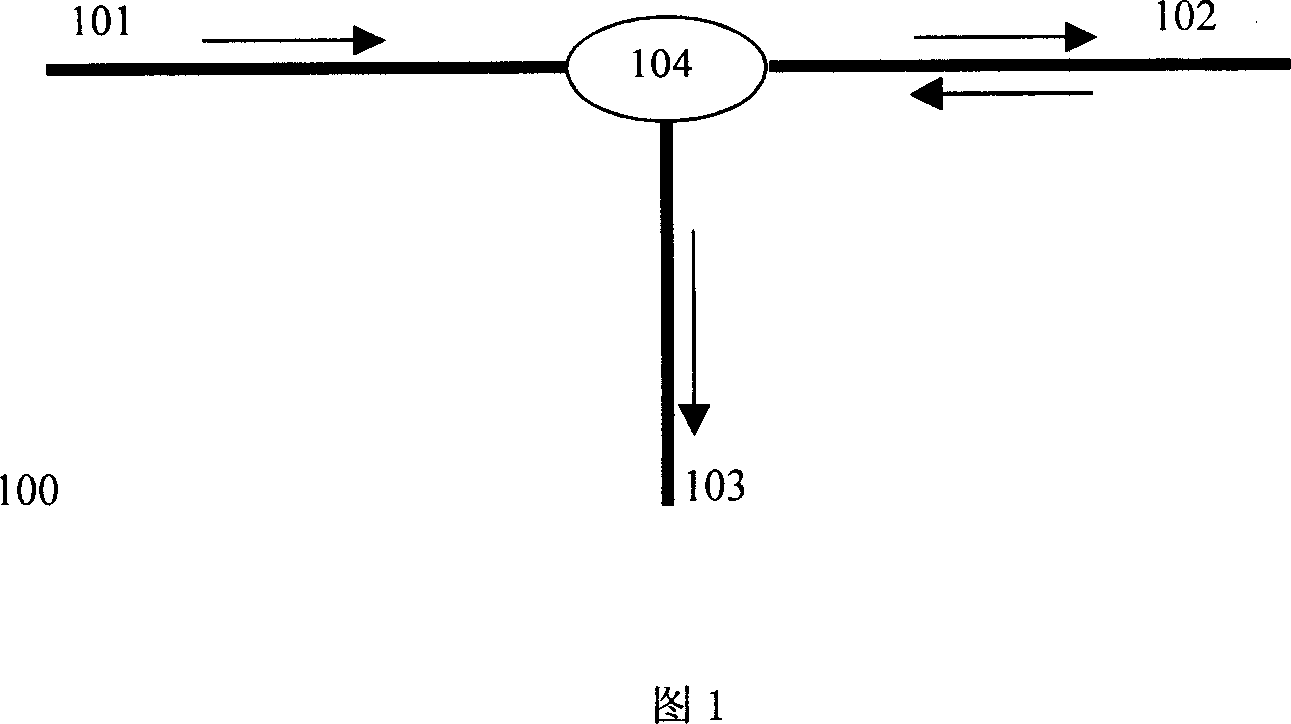

[0022] Figure 1 shows the 100 three-port all-fiber circulator, 101 is the first port of the 100 three-port all-fiber circulator; 102 is the second port of the 100 three-port all-fiber circulator; 103 is the 100 three-port all-fiber circulator The third port; 104 is the coupling part of the 100 three-port all-fiber circulator.

[0023] Two fibers of different materials are made into a coupler by using the fusion taper technology, so that the light beams in the 101 and 103 fibers are coupled into the 102 fibers, of which 103 and 102 are straight-through arms, and the 101 fiber is the coupling arm. Due to the directional output and directional isolation functions of the coupling part, the beam injected by the 101 fiber only has an output beam in the 102 fiber; when the 102 fiber is used as the input port, the output beam is obtained in the 103 fiber, and the beams from 101 to 102 and 102 to 103 can be circled. Function.

Embodiment 2

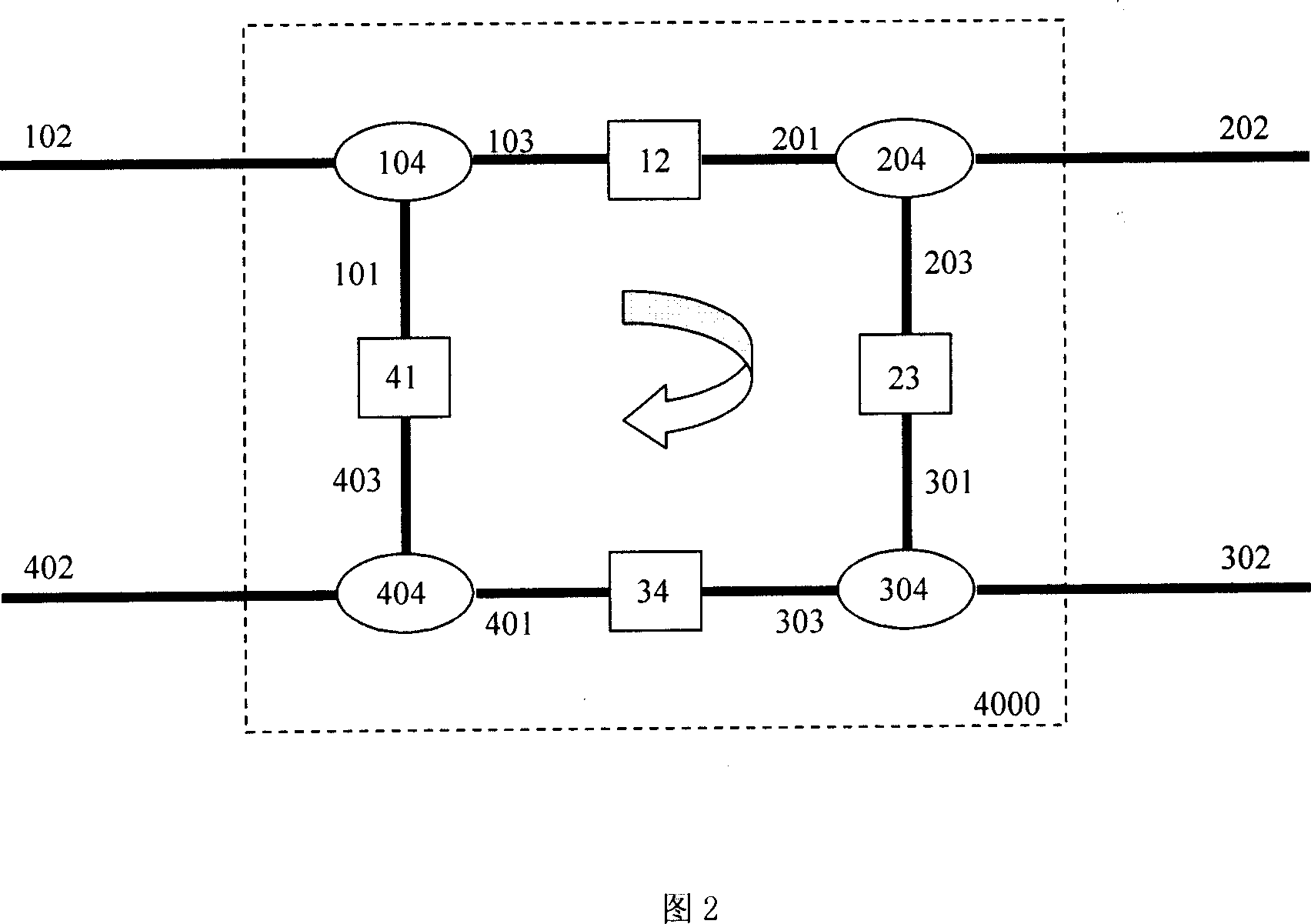

[0025] Figure 2 shows a four-port all-fiber circulator composed of four three-port all-fiber circulators, the light beam can be transmitted to the next port in a clockwise direction, 102, 202, 302, and 402 are the four-port all-fiber circulators. ports, 12, 23, 34, and 41 are four connection points between the four three-port all-fiber circulators, and 104, 204, 304, and 404 are the coupling parts of the four three-port all-fiber circulators.

[0026] FIG. 2 shows an embodiment of a four-port all-fiber circulator. The circulator 4000 consists of four three-port all-fiber circulators and four connection points.

[0027] The circulator 4000 performs the following functions: The first function: the light entering the circulator 4000 from the optical fiber 102 is introduced into the optical fiber 202 through the coupling part 104, the optical fiber 103, the connection point 12, the optical fiber 201, and the coupling part 204, realizing the first of the 4000 circulator beam transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com