Electric hammer tool handle with vibration damping function

A technology of electric hammer and handle, which is applied in the direction of striking tools, manufacturing tools, light impact tools, etc. It can solve the problems of the weakening of elastic material performance and use time, and achieve the effects of reducing vibration and noise, convenient use, and reducing wear and friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

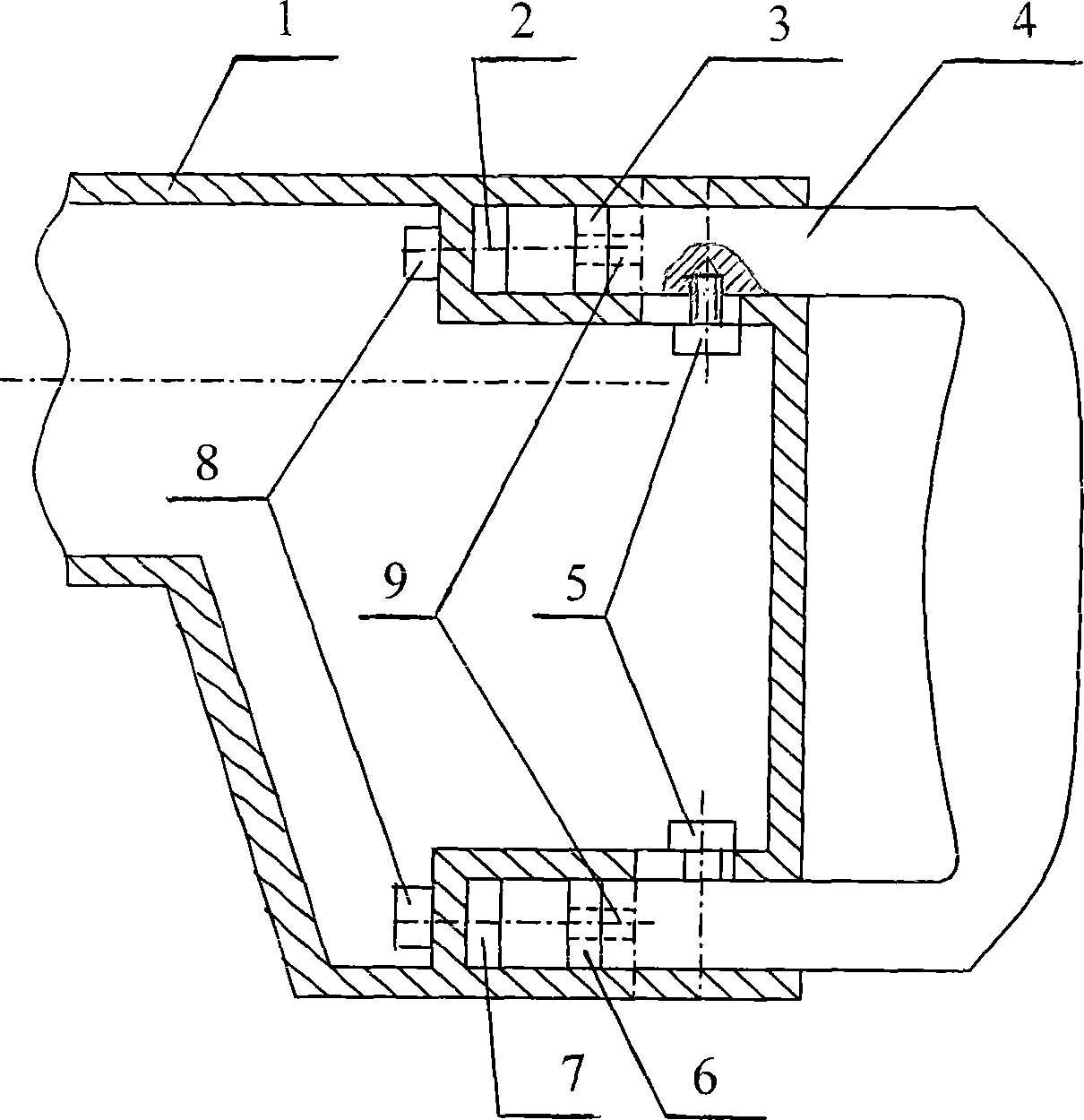

[0013] As shown in the drawings, the present invention is equipped with a pair of permanent magnets 2, 3, 7 and 6 constitute the phase connection of the repelling magnetic spring, and the screws 5 pass through the guide grooves of the two inner holes of the shell 1 of the electric hammer tool respectively, and are fixed on the two sides of the "c"-shaped electric hammer handle 4, and the screws 5 and the guide grooves form Slip fit. Repulsive magnetic springs are used to absorb vibrations generated by equipment during operation.

[0014] The two pairs of permanent magnets 2 and 3, 7 and 6 can move relatively axially along the two inner holes of the housing 1, and the first permanent magnet 2 and the third permanent magnet 7 are respectively fixed on the housing of the electric hammer tool with screws 8 1. At the bottom of the two inner holes, the second permanent magnet 3 and the fourth permanent magnet 6 are respectively fixed on the end face of the "c" shaped electric hamme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com