Helical corrugation flexible rubber water sealing envelope

A rubber sealing and screw technology, applied in the sealing of the engine, other washing machines, washing devices, etc., can solve the problem of vibration damage and aggravation. Problems such as the automatic pulsator washing machine not working properly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

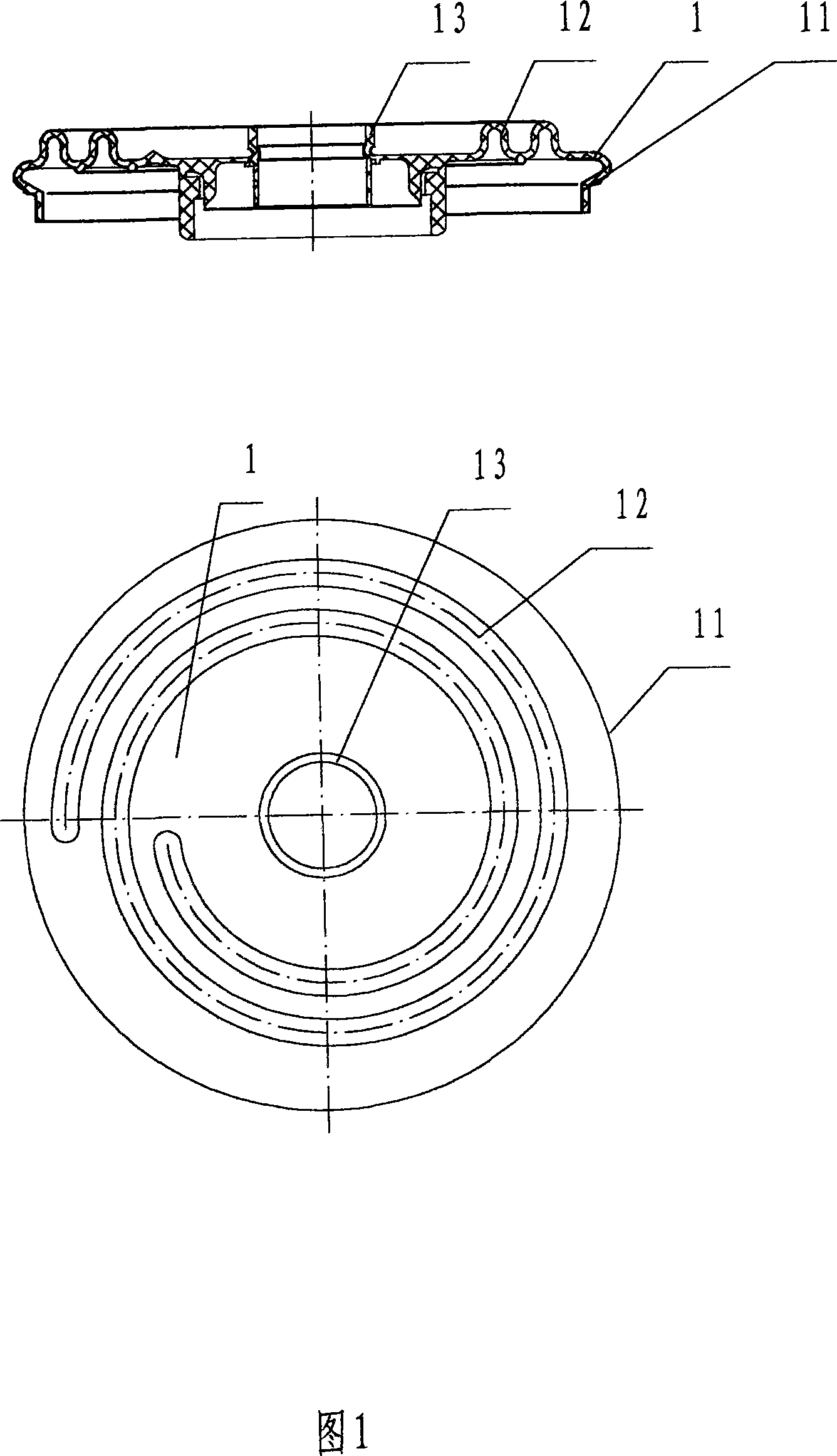

[0016] Referring to Fig. 1, a spiral corrugated flexible rubber water seal 1 of the present invention includes an integrated bowl-shaped curtained thin-walled rubber product composed of an outer ring section 11, a spiral corrugated section 12, and an inner sleeve section 13, wherein: the The outer ring segment 11 is shaped like an inwardly inclined conical pipe wall; the spiral corrugated segment 12 is a raised water wave thread that rotates from the inside to the outside; the inner sleeve segment 13 is a cylindrical sleeve.

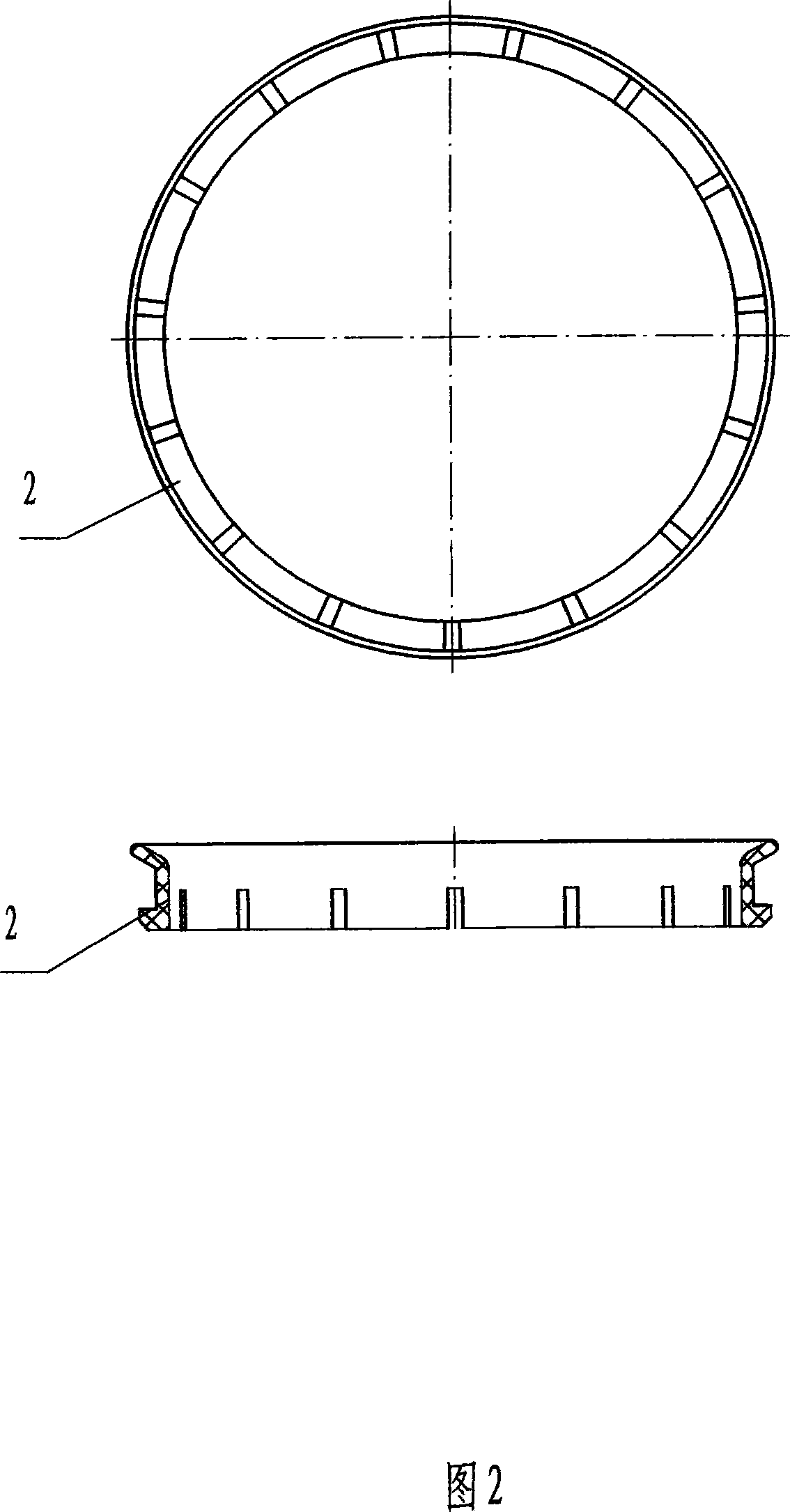

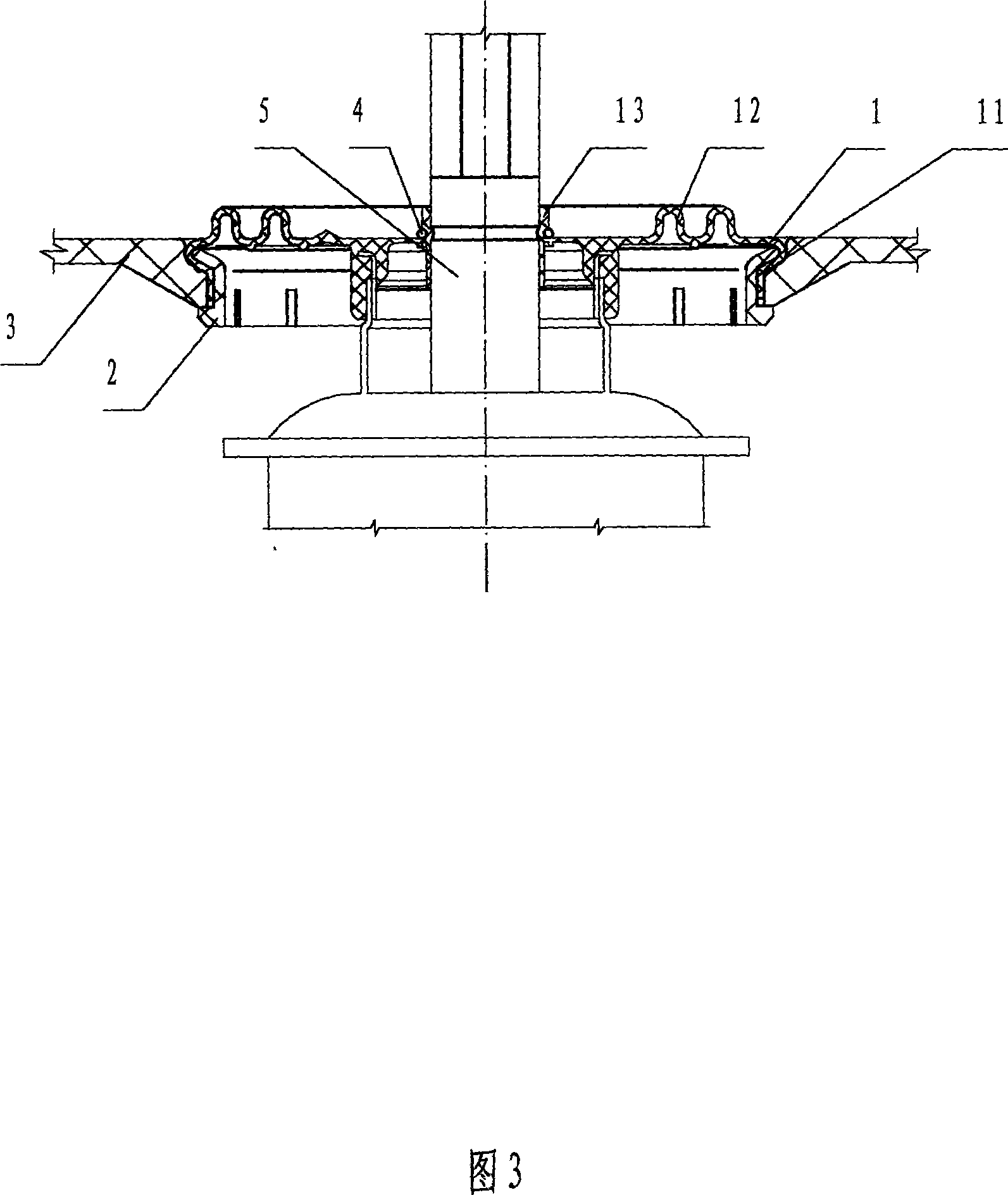

[0017] When assembling, refer to Fig. 2, Fig. 3 and Fig. 4, put the inner wall of the outer ring section 11 of the spiral corrugated flexible rubber water sealing sleeve 1 on the outer wall of the collar 2, and put the inner sleeve section 13 into the shell and barrel. On the drive sleeve shaft 5 of the automatic pulsator washing machine 6, push down the spiral corrugated flexible rubber sealing water jacket 1 to press the collar 2 into the center hole at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com