Method for determining aluminum electrolyser aluminum liquid height

A technology of aluminum liquid height and aluminum electrolytic cell, which is applied in the direction of measuring device, liquid/fluid solid measurement, liquid level indicator, etc., can solve the problems of easy formation of denudation pits, complicated measurement process, and poor data accuracy, so as to avoid artificial The influence of factors, the effect of uniform measurement tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

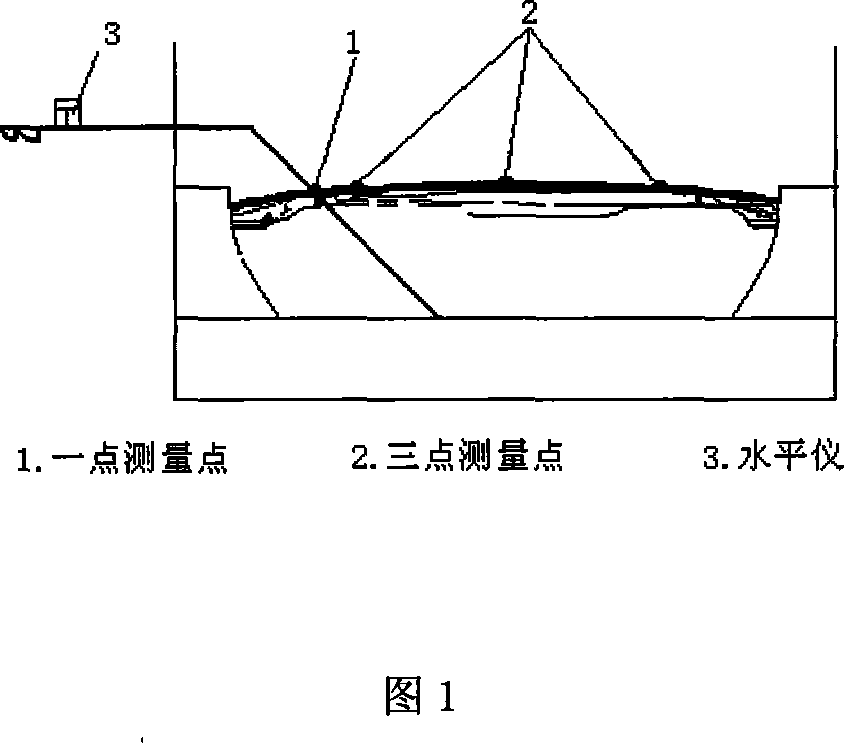

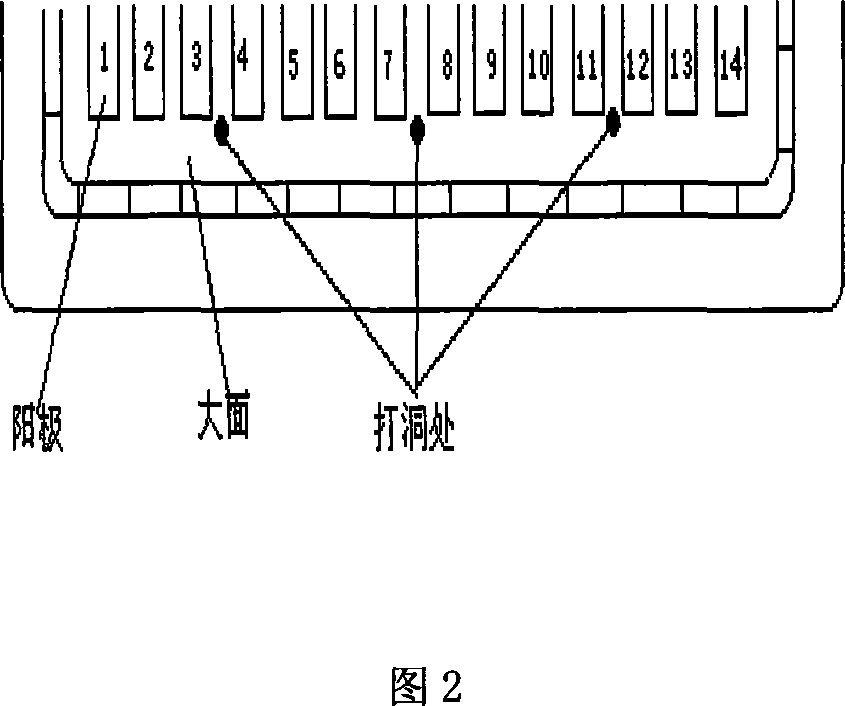

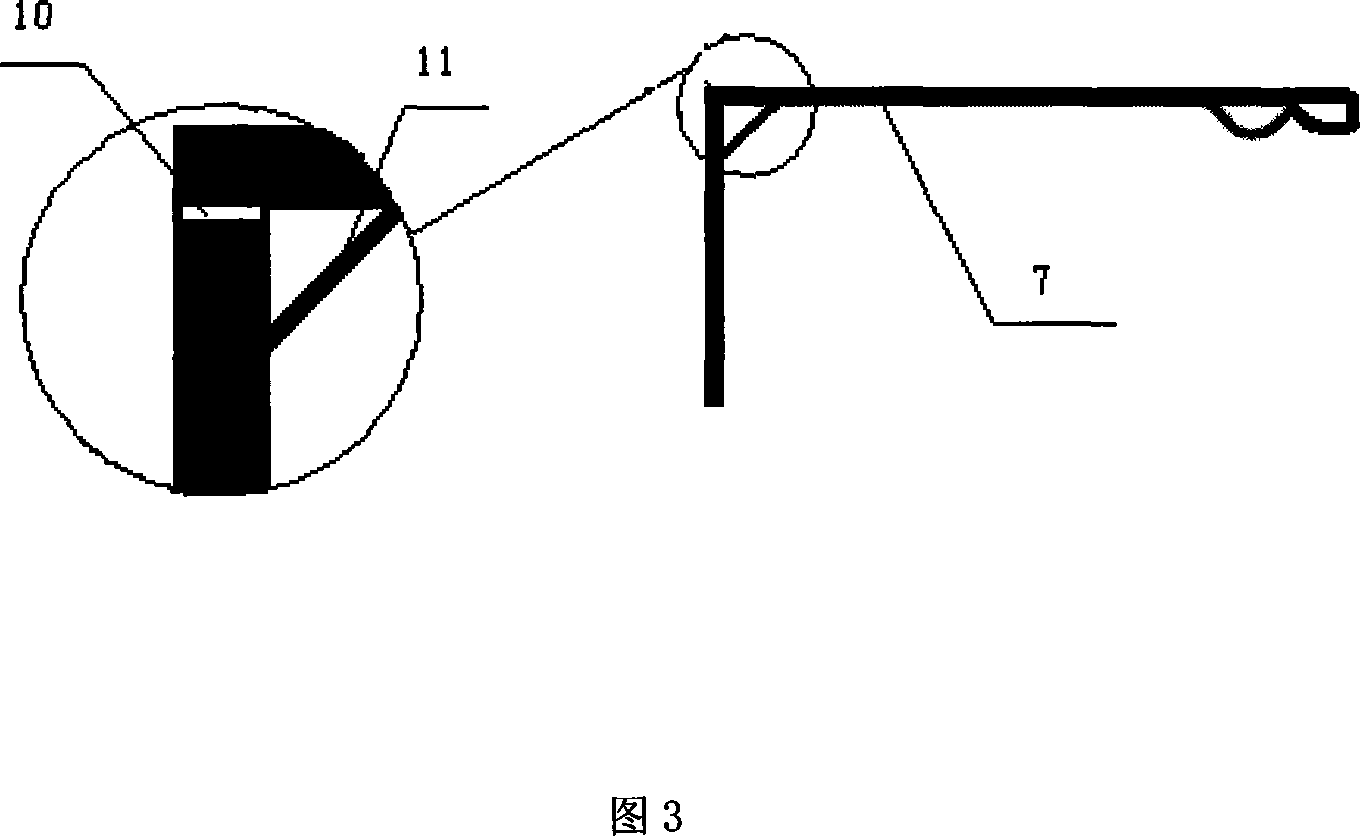

[0035] The measuring method of the present invention changes the traditional method of measuring the height of the aluminum liquid by the downward measurement method, that is, the distance from the top of the tool to the upper surface of the aluminum liquid, and adopts the method of measuring the distance from the upper surface of the aluminum liquid to the cathode surface from top to bottom to measure the height of the aluminum liquid . Since the cathode surface of each electrolytic cell of each series has the same height to the furnace platform, and the distance is fixed, a measuring support frame 3 can be placed on the aluminum outlet furnace platform, and its height is fixed and not easy to deform. The distance is also constant. Put the right-angle measuring drill on the surface of the support frame, measure the boundary line between the electrolyte and the molten aluminum, and measure the distance from the boundary line to the 10 mark on the root of the measuring drill to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com