A Process Model Modeling and Correction Method Based on Pattern Density

A pattern density and process model technology, which is applied in the direction of instruments, calculations, electrical digital data processing, etc., can solve the problems that the accuracy of the model is difficult to be guaranteed, the pattern density changes in a large range, and the test pattern density scale range is large, so as to improve Accuracy, the effect of improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

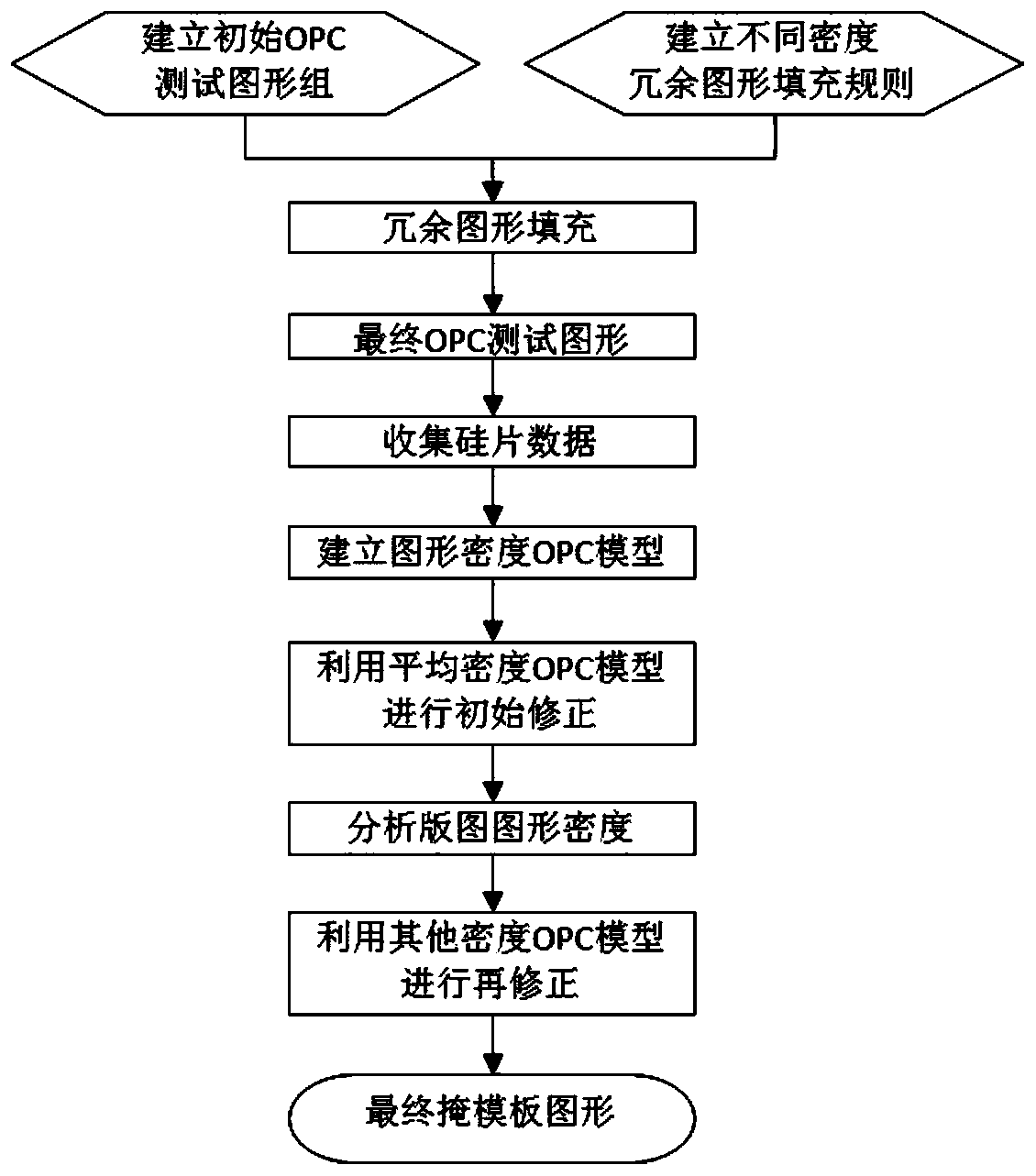

Method used

Image

Examples

Embodiment 1

[0078] Those skilled in the art know that from the actual product pattern density analysis, if redundant pattern processing is added, the typical pattern density ranges from 10% to 80%, and the average pattern density is about 30% to 40%. Metal layers and The pattern density of the active region layer is slightly higher, and the density of the polysilicon layer is slightly lower.

[0079] In this embodiment, the case where N is equal to 3 is selected for detailed description.

[0080] Assuming that the average density is 40%, the low density is 20%, and the high density is 60% as the target test pattern density, and three groups of OPC test patterns are respectively designed to establish models with three different pattern density ranges. The specific steps can be as follows:

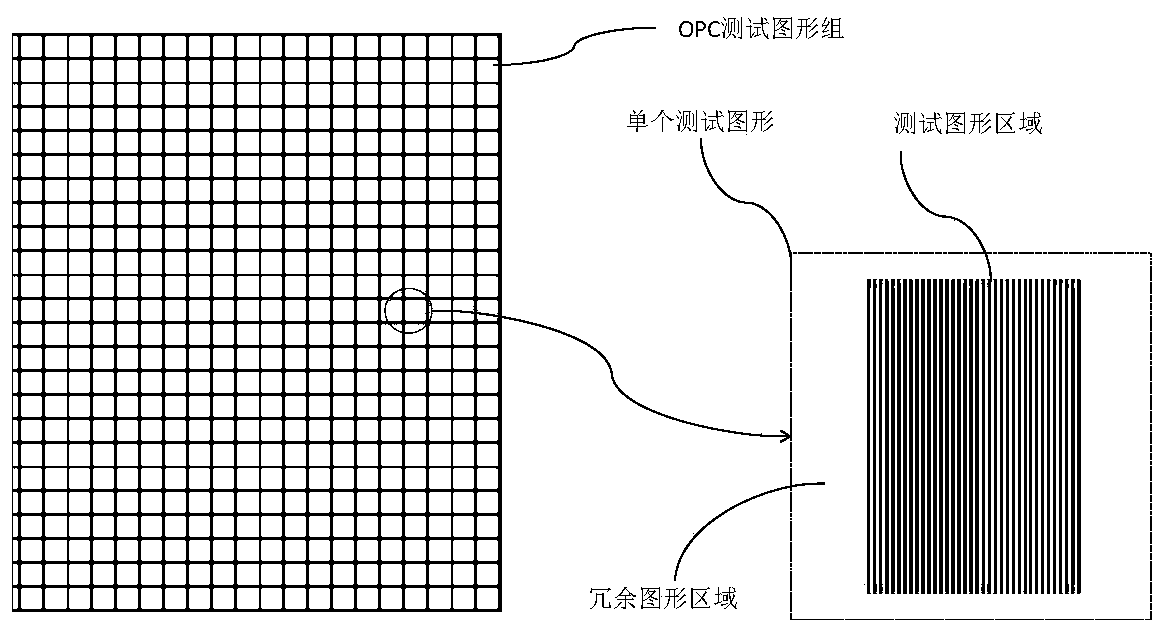

[0081] ①. According to the layout design rules (Design Rule) and lithography target, design the initial test pattern group required for OPC model calibration. These test patterns can include the pattern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com