Vaporized hydrogen peroxide concentration detector

A hydrogen peroxide, gas phase technology, applied in the field of sterilization and purification, can solve the problem of inability to know the quantity and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

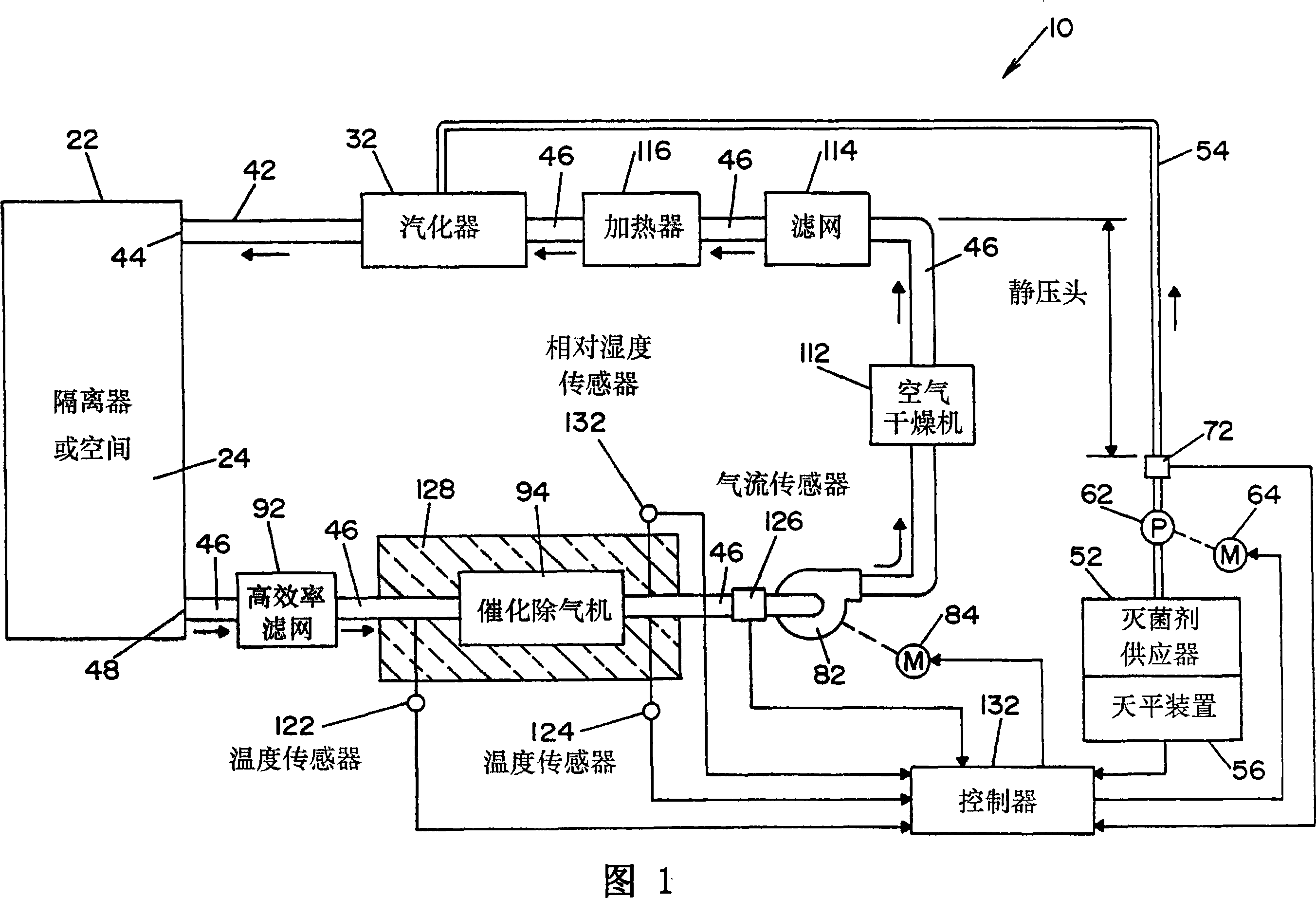

[0038] Referring to the accompanying drawings, the illustrations therein are only for illustration, but not for limiting the preferred embodiments of the present invention. FIG. 1 is a gas phase hydrogen peroxide sterilization system 10 to illustrate a preferred embodiment of the present invention. System 10 includes a number of components operable to determine the presence and / or concentration of hydrogen peroxide, a two-component, vapor-phase sterilant, as will be described in a particular case hereinafter. Of course, the present invention also hopes to find favorable applications in other aspects of determining the concentration of multi-component, gas-phase sterilants.

[0039] In the embodiment shown in the drawings, the system 10 includes:

[0040] An isolator or space 22 that defines an interior sterilization chamber or region 24 . Items to be sterilized or decontaminated are to be placed in an isolator (space 22);

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com