use eu 2+ A Method for Detecting Explosive TNP by f-f Transition Spectroscopy

A technology of f-f and explosives, applied in fluorescence/phosphorescence, measuring devices, material analysis through optical means, etc., can solve the problems of bulky, expensive chromatographic equipment, complicated operation, etc., and achieve simple detection methods, good detection results, Effects that are easy to scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] BaAlF 5 : Eu 2+ Preparation of nanoparticles

[0020] 1. Weigh 2mmolAlCl 3 ·6H 2 O, 1.92 mmol BaCl 2 ·6H 2 O, 0.08mol EuCl 2 Dissolve 10mL of distilled water in a 50mL beaker, add a rotor to the beaker, place the beaker on a magnetic stirrer and stir for 20min to fully dissolve to obtain a mixed solution ①.

[0021] 2. Weigh 2mmol NH 4 HF 2 Dissolve in 5mL distilled water, and slowly drop it into the mixed solution ① after fully dissolved, and stir for 20min to obtain the mixed solution ②.

[0022] 3. Transfer the mixed solution ② to a 25mL reactor and heat at 200°C for 24h.

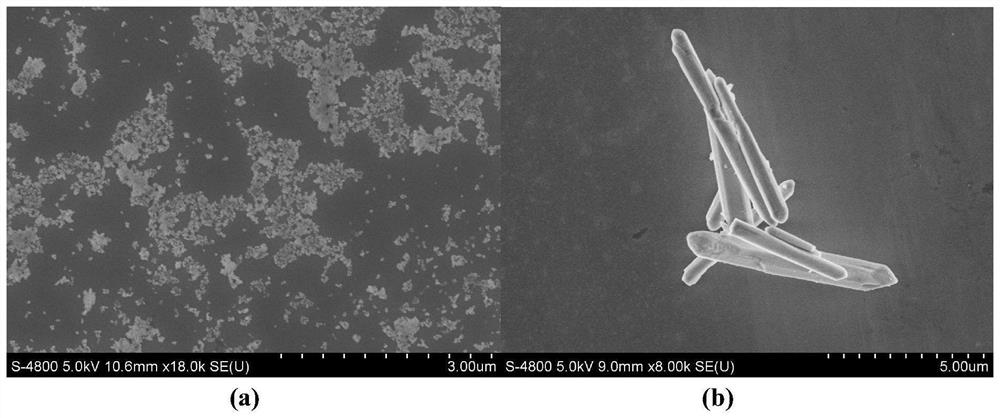

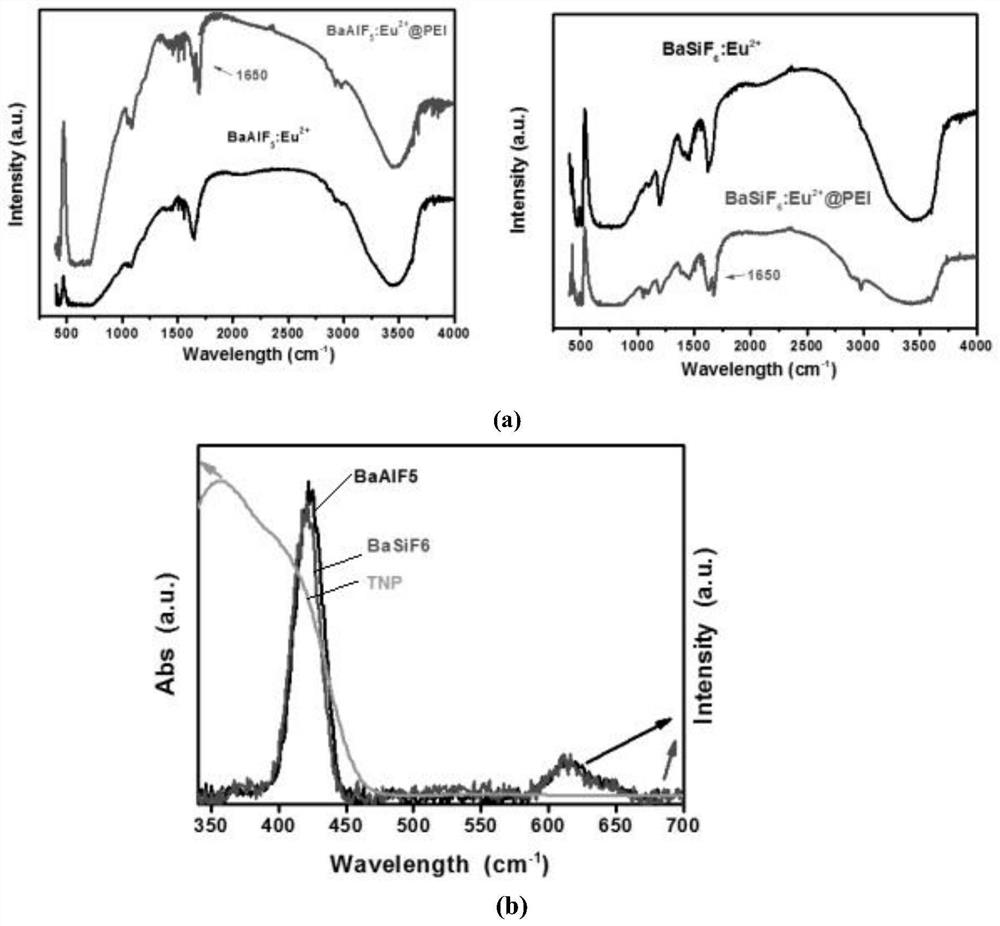

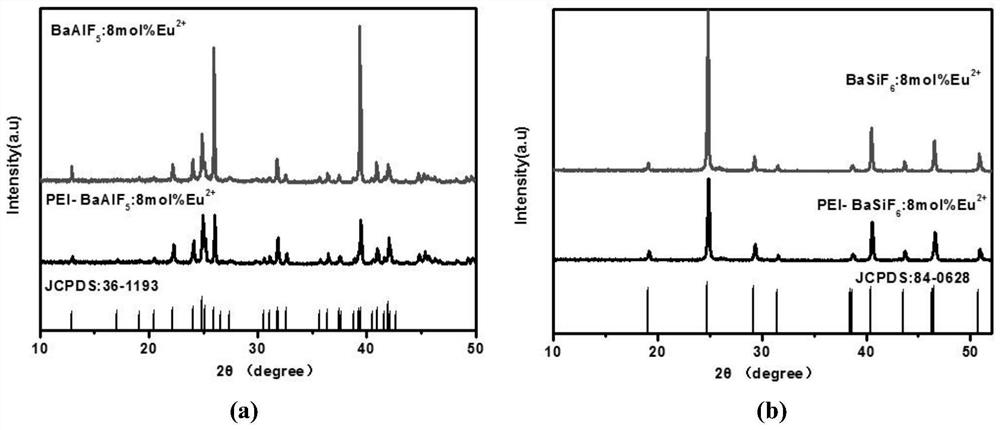

[0023] 4. After taking out the reaction kettle, after cooling to room temperature, centrifuge at a speed of 5000rpm / min for 10 minutes, discard the supernatant, and wash the precipitate with distilled water 4 times. After drying, carry out component analysis, by XRD pattern image 3 (a) It can be seen that pure phase BaAlF has been obtained 5 : Eu 2 + Nanoparticles.

[0024] BaAlF ...

Embodiment 2

[0028] BaSiF 6 :Eu 2+ Preparation of nanoparticles

[0029] 1. Weigh 2g CTAB and dissolve it in a mixed solution of 50mL cyclohexane and 2mL n-butanol. After magnetically stirring in a water bath at 60°C for 30min, the solution turns light yellow and transparent. Two copies of the same solution are prepared.

[0030] 2. Dissolve 1mLBaCl 2 (1mol / L) and citric acid (CA) mixed solution and 1mLH 2 SiF 6 (10%) and CA mixed solutions were added to the two solutions obtained in step 1, and the stirring was continued for 30 min.

[0031] 3. The two solutions were mixed, stirred vigorously at room temperature for 1 hour, then transferred to a 100 mL reactor and heated at 120°C for 12 hours.

[0032] 4. After taking out the reaction kettle, after cooling to room temperature, centrifuge at 9000rpm / min for 10 minutes, discard the supernatant, and wash the precipitate 4 times with ethanol and distilled water. Composition analysis after drying, from the XRD pattern image 3 (b) It c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com