Patents

Literature

44 results about "Hydrogen peroxide generation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High performance orr (oxygen reduction reaction) pgm (pt group metal) free catalyst

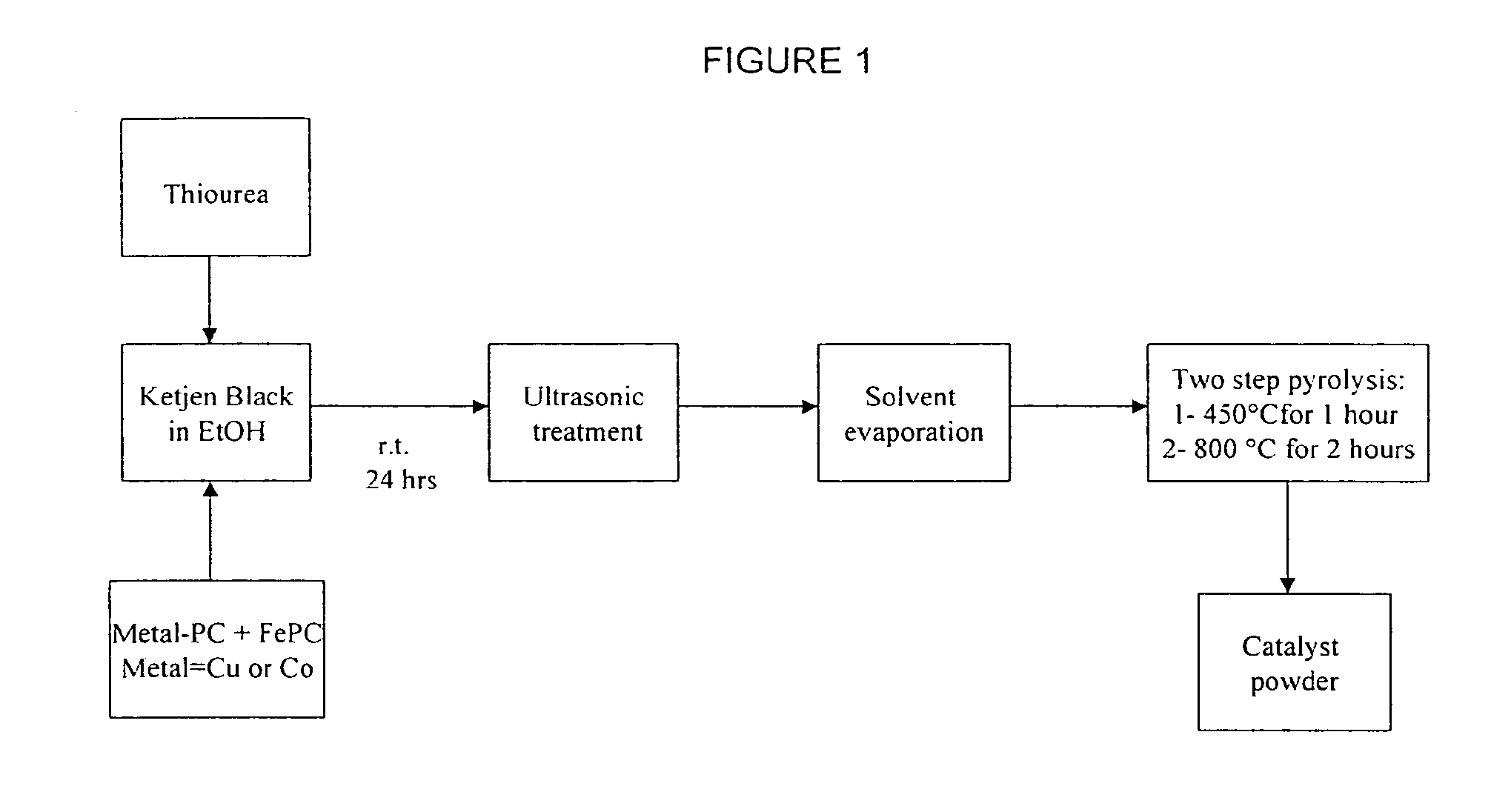

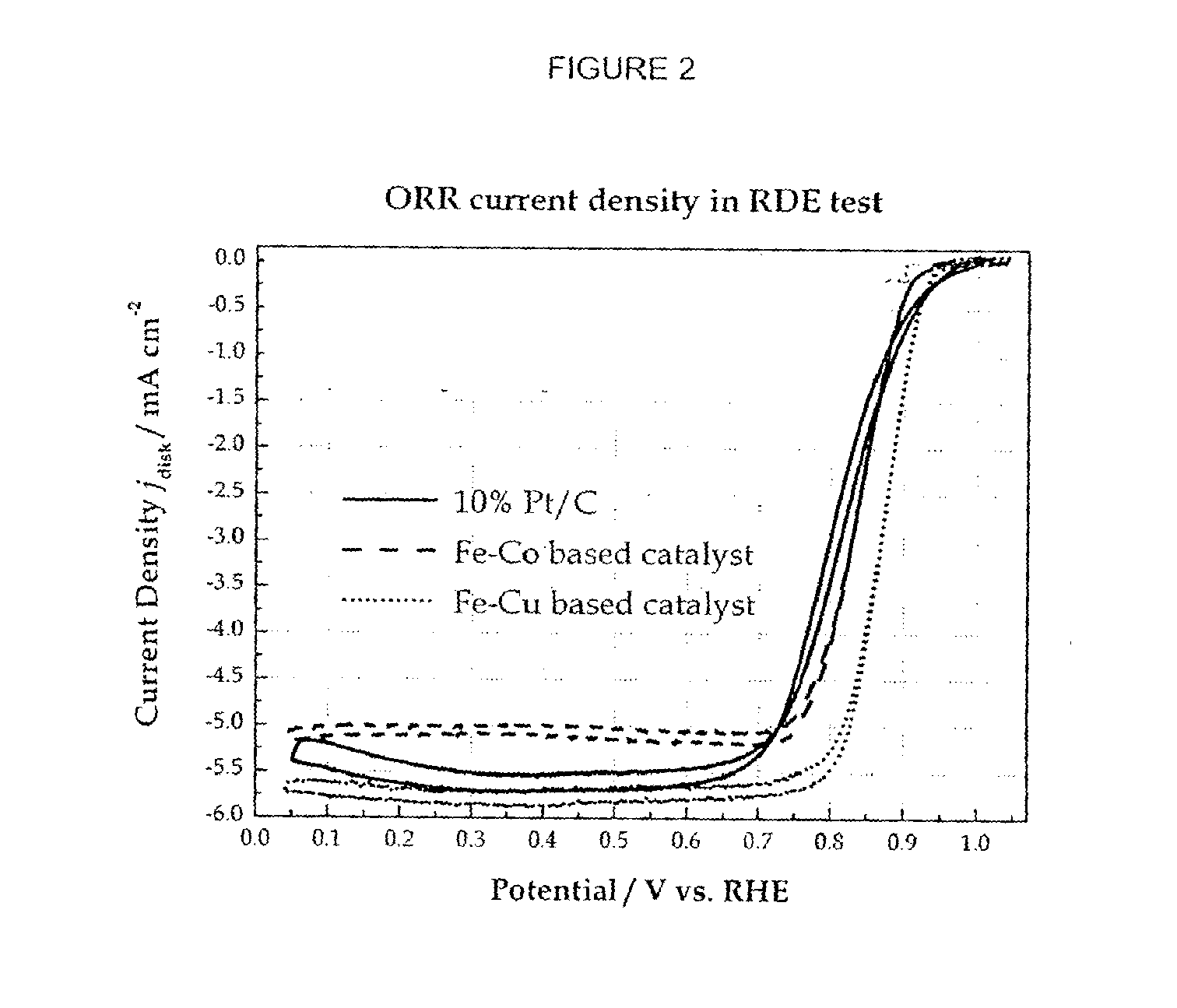

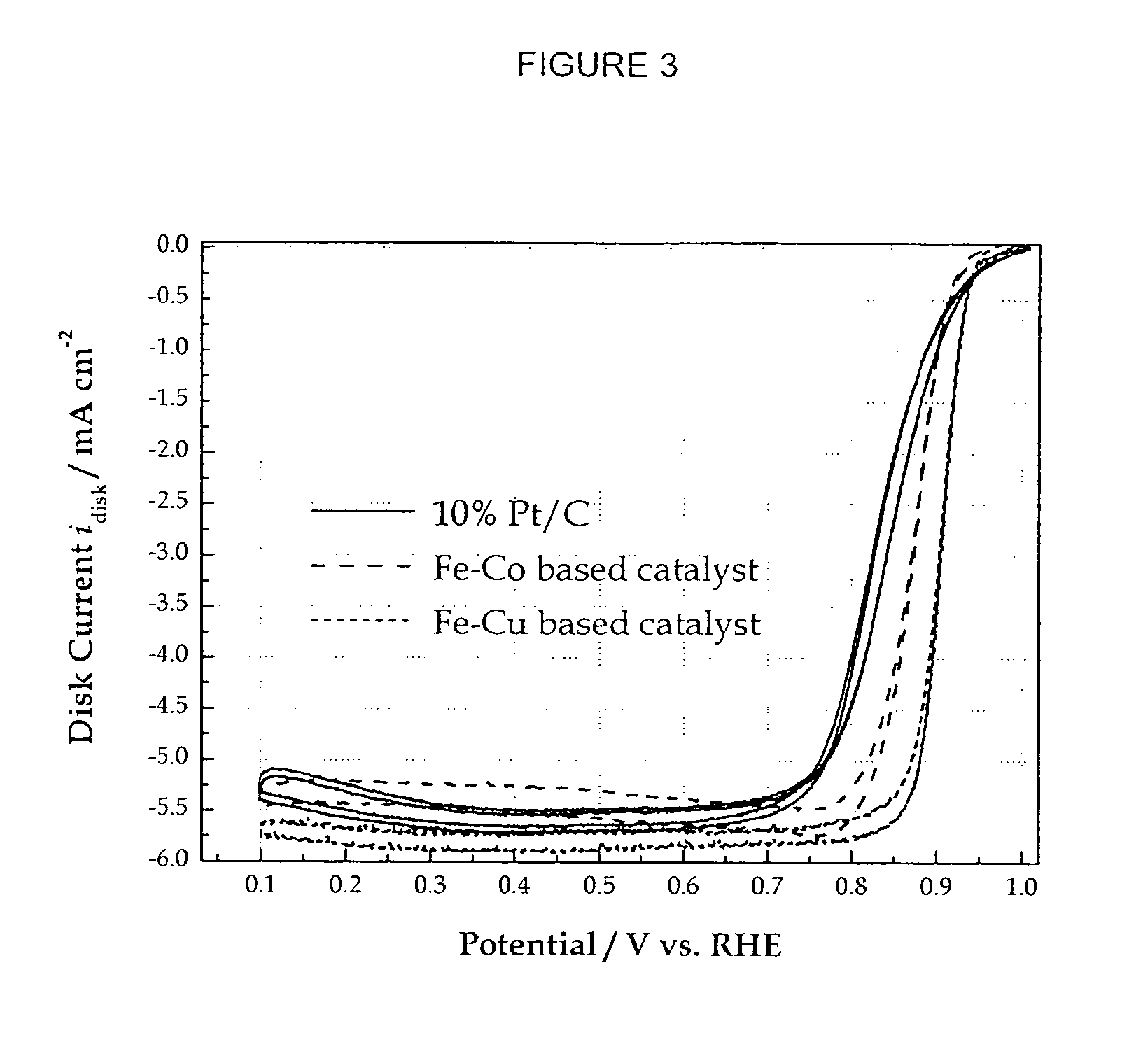

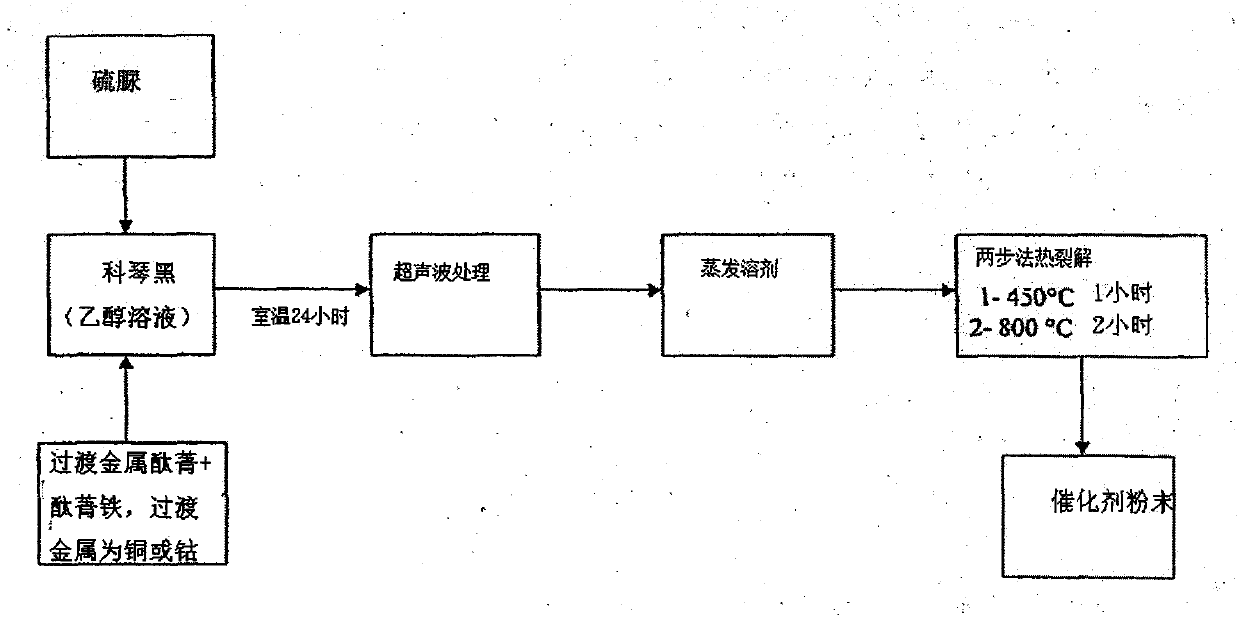

InactiveUS20110034325A1Improve performanceFuel and primary cellsCell electrodesAlcoholPhthalocyanine

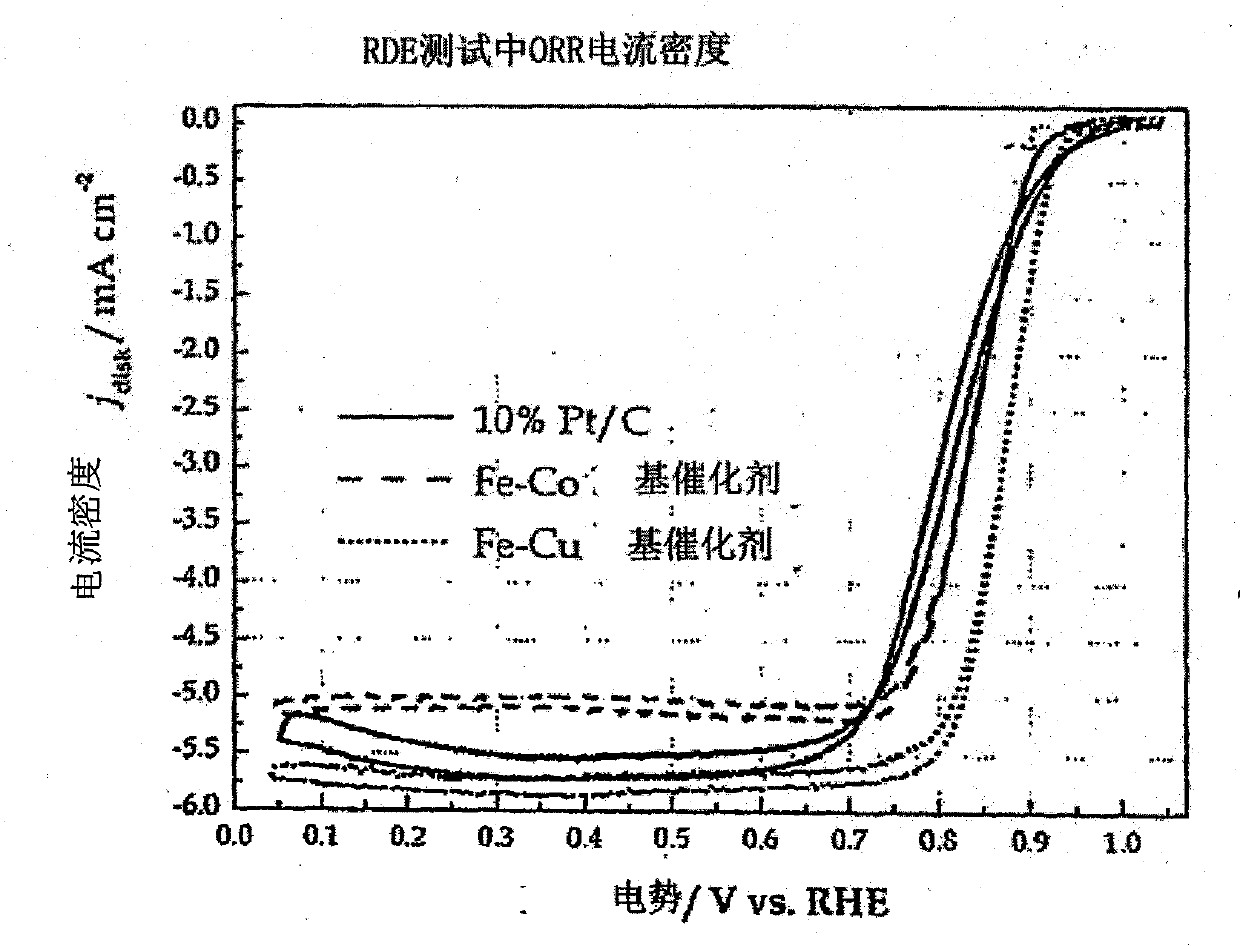

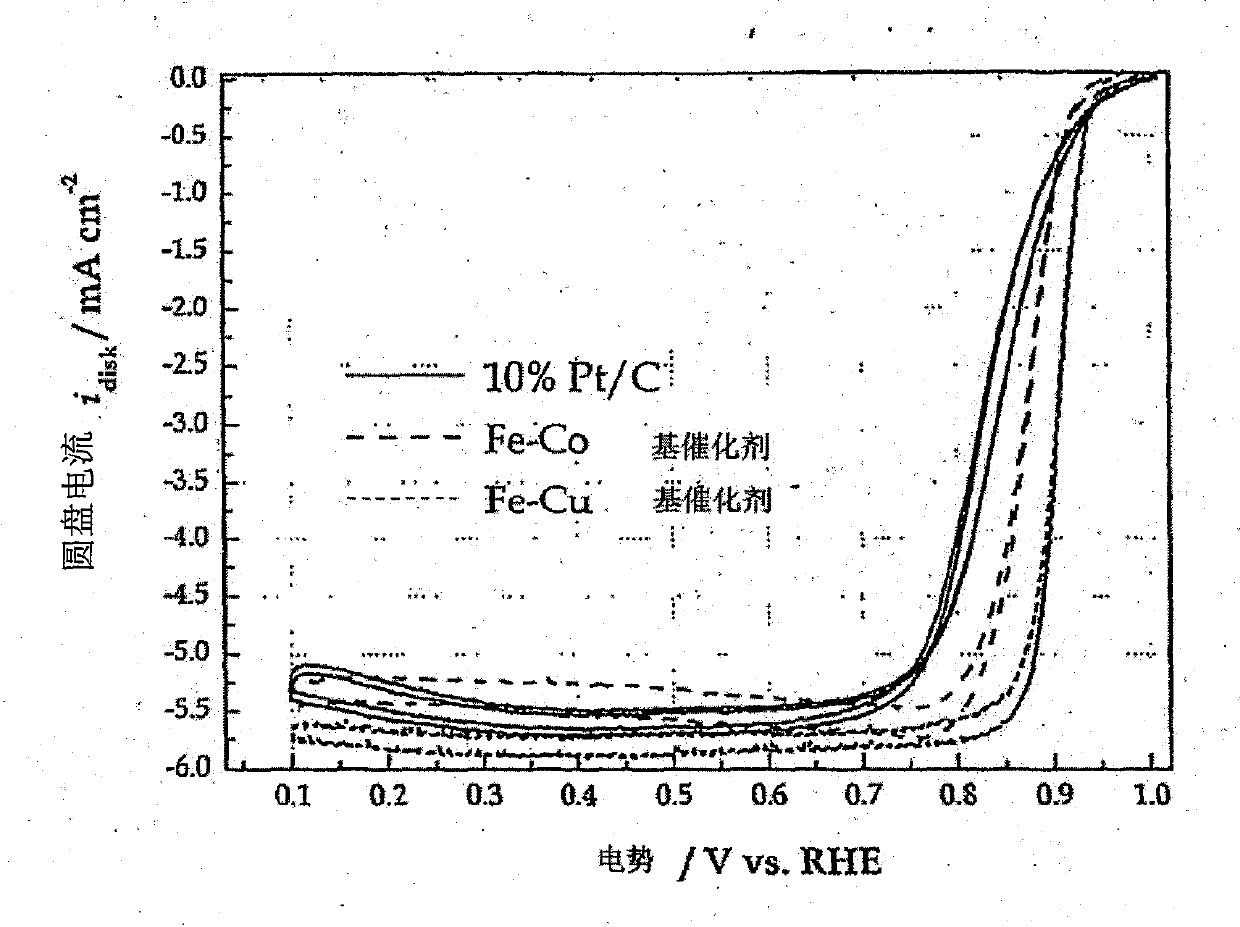

Herein are disclosed PGM-free catalysts, made starting from transition metal phthalocyanine complexes, useful for catalytic ORR, and more particularly, alcohol tolerant catalysts as cathode material for ORR in alkaline and acid medium, characterized by low hydrogen peroxide generation and having better performance, stability and activity.

Owner:ACTA SPA

High performance ORR (oxygen reduction reaction) PGM (pt group metal) free catalyst

Herein are disclosed PGM-free catalysts, made starting from transition metal phthalocyanine complexes, useful for catalytic ORR, and more particularly, alcohol tolerant catalysts as cathode material for ORR in alkaline and acid medium, characterized by low hydrogen peroxide generation and having better performance, stability and activity.

Owner:ACTA SPA

Treatment method of landfill leachate

InactiveCN104891733ALow costImprove production efficiencyMultistage water/sewage treatmentSeparation technologyOxygen

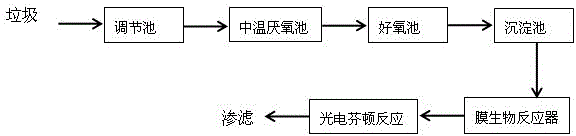

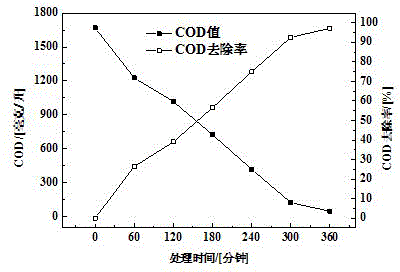

The invention relates to a treatment method of landfill leachate. Pretreatment is performed through anaerobic treatment, aerobic treatment and a membrane bioreactor, and organic pollution ingredients which are easy to biodegrade are sufficiently degraded at a lower cost; deep degradation treatment is performed through a photoelectric Fenton reaction, and pollution ingredients which are difficult to biodegrade are sufficiently and quickly degraded; hydrogen peroxide is continuously produced through a gas diffusion electrode so as to maintain the Fenton reaction; the production efficiency of the hydrogen peroxide is improved by using 2-ethyl-anthraquinone as a catalyst; the regeneration of ferrous ions is ensured by using ultraviolet rays for illumination, and the Fenton reaction is circularly performed. The medicament cost is reduced, sludge containing iron is hardly produced, a membrane separation technology is not used in a final treatment link, organic waste is efficiently degraded and discharged, a concentrated solution cannot be produced, and the cost is far lower than that by using a membrane separation technology.

Owner:BEIJING UNIV OF CHEM TECH

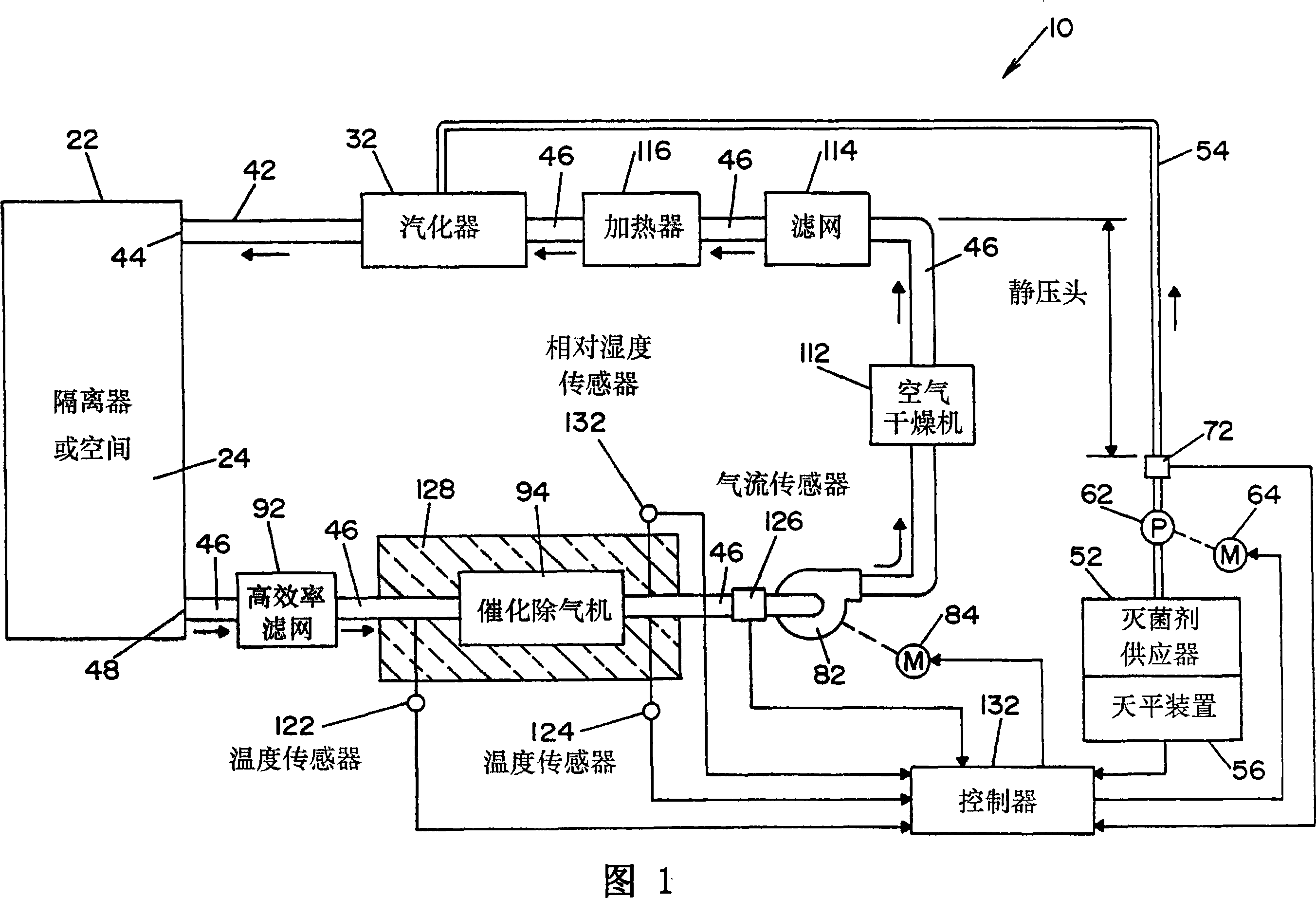

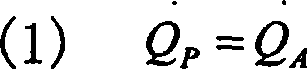

Vaporized hydrogen peroxide concentration detector

InactiveCN101080242AJudgment concentrationNo need to interveneLavatory sanitoryFire rescueEnvironmental engineeringHydrogen peroxide generation

A vapor decontamination system for decontaminating a defined region. The system is comprised of a chamber defining a region, and a generator for generating vaporized hydrogen peroxide from a solution of hydrogen peroxide and water. A closed loop circulating system is provided for supplying the vaporized hydrogen peroxide to the region. A destroyer breaks down the vaporized hydrogen peroxide, and sensors upstream and downstream from the destroyer are operable to sense moisture in the system and provide electrical signals indicative thereof. A controller determines the presence of vaporized hydrogen peroxide in the region based upon the electrical signals from the sensors.

Owner:AMERICAN STERILIZER CO

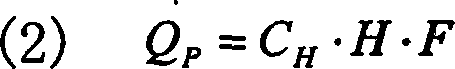

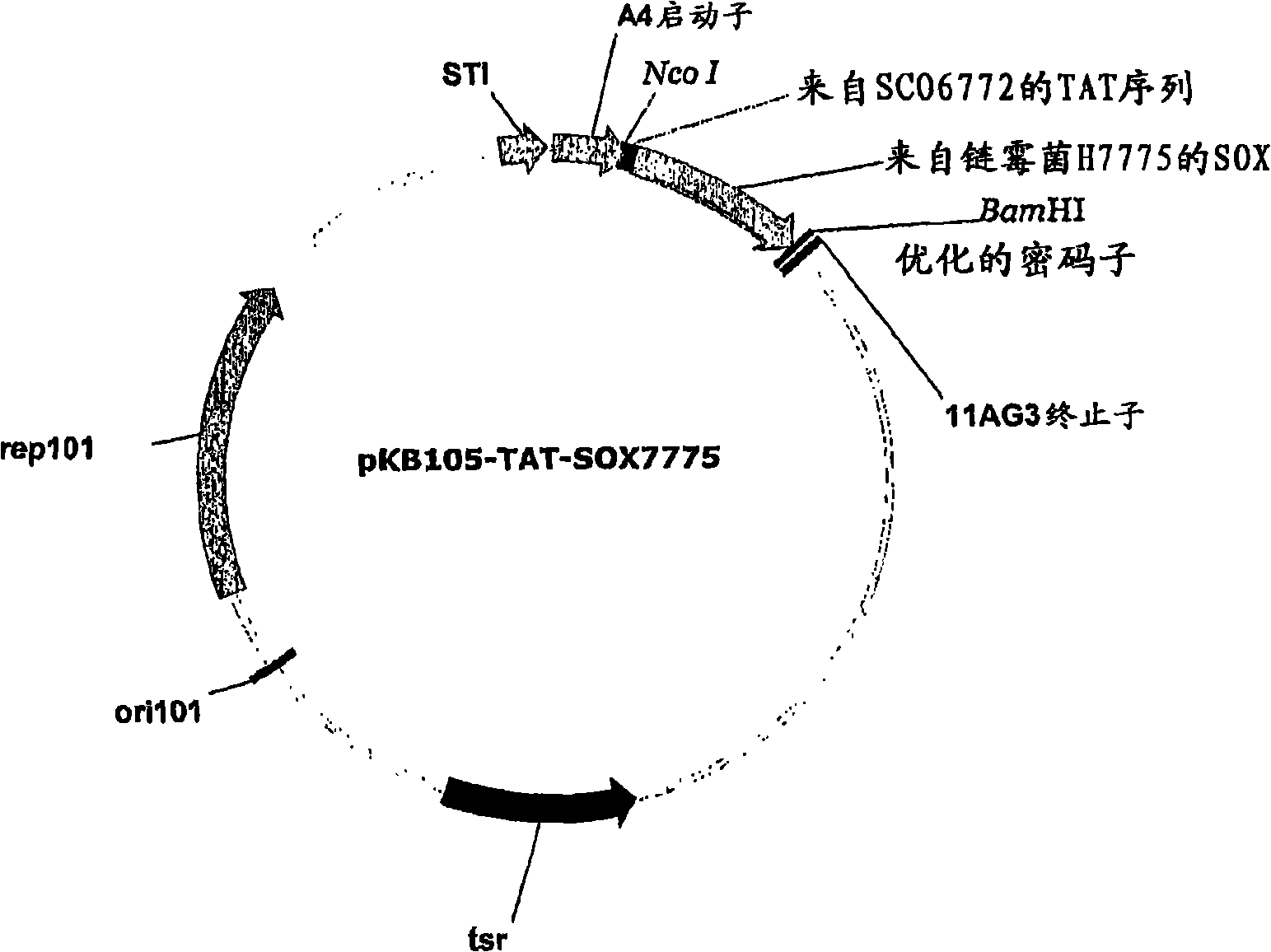

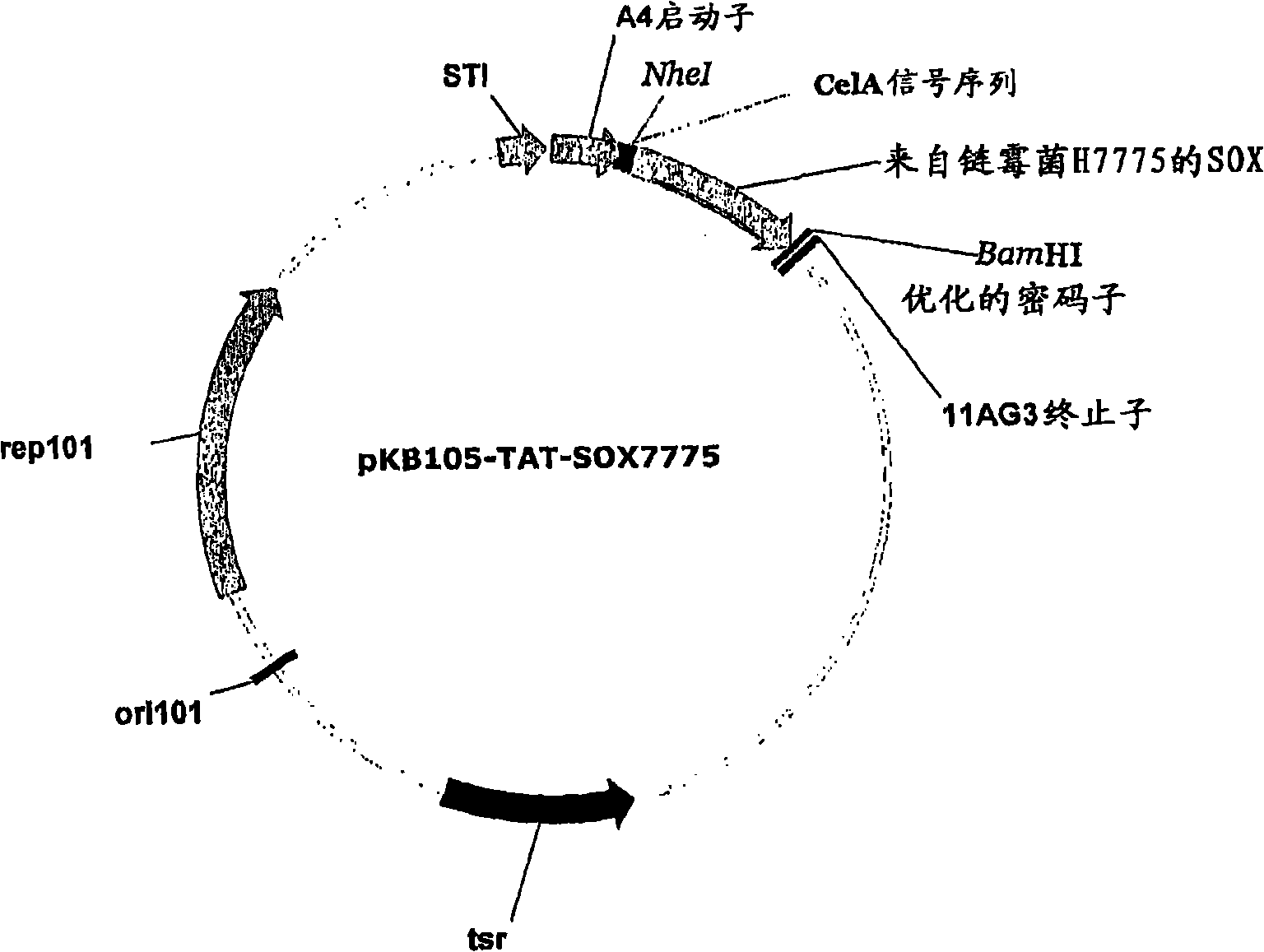

Lactobacillus reuteri and application of lactobacillus reuteri in preparing vaginal antibacterial drug

ActiveCN107267415AActive and stable biological propertiesAdhesionAntibacterial agentsAntimycoticsDiseaseGynecological disease

The invention provides lactobacillus reuteri and an application of the lactobacillus reuteri in preparing a vaginal antibacterial drug. The lactobacillus reuteri is collected in China General Microbiological Culture Collection Center with a collection number of CGMCC No. (China General Microbiological Culture Collection Center number) 14110. A study of metabolic performance of the lactobacillus reuteri finds that the strain has better lactic acid production capacity, very strong hydrogen peroxide generation capacity, very strong antibacterial capacity on pathogenic bacteria and excellent vaginal epithelial cell adhesive capacity compared with the common lactobacillus reuteri. Based on the above novel properties found, the novel application of the lactobacillus reuteri in preparing the vaginal antibacterial drug is determined, and treatment of multiple bacterial vaginal diseases can be achieved. The lactobacillus reuteri has a significant effect on the bacterial vaginal diseases, is safe, nontoxic and good in stability and can be stored for a long term. The invention further relates to an application of the lactobacillus reuteri in drugs for preventing and / or treating gynecological diseases.

Owner:广东强基药业有限公司

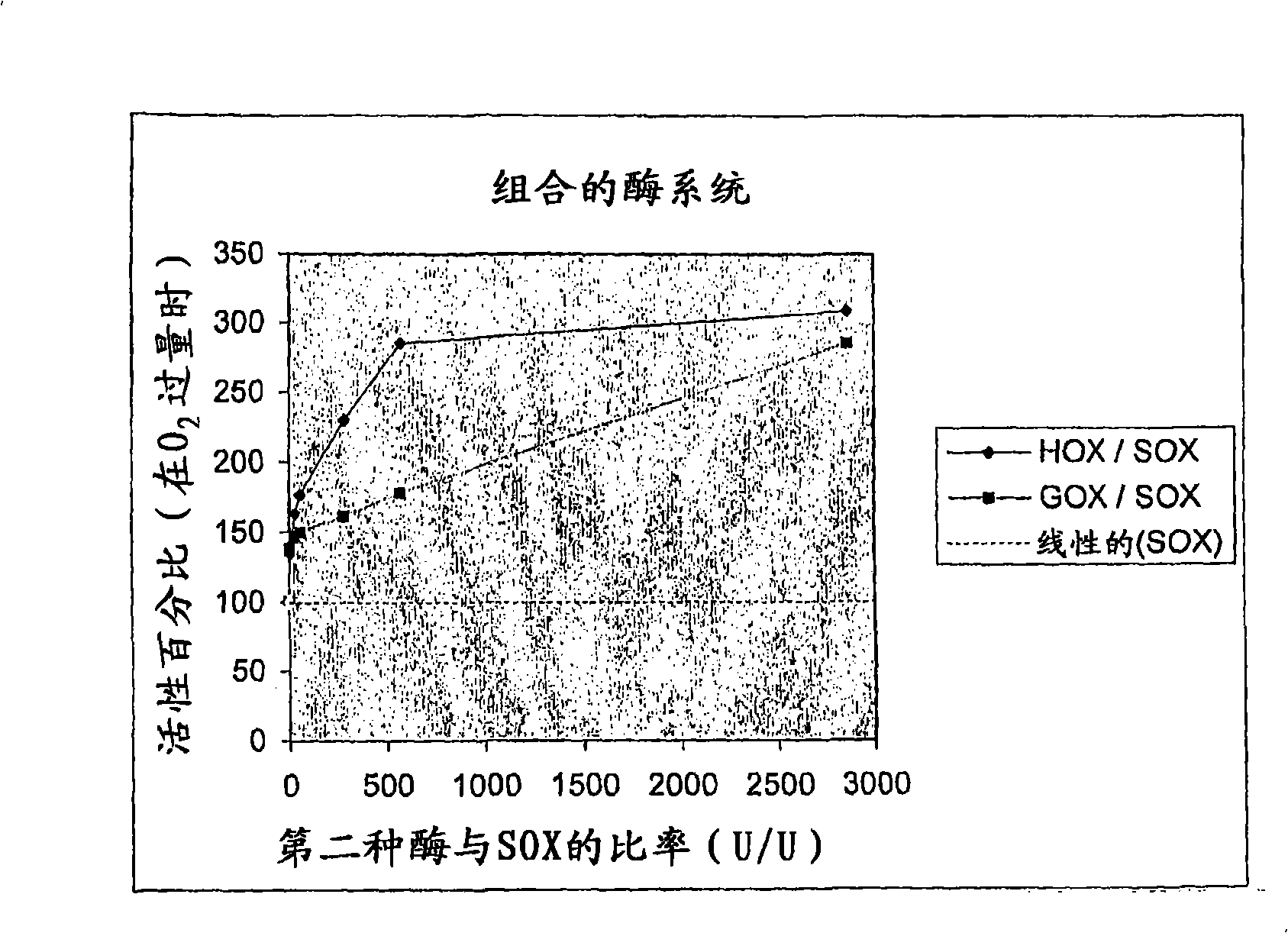

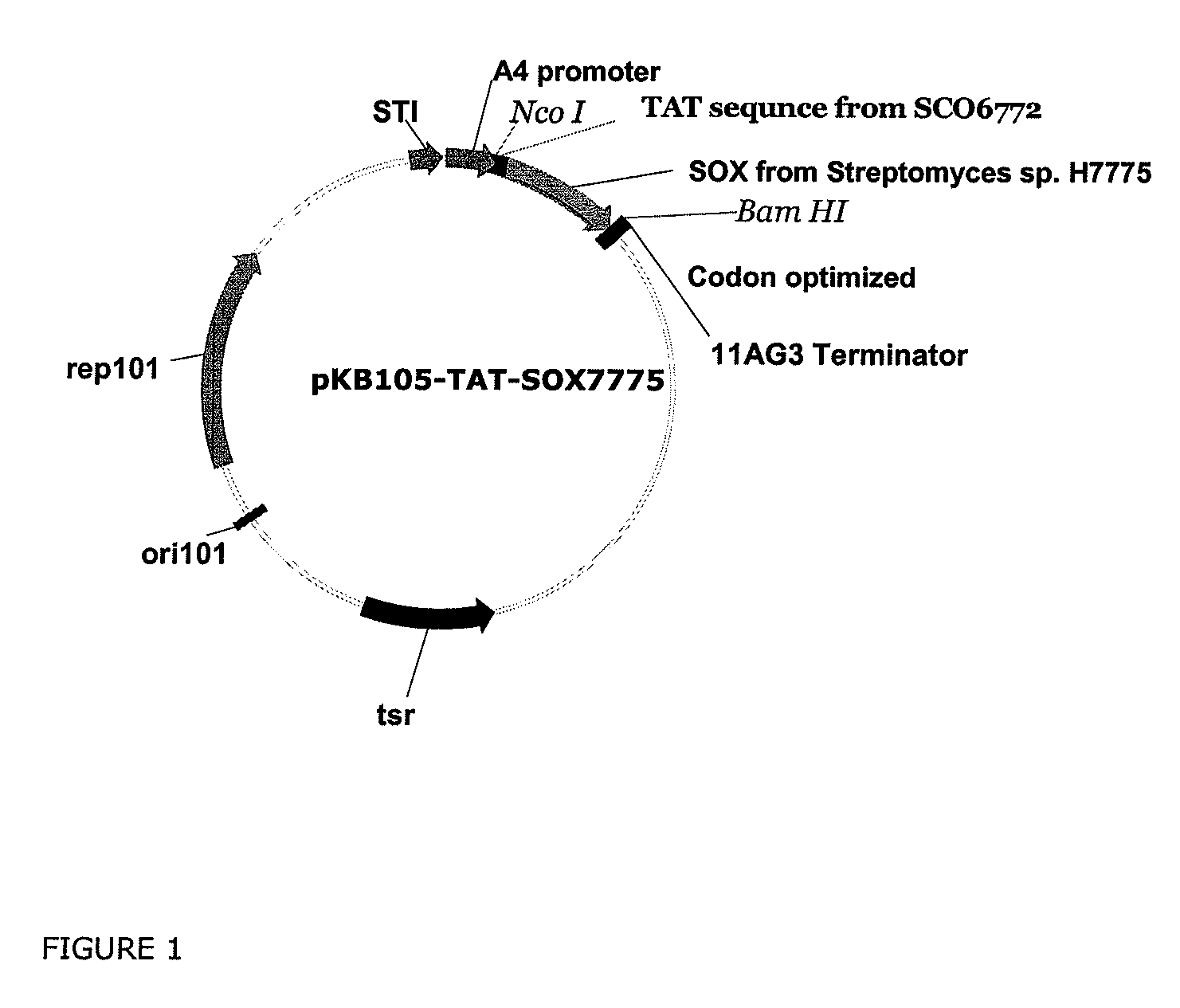

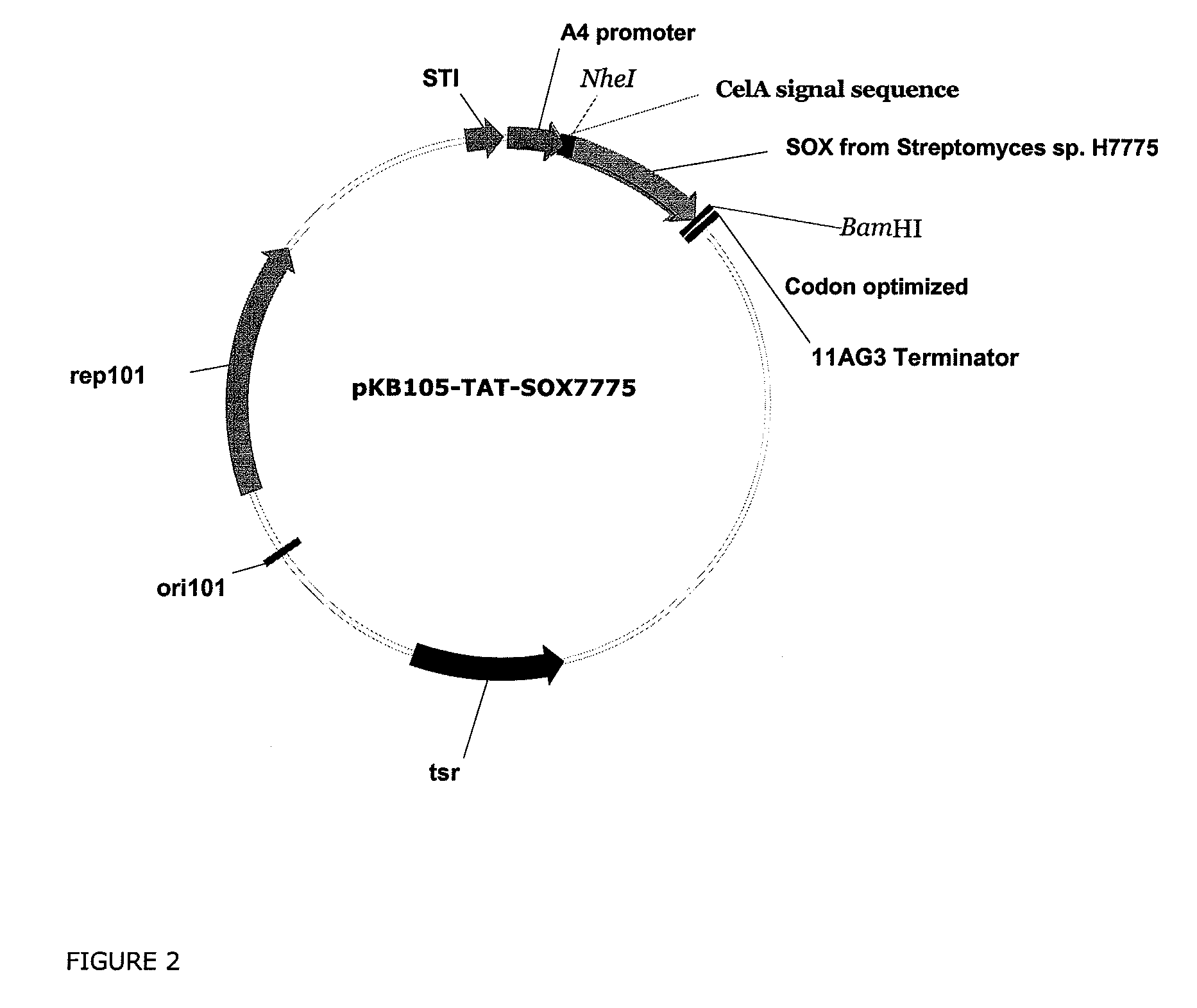

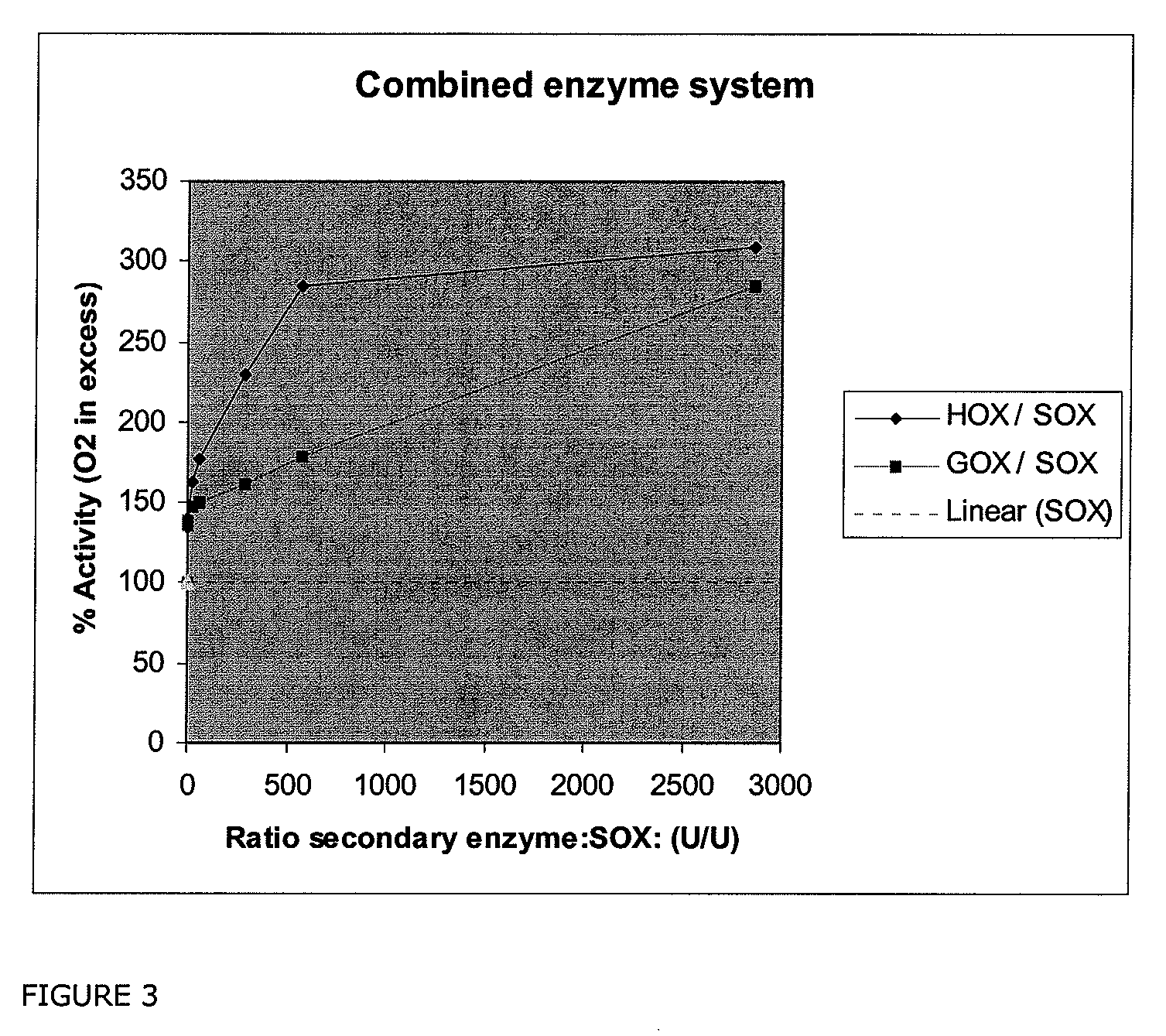

A composition comprising a coupled enzyme system

InactiveCN101316576ABeneficial probiotic effectExtended shelf lifeAntibacterial agentsCosmetic preparationsCouplingEnzyme system

The present invention relates to a composition comprising a coupled enzyme system for the rapid and efficient production of hydrogen peroxide by the coupling of a first enzyme system capable of hydrogen peroxide generation, to a second enzyme system which utilizes the non hydrogen peroxide product of the first enzyme system, and optionally is capable of generating further hydrogen peroxide.

Owner:DUPONT NUTRITION BIOSCIENCES APS

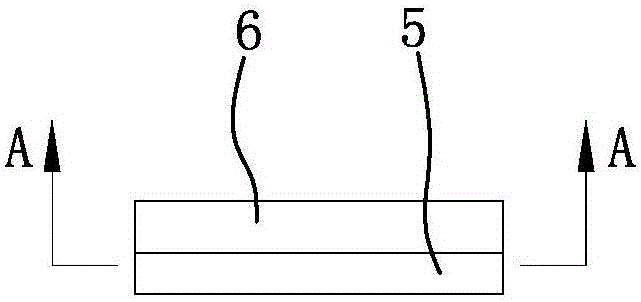

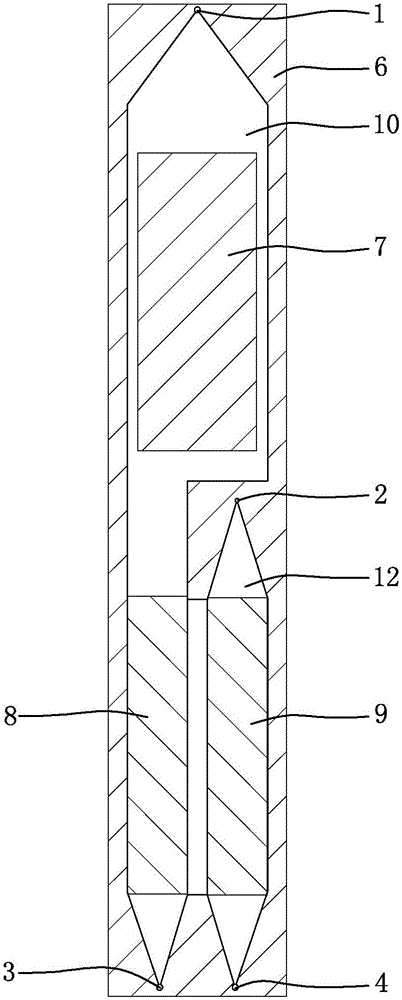

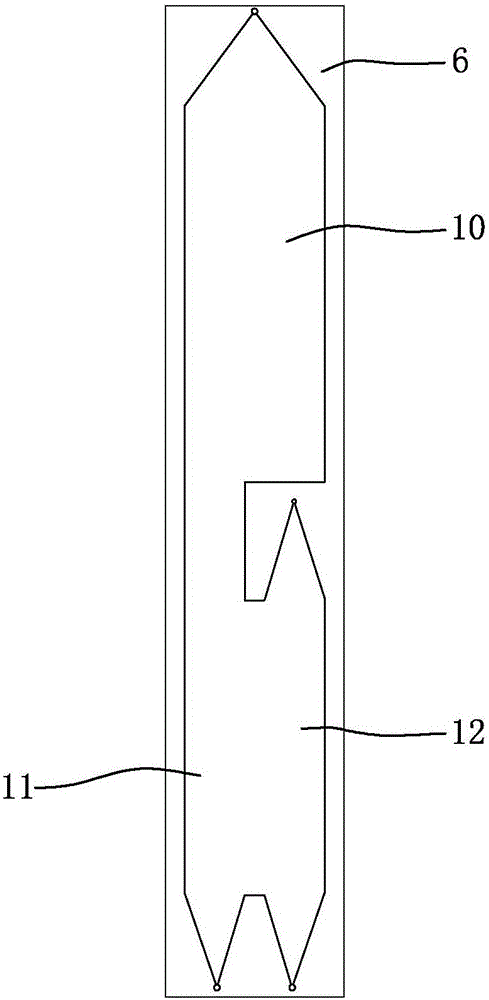

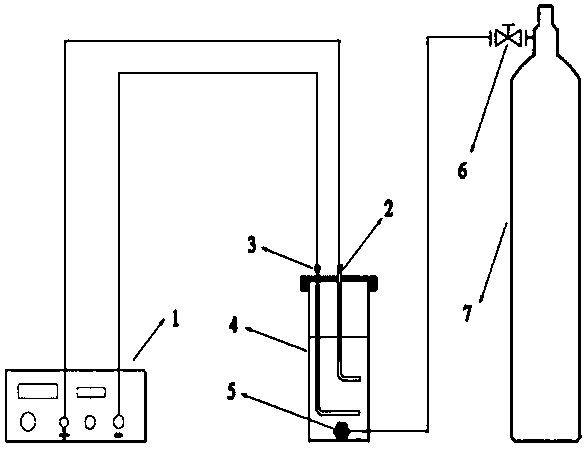

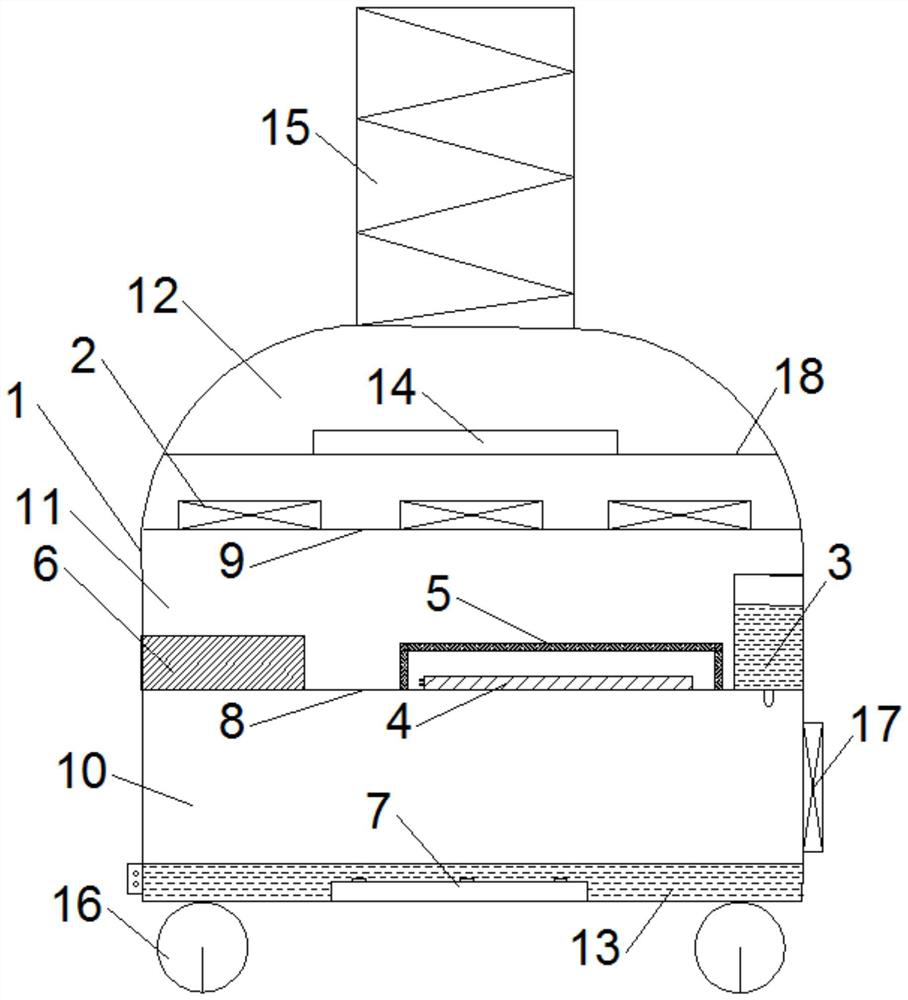

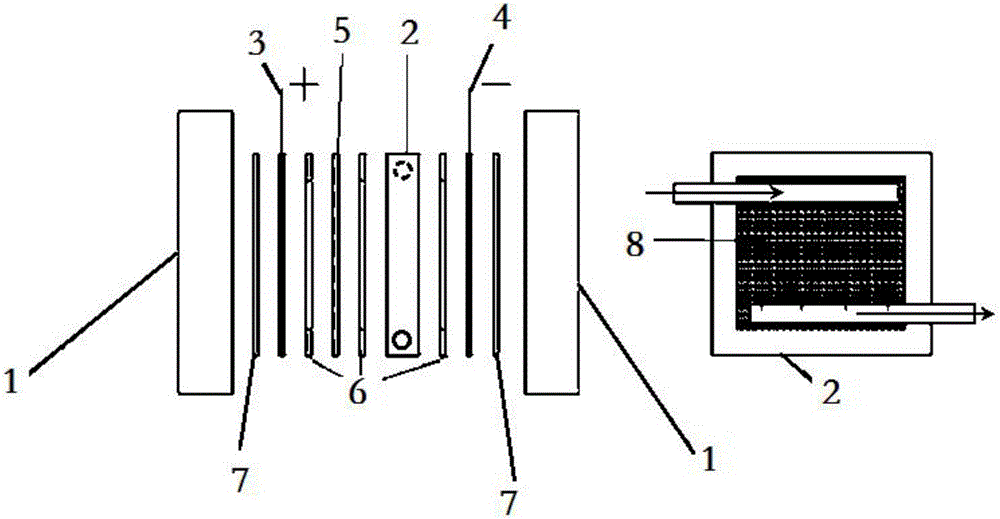

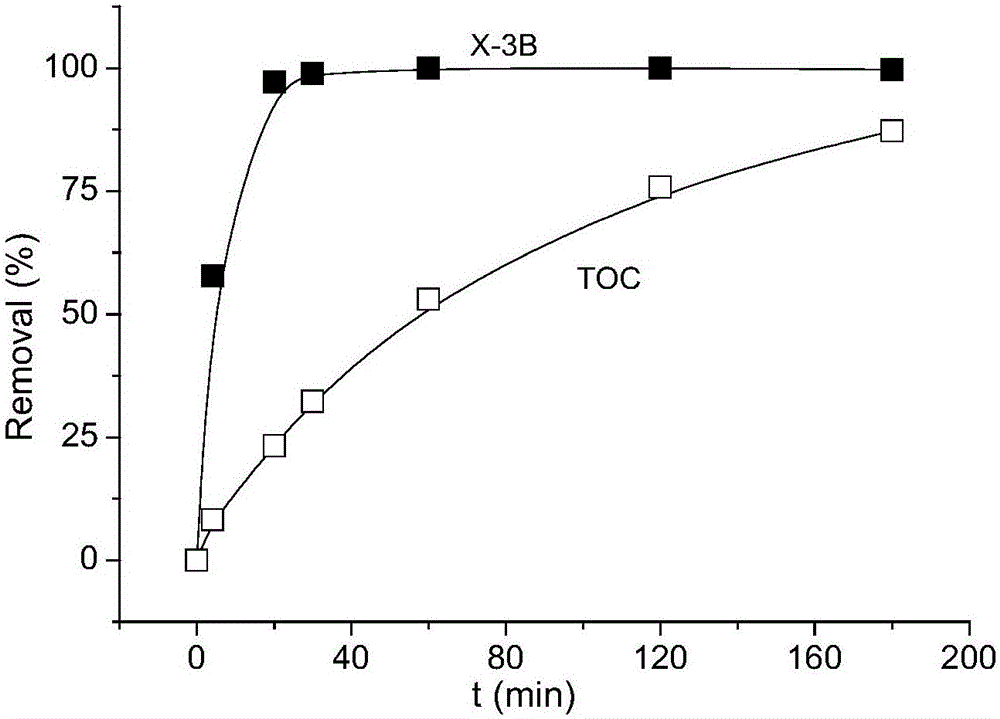

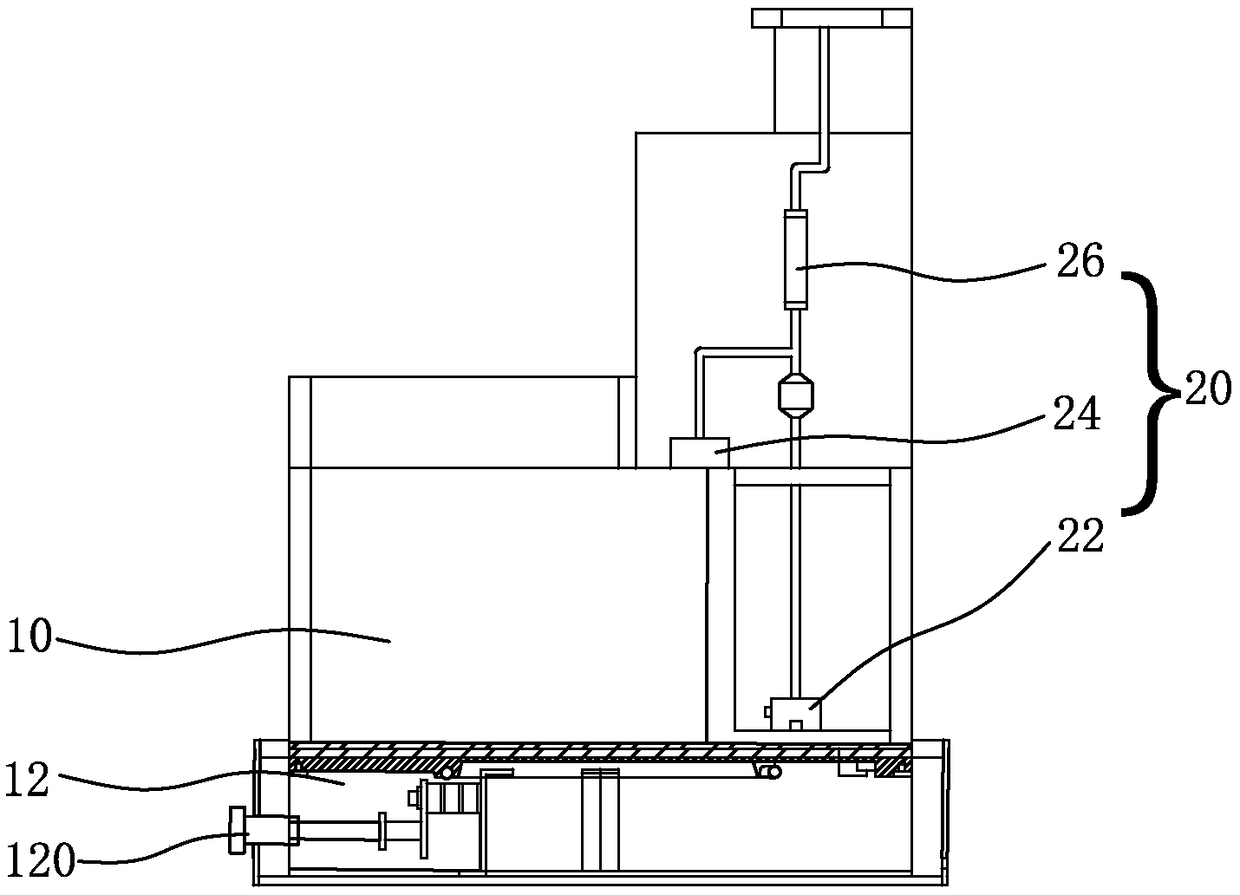

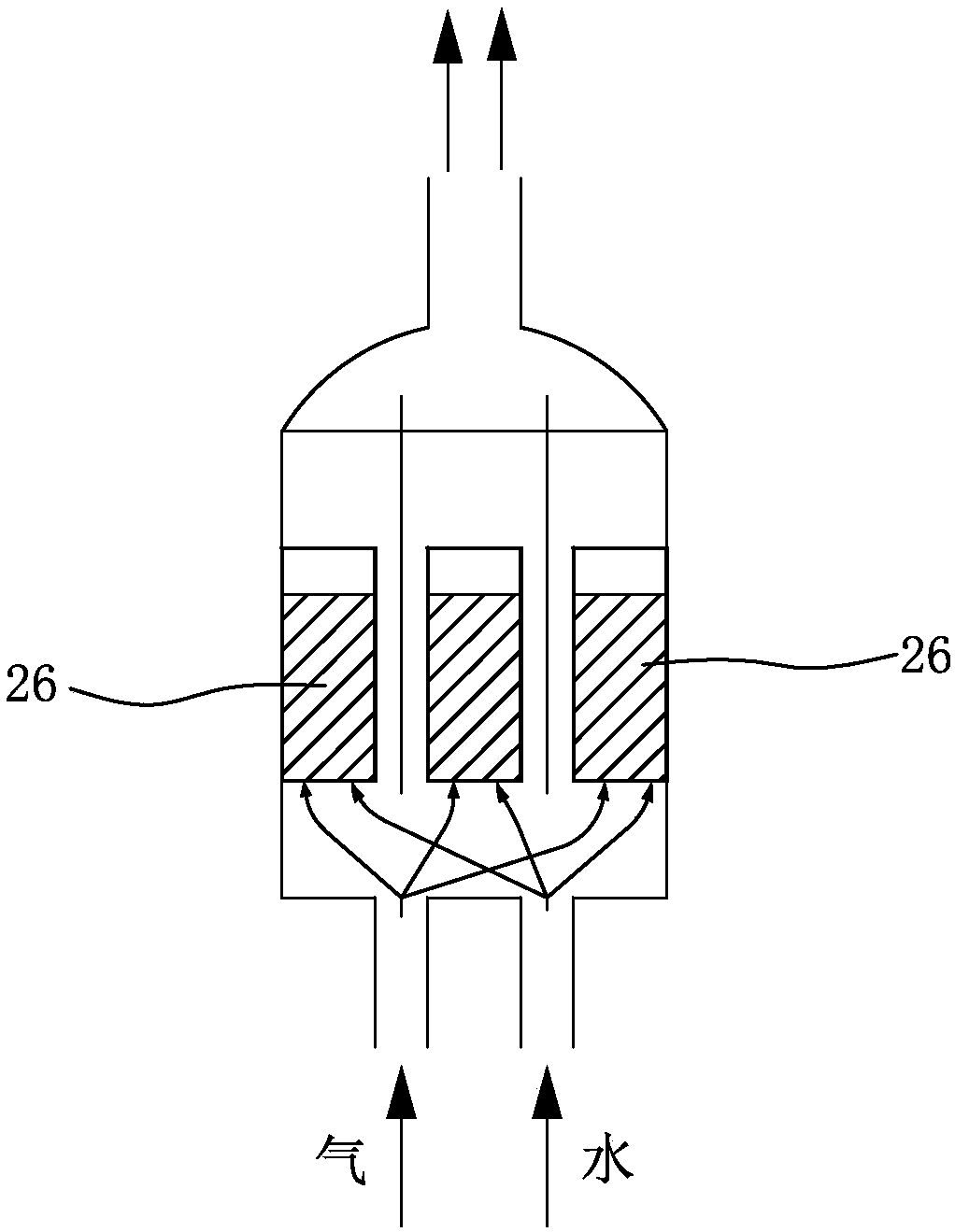

Photocatalytic hydrogen peroxide generation and photocatalytic fuel cell coupling system

ActiveCN106486687AStrong oxidation abilityImprove performanceFinal product manufactureRegenerative fuel cellsChemistryCathode

The invention discloses a photocatalytic hydrogen peroxide generation and photocatalytic fuel cell coupling system. A groove-shaped cavity is formed in a reaction cavity body and is sealed by conductive glass, the front portion of the cavity is a reaction chamber, the rear portion is provided with a cathode chamber and an anode chamber arranged side by side and communicated mutually, a photocatalyst layer is arranged in the reaction chamber, a cathode catalyst layer is arranged in the cathode chamber, an anode photocatalyst layer is arranged in the anode chamber, and the photocatalyst layer, the cathode catalyst layer and the anode photocatalyst layer are supported on the conductive glass. The system integrates photocatalytic hydrogen peroxide generation and simultaneous power generation of organic matter from photocatalytic fuel cell disposal, is simple in structure and low in cost and has the advantages of being free of membranes, large in specific surface area, high in mass transfer efficiency, accurate in flow control, short in contact time, easy to enlarge, uniform in lighting, small in optical path loss and the like, and the performance is effectively improved. The organic matter in water can be utilized to generate power, environmental pollution can be controlled, and meanwhile electric energy can be also obtained.

Owner:CHONGQING UNIV

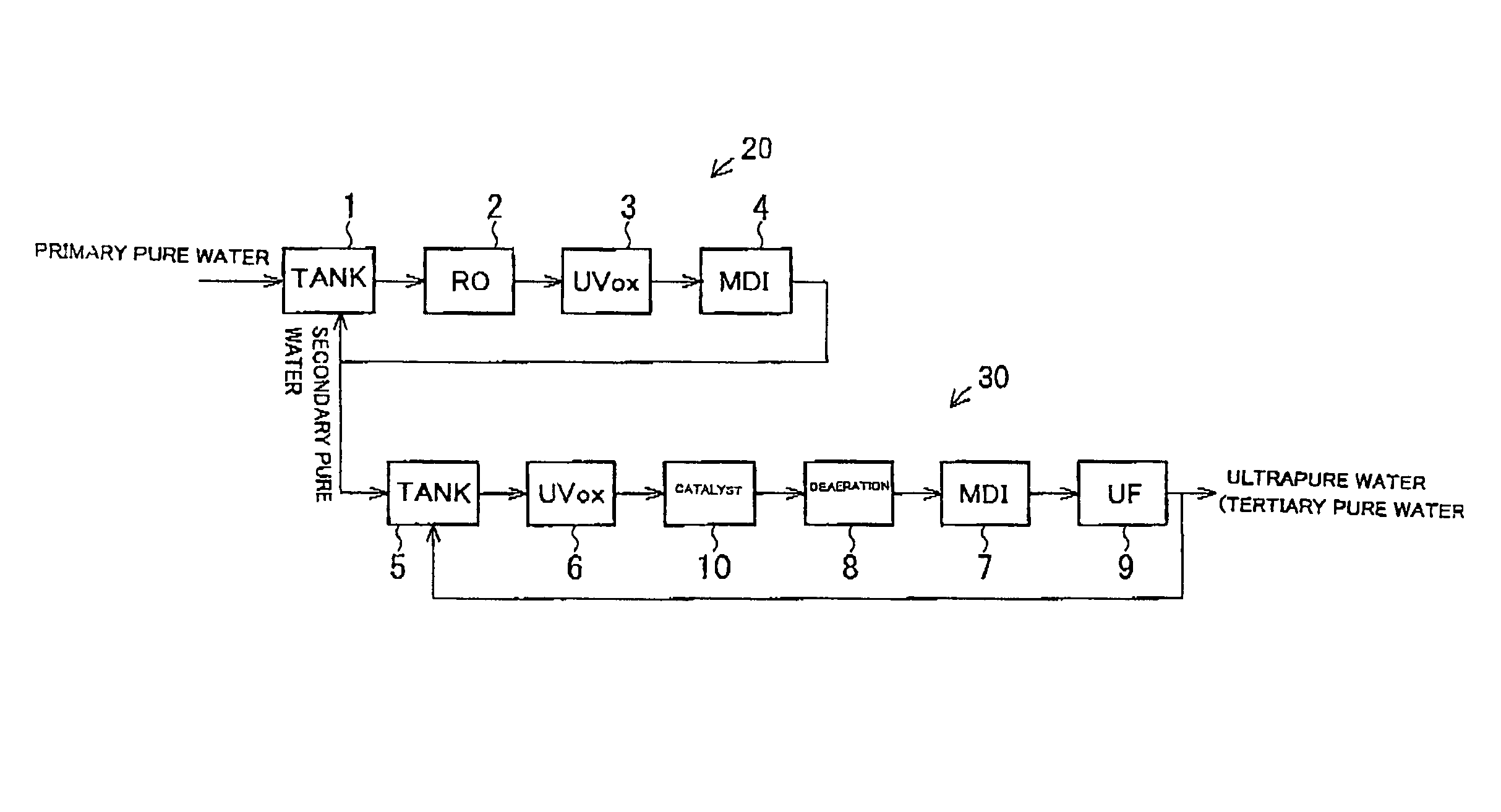

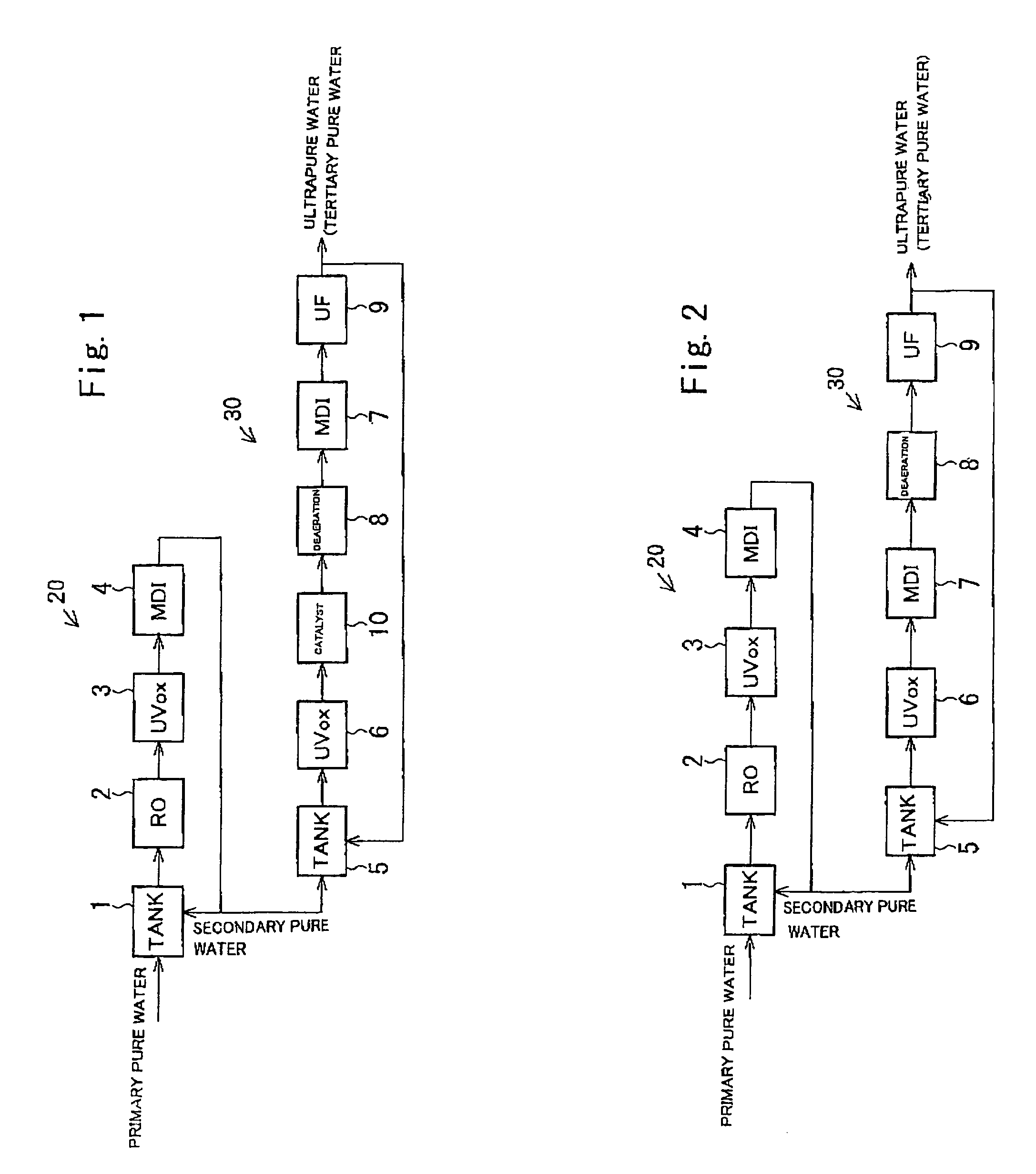

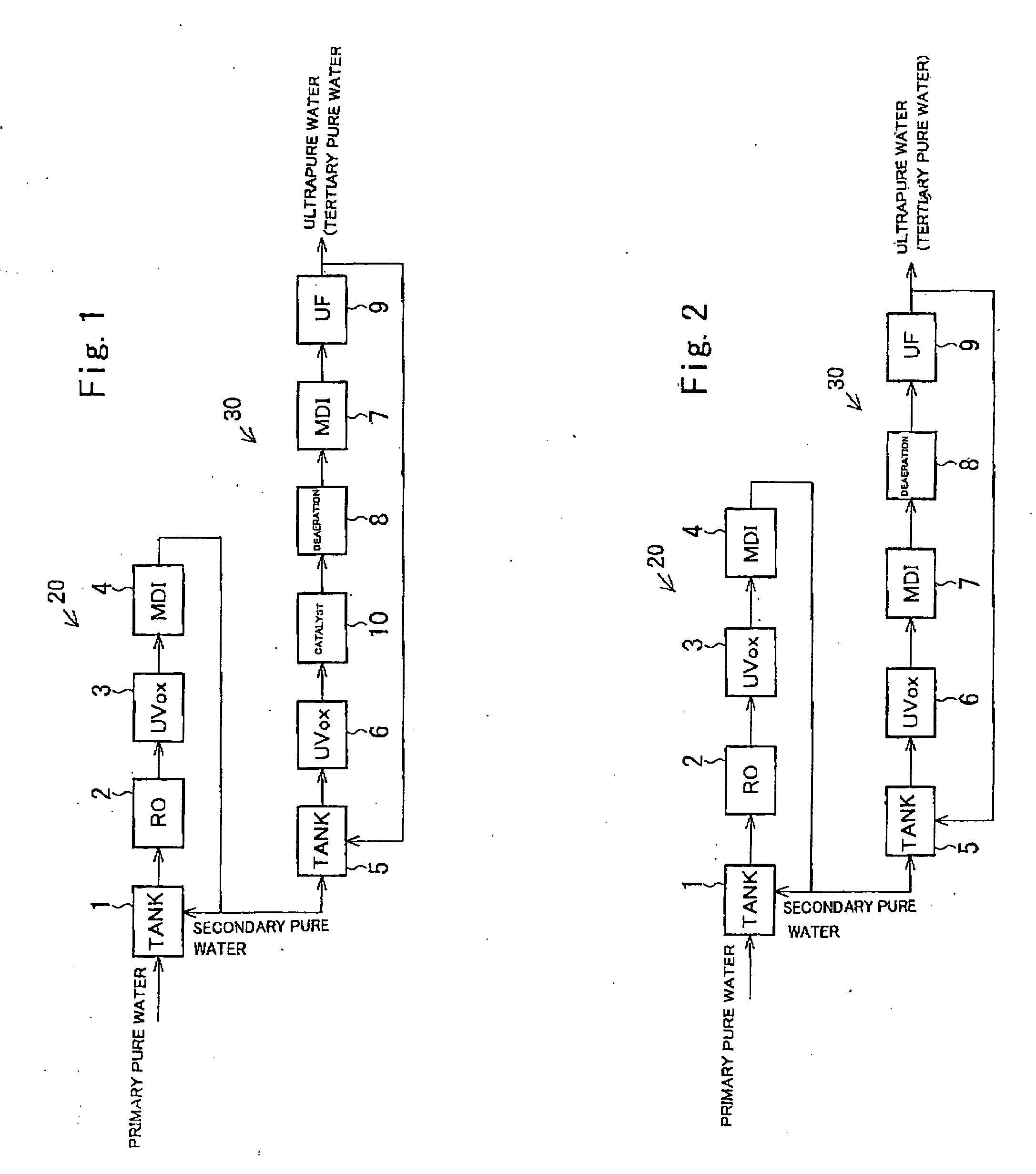

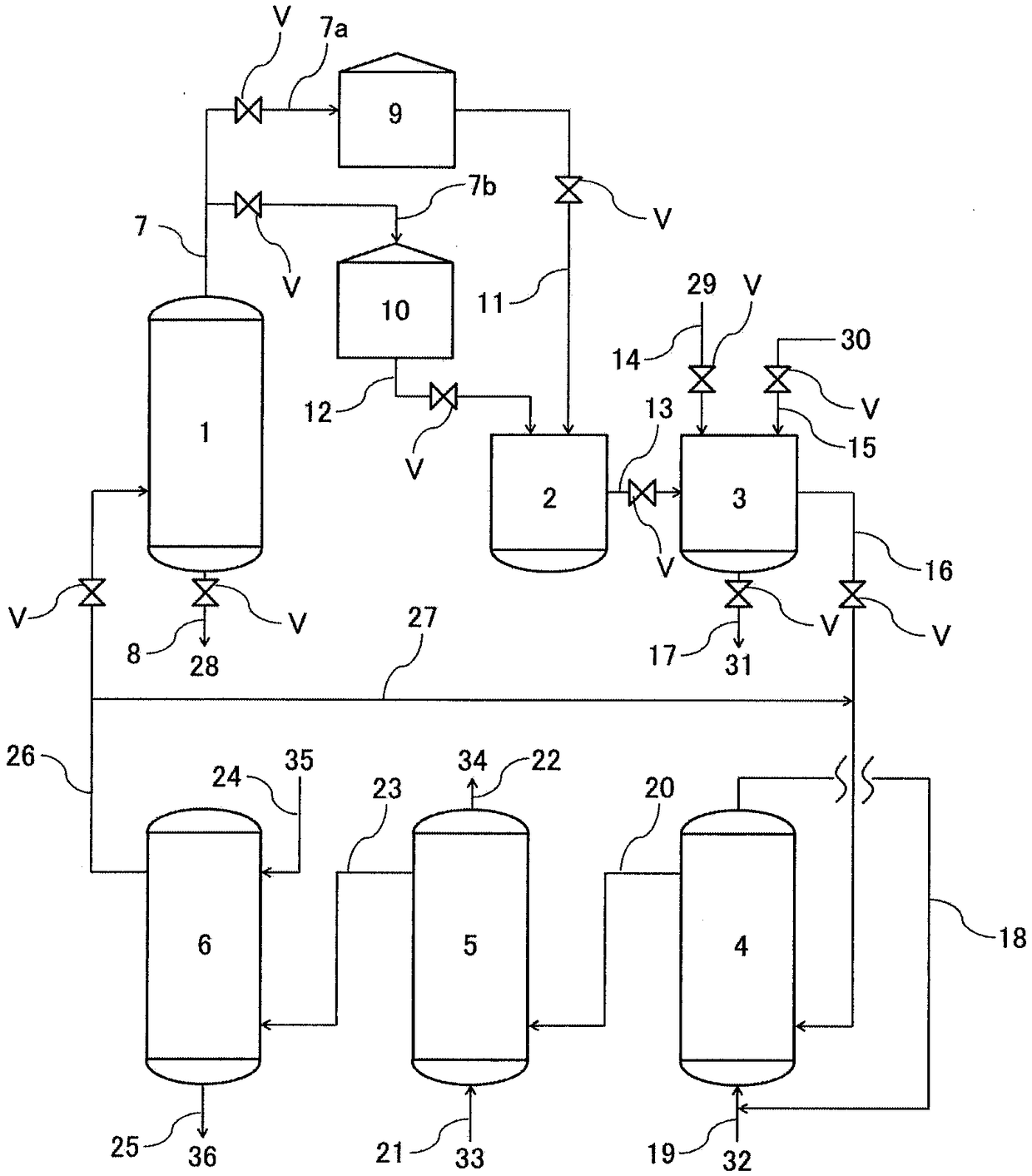

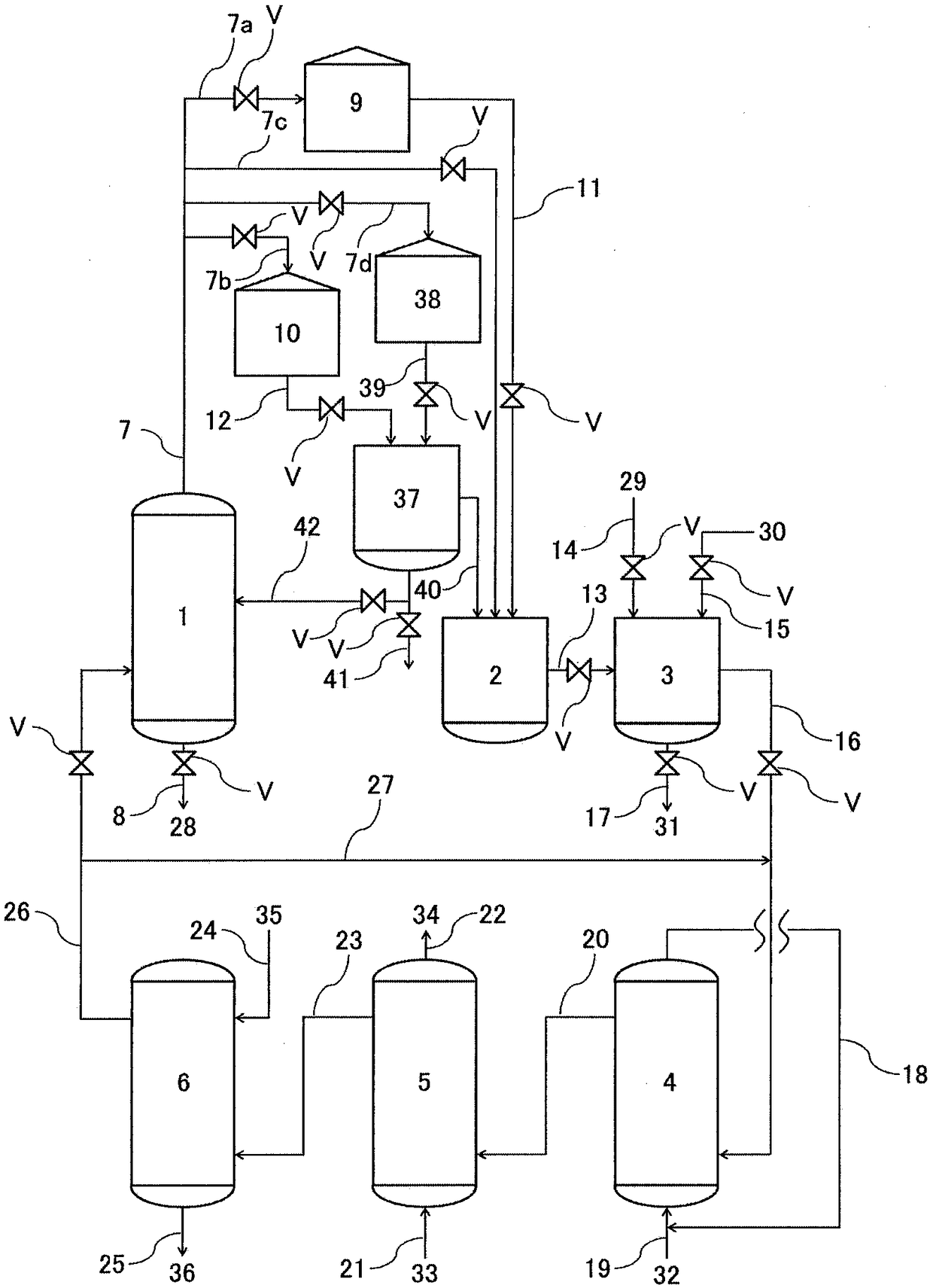

Pure water manufacturing method and pure water manufacturing apparatus

ActiveUS8480906B2Generation of hydrogen is minimizedMinimizationWater treatment parameter controlWater/sewage treatment by irradiationHydrogenUltraviolet

In production of ultrapure water by purifying primary pure water with a secondary pure water manufacturing apparatus and a tertiary pure water manufacturing apparatus, high-purity ultrapure water is produced, wherein generation of hydrogen peroxide is minimized and the concentrations of TOC, DO, and hydrogen peroxide are reduced to the limit. In an ultrapure water manufacturing system, each of the secondary pure water manufacturing apparatus and the tertiary pure water manufacturing apparatus includes an ultraviolet oxidation device and a deionization device, downstream therefrom, by using an ion exchange resin. UV light control is performed in such a way that the hydrogen peroxide concentration results in 1 to 30 μg / L and the TOC concentration results in 1 to 10 μg / L at the outlet of the ultraviolet oxidation apparatus of the secondary pure water manufacturing apparatus and, in addition, the TOC concentration results in 0.1 to 5 μg / L at the outlet of the ultraviolet oxidation apparatus of the tertiary pure water manufacturing apparatus. UV light control is performed in such a way that the TOC concentration results in 1 to 10 μg / L at the outlet of the ultraviolet oxidation apparatus of the secondary pure water manufacturing apparatus and, in addition, the hydrogen peroxide concentration results in 1 to 20 μg / L and the TOC concentration results in 0.1 to 5 μg / L at the outlet of the ultraviolet oxidation apparatus of the tertiary pure water manufacturing apparatus.

Owner:KURITA WATER INDUSTRIES LTD

Preparation method and application of novel gas diffusion electrode

InactiveCN108085714ALow costImprove catalytic performancePulp bleachingElectrode shape/formsCatalytic effectOxidation reduction

The invention belongs to the technical field of electrochemical oxygen cathode reducing system pulp bleaching, and relates to the technology of hydrogen peroxide generation through electrochemical catalysis oxygen cathode reducing, in particular to a preparation method and application of a novel gas diffusion electrode. The method specifically includes the steps of treating a stainless steel wiremesh, preparing novel graphite / teflon paste and manufacturing the gas diffusion electrode. According to the preparation method and application of the novel gas diffusion electrode, zirconium oxide andgraphite are matched for use, and cost can be greatly reduced; furthermore, the catalytic effect is good, the zirconium oxide has an oxidation-reduction character, oxygen can be supplied in a reducing atmosphere, and oxygen consumption can happen in an oxidizing atmosphere; and moreover, metallic oxide is doped into powdered graphite to manufacture an electrode material, stripping cannot occur easily, and the practical and promotional value is made better.

Owner:QILU UNIV OF TECH

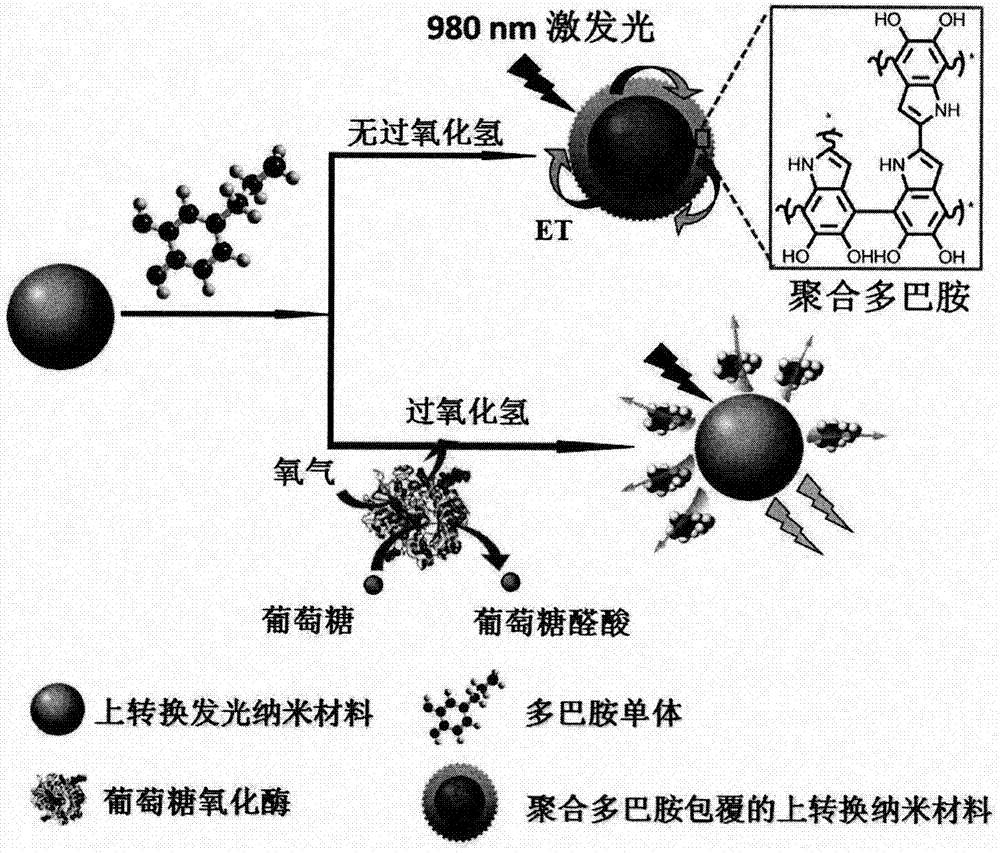

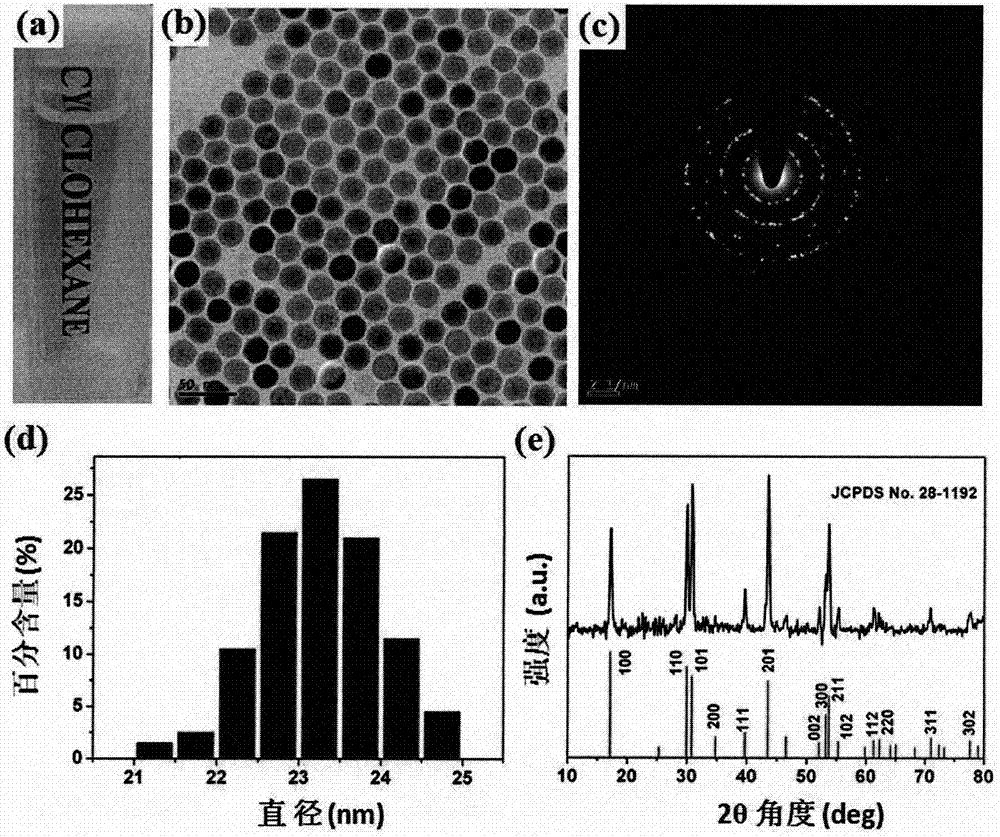

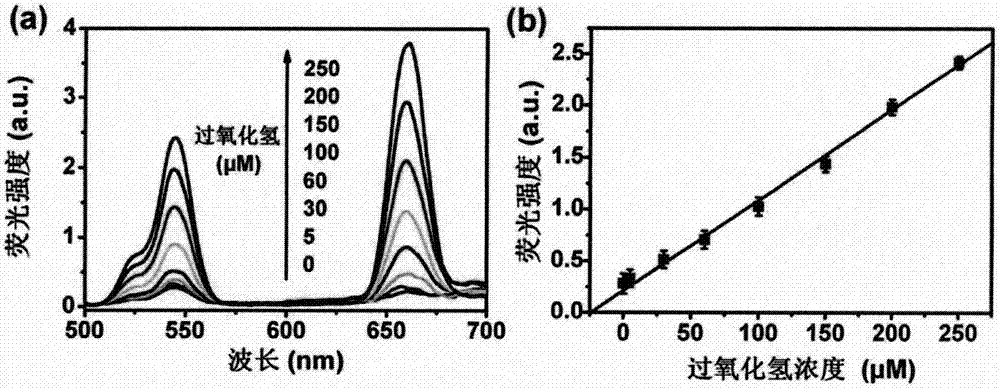

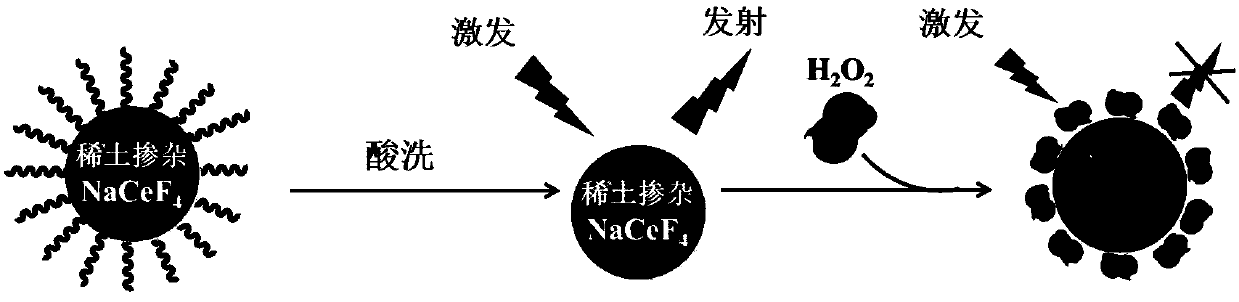

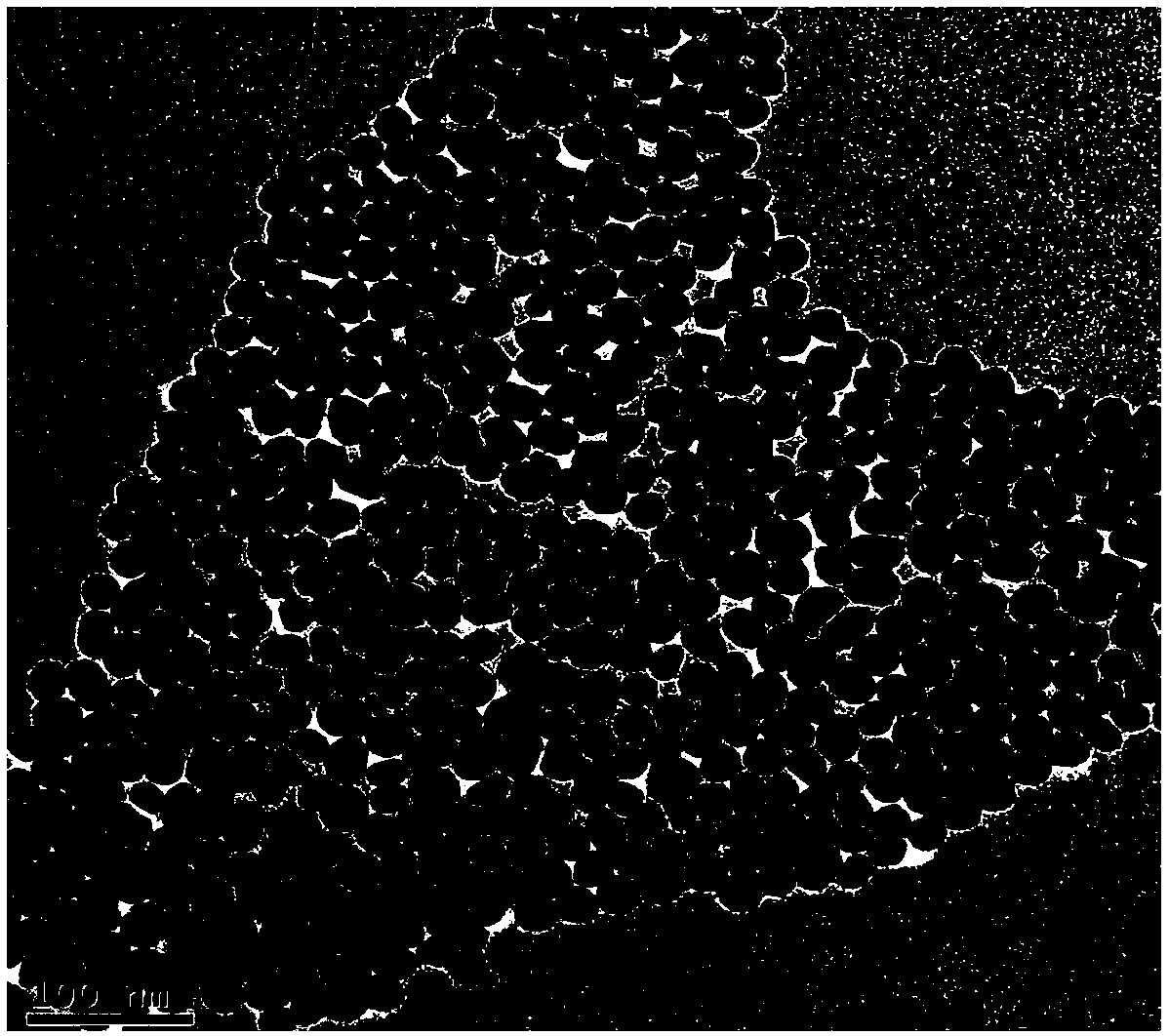

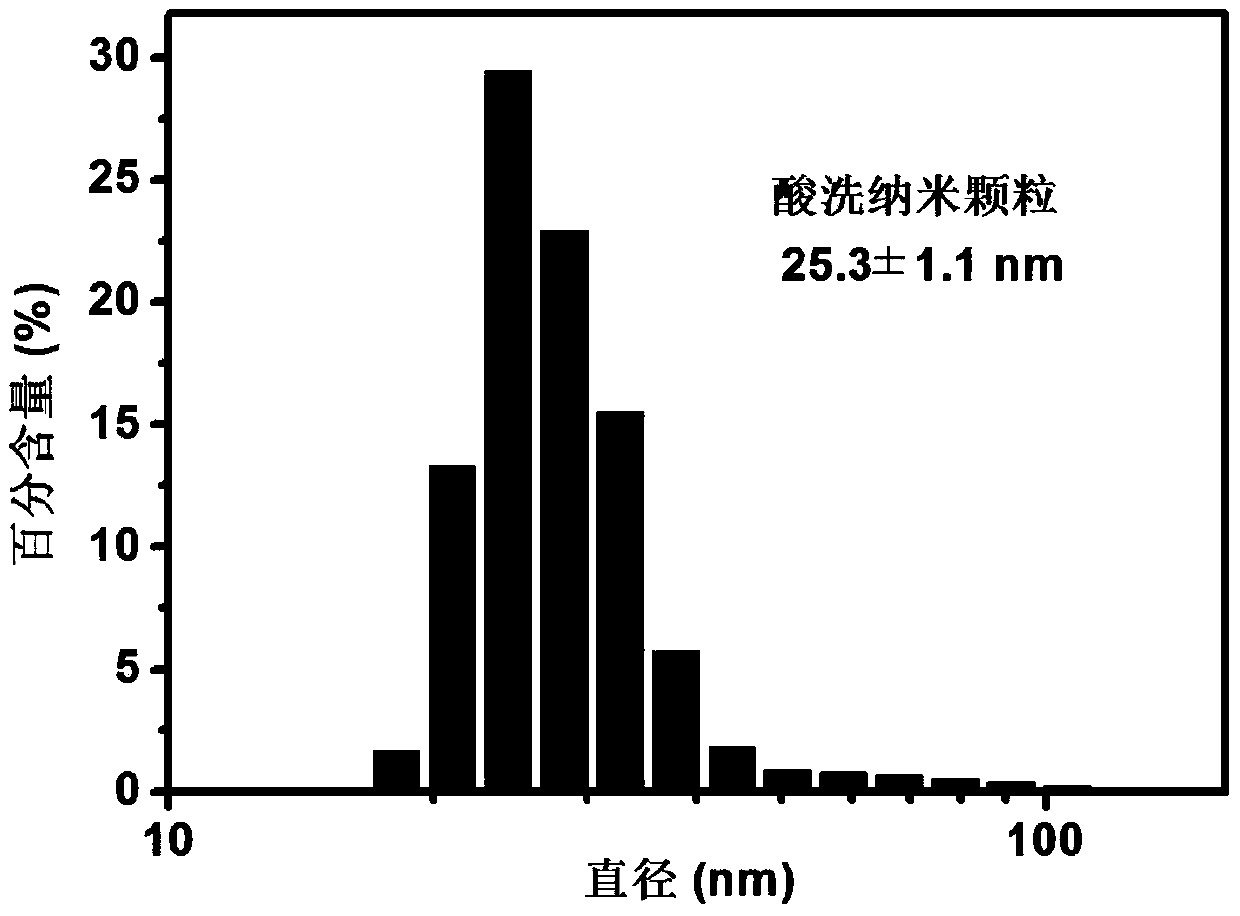

Upconversion fluorescence resonance energy transfer detection composition and detection method based on dopamine polymerization reaction regulation

ActiveCN107402198AShorten the energy transfer distanceRealize detectionFluorescence/phosphorescenceComplex systemQuenching

The invention discloses upconversion fluorescence resonance energy transfer detection composition and a detection method. An upconversion fluorescence nanomaterial without oleic acid ligand is adopted as a fluorescence donor in the method, the energy transfer distance between the fluorescence donor and a fluorescence receptor is effectively shortened, the quenching capacity is excellent, and the detection sensitivity can be effectively improved. Besides, the adopted upconversion fluorescence resonance energy transfer system can effectively avoid interference of background fluorescence in a complex biological system, can be used for detecting hydrogen peroxide or hydrogen peroxide generation system related substances, can also be used for further detecting hydrogen peroxide or hydrogen peroxide generation system related substances in serum or whole blood samples, has the advantages of being convenient to operate, good in anti-interference performance, rapid, sensitive, economical, practical and the like, can provide theoretical basis and technological support for real-time monitoring of hydrogen peroxide and glucose in complex systems and has certain clinical application potentials.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Composition Comprising A Coupled Enzyme System

InactiveUS20090142281A1Beneficial teeth bleachingGood whitening effectAntibacterial agentsPeptide/protein ingredientsCouplingEnzyme system

The present invention relates to a composition comprising a coupled enzyme system for the rapid and efficient production of hydrogen peroxide by the coupling of a first enzyme system capable of hydrogen peroxide generation, to a second enzyme system which utilizes the non hydrogen peroxide product of the first enzyme system, and optionally is capable of generating further hydrogen peroxide.

Owner:DUPONT NUTRITION BIOSCIENCES APS

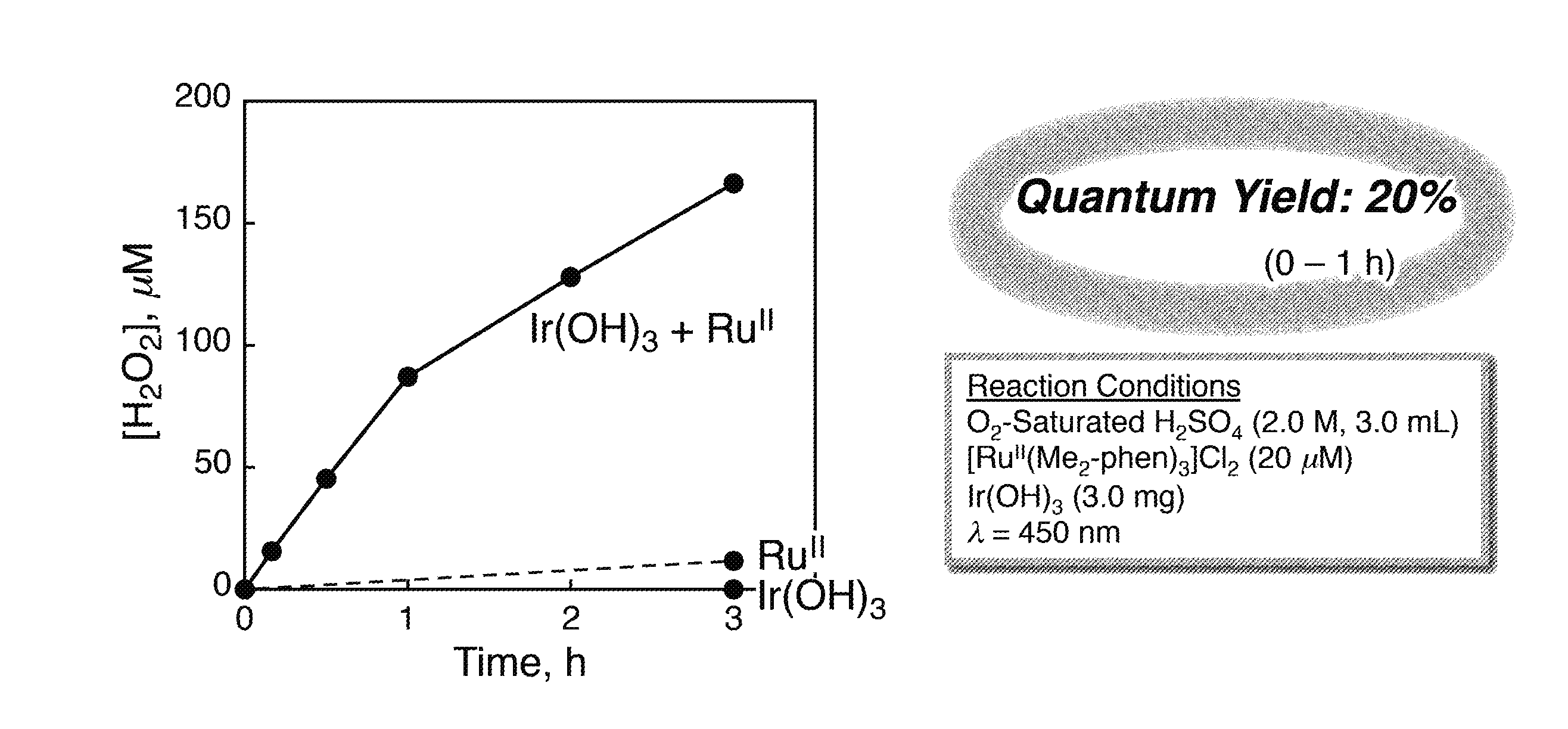

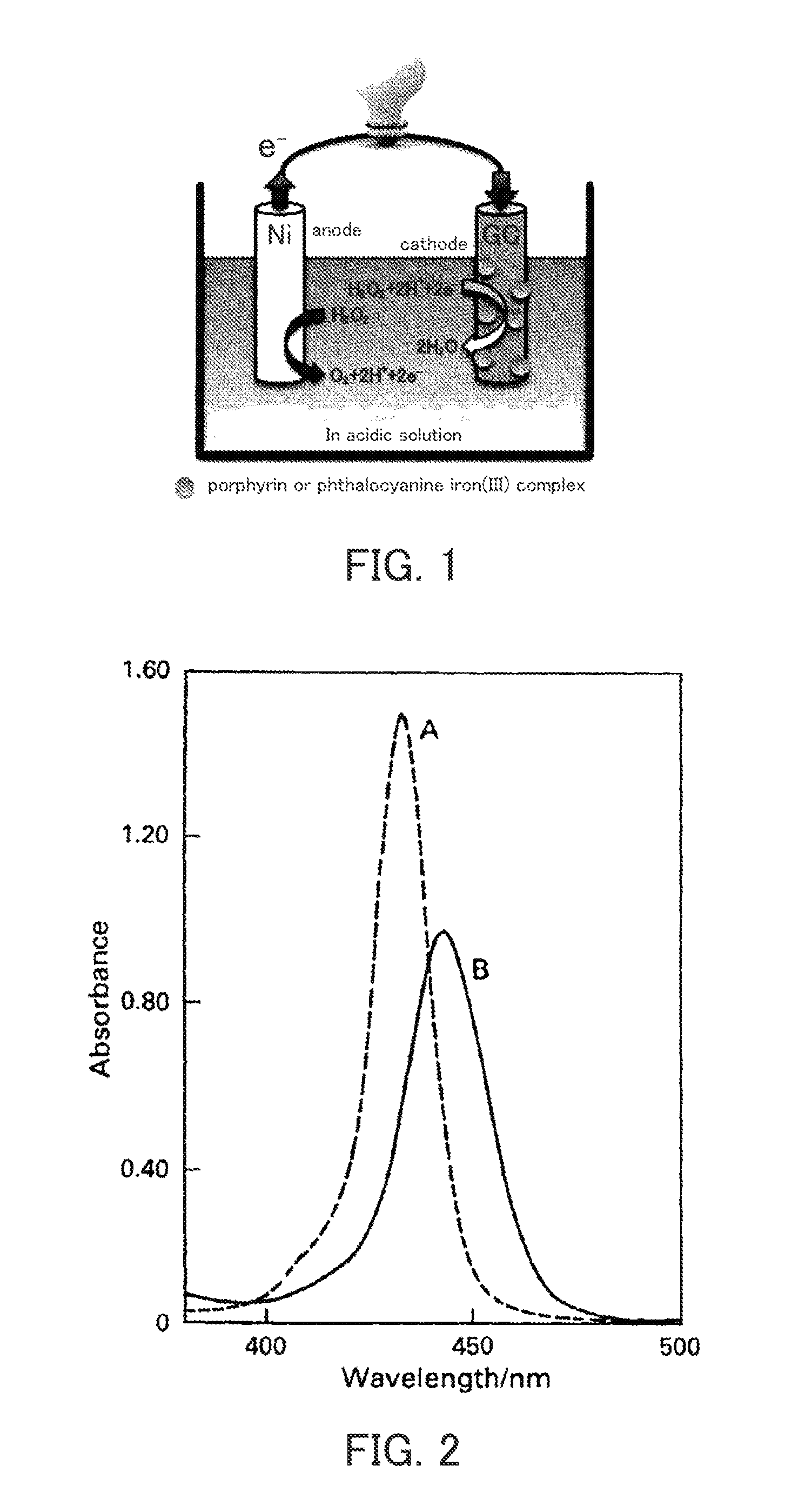

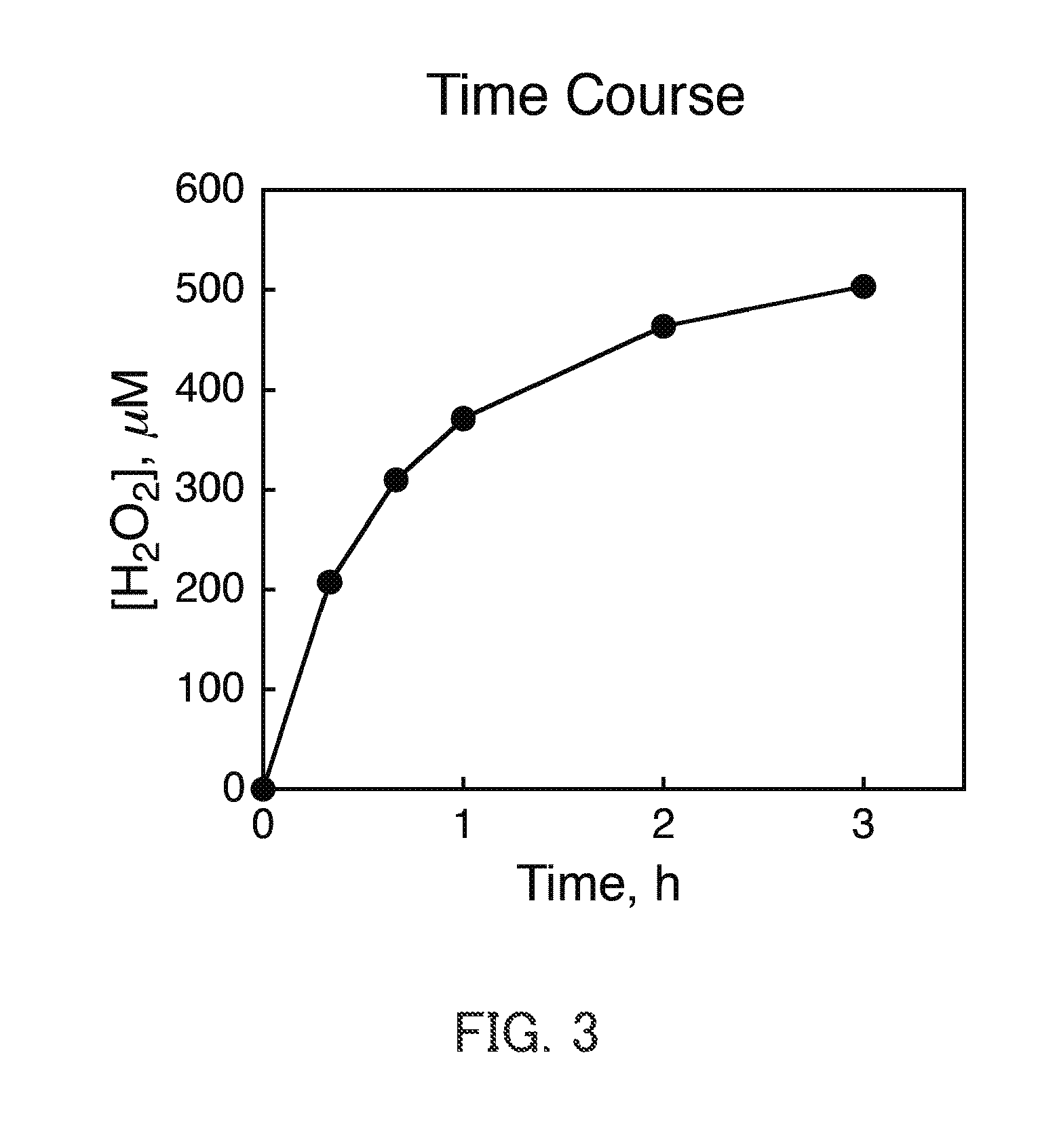

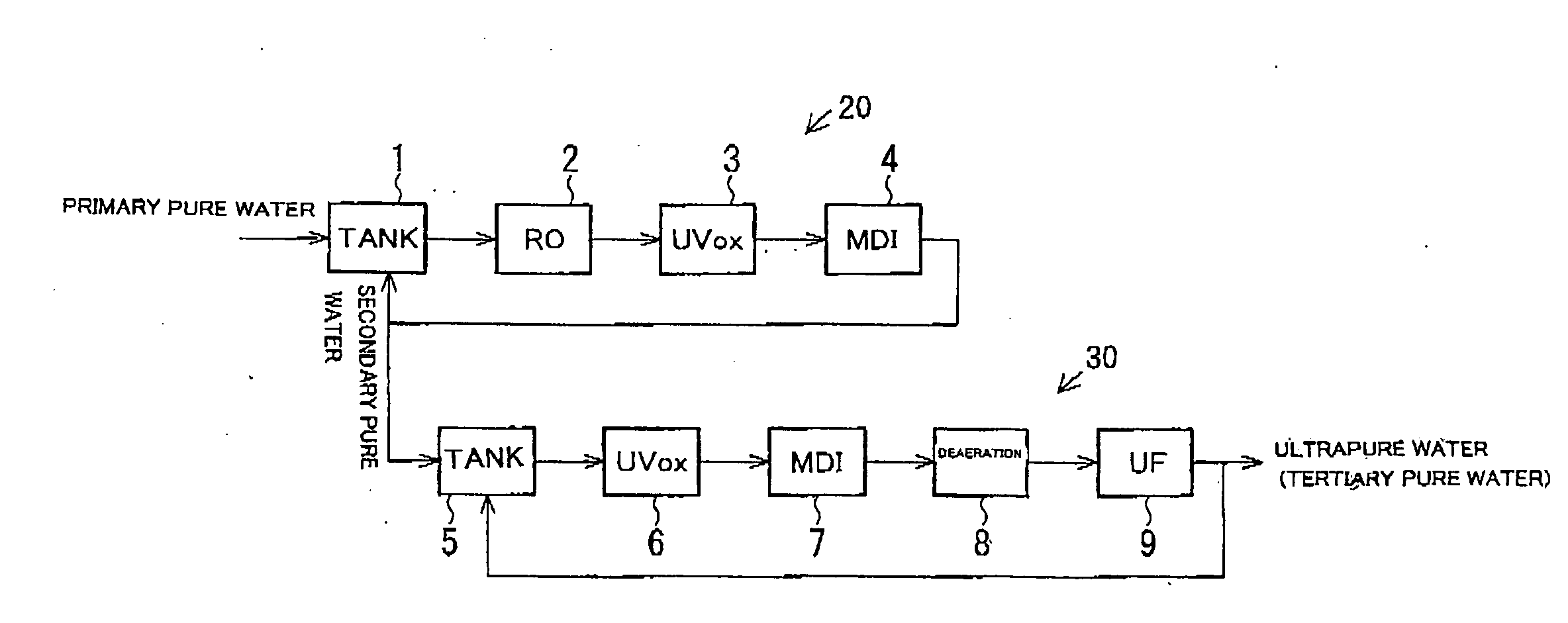

Method for producing hydrogen peroxide, kit for producing hydrogen peroxide, and fuel battery

InactiveUS20140141346A1Low costLow cost productionOxygen/ozone/oxide/hydroxidePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesFuel cellsOxygen

The present invention provides a method and a kit for producing hydrogen peroxide, capable of producing hydrogen peroxide at low cost. The present invention further provides a fuel battery capable of utilizing hydrogen peroxide as a low-cost fuel. The method for producing hydrogen peroxide of the present invention includes a hydrogen peroxide generation step of irradiating a reaction system containing water, a water oxidation catalyst, a transition metal complex, and oxygen (O2) with light to generate hydrogen peroxide. The kit of the present invention includes the transition metal complex and the water oxidation catalyst that are used in the method for producing hydrogen peroxide of the present invention. The fuel battery of the present invention includes a fuel container and a fuel battery cell, and the fuel container contains the transition metal complex and the water oxidation catalyst that are used in the method for producing hydrogen peroxide of the present invention.

Owner:OSAKA UNIV

Pure Water Manufacturing Method And Pure Water Manufacturing Apparatus

ActiveUS20110210072A1Reduce adverse effectsReduce concentrationWater treatment parameter controlWater/sewage treatment by irradiationHydrogenUltraviolet

In production of ultrapure water by purifying primary pure water with a secondary pure water manufacturing apparatus and a tertiary pure water manufacturing apparatus, high-purity ultrapure water is produced, wherein generation of hydrogen peroxide is minimized and the concentrations of TOC, DO, and hydrogen peroxide are reduced to the limit. In an ultrapure water manufacturing system, each of the secondary pure water manufacturing apparatus and the tertiary pure water manufacturing apparatus includes an ultraviolet oxidation device and a deionization device, downstream therefrom, by using an ion exchange resin. UV light control is performed in such a way that the hydrogen peroxide concentration results in 1 to 30 μg / L and the TOC concentration results in 1 to 10 μg / L at the outlet of the ultraviolet oxidation apparatus of the secondary pure water manufacturing apparatus and, in addition, the TOC concentration results in 0.1 to 5 μg / L at the outlet of the ultraviolet oxidation apparatus of the tertiary pure water manufacturing apparatus. UV light control is performed in such a way that the TOC concentration results in 1 to 10 μg / L at the outlet of the ultraviolet oxidation apparatus of the secondary pure water manufacturing apparatus and, in addition, the hydrogen peroxide concentration results in 1 to 20 μg / L and the TOC concentration results in 0.1 to 5 μg / L at the outlet of the ultraviolet oxidation apparatus of the tertiary pure water manufacturing apparatus.

Owner:KURITA WATER INDUSTRIES LTD

Method for detecting hydrogen peroxide and relevant target object on the basis of nanoprobe

ActiveCN110411990AAccurate determination of concentrationEasy to operateFluorescence/phosphorescenceOxidation reductionUric acid

The invention belongs to the technical field of biological detection, and discloses a method for detecting a hydrogen peroxide and a relevant target object on the basis of a nanoprobe. The method adopts a water-soluble rare earth doped NaCeF4 nanomaterial as a fluorescence probe, rare earth ion luminescence is quenched through the oxidation-reduction reaction of the hydrogen peroxide and a ceriumion, and the change of doped rare earth ion fluorescence intensity is used for realizing the detection of hydrogen peroxide concentration. The method can be used for detecting the hydrogen peroxide instandard solution or reactants in an enzymatic reaction for generating the hydrogen peroxide, and the detection of the hydrogen peroxide, biological enzymes or zymolyte (such as uric acid) in serumscan be realized. The method has the advantages of being convenient in operation, good in anti-interference performance, quick, sensitive, economic, practical and the like, a theoretical foundation andtechnical support are provided for solving the real-time detection of the relevant substances of uric acid and hydrogen peroxide generation systems in a complex system, and the method has certain clinic application potential.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

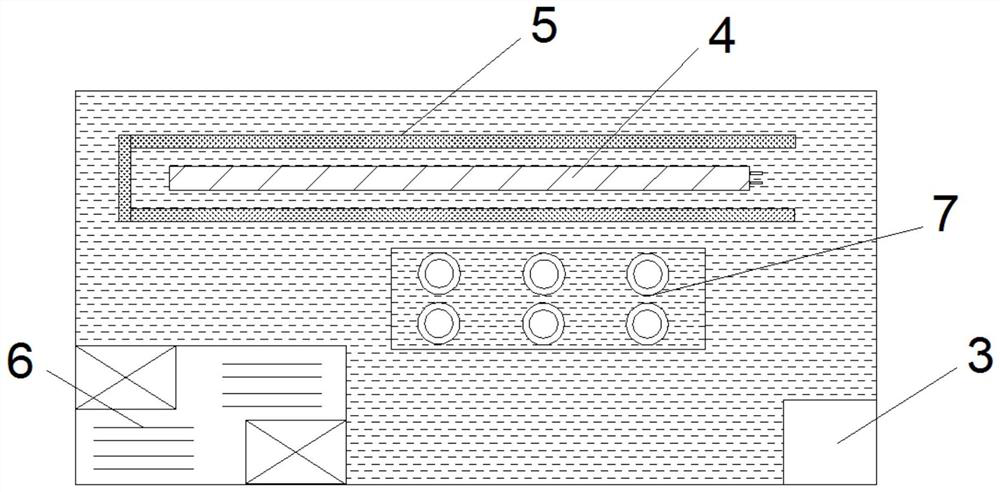

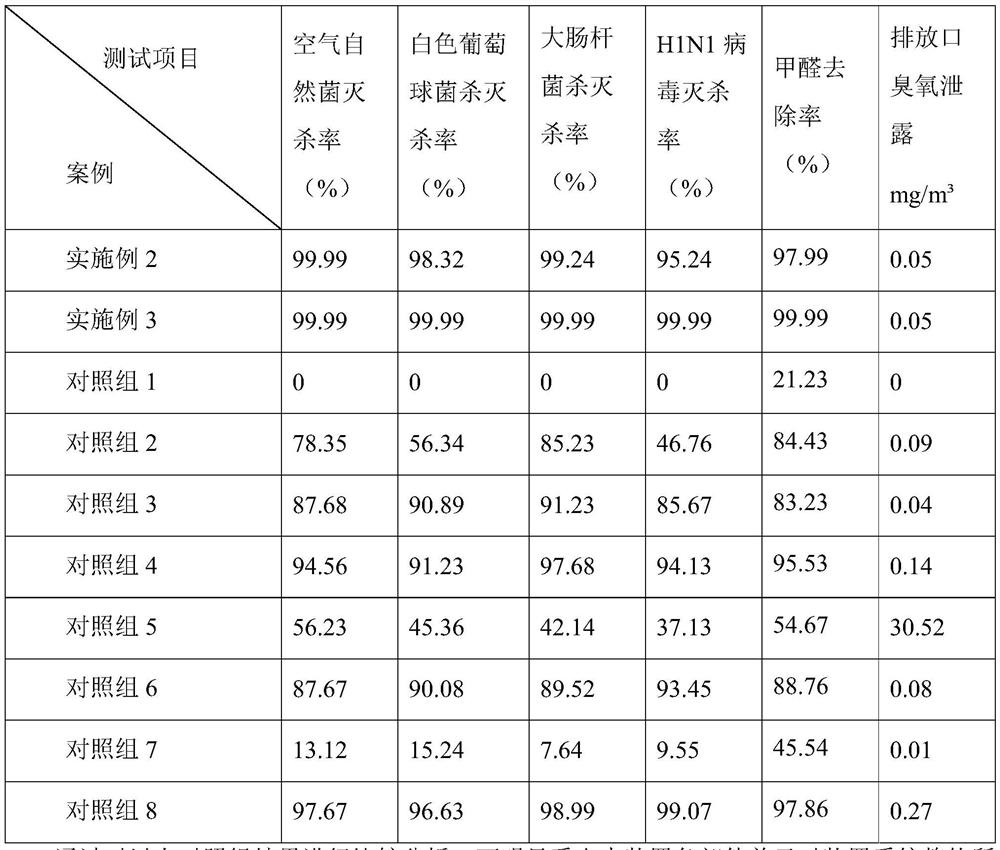

Device and method for air aerosol disinfection and organic gas degradation

PendingCN111829099AEfficient degradationImprove reaction efficiencyLighting and heating apparatusDispersed particle separationAir decontaminationUltraviolet lights

The invention discloses a device and a method for air aerosol disinfection and organic gas degradation, and belongs to the technical field of air purification. A first mesh clapboard and a second meshclapboard divide the inside of a box body into an atomization bin, a reaction bin and a mixing bin; the box body is provided with an air inlet and an air outlet; an internal fan is arranged in the mixing bin; a hydrogen peroxide generation device is used for providing hydrogen peroxide for a water pool; an ultrasonic atomizer is arranged in the water pool; the ultrasonic atomizer is used for atomizing water and hydrogen peroxide in the water pool, and mixing the atomized water and hydrogen peroxide with the air to form atomized air; an ozone generator is used for generating ozone, and cooperating with a ultraviolet light lamp tube and a photocatalysis mesh plate to make the ozone and the atomized air flowing through the reaction bin perform mixed reaction so as to form reaction air; and the reaction air passes through the mixing bin and then is exhausted from the air outlet. The device and the method for air aerosol disinfection and organic gas degradation, provided by the invention,can effectively perform air aerosol disinfection and organic gas degradation, have high reaction efficiency, perform purification sufficiently, and are safe and reliable.

Owner:CHENGDU SCI & TECH DEV CENT CHINA ACAD OF ENG PHYSICS

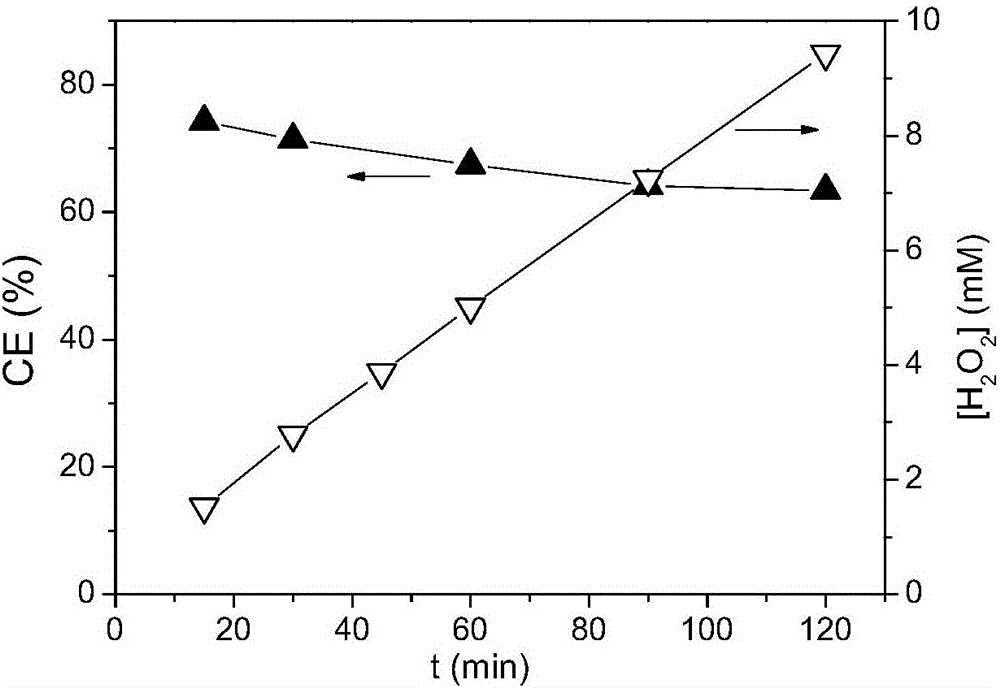

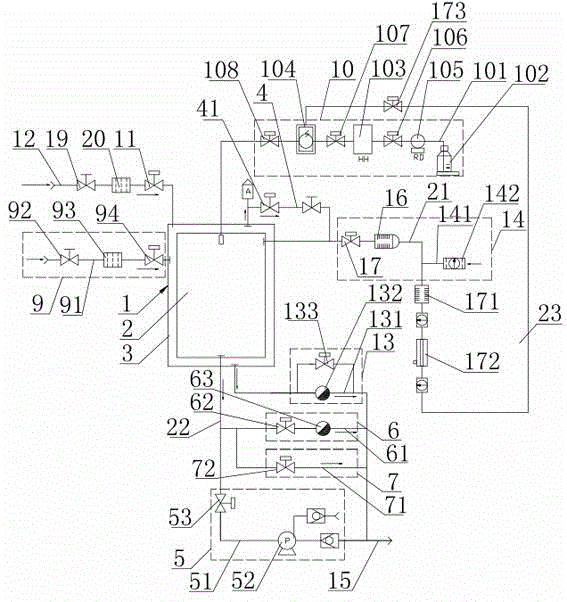

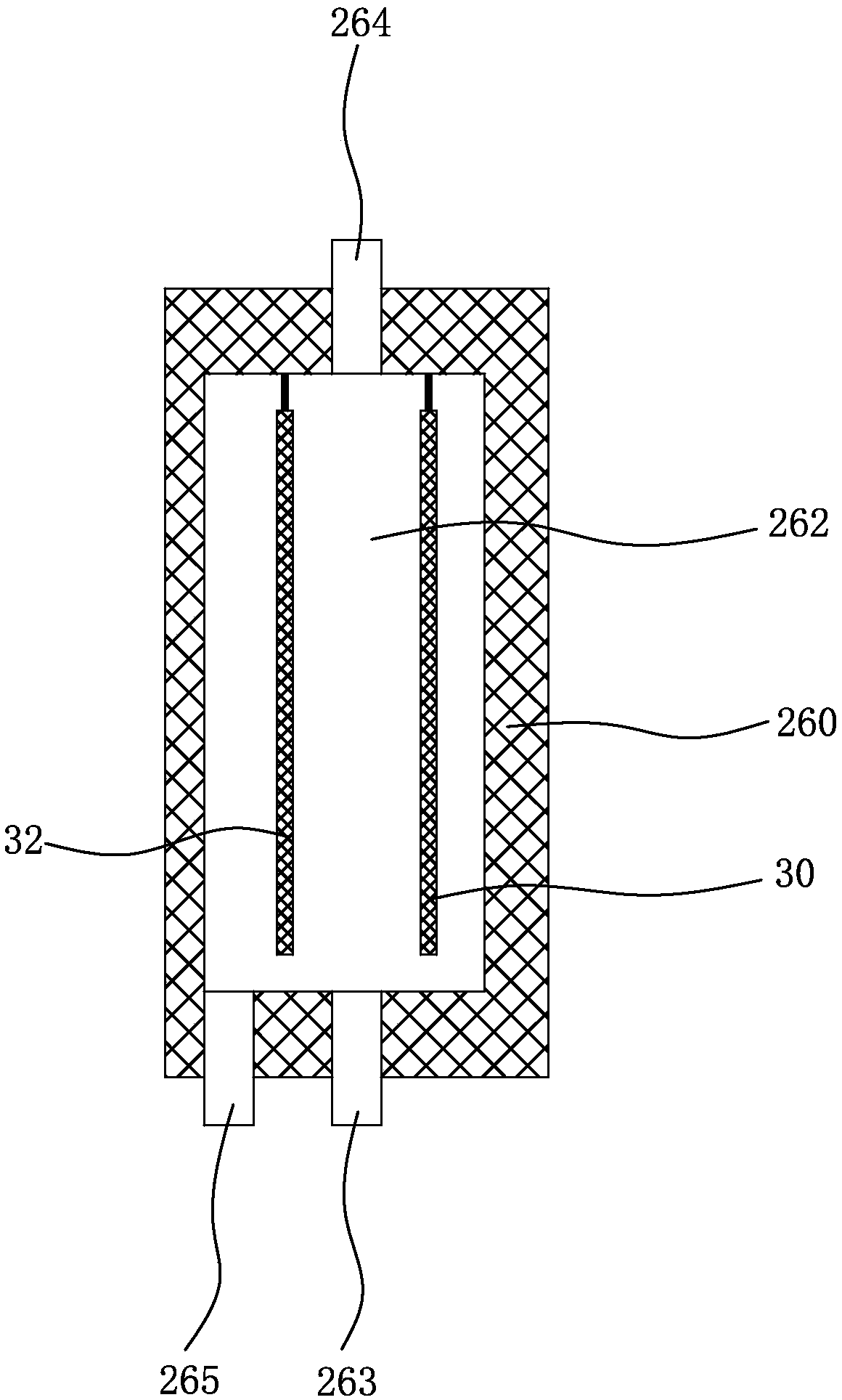

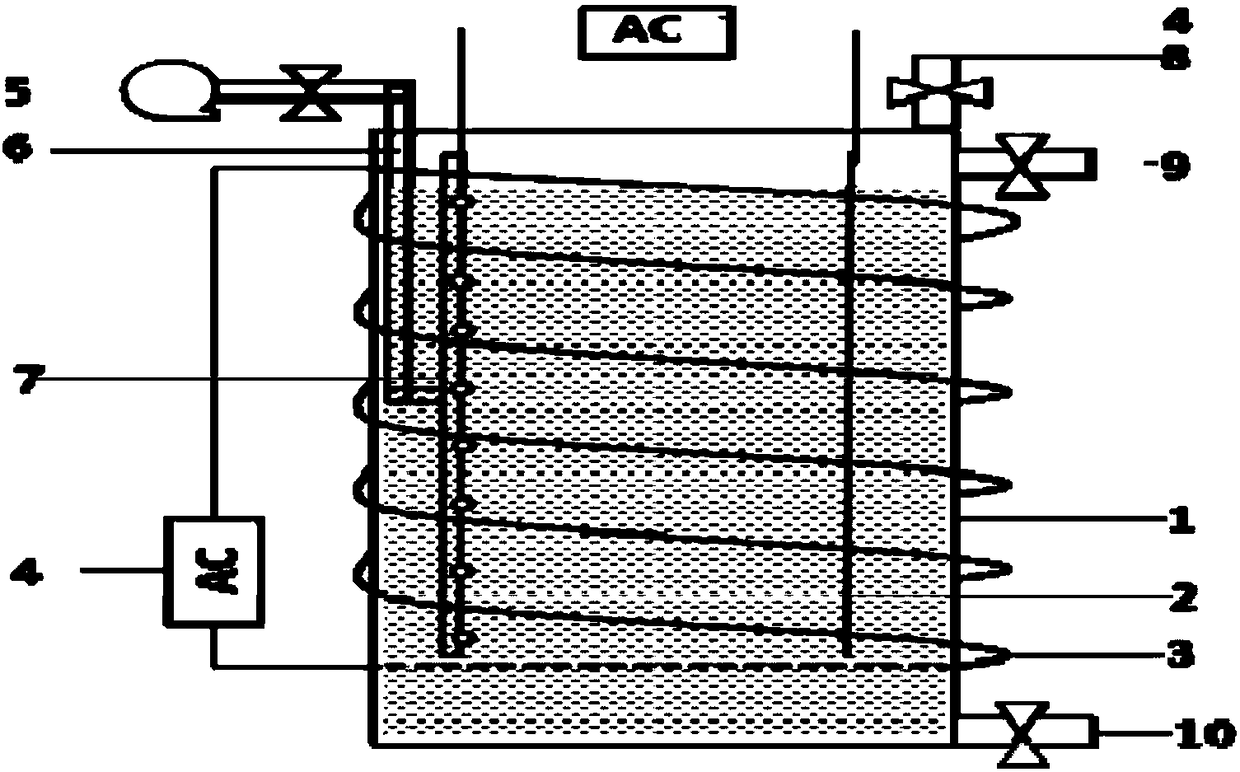

Electro-Fenton reactor and reaction method for treating organic wastewater

InactiveCN106219684AImprove processing efficiencyGuaranteed tightnessWater treatment compoundsWater/sewage treatment by electrochemical methodsFenton reactionWastewater

The invention discloses an electro-Fenton reactor and reaction method for treating organic wastewater. The electro-Fenton reactor comprises an anode, a diaphragm, a three-dimensional cathode and a cathode collector plate, which are assembled by bolts to form the plate-and-frame electro-Fenton reactor. When the electro-Fenton reaction method is used for treating organic wastewater, the organic wastewater and oxygen-containing gas are introduced into a three-dimensional-cathode-filled cathode frame; and after a direct current is introduced between the electrodes, oxygen at the cathode is reduced to generate hydrogen peroxide, and the hydrogen peroxide and external ferrous ions or ferrous ions generated by the anode are subjected to Fenton reaction under acidic conditions to generate strong-oxidizing-property hydroxy free radicals which are used for oxidative degradation of organic pollutants. The electro-Fenton reactor and reaction method have the advantages of high hydrogen peroxide generation efficiency and high organic wastewater treatment efficiency, and can easily implement scale-up production.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

High-temperature and low-temperature sterilization cabinet

The invention discloses a high-temperature and low-temperature sterilization cabinet which comprises a cabinet body, wherein an inner cavity of the cabinet body serves as a sterilization chamber; the cabinet body adopts a jacket-type structure; a steam input mechanism and a jacket-layer water draining mechanism are communicated with a jacket layer respectively; a steam communication pipe provided with a control valve is communicated between the jacket layer and the sterilization chamber; a vacuuming mechanism, an inner cavity draining mechanism, an inner cavity exhausting mechanism and an air replenishment mechanism are communicated with the sterilization chamber respectively; the sterilization chamber is further communicated with a hydrogen peroxide generation mechanism; the jacket layer is further communicated with a refrigerant input pipe provided with a first control valve; the refrigerant input pipe is communicated with a refrigerant source. According to the high-temperature and low-temperature sterilization cabinet, the sterilization chamber can be used for high-temperature sterilization and also can be switched to be used for low-temperature sterilization; the high-temperature and low-temperature sterilization cabinet has the advantages that temperature in the sterilization chamber can be quickly reduced to meet low-temperature sterilization requirements, so that a plurality of sterilization workshops only need to be configured with one sterilization cabinet, the equipment configuration cost is greatly reduced, and the occupied space of the sterilization workshops is greatly reduced.

Owner:ZHANGJIAGANG HUANYU PHARMA EQUIP

Assay method

InactiveUS20130337481A1Avoid the needPractical limitationMaterial analysis by observing effect on chemical indicatorMicrobiological testing/measurementOptical propertyPeroxidase

The invention provides an assay method for determining a level of haptoglobin in a sample comprising the steps of: (i) mixing haemoglobin with the sample to be assayed so as to form a haptoglobin-haemoglobin complex with haptoglobin present in the sample; (ii) contacting the product of step (i) with reagents for generating hydrogen peroxide and one or more chromogens which undergo a spectroscopically detectable change when peroxidase activity is present, in the presence of a buffer, under conditions in which hydrogen peroxide is generated from said reagents and forms a substrate for the peroxidise activity of the haptoglobin-haemoglobin complex present, and wherein the pH of the buffer is within a range which is sufficiently low that the peroxidise activity of any uncomplexed haemoglobin is substantially suppressed but sufficiently high that hydrogen peroxide generation occurs; (iii) determining the peroxidase activity of the haptoglobin-haemoglobin complex by measuring the change in an optical property of the reaction mixture; and (iv) correlating the level of peroxidise activity of the haptoglobin-haemoglobin complex with the amount of haptoglobin in the sample. A kit for use in such a method is also provided.

Owner:REACTIVLAB

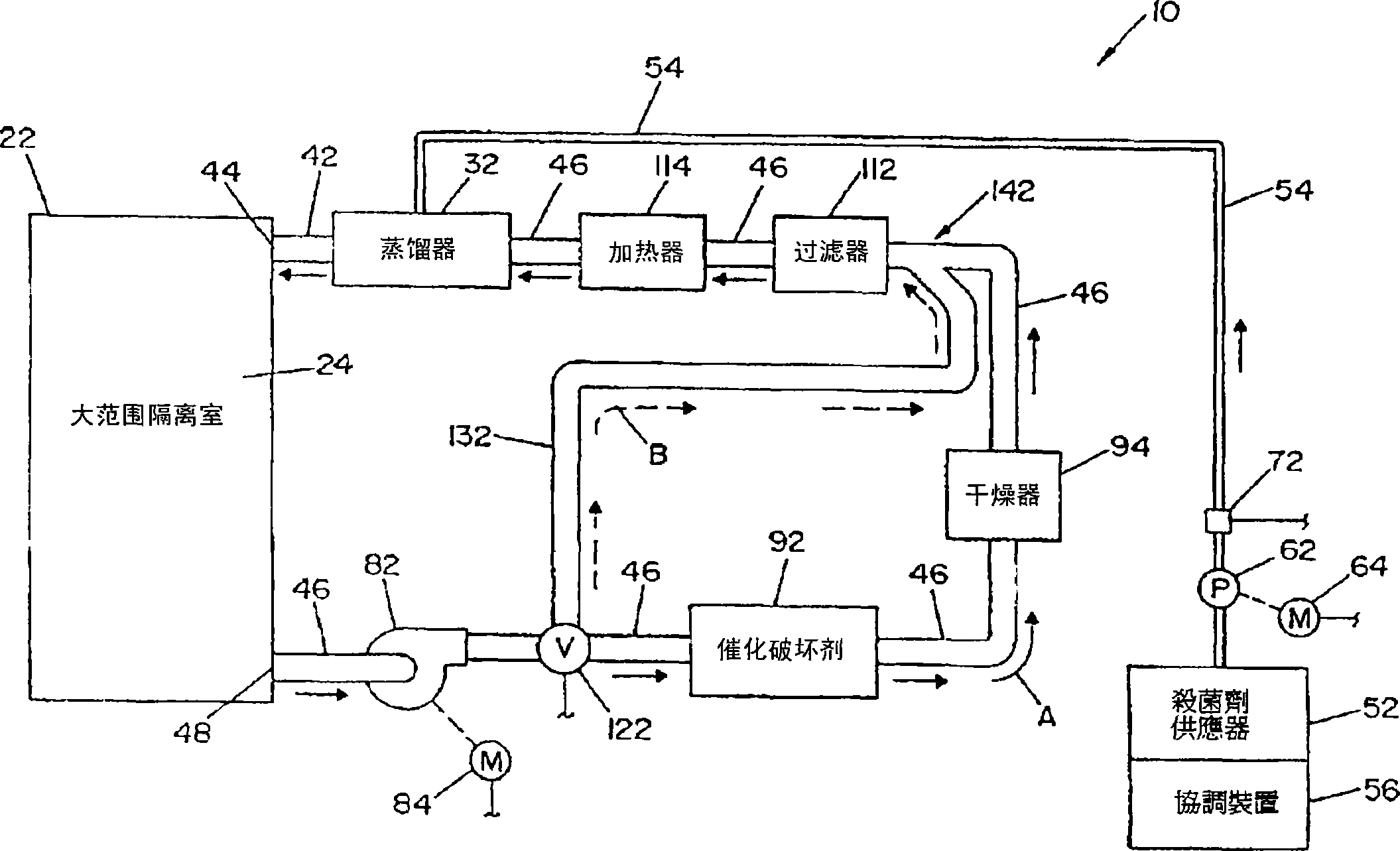

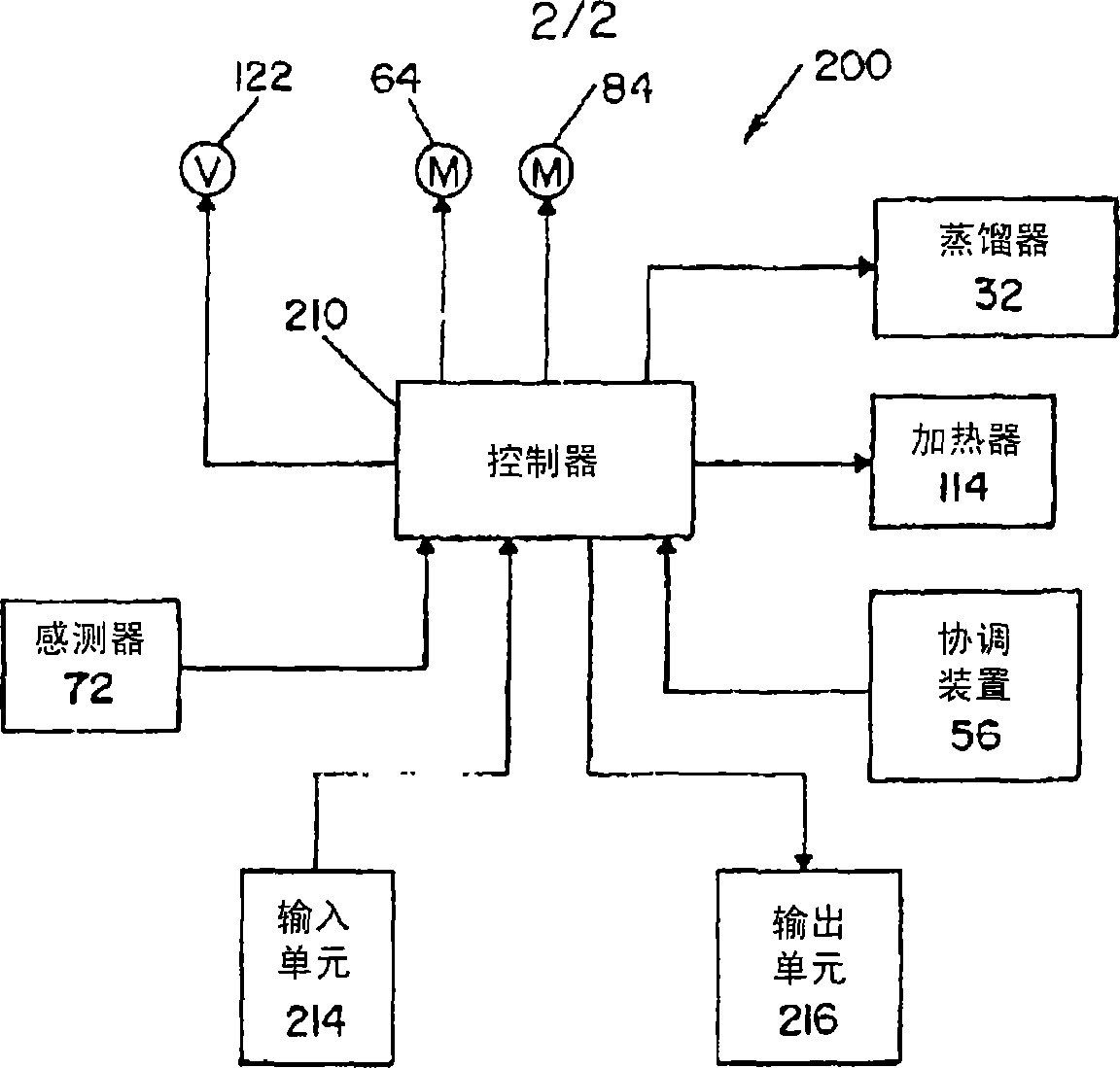

System and method for increasing concentration of sterilant in region

ActiveCN1859928AIncreased concentration of hydrogen peroxideShorten cycle timeLavatory sanitoryChemicalsClosed loopAqueous solution

A vapor decontamination system for decontaminating a defined region. The system is comprised of a chamber defining a region, and a generator for generating vaporized hydrogen peroxide from a solution of hydrogen peroxide and water. A closed loop circulating system is provided for supplying the vaporized hydrogen peroxide to the region. A destroyer within the closed loop circulating system breaks down the vaporized hydrogen peroxide. A bypass conduit is provided to bypass the destroyer. A controller causes vaporized hydrogen peroxide from the generator to bypass the destroyer during a predetermined phase of operation.

Owner:AMERICAN STERILIZER CO

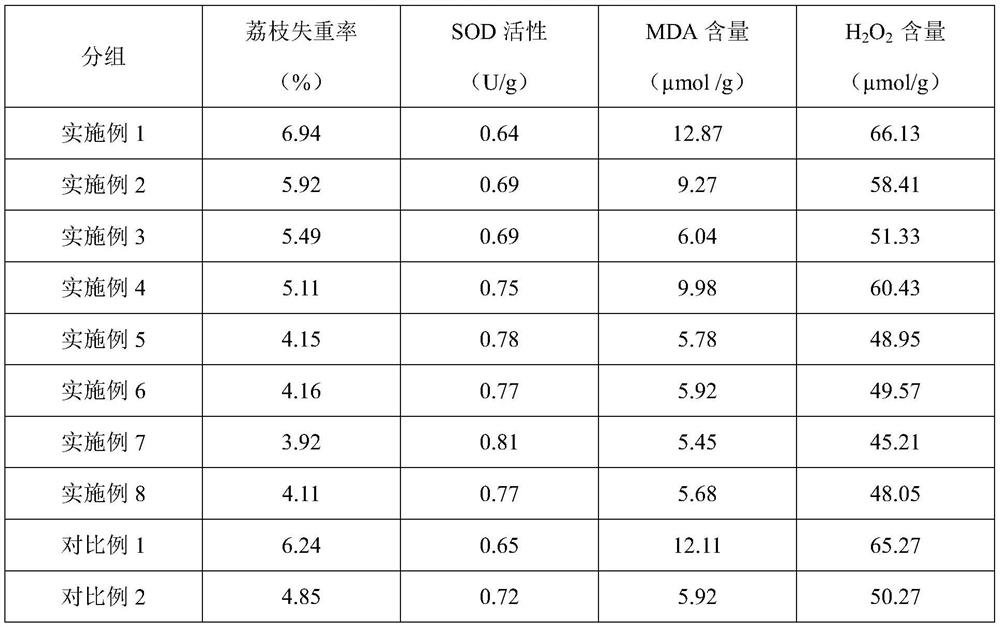

Litchi fresh-keeping method

InactiveCN113080252AAvoidance of aggressionNO content increasedFruits/vegetable preservation by heatingFruits/vegetable preservation by coatingBiotechnologySuperoxide dismutases

The invention discloses a litchi fresh-keeping method, and belongs to the technical field of storage and fresh-keeping of fruits and vegetables. The litchi fresh-keeping method comprises the following steps: soaking cleaned litchis in Sportak, then performing soaking in sodium nitroprusside, spraying a vegetable gum solution on the surfaces of the litchis, then carrying out heat treatment, and storing the litchis in a low-temperature closed environment. According to the fresh-keeping method, the low-temperature storage time of the litchis is prolonged to the maximum extent, loss of moisture of the litchis is reduced, generation of malonaldehyde and hydrogen peroxide in the litchis is reduced, the activity of superoxide dismutase in the litchis is improved, rotting and browning of the litchis are effectively prevented, the fresh-keeping effect is good, chemical substances such as sulfur are not contained, the preserved litchis are good in taste, green and environment-friendly, and the preservation process is simple and easy to popularize.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Domestic sterilizing device

ActiveCN109498825AImprove the bactericidal effectImprove sterilization efficiencyChemicalsElectrolysisEnvironmental engineering

The invention relates to the field of sterilizing devices, in particular to a domestic sterilizing device. The domestic sterilizing device comprises a sterilizing cylinder and a hydrogen peroxide generation system, wherein the sterilizing cylinder is further provided with a heating device which enables water in the sterilizing cylinder to be at a constant temperature; the hydrogen peroxide generation system comprises a water pump, an air pump and a plurality of electrolysis unit cells; each electrolysis unit cell comprises a shell provided with an electrolysis cavity; a cathode electrode and an anode electrode are distributed in each electrolysis cavity; the shell is further provided with a water inlet communicating with the electrolysis cavities, a water outlet and an aeration opening; water in the sterilizing cylinder is delivered into the electrolysis cavities from the water inlet via the water pump and returns into the sterilizing cylinder from the water outlet; and the air pump isconnected with the aeration opening. The problem that an existing hydrogen peroxide generation device is not suitable for a domestic sterilizing device is solved.

Owner:XIAMEN UNIV OF TECH

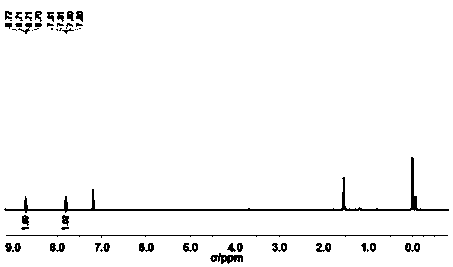

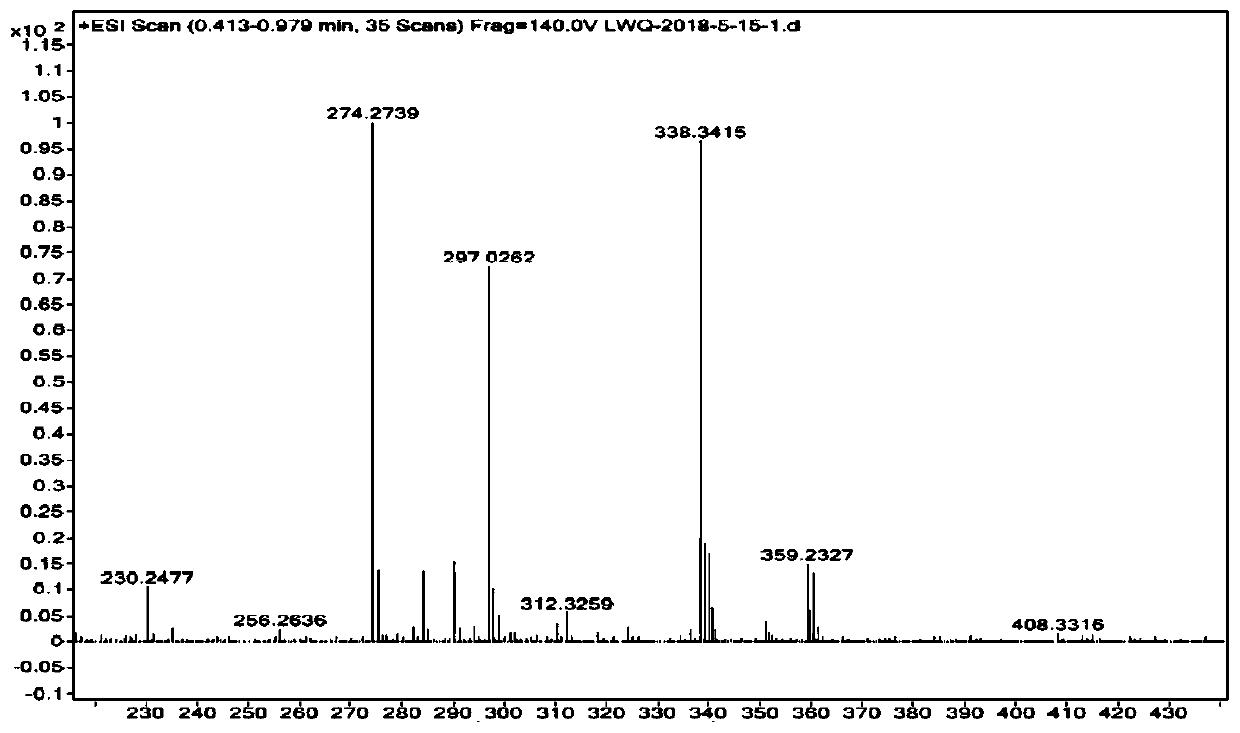

Macrocyclic compound as well as preparation method and application thereof

ActiveCN111205456AMild reaction conditionsEasy to scale up and synthesizeElectrodesChemical synthesisHigh concentration

The invention relates to the field of organic chemical synthesis, and in particular, relates to a macrocyclic compound as well as a preparation method and application thereof. The preparation method of the macrocyclic compound comprises the steps: carrying out a reaction on a monomer with a benzyl bromide compound with a symmetrical structure to prepare a first macrocyclic compound, wherein the monomer has a structure represented by a formula I. The material disclosed by the invention is synthesized at normal temperature, reaction conditions are mild, and amplification synthesis can be easilyrealized; the material is not subjected to high-temperature pyrolysis and is free of metal doping, and the material is directly used for oxygen cathode reduction of a fuel cell and has excellent hydrogen peroxide generation performance. The material is an ionic carbon material, so that the selectivity of hydrogen peroxide is improved. The material provided by the invention can be made into a membrane electrode with a sandwich structure, has relatively large current and good stability, and has high-concentration hydrogen peroxide production potential.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

Assay method

InactiveCN103492881AMaterial analysis by observing effect on chemical indicatorMicrobiological testing/measurementCoboglobinAssay

The invention provides an assay method for determining a level of haptoglobin in a sample comprising the steps of: (i) mixing haemoglobin with the sample to be assayed so as to form a haptoglobin-haemoglobin complex with haptoglobin present in the sample; (ii) contacting the product of step (i) with reagents for generating hydrogen peroxide and one or more chromogens which undergo a spectroscopically detectable change when peroxidase activity is present, in the presence of a buffer, under conditions in which hydrogen peroxide is generated from said reagents and forms a substrate for the peroxidise activity of the haptoglobin-haemoglobin complex present, and wherein the pH of the buffer is within a range which is sufficiently low that the peroxidise activity of any uncomplexed haemoglobin is substantially suppressed but sufficiently high that hydrogen peroxide generation occurs; (iii) determining the peroxidase activity of the haptoglobin-haemoglobin complex by measuring the change in an optical property of the reaction mixture; and (iv) correlating the level of peroxidise activity of the haptoglobin-haemoglobin complex with the amount of haptoglobin in the sample. A kit for use in such a method is also provided.

Owner:REACTIVLAB

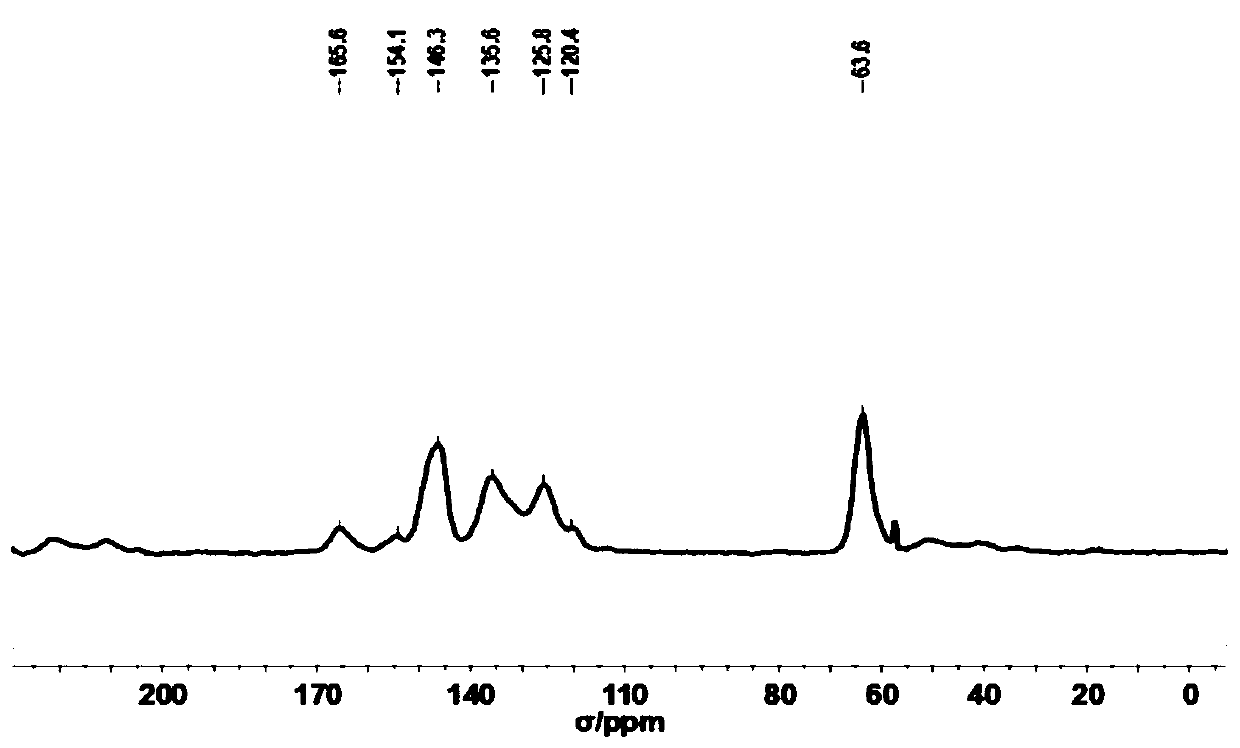

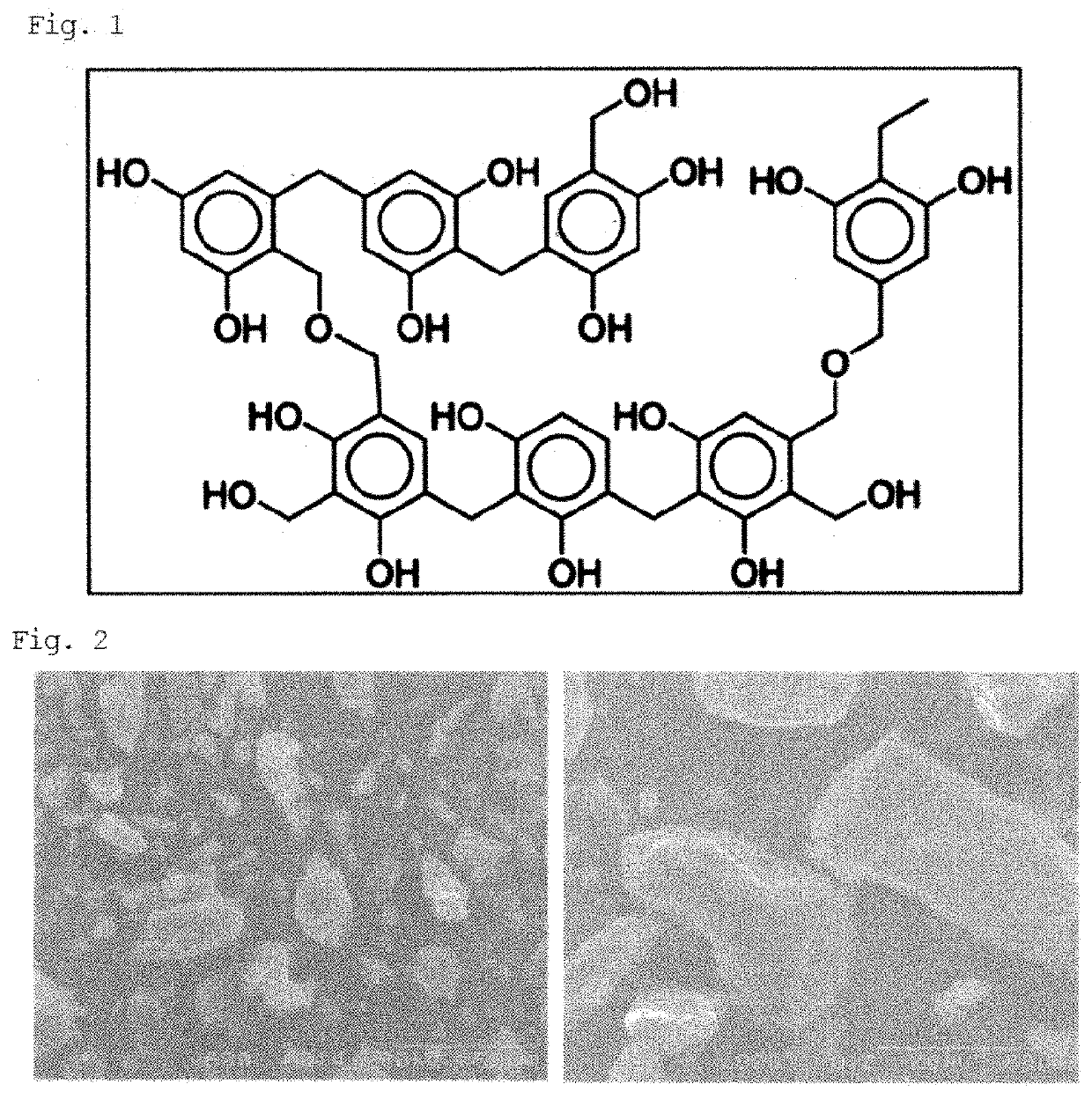

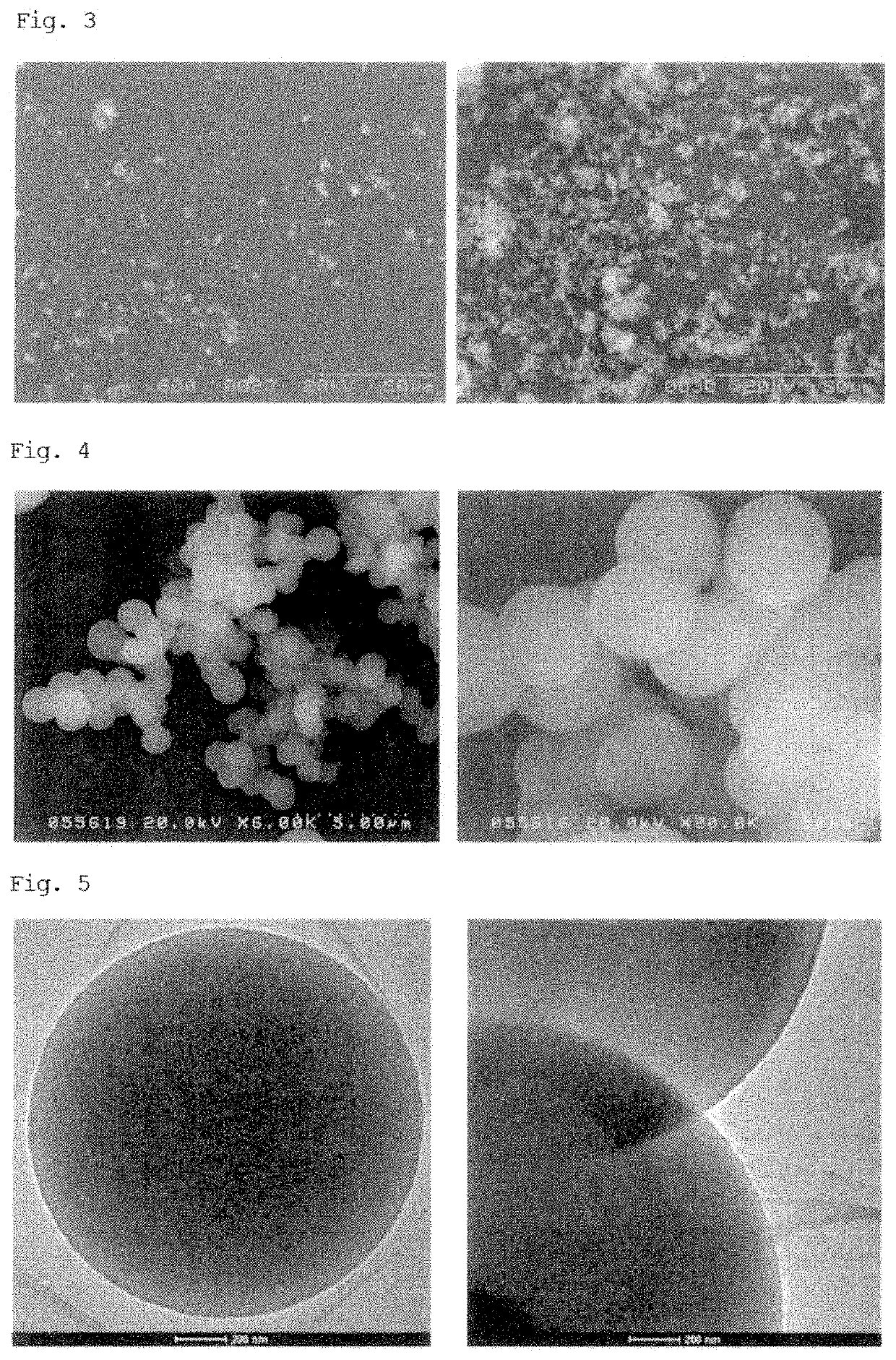

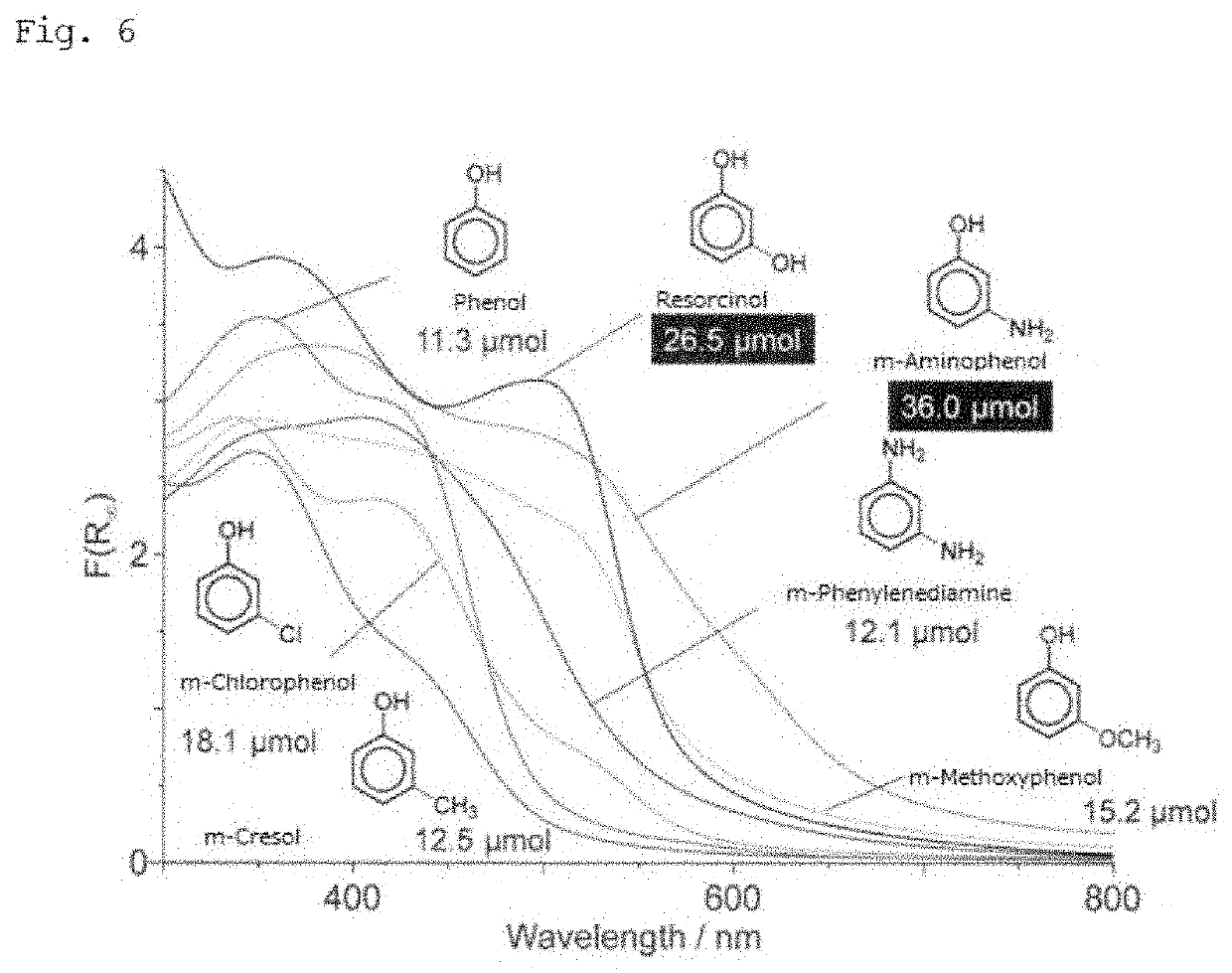

Method for producing hydrogen peroxide, kit for hydrogen peroxide production, organic polymer photocatalyst used in said method and kit, and method for producing said organic polymer photocatalyst

ActiveUS20200048089A1Improve securityImprove production efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesValence bandPolymer science

The present invention provides a hydrogen peroxide production method and a hydrogen peroxide production kit that are capable of producing hydrogen peroxide more efficiently and at lower costs than conventional methods. Specifically, the present invention provides a hydrogen peroxide production method comprising: (1) a hydrogen peroxide generation step of generating hydrogen peroxide by irradiating a reaction system containing water, an organic polymer photocatalyst, and O2 with light, wherein (2) the organic polymer photocatalyst comprises an organic polymer having a structure such that a monocyclic or polycyclic aromatic compound and / or a monocyclic or polycyclic heteroaromatic compound is / are linked by a bridging group, and (3) the organic polymer has a band structure such that a conduction band (CB) has a potential lower than the potential of two-electron reduction of O2, and a valance band (VB) has a potential higher than the potential of four-electron oxidation of water.

Owner:OSAKA UNIV

Method of selectively measuring triglycerides

InactiveUS20050255536A1Quick upgradeNot easy to changeMicrobiological testing/measurementDisease diagnosisTest sampleGlycerol

The present invention relates to a reagent for selective measurement of triglycerides contained in very low density lipoprotein and intermediate density lipoprotein or in very low density lipoprotein in a test sample, including a first reagent that contains a first selective reaction promoter, which is an ether or ester compound of a polyoxyalkylene capable of reacting lipoprotein lipase selectively with triglycerides contained in low density lipoprotein and high density lipoprotein; lipoprotein lipase; enzymes which catalyze a series of reactions leading to the generation of hydrogen peroxide or a reduced coenzyme from glycerol; and an enzyme which catalyzes a reaction leading to the conversion of hydrogen peroxide or a reduced coenzyme into another substance, and a second reagent that contains a second selective reaction promoter, which is capable of reacting lipoprotein lipase selectively with triglycerides contained in very low density lipoprotein, intermediate density lipoprotein, low density lipoprotein and high density lipoprotein and to a method for selective measurement of triglycerides contained in very low density lipoprotein and intermediate density lipoprotein or in very low density lipoprotein in a test sample which uses the above reagent.

Owner:SHINO TEST +1

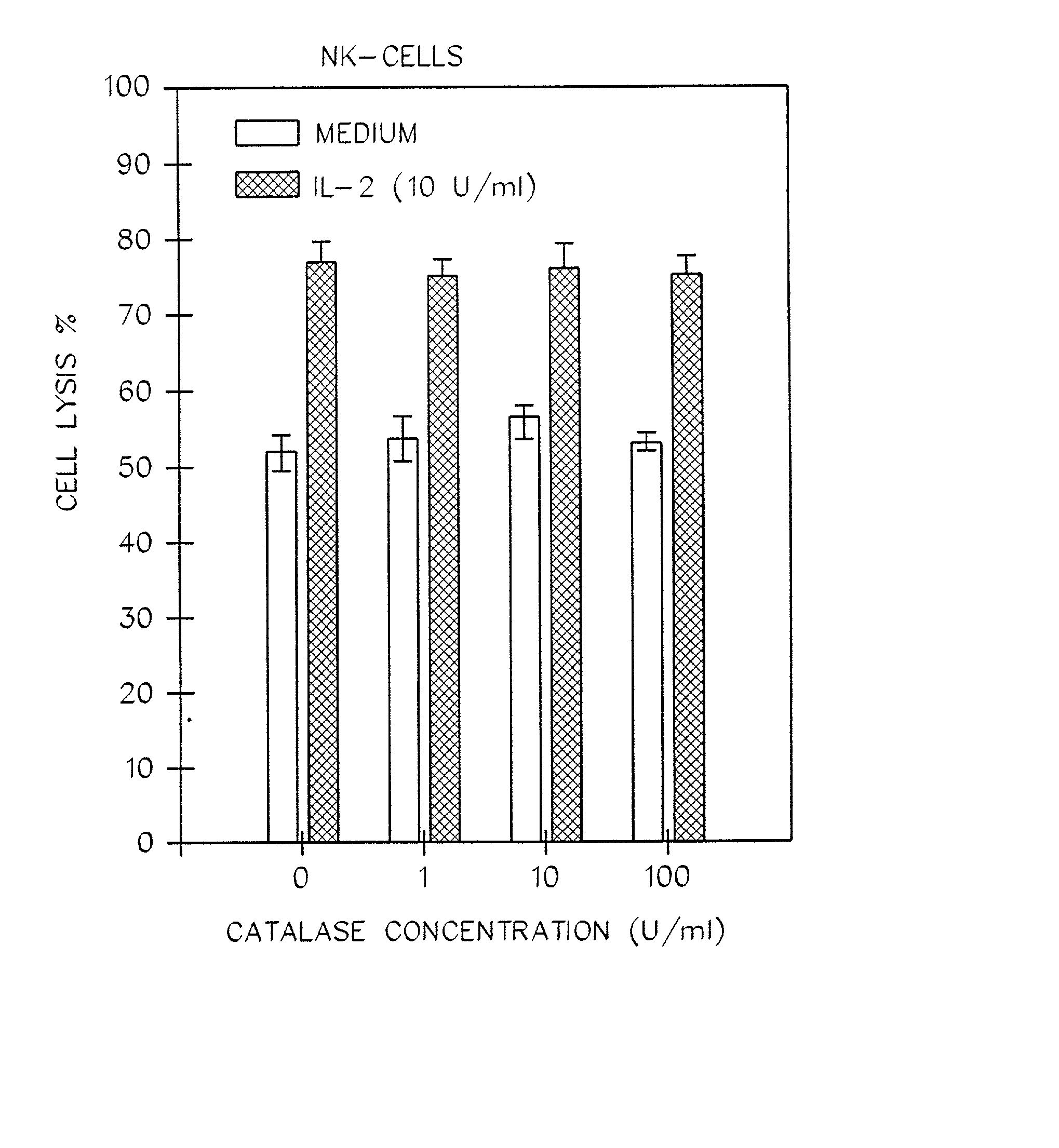

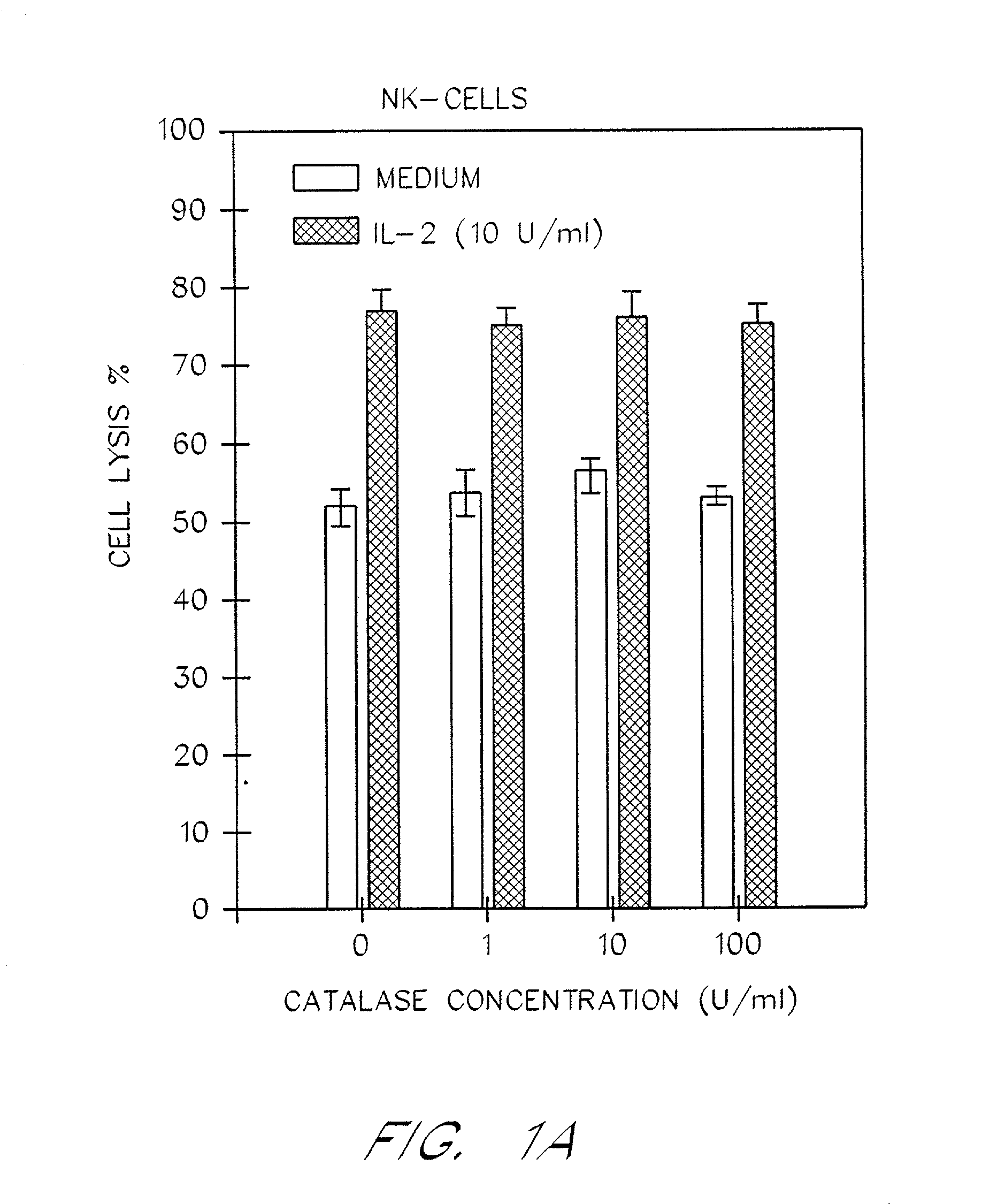

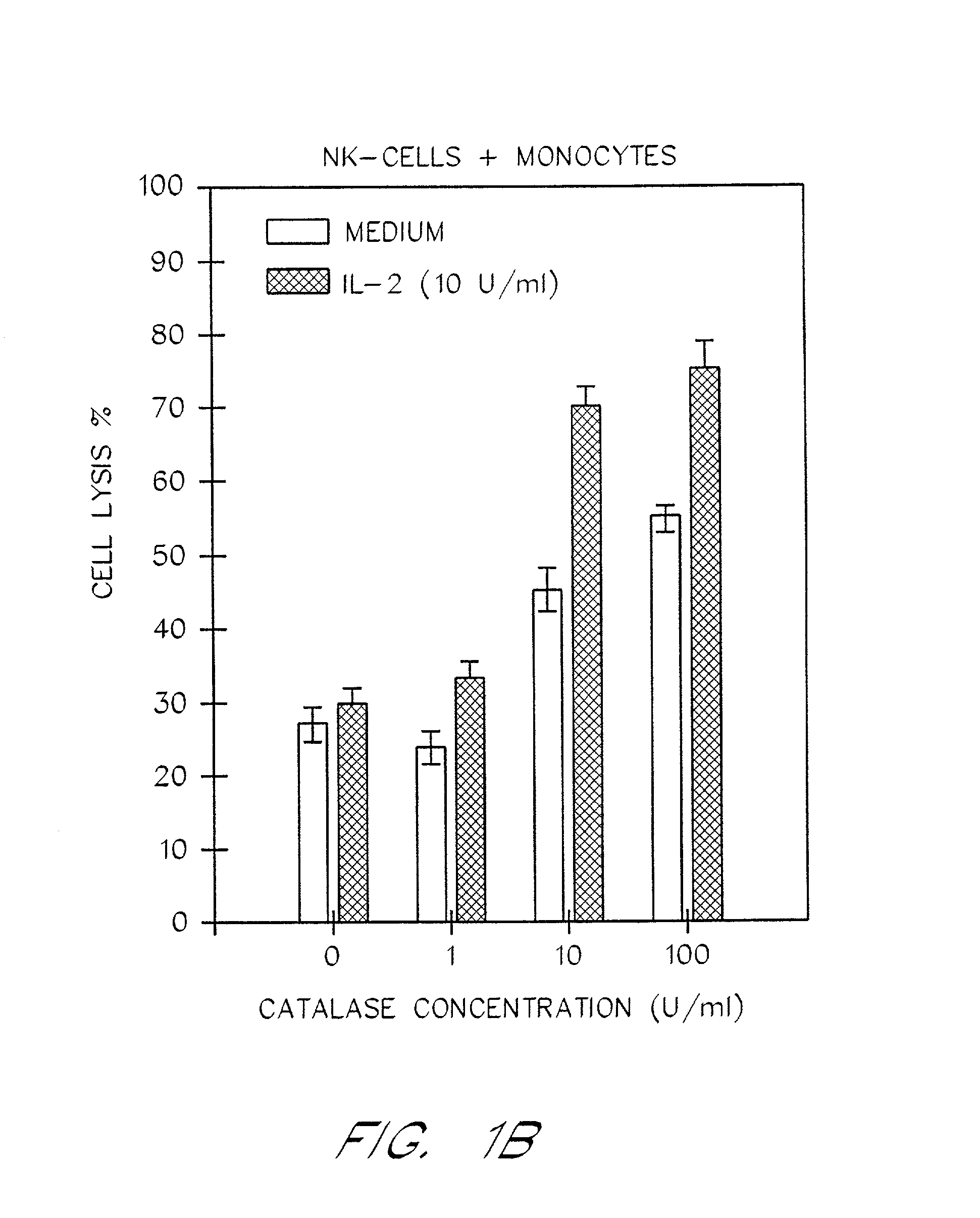

Enhanced activation of natural killer cells using an NK cell activator and a hydrogen peroxide scavenger or inhibitor

InactiveUS20020119119A1Reduce inhibitionNot alter suppressionBiocidePeptide/protein ingredientsSerotoninIfn alpha

A method for providing activated natural killer (NK) cells comprising the steps of administering to a population of cells which includes lymphocytes and monocytes, an effective amount of an NK cell activating cytokine or a NK cell activating flavonoid, wherein said NK cell activating cytokine is not IL-2 or IFN-alpha; and administering a compound effective to inhibit the production or release of hydrogen peroxide selected from the group consisting of histamine, other H2 receptor agonists, and serotonin.

Owner:HELLSTRAND JAN URBAN KRISTOFFER +1

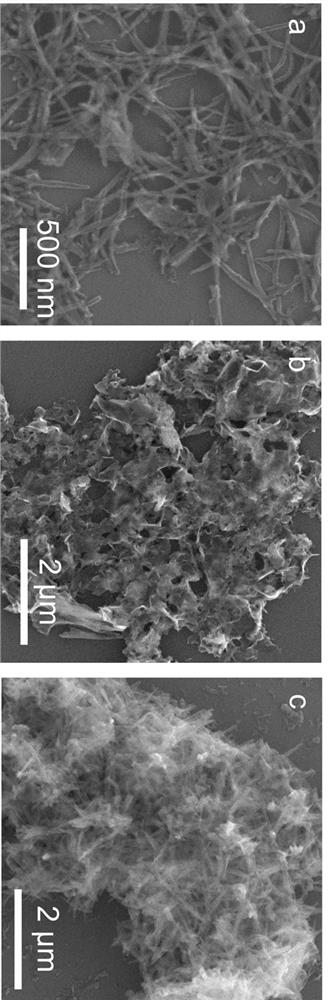

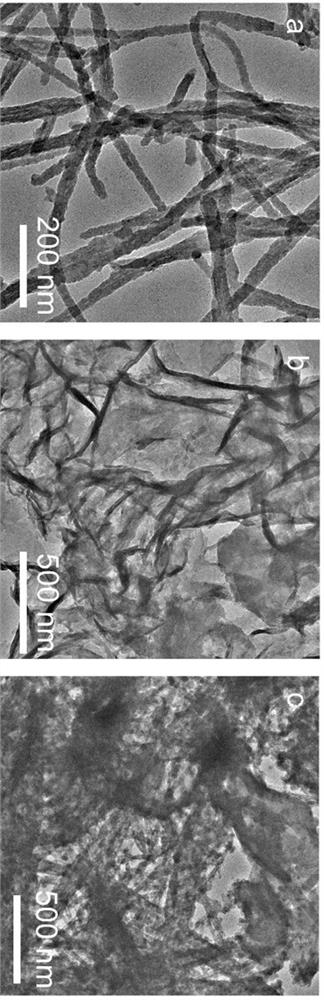

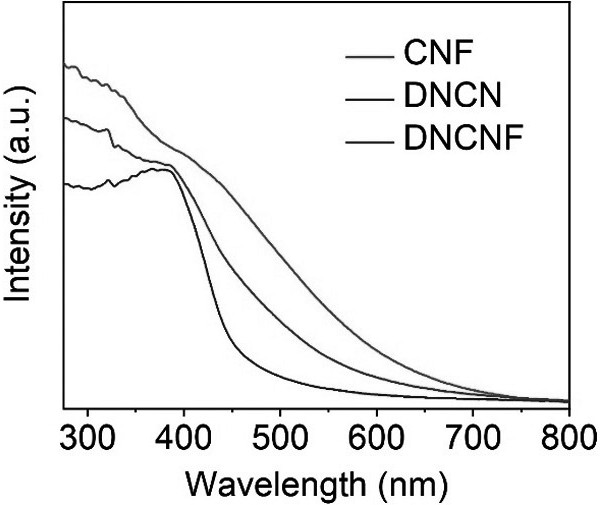

Carbon nitride-based homo-junction for photocatalytic production of hydrogen peroxide, and preparation method and application thereof

ActiveCN112742436AEffective separation efficiencyExcellent photocatalytic synthesis of hydrogen peroxide activityPhysical/chemical process catalystsPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesQuantum efficiencyCarbon nitride

The invention discloses a carbon nitride-based homo-junction for photocatalytic production of hydrogen peroxide, and a preparation method and application thereof, and belongs to the technical field of material chemistry. The method comprises synthesis and acidification of flaky carbon nitride (hereinafter referred to as DNCN), synthesis of fibrous carbon nitride (hereinafter referred to as CNF), preparation of carbon nitride-based homo-junctions (hereinafter referred to as DNCNF), characterization of micro-structures of the carbon nitride-based homo-junctions, generation rate of hydrogen peroxide under visible light (lambda>420 nm) and apparent quantum efficiency of the DNCNF under different single wavelengths. The invention provides a synthesis method of a carbon nitride homo-junction, and proves that the carbon nitride homo-junction has good hydrogen peroxide generation capability under visible light.

Owner:HUANGHE S & T COLLEGE

Electromagnetic field coupling electro-Fenton reaction device

InactiveCN108275754AAvoid AggregationEvenly distributedWater treatment compoundsWater/sewage treatment apparatusElectromagnetic field couplingEngineering

The invention belongs to the technical field of industrial wastewater treatment and particularly relates to an electromagnetic field coupling electro-Fenton reaction device which comprises a reactor,an electrode, a solenoid coil, a direct-current voltage regulator, an air blower, an air inlet pipe, an air distribution plate, an air exhaust, a water inlet and a water outlet. The device utilizes mutual cooperation of an electromagnetic field and electro-Fenton reaction, the electromagnetic field generates a magnetic field with an adjustable strength, so that charged ions such as iron ions generate movement, and aggregation reaction is avoided; in an electro-Fenton reaction system, an air hole for air or oxygen is formed in a cathode plate, the cathode plate is reacted with the introduced oxygen to produce hydrogen peroxide under the action of currents without adding extra hydrogen peroxide, and the production efficiency of the hydrogen peroxide is improved at the same time, so that popularization and application of equipment are improved.

Owner:FOSHAN WANSHAN ENVIRONMENTAL PROTECTION TECH CO LTD

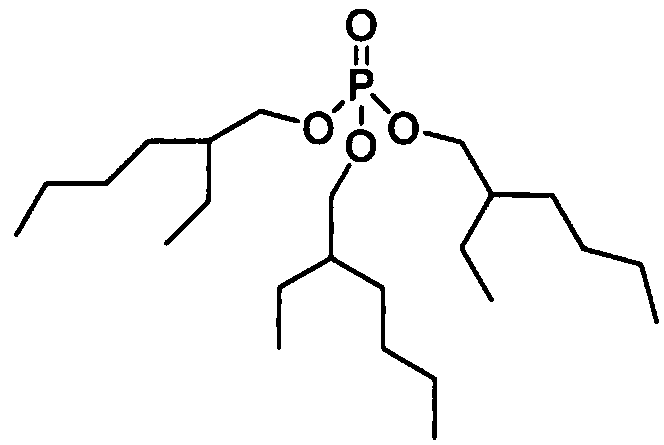

Method for producing hydrogen peroxide

PendingCN109467056AEfficient recyclingImprove efficiencyPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesGroup 5/15 element organic compoundsPhosphateDistillation

The present invention provides a method for obtaining a high-quality regenerated working solution by removing an inactive material from a working solution containing trioctyl phosphate (TOP). A methodfor producing hydrogen peroxide includes a hydrogen peroxide production process of hydrogenating and then oxidizing a working solution containing aromatic hydrocarbons, TOP, and anthraquinones, to generate hydrogen peroxide, extracting the hydrogen peroxide from the working solution, after hydrogen peroxide extraction, the working solution returning to a hydrogenating process to cycle; a workingsolution regeneration process of removing the inactive material of a by-product of hydrogen peroxide generation from the working solution to prepare a crude regeneration working solution; and a step of performing alkali cleaning on the crude regeneration working solution to prepare a regeneration working solution for recycling, the working solution regeneration step comprising: i) a first distillation step of recovering aromatic hydrocarbons by distillation under atmospheric pressure or less; ii) then, a second distillation step of distilling and recovering the anthraquinones and the TOP underlower pressure and at temperature of 160 DEG C or higher.

Owner:MITSUBISHI GAS CHEM CO INC

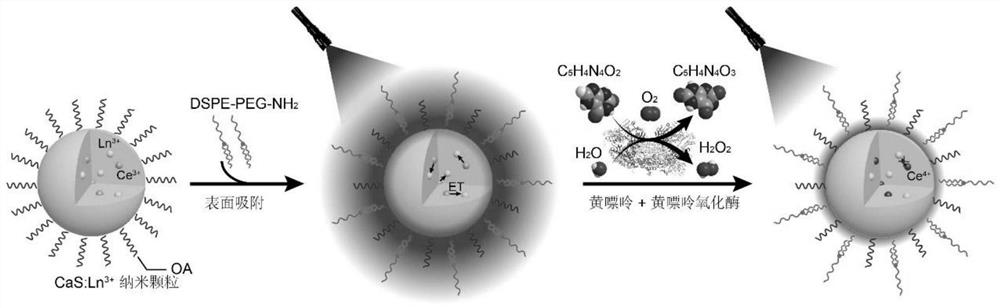

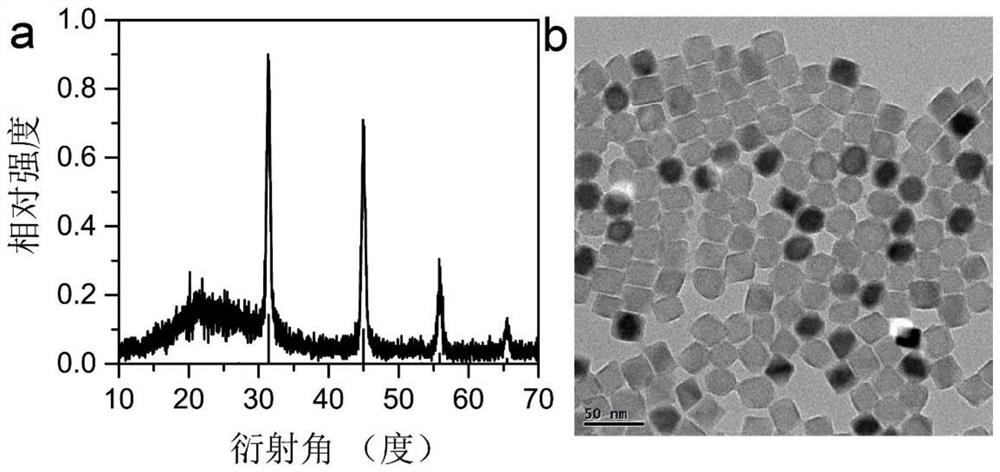

Method for detecting hydrogen peroxide and related targets based on CaS nano fluorescent probe

PendingCN111829993AAccurate determination of concentrationEasy to operateFluorescence/phosphorescenceFluoProbesRare earth ions

The invention belongs to the technical field of biological detection, and discloses a method for detecting hydrogen peroxide and related targets based on a nanoprobe. According to the method, a water-soluble rare earth doped CaS: Ce<3+> / Ln<3+> nano material is used as a fluorescent probe, rare earth ion luminescence is quenched through an oxidation-reduction reaction of hydrogen peroxide and cerium ions, and the concentration of hydrogen peroxide is detected by utilizing the change of the fluorescence intensity of doped rare earth ions. The method can be used for detecting hydrogen peroxide ina standard solution or reactants in an enzymatic reaction for generating hydrogen peroxide, can further realize the detection of hydrogen peroxide, biological enzyme or substrate (such as xanthine) in the serum, has the advantages of being simple and convenient to operate, good in anti-interference performance, rapid, sensitive, economical, practical and the like, can provide theoretical basis and technical support for real-time detection of hydrogen peroxide and hydrogen peroxide generation system related substances in a complex system, and has certain clinical application potential.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com