Electro-Fenton reactor and reaction method for treating organic wastewater

A technology of organic wastewater and reactors, applied in chemical instruments and methods, water/sewage treatment, special compound water treatment, etc., can solve the problems of low generation rate, short electrode life, difficult to scale up, etc., and achieve high production efficiency, High processing efficiency and easy to scale up effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation technology of carbon black-polytetrafluoroethylene coated graphite particle comprises the steps:

[0045] (1) Mix carbon black, polytetrafluoroethylene emulsion, and water, and stir electrically at a speed of 500 rpm for 0.5 h to obtain a mixed solution A1;

[0046] (2) adding flake graphite into the mixed solution A1, and electric stirring at a speed of 800 rpm for 2 hours to obtain the mixed solution B1;

[0047] (3) Transfer the mixed solution B1 to a vacuum rotary evaporator, evaporate at 60°C until there is no obvious water, then raise the temperature to 90°C, and rotary evaporate for 1 hour to obtain substance A1;

[0048] (4) put substance A1 into a muffle furnace for calcination at 360° C. for 2 hours, and obtain substance B1 after cooling;

[0049] (5) Mix carbon black, polytetrafluoroethylene emulsion, water, and surfactant Triton X-100, and stir electrically at a speed of 500 rpm for 0.5 h to obtain a mixed solution A2;

[0050] (6) Add the ...

Embodiment 1

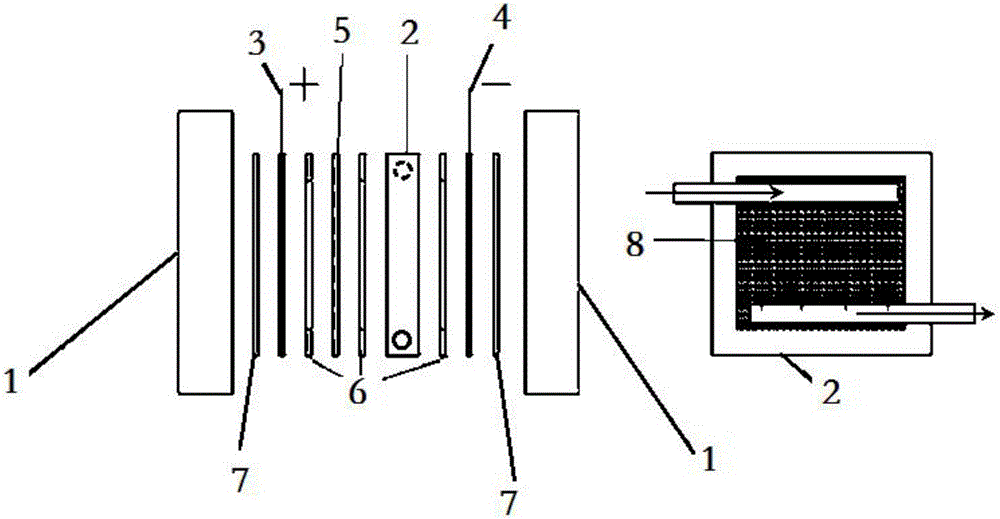

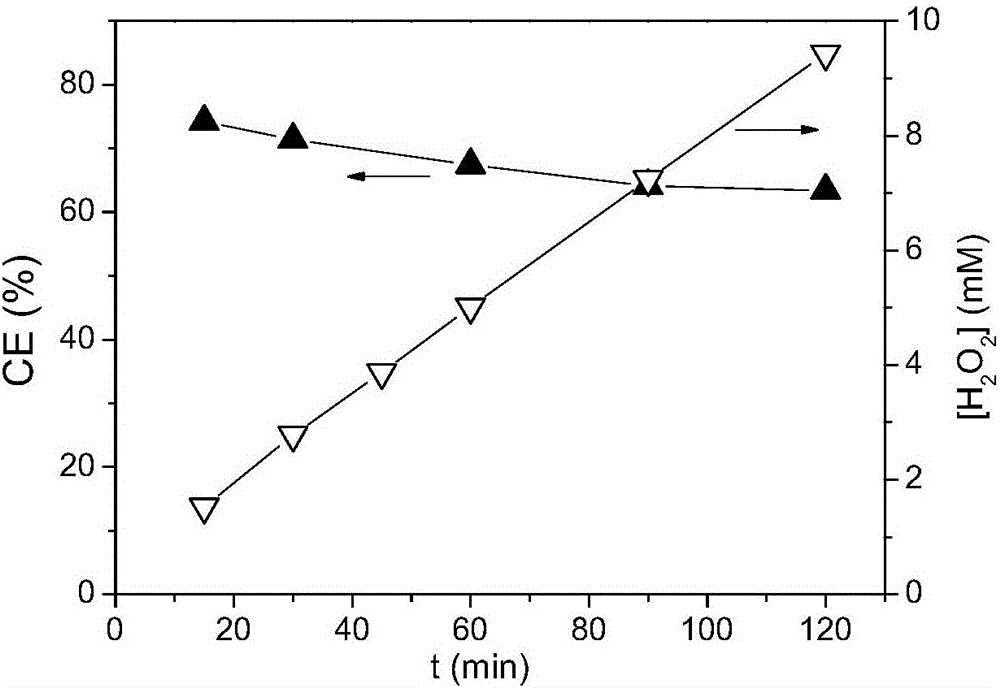

[0058] use as figure 1 The shown electro-Fenton reactor prepares acidic hydrogen peroxide solution. The specific test conditions are as follows: the anode is a titanium-coated lead dioxide electrode (80×70mm), and the apparent area of the electrode is 30cm 2 , nylon diaphragm, nickel cathode collector plate, three-dimensional cathode is made of carbon black-polytetrafluoroethylene coated graphite particles filled in cathode frame 2 (filling density 0.6g / cm 3 ), the size of the cathode frame 2 is 70×80×14mm, and the effective volume is 50×60×14mm. Carbon black-polytetrafluoroethylene coated graphite particles select carbon black as Vulcan X-72R, polytetrafluoroethylene emulsion concentration is 60wt%, flake graphite particle size is 40 mesh, carbon black, polytetrafluoroethylene emulsion, water, TritonX The dosage ratio of -100 and flake graphite is 14g: 25ml: 1.1L: 0.5ml: 330g. Cycle electrolysis 800ml 0.05M Na with pH 3 2 SO 4 solution, Na 2 SO 4 The mixture of solut...

Embodiment 2

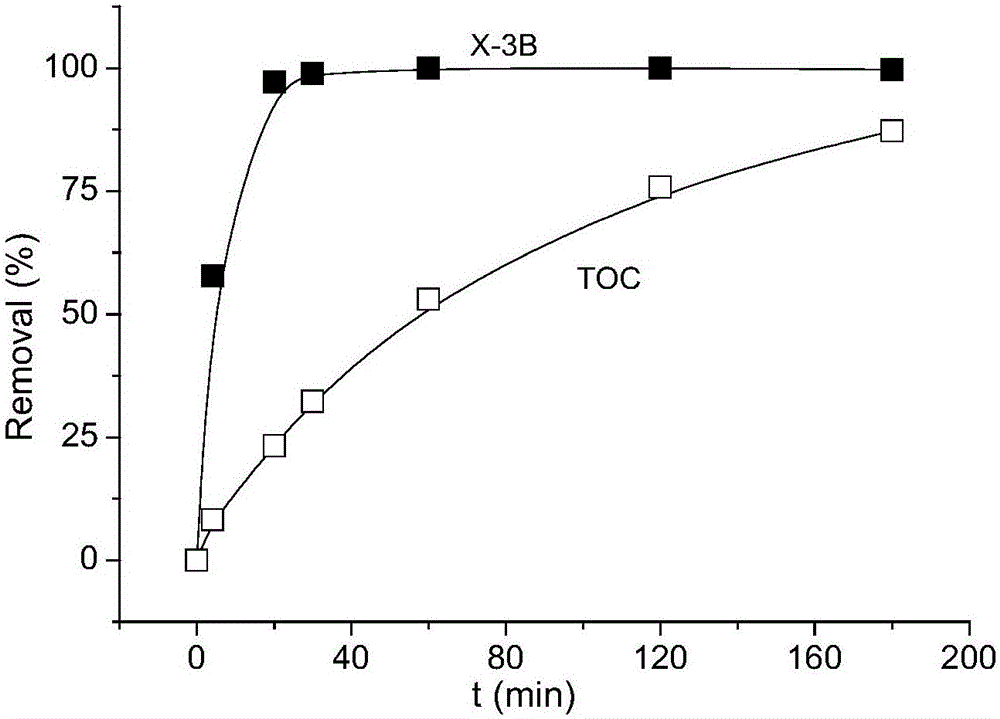

[0060] use as figure 1 The electro-Fenton reactor shown treats simulated wastewater with Reactive Brilliant Red X-3B. The specific test conditions are as follows: the anode is a titanium-coated lead dioxide electrode (80×70mm), and the apparent area of the electrode is 30cm 2 , nylon diaphragm, nickel cathode collector plate, three-dimensional cathode is made of carbon black-polytetrafluoroethylene coated graphite particles filled in cathode frame 2 (filling density 0.6g / cm 3 ), the size of the cathode frame 2 is 70×80×14mm, and the effective volume is 50×60×14mm. Carbon black-polytetrafluoroethylene coated graphite particles select carbon black as Vulcan X-72R, polytetrafluoroethylene emulsion concentration is 60wt%, flake graphite particle size is 40 mesh, carbon black, polytetrafluoroethylene emulsion, water, TritonX The dosage ratio of -100 and flake graphite is 14g: 25ml: 1.1L: 0.5ml: 330g. Circulating electrolysis of 800ml 123mg / L reactive brilliant red X-3B simulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com