Device and method for air aerosol disinfection and organic gas degradation

A technology of organic gas and aerosol, applied in the field of air purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

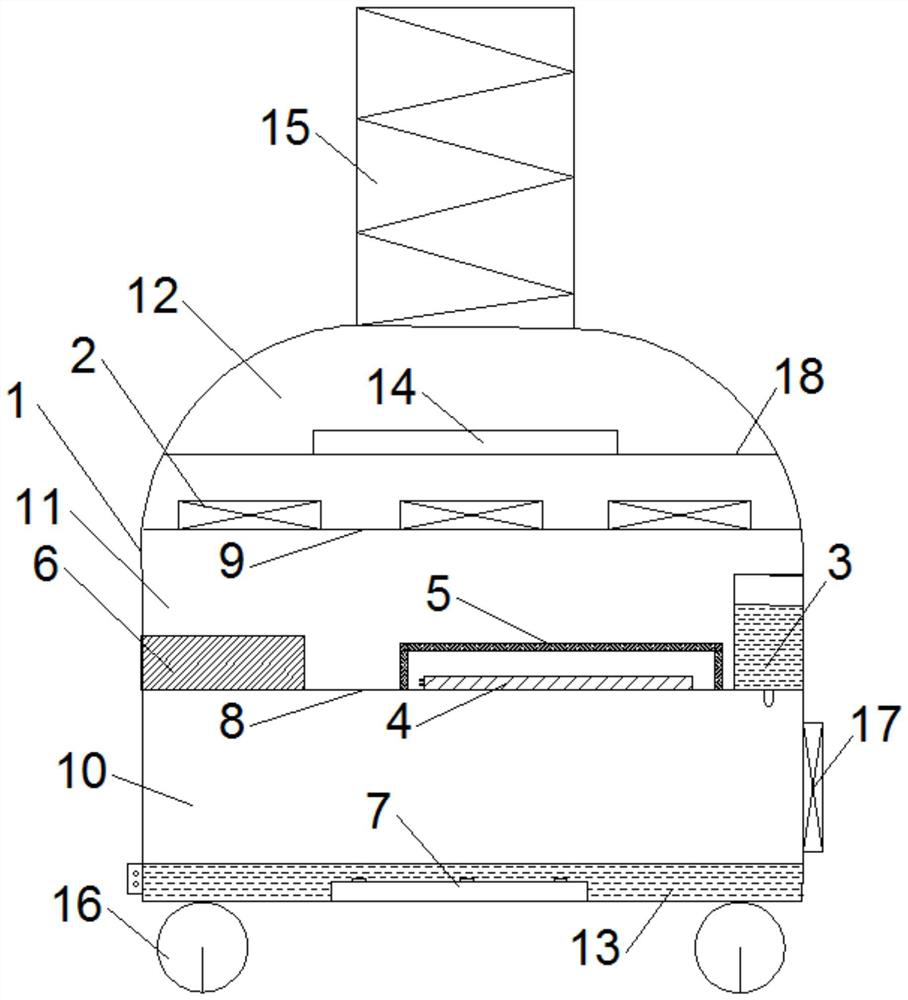

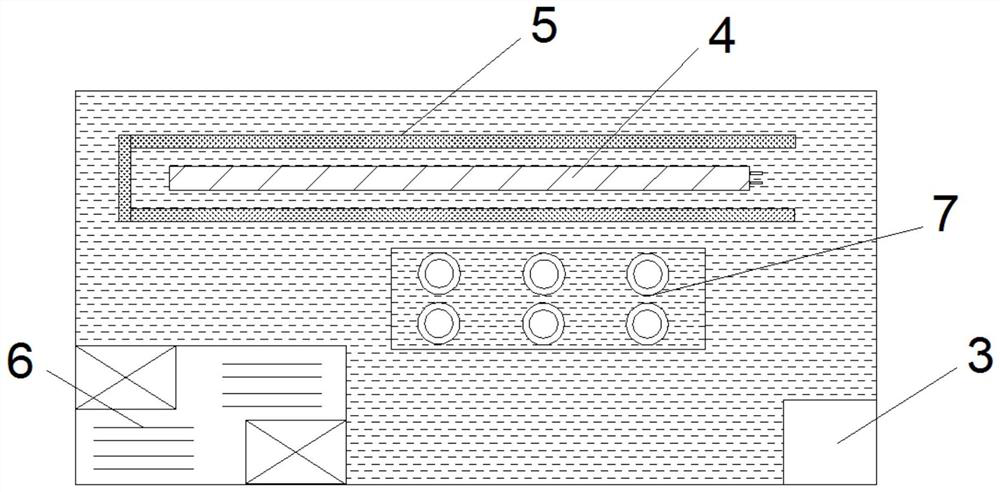

[0024] See attached Figure 1~2 . A device for air aerosol disinfection and organic gas degradation, including a box body 1, an internal fan 2, a hydrogen peroxide generator 3, an ultraviolet lamp 4, a photocatalytic screen 5, an ozone generator 6 and an ultrasonic atomizer 7; the first mesh partition 8 and the second mesh partition 9 above the first mesh partition 8 are arranged in the box body 1; the first mesh partition 8 and the second mesh partition 9 will box The interior of the body 1 is sequentially divided into an atomization chamber 10, a reaction chamber 11 and a mixing chamber 12 from bottom to top; the box body 1 is provided with an air inlet connected to the atomization chamber 10 and an air outlet connected to the mixing chamber 12; The mixing chamber 12 is provided with an internal fan 2; the internal fan 2 is used to provide power for air to enter from the air inlet, pass through the atomization chamber 10, the reaction chamber 11 and the mixing chamber 12 in...

Embodiment 2

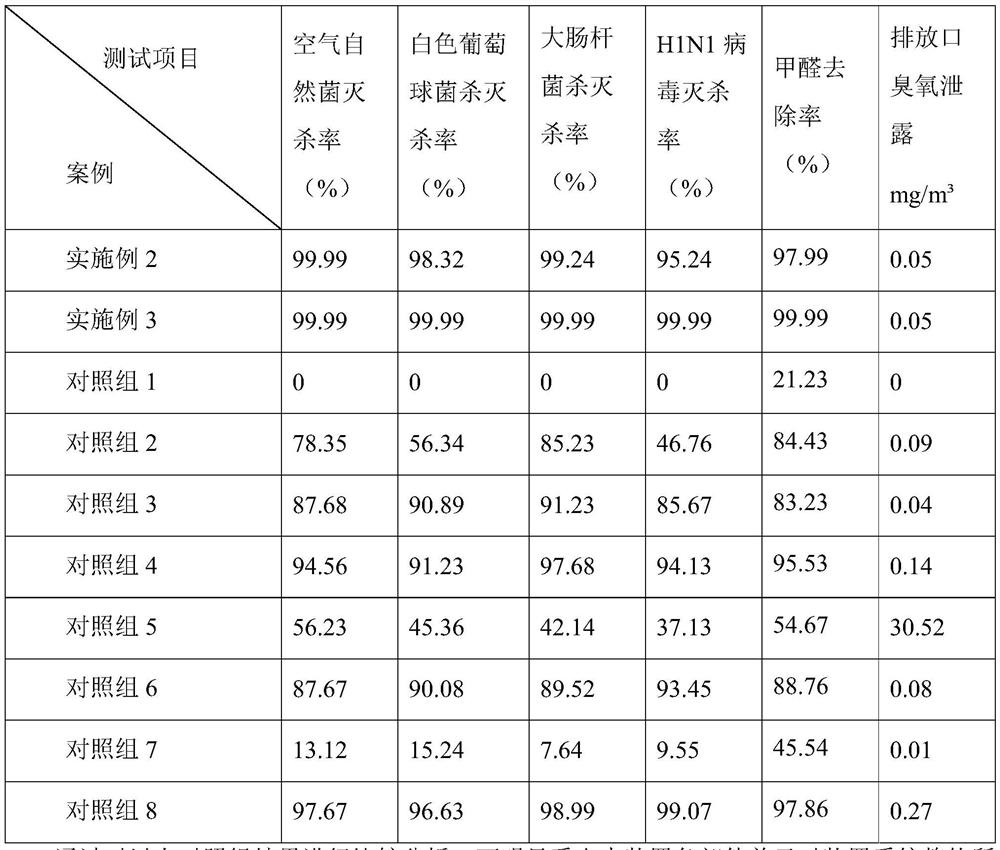

[0026] See attached Figure 1~2 . A device for air aerosol disinfection and organic gas degradation, including a box body 1, an internal fan 2, a hydrogen peroxide generator 3, an ultraviolet lamp 4, a photocatalytic screen 5, an ozone generator 6 and an ultrasonic atomizer 7; the first mesh partition 8 and the second mesh partition 9 above the first mesh partition 8 are arranged in the box body 1; the first mesh partition 8 and the second mesh partition 9 will box The interior of the body 1 is sequentially divided into an atomization chamber 10, a reaction chamber 11 and a mixing chamber 12 from bottom to top; the box body 1 is provided with an air inlet connected to the atomization chamber 10 and an air outlet connected to the mixing chamber 12; The mixing chamber 12 is provided with an internal fan 2; the internal fan 2 is used to provide power for air to enter from the air inlet, pass through the atomization chamber 10, the reaction chamber 11 and the mixing chamber 12 in...

Embodiment 3

[0031] See attached Figure 1~2. A device for air aerosol disinfection and organic gas degradation, including a box body 1, an internal fan 2, a hydrogen peroxide generator 3, an ultraviolet lamp 4, a photocatalytic screen 5, an ozone generator 6 and an ultrasonic atomizer 7; the first mesh partition 8 and the second mesh partition 9 above the first mesh partition 8 are arranged in the box body 1; the first mesh partition 8 and the second mesh partition 9 will box The interior of the body 1 is sequentially divided into an atomization chamber 10, a reaction chamber 11 and a mixing chamber 12 from bottom to top; the box body 1 is provided with an air inlet connected to the atomization chamber 10 and an air outlet connected to the mixing chamber 12; The mixing chamber 12 is provided with an internal fan 2; the internal fan 2 is used to provide power for air to enter from the air inlet, pass through the atomization chamber 10, the reaction chamber 11 and the mixing chamber 12 in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com